How to Make Wire Nails – Step-by-Step Manufacturing Guide

Price: ₹50000

How to Make Wire Nails – Step-by-Step Manufacturing Guide

Wire nails are essential fasteners widely used in construction, carpentry, and industrial applications. Understanding how to make wire nails is crucial for manufacturers, entrepreneurs, and hobbyists interested in nail production.

This guide explains the complete wire nail manufacturing process from raw material to finished product.

Step 1: Selecting and Preparing Raw Wire

-

The process begins with high-quality steel wire, usually ranging from 1 mm to 6 mm in diameter.

-

The wire is cleaned and straightened to ensure smooth feeding into the machine.

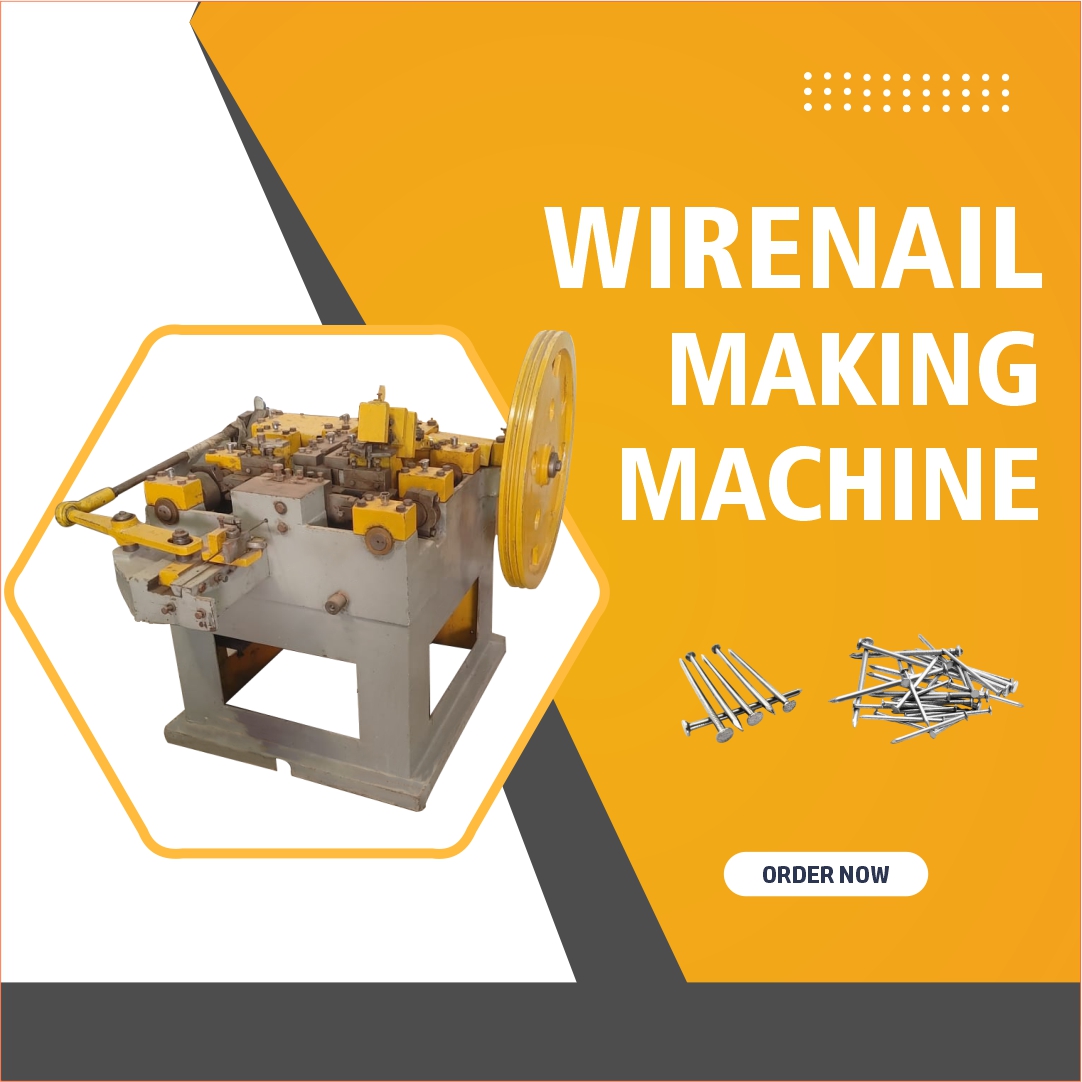

Step 2: Feeding the Wire into the Nail Making Machine

-

The wire coil is fed manually or automatically into the nail making machine.

-

Feed rollers ensure steady wire movement and precise control.

Step 3: Cutting Wire to Nail Length

-

The machine cuts the wire into pieces matching the desired nail length.

-

Accurate cutting ensures uniform nail size and quality.

Step 4: Forming the Nail Head

-

The machine presses the top end of the cut wire to create a strong, flat nail head.

-

This step ensures nails stay firmly in place when hammered.

Step 5: Shaping the Nail Point

-

The machine sharpens the bottom end into a tapered or diamond-shaped point.

-

This helps the nail penetrate wood or other materials easily.

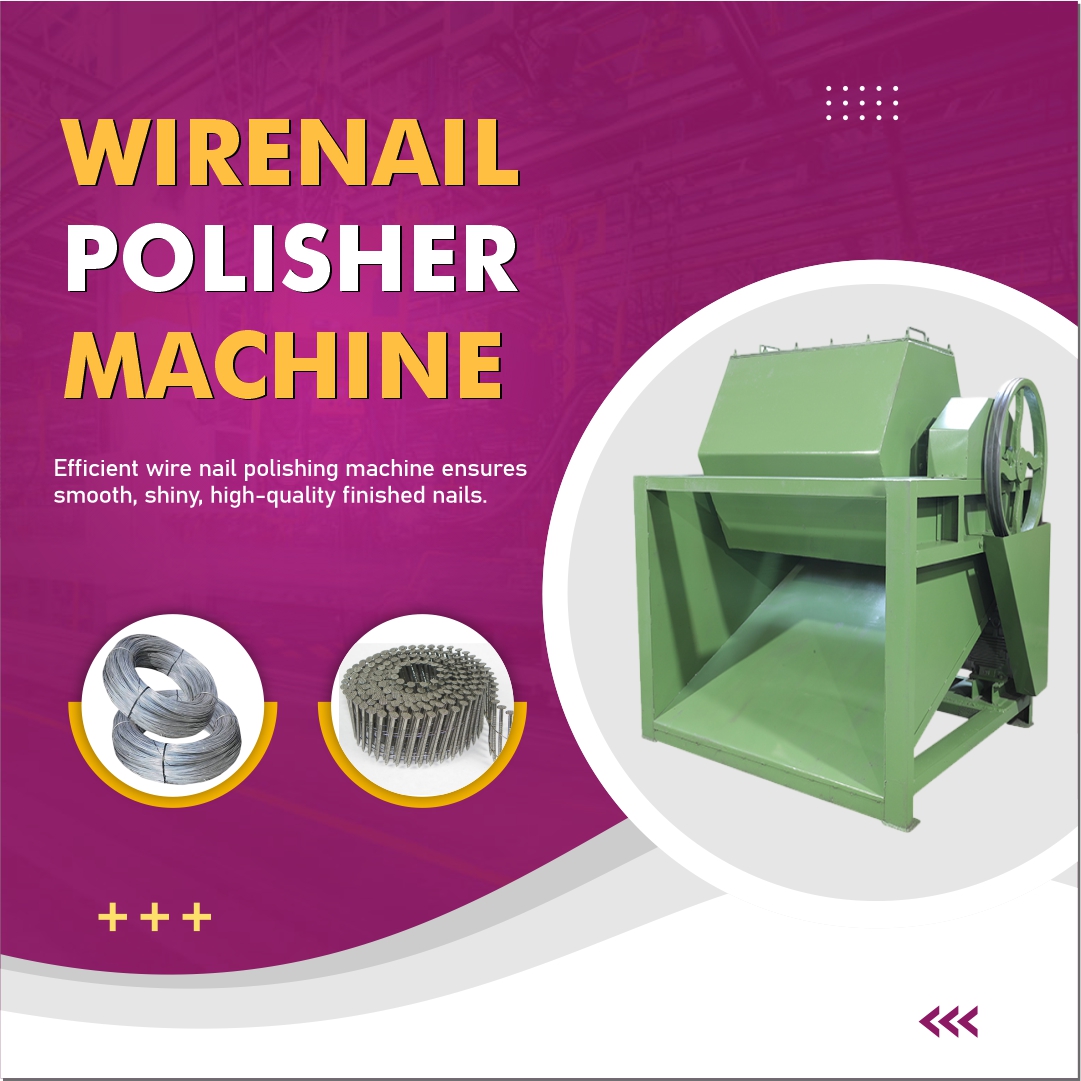

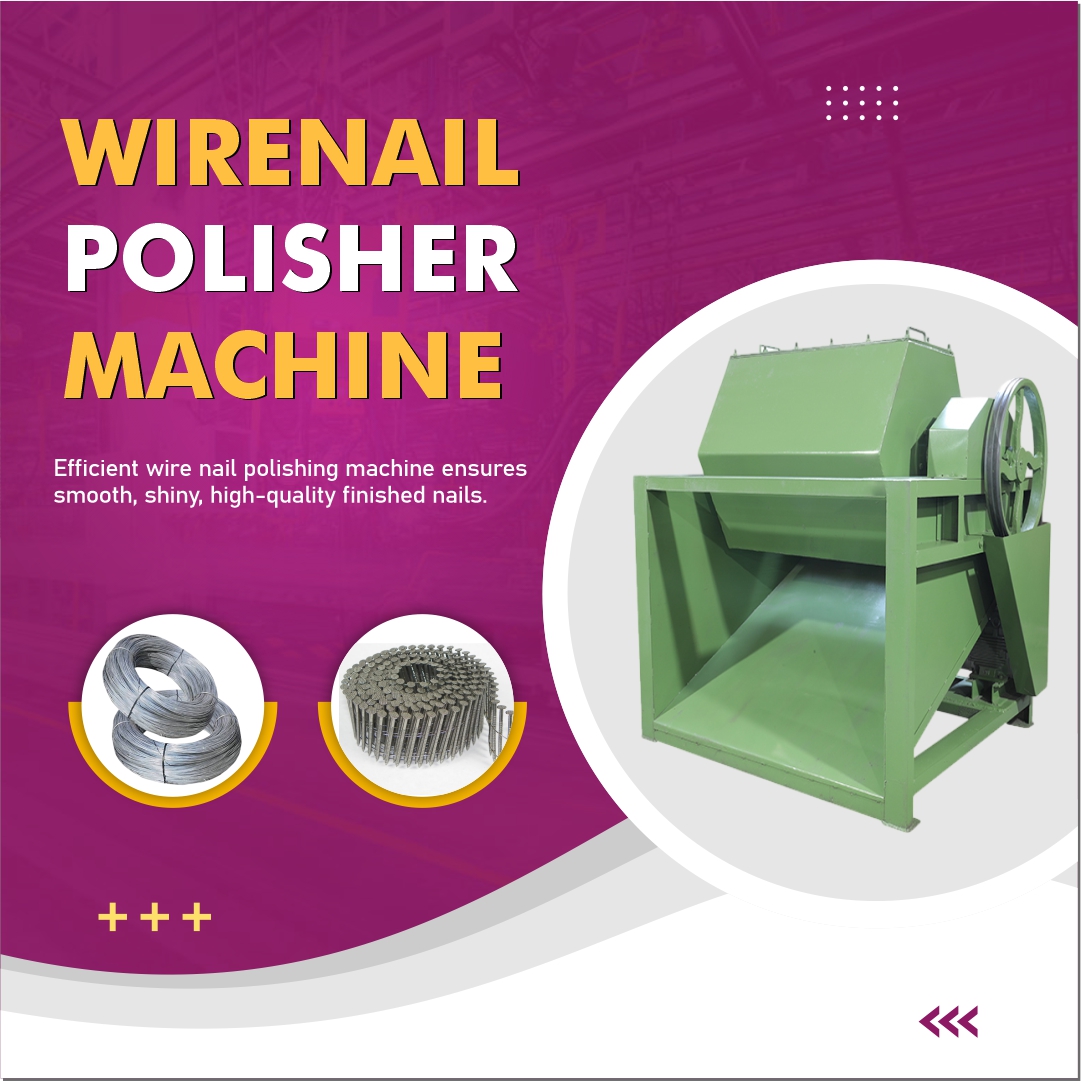

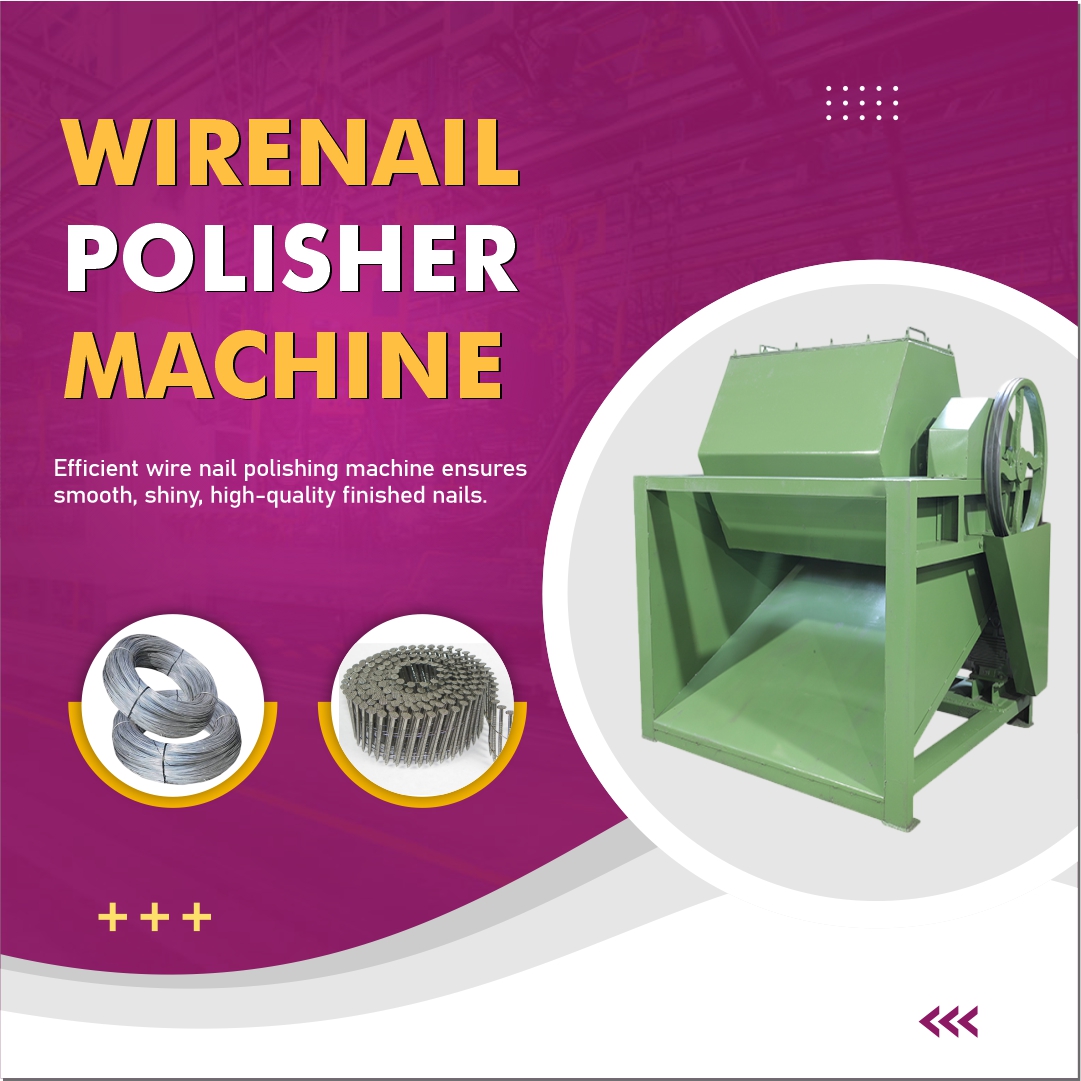

Step 6: Polishing the Nails (Optional)

-

Nails may be polished in a rotating drum to remove burrs and improve finish.

-

Polished nails resist rust and have a better aesthetic.

Step 7: Packaging the Finished Nails

-

After production, nails are counted and packed into bundles or boxes.

-

Proper packaging protects nails during storage and transport.

Machinery Required for Wire Nail Making

-

Wire Nail Making Machine (semi or fully automatic)

-

Wire Straightening Machine

-

Polishing Drum (optional)

-

Packaging Equipment

Why Choose ASVR Engineering?

ASVR Engineering offers reliable and durable wire nail making machines that ensure high-quality nail production. With expert support and spare parts availability, we help you start and grow your nail manufacturing business efficiently.

Contact Us for Wire Nail Making Machines

-

📞 Phone: +91-9650471301

-

✉️ Email: asveng2@gmail.com

-

🌐 Website: www.asvrengineering.com

Buy Now

(9).jpg)

(9).jpg)

(9).jpg)

(10).jpg)

(10).jpg)

(10).jpg)

(9).jpg)

(9).jpg)

(9).jpg)