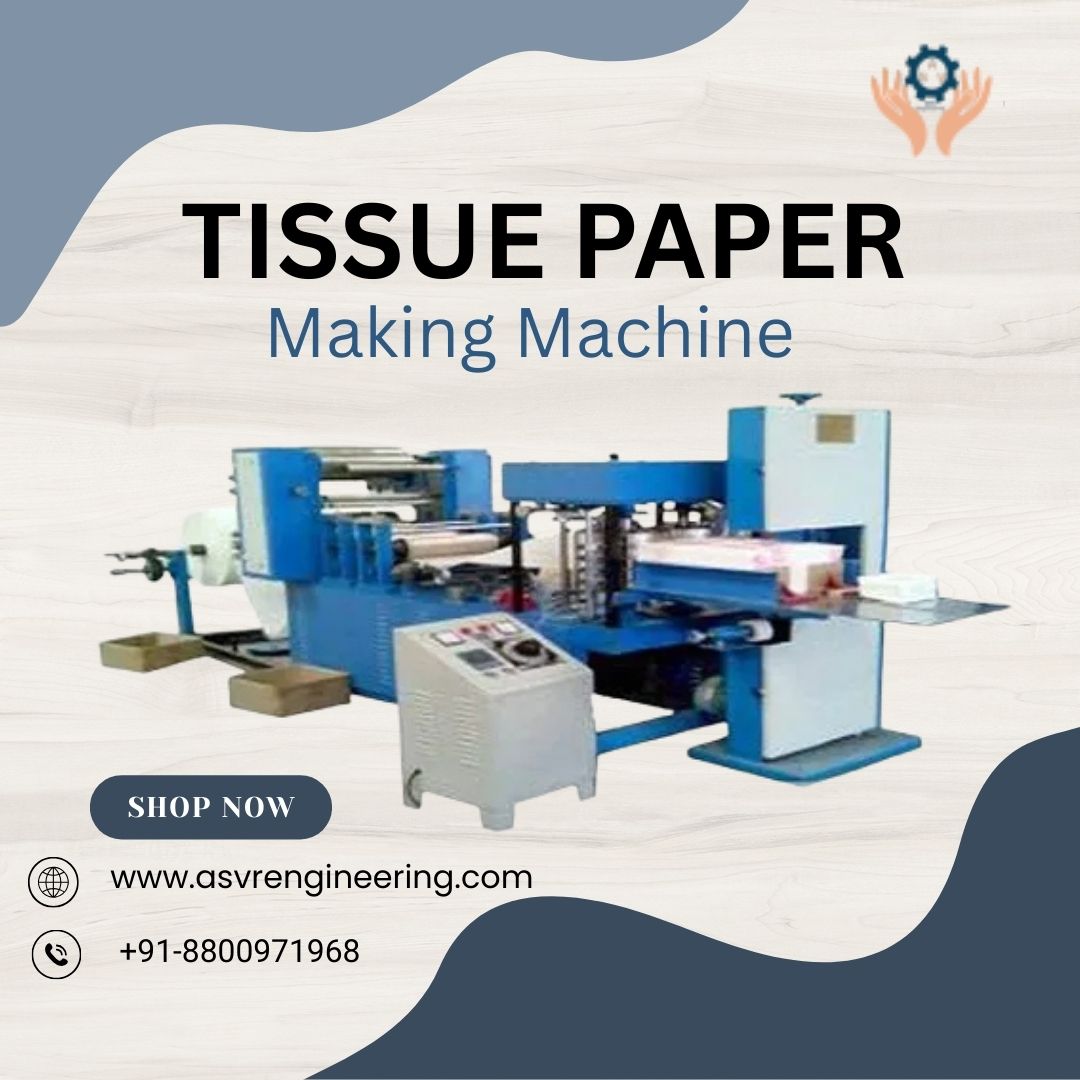

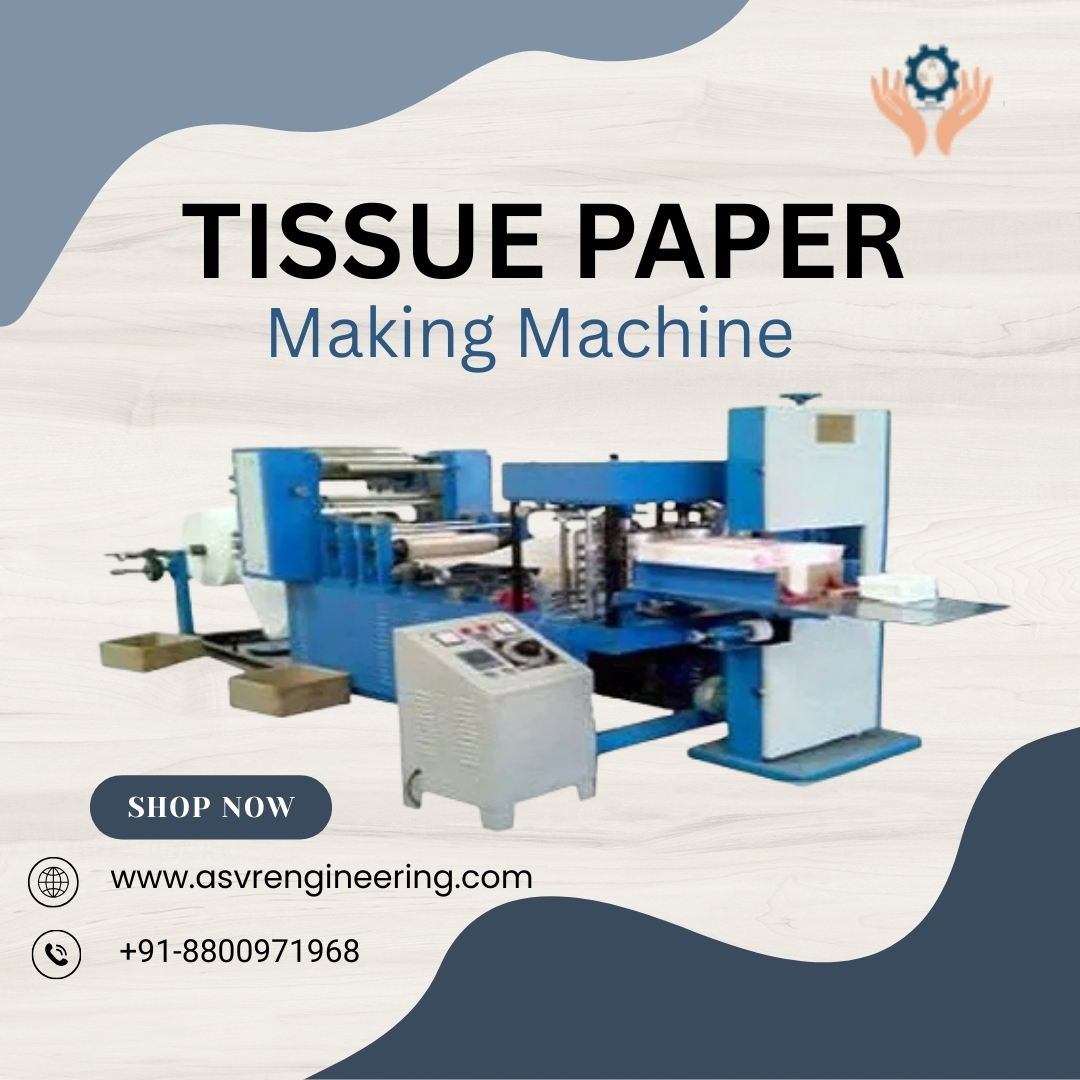

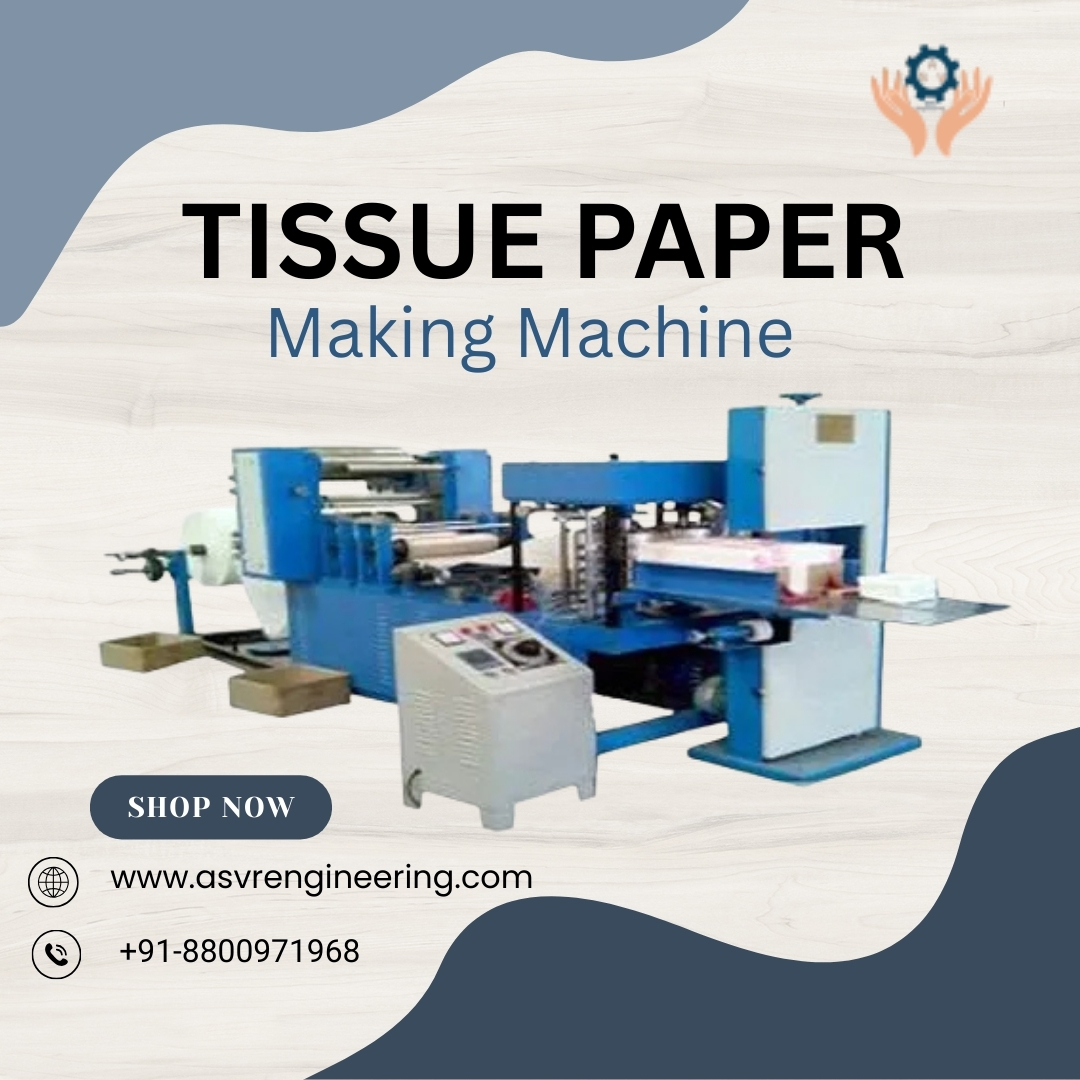

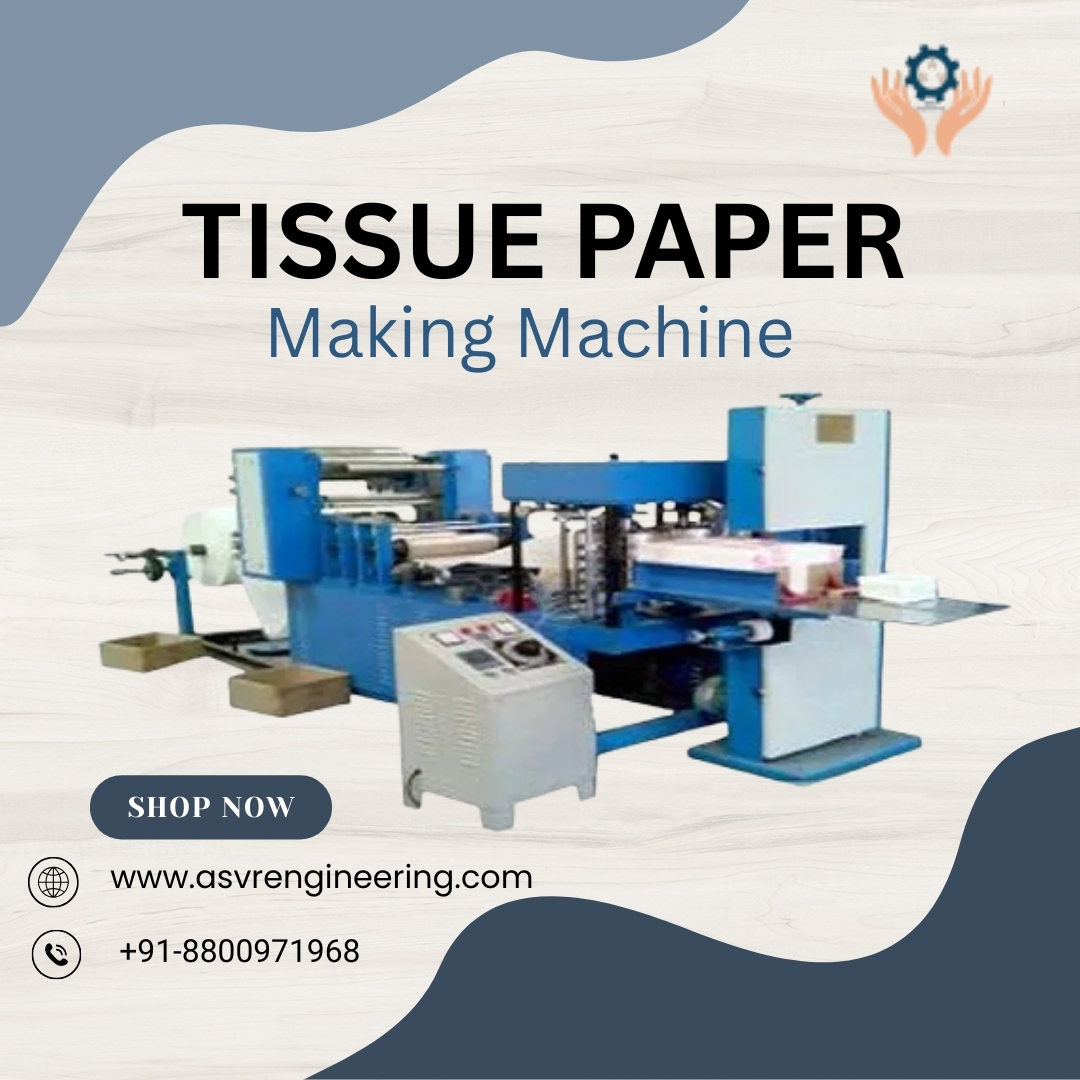

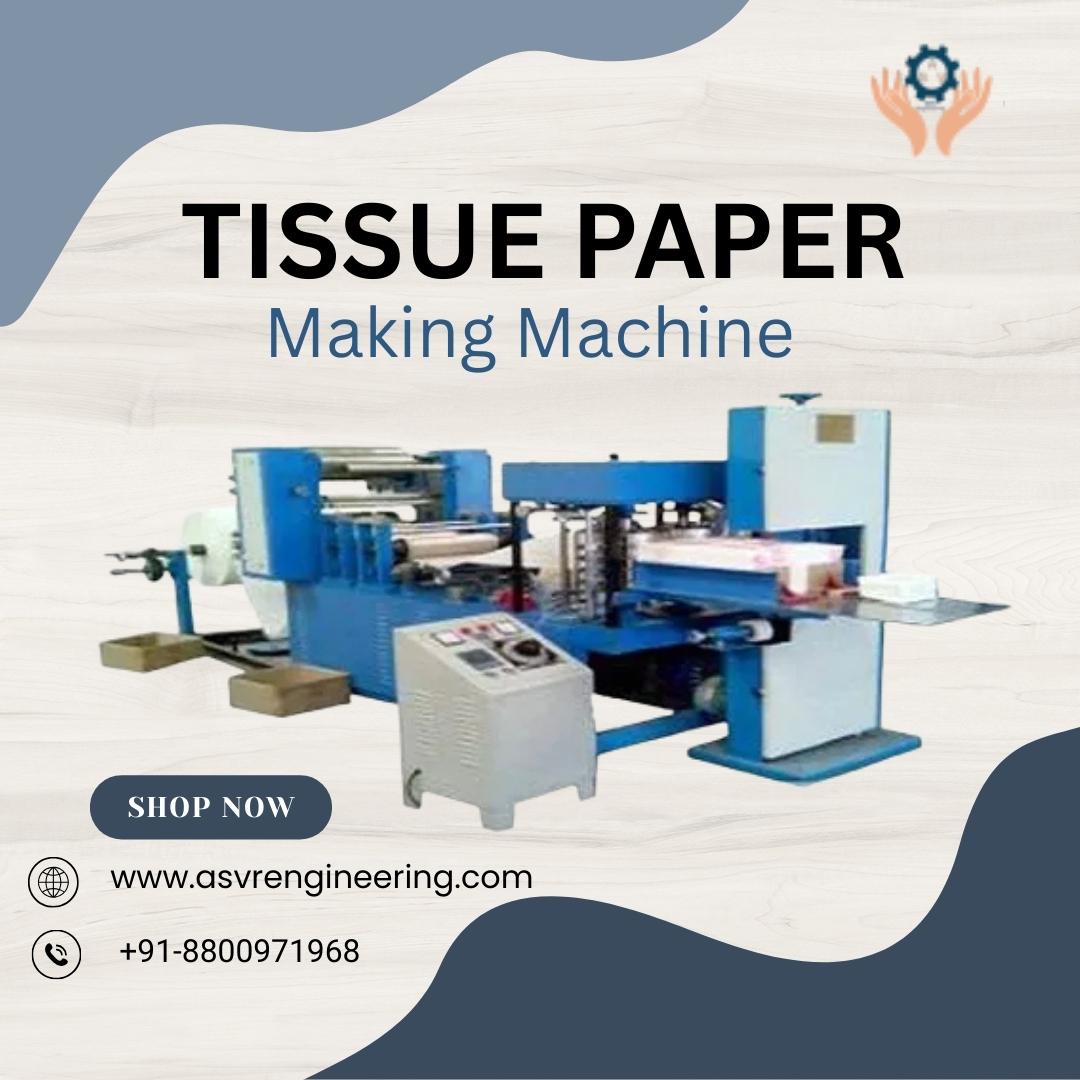

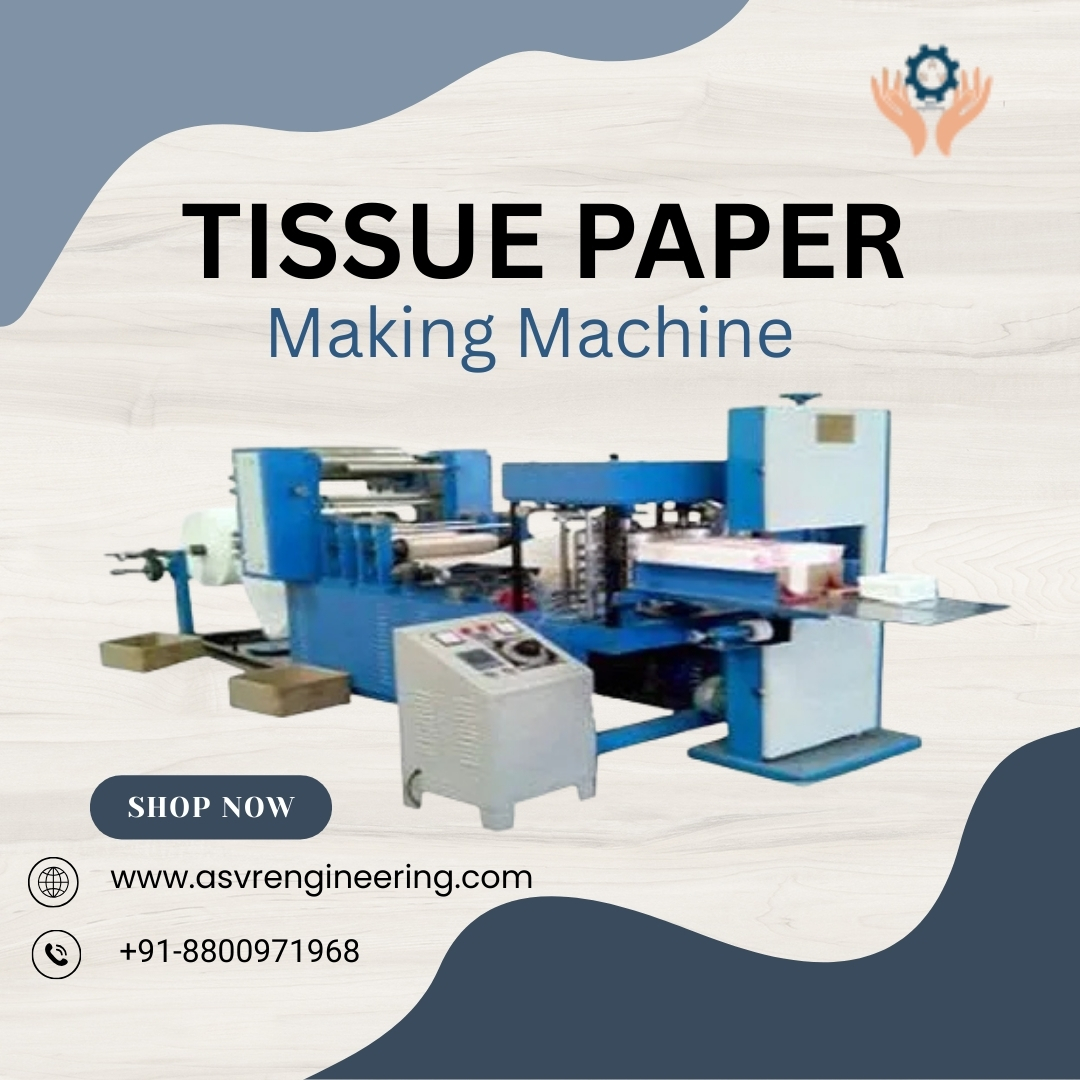

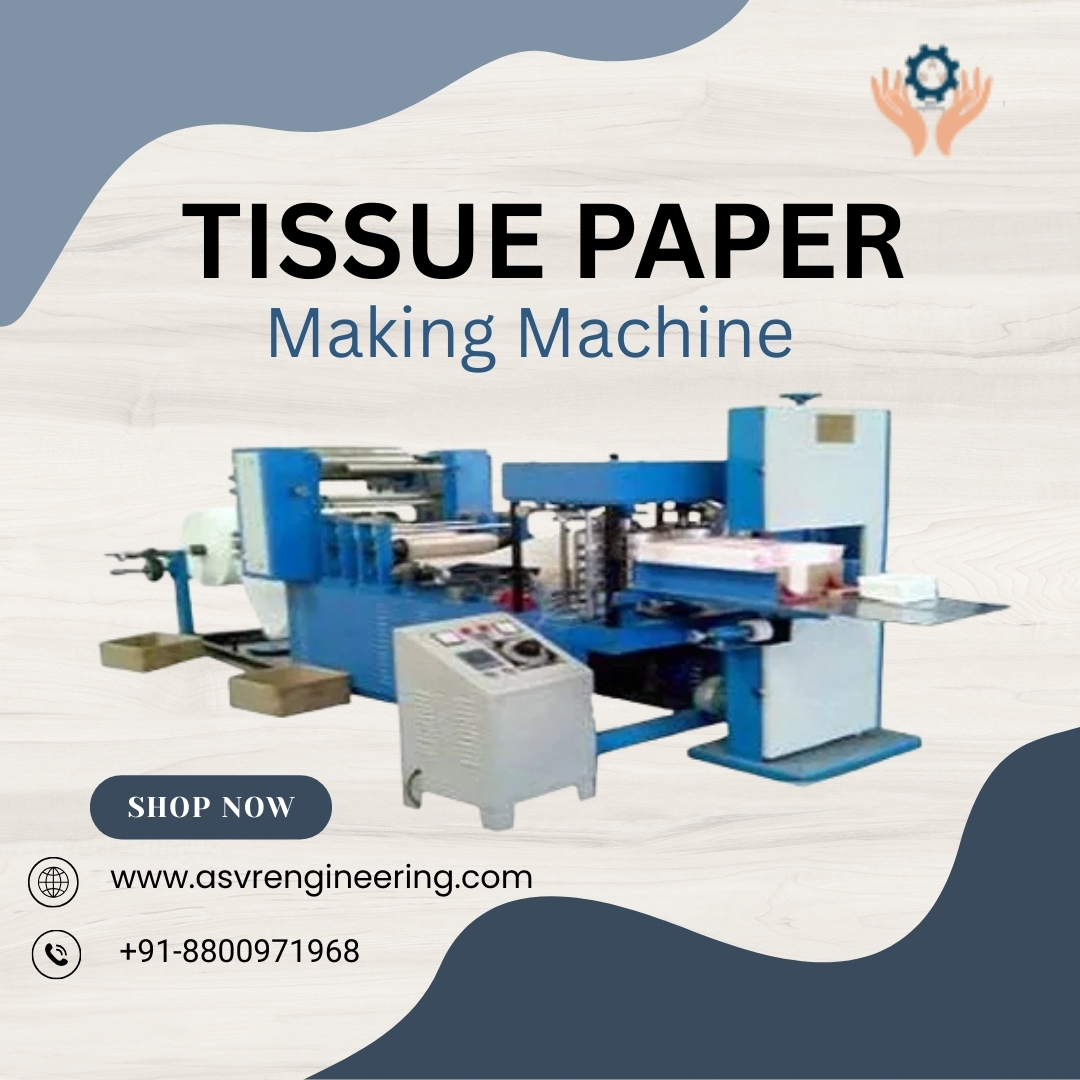

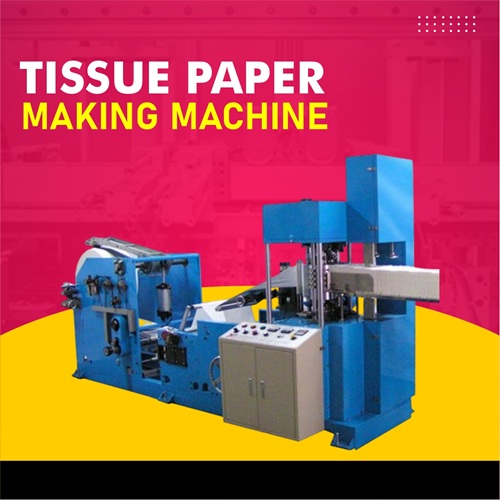

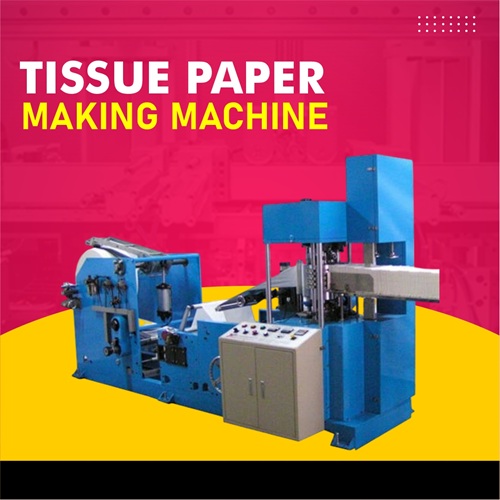

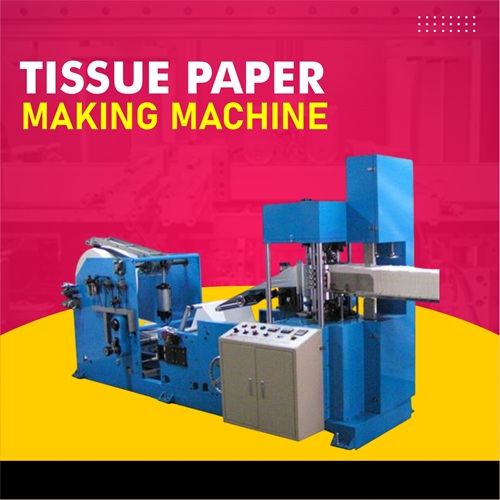

Tissue Paper Making Machine

Price: ₹443000

The tissue paper industry has witnessed rapid growth over the last decade due to increasing hygiene awareness, urbanization, hospitality expansion, healthcare needs, and rising disposable income. From homes and offices to hospitals, hotels, restaurants, and public facilities, tissue paper products have become an everyday necessity. At the heart of this growing demand lies the Tissue Paper Machine, a specialized industrial system designed to manufacture high-quality tissue products efficiently, consistently, and economically.

A modern tissue paper machine is engineered to convert pulp or paper reels into finished tissue products such as toilet rolls, facial tissues, paper napkins, kitchen towels, and jumbo rolls. These machines combine precision engineering, automation, and robust construction to ensure high output, minimal wastage, and superior product quality. Investing in the right tissue paper machine not only ensures smooth production but also plays a vital role in long-term business profitability.

What is a Tissue Paper Machine?

A tissue paper machine is an industrial manufacturing unit used to produce soft, lightweight, absorbent paper products commonly used for hygiene and cleaning purposes. Depending on the configuration, the machine can perform multiple operations such as paper rewinding, embossing, perforation, cutting, folding, and packaging.

These machines are available in manual, semi-automatic, and fully automatic variants, allowing manufacturers to choose based on production capacity, labor availability, budget, and scale of operations. Whether you are a startup entering the tissue paper business or an established manufacturer looking to expand production, selecting the right tissue paper machine is a critical decision.

Types of Tissue Paper Machines

1. Toilet Paper Making Machine

This machine is designed specifically for manufacturing toilet rolls used in residential, commercial, and institutional settings. It produces soft, perforated rolls with uniform thickness and high absorbency. The machine can handle jumbo rolls and convert them into finished toilet paper rolls efficiently.

2. Facial Tissue Paper Machine

Facial tissue machines produce ultra-soft, lightweight tissues suitable for personal hygiene. These machines focus on smooth texture, precise folding, and consistent sheet size, making them ideal for premium tissue products.

3. Napkin Tissue Paper Machine

Napkin tissue paper machines are widely used in hotels, restaurants, food courts, and events. They produce folded or unfolded napkins with embossing options for branding and improved absorbency.

4. Jumbo Roll Tissue Machine

This machine is used for producing large parent rolls that are later converted into finished tissue products. It is ideal for manufacturers supplying raw material to converting units.

5. Automatic Tissue Paper Machine

Automatic machines offer high-speed production with minimal human intervention. Features such as auto tension control, PLC systems, and synchronized cutting ensure efficiency, consistency, and reduced labor costs.

6. Semi-Automatic Tissue Paper Machine

Semi-automatic machines strike a balance between affordability and performance. They require limited manual operation while still delivering reliable output and quality.

Key Components of a Tissue Paper Machine

A high-quality tissue paper machine consists of several precision-engineered components working together seamlessly:

-

Rewinding Unit – Converts jumbo rolls into smaller rolls with uniform tension.

-

Embossing Unit – Enhances softness, thickness, and aesthetic appeal.

-

Perforation System – Ensures easy tearing and consistent sheet length.

-

Cutting Unit – Delivers accurate roll size and clean edges.

-

Core Loading System – Inserts cardboard cores efficiently.

-

Drive System – High-performance motors ensure smooth and stable operation.

-

Control Panel – User-friendly interface for speed, tension, and operation control.

Each component plays a vital role in ensuring smooth production and high-quality output.

Manufacturing Process of Tissue Paper

The tissue paper manufacturing process involves several stages:

-

Raw Material Preparation

The process begins with pulp or recycled paper, depending on product requirements and sustainability goals. -

Paper Formation

The pulp is processed to form thin, lightweight tissue paper sheets with controlled thickness and softness. -

Drying & Reeling

The paper is dried and wound into jumbo rolls for further processing. -

Rewinding & Embossing

Jumbo rolls are rewound, embossed, and perforated to enhance quality and usability. -

Cutting & Packaging

The finished rolls or sheets are cut to size and packaged for distribution.

A well-designed tissue paper machine ensures efficiency at every stage, minimizing waste and maximizing productivity.

Advantages of Investing in a Tissue Paper Machine

-

High Market Demand – Tissue paper products are essential and consistently in demand.

-

Scalable Production – Machines can be upgraded or expanded as business grows.

-

Cost Efficiency – Automated systems reduce labor costs and material wastage.

-

Consistent Quality – Uniform thickness, softness, and strength in every batch.

-

Quick ROI – High demand and efficient production lead to faster returns on investment.

-

Customization Options – Ability to produce different sizes, embossing patterns, and packaging styles.

Why Choose ASVR Engineering for Tissue Paper Machines

ASVR Engineering is a trusted name in industrial machinery manufacturing, known for delivering reliable, durable, and high-performance tissue paper machines. With a strong focus on quality engineering and customer satisfaction, the company offers solutions tailored to diverse production requirements.

Key Strengths

-

Robust machine construction using premium-grade materials

-

Advanced technology for smooth and efficient operation

-

Energy-efficient designs for reduced operational costs

-

Custom-built machines to match specific production needs

-

Dedicated after-sales support and technical assistance

ASVR Engineering combines industry expertise with innovation to deliver machines that perform consistently even under demanding production conditions.

Applications of Tissue Paper Products

Tissue paper manufactured using advanced machines is widely used across multiple sectors:

-

Households for daily hygiene

-

Hospitals and healthcare centers

-

Hotels, restaurants, and catering services

-

Offices and commercial spaces

-

Airports, malls, and public restrooms

-

Beauty salons and spas

The versatility of tissue paper products ensures a stable and growing market for manufacturers.

Maintenance & Operational Efficiency

Proper maintenance of a tissue paper machine ensures long service life and uninterrupted production. Regular lubrication, timely replacement of wear parts, and routine inspection of electrical and mechanical systems help maintain peak performance. Machines supplied by ASVR Engineering are designed for easy maintenance, reducing downtime and improving overall operational efficiency.

Future Scope of Tissue Paper Manufacturing Business

With increasing focus on cleanliness, hygiene, and sustainability, the tissue paper industry is expected to grow steadily in the coming years. Eco-friendly products, recycled paper usage, and energy-efficient machines are shaping the future of this sector. Investing in a modern tissue paper machine today positions manufacturers to capitalize on this growing demand and evolving market trends.

Contact Information

For detailed specifications, pricing, and customized tissue paper machine solutions, contact:

📞 +91-8076004849

📞 +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now