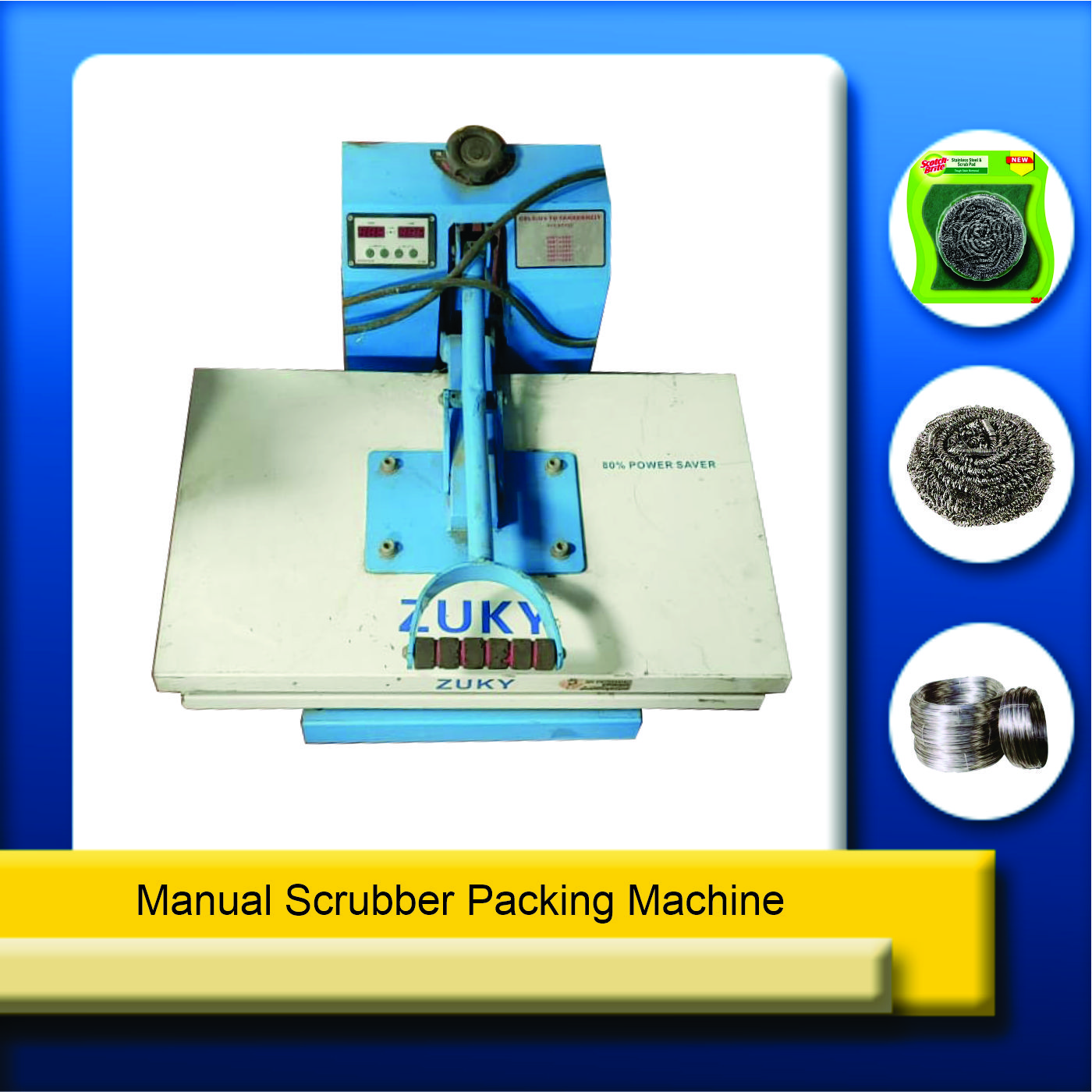

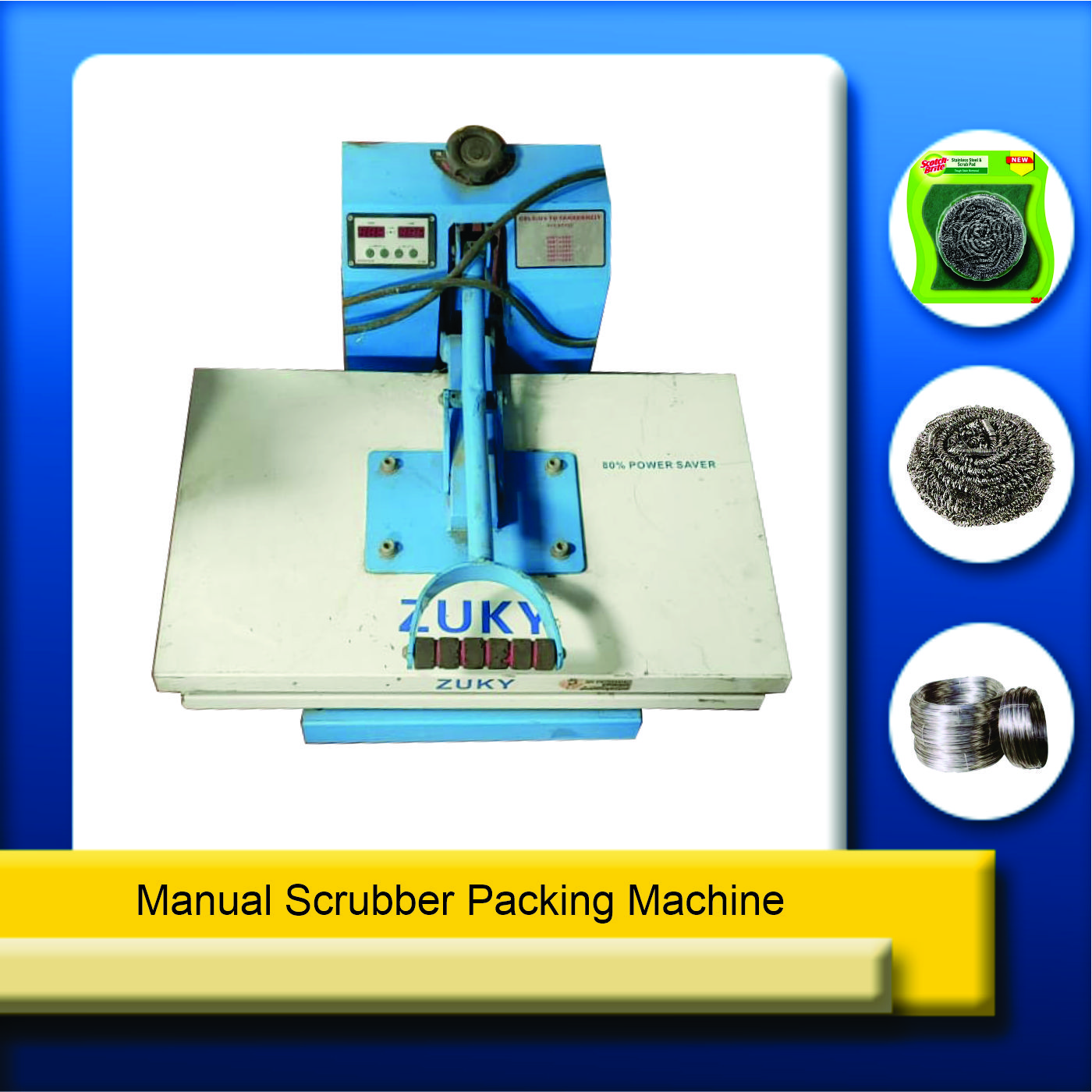

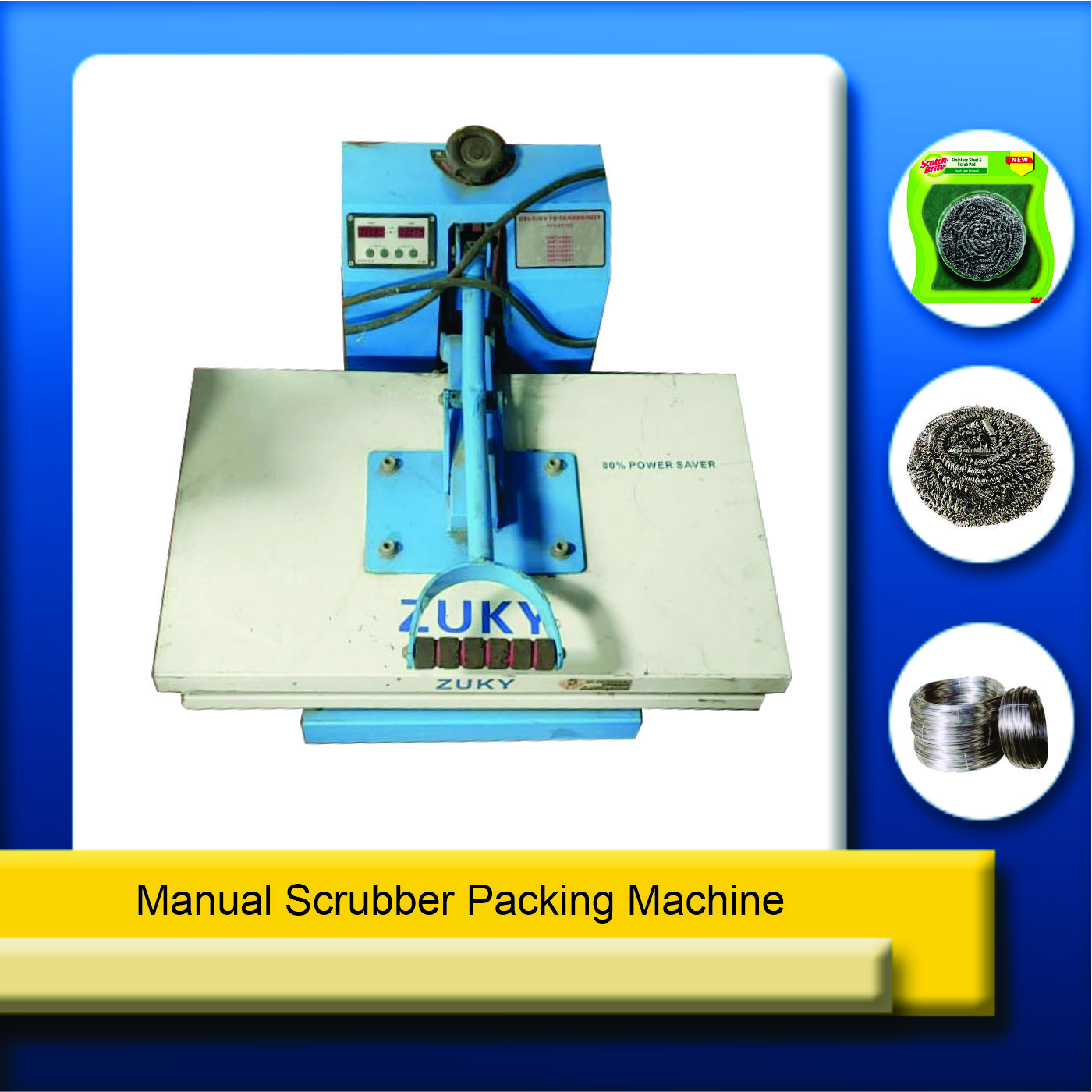

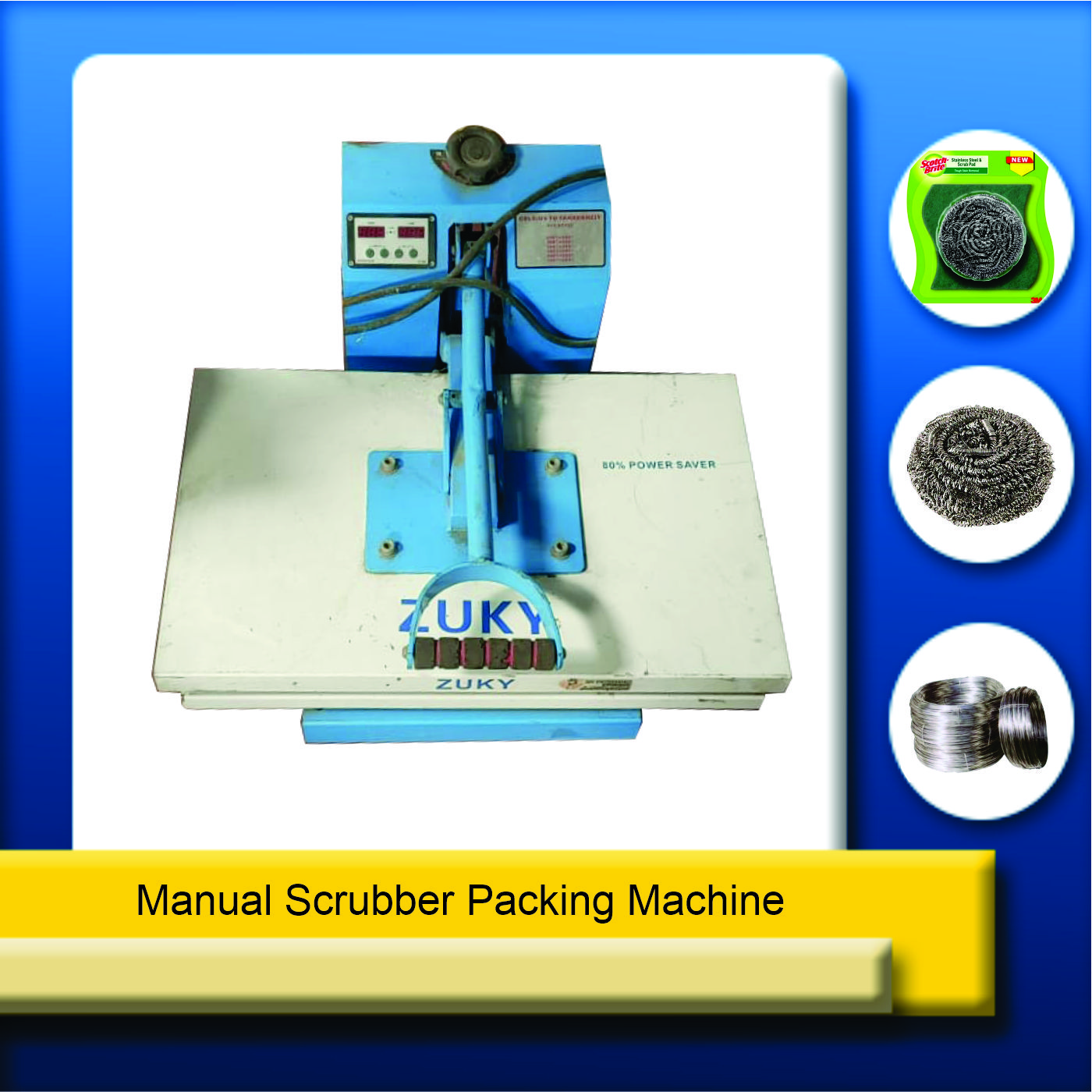

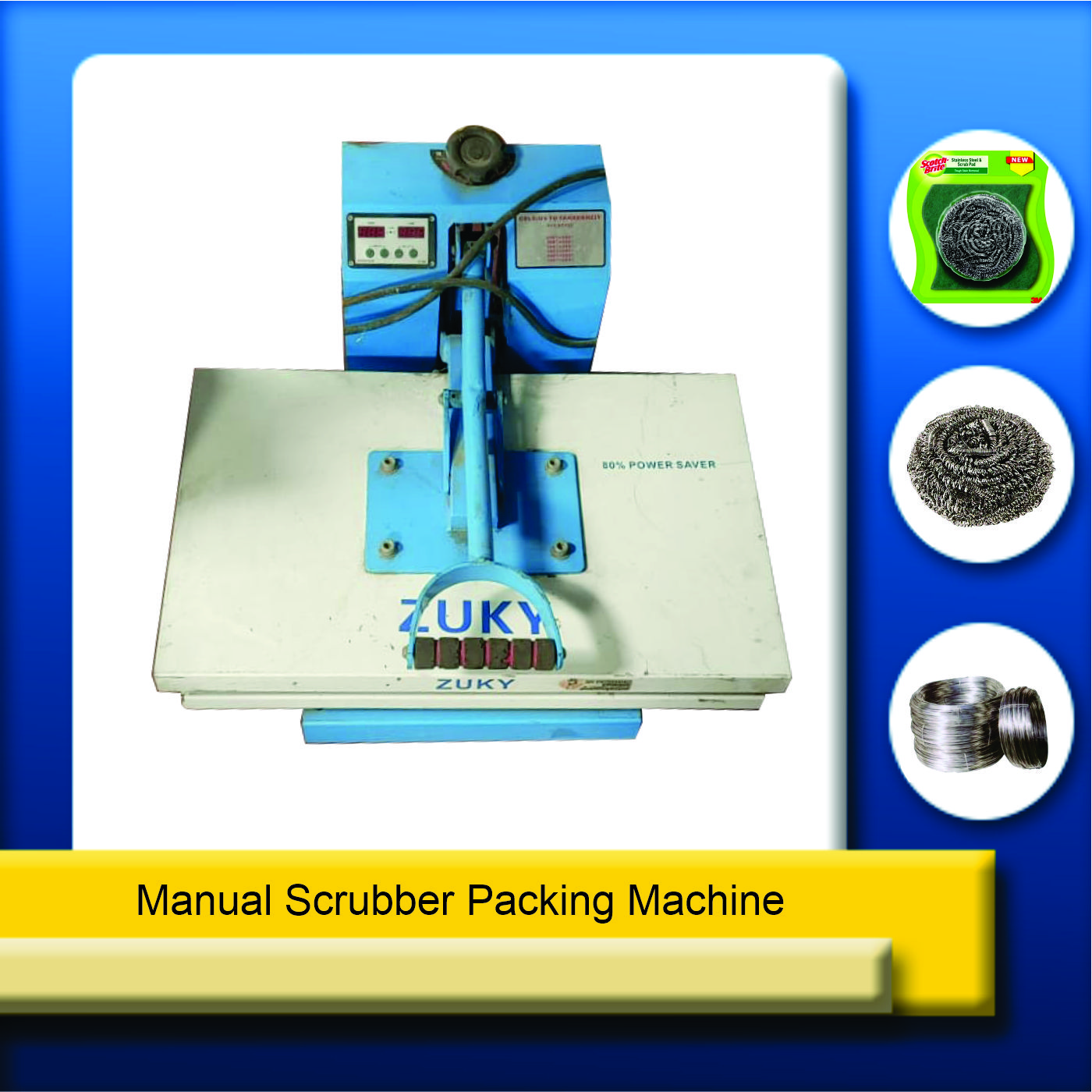

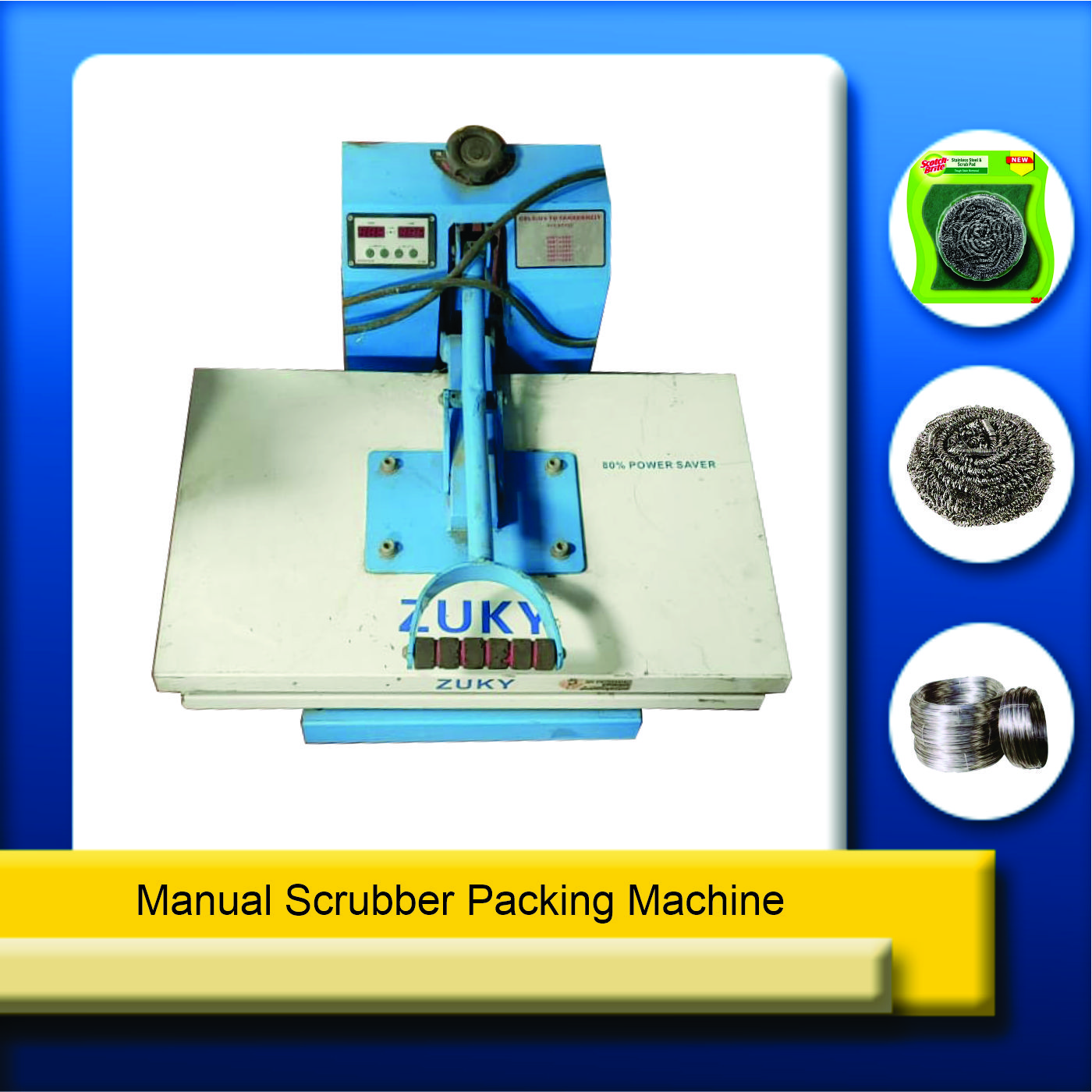

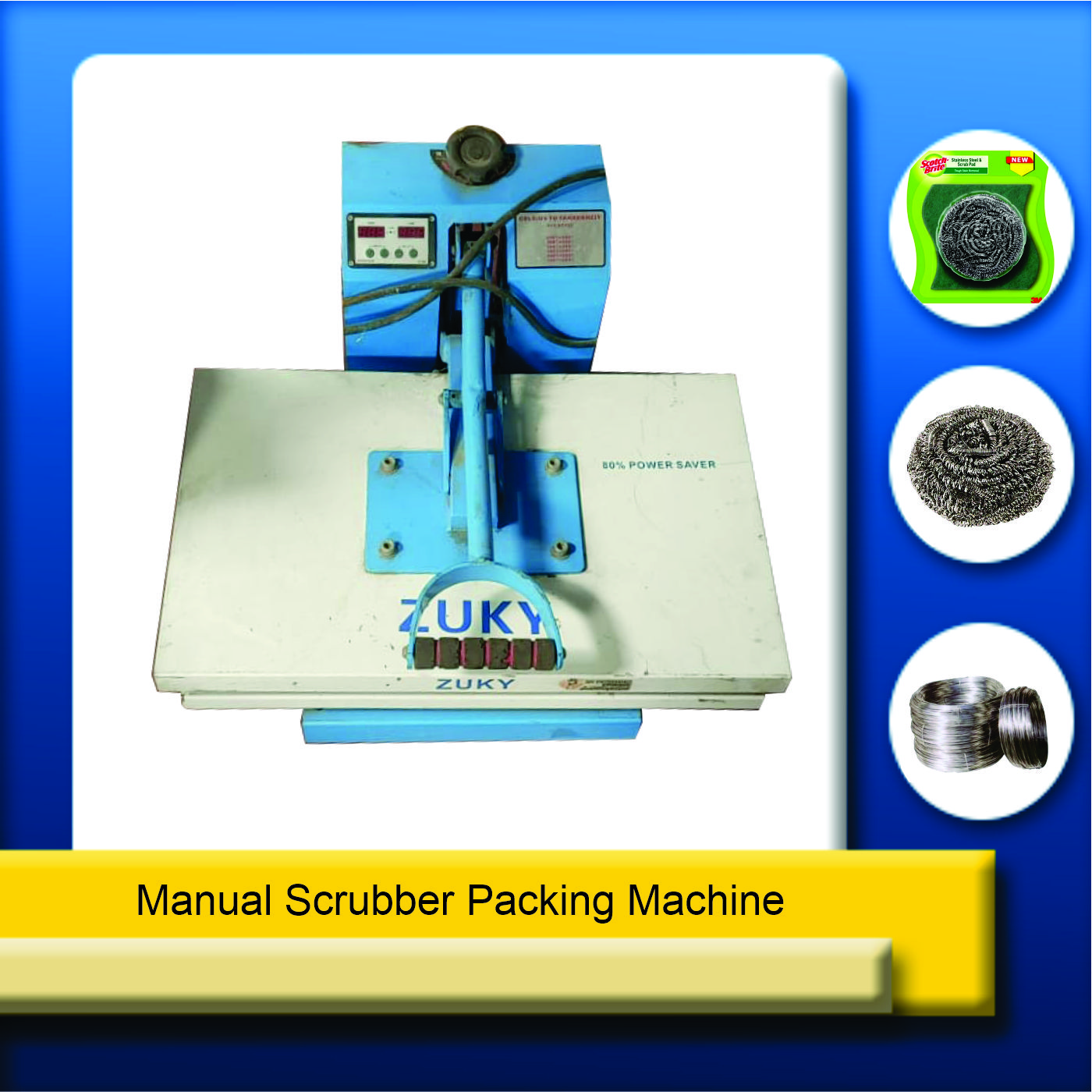

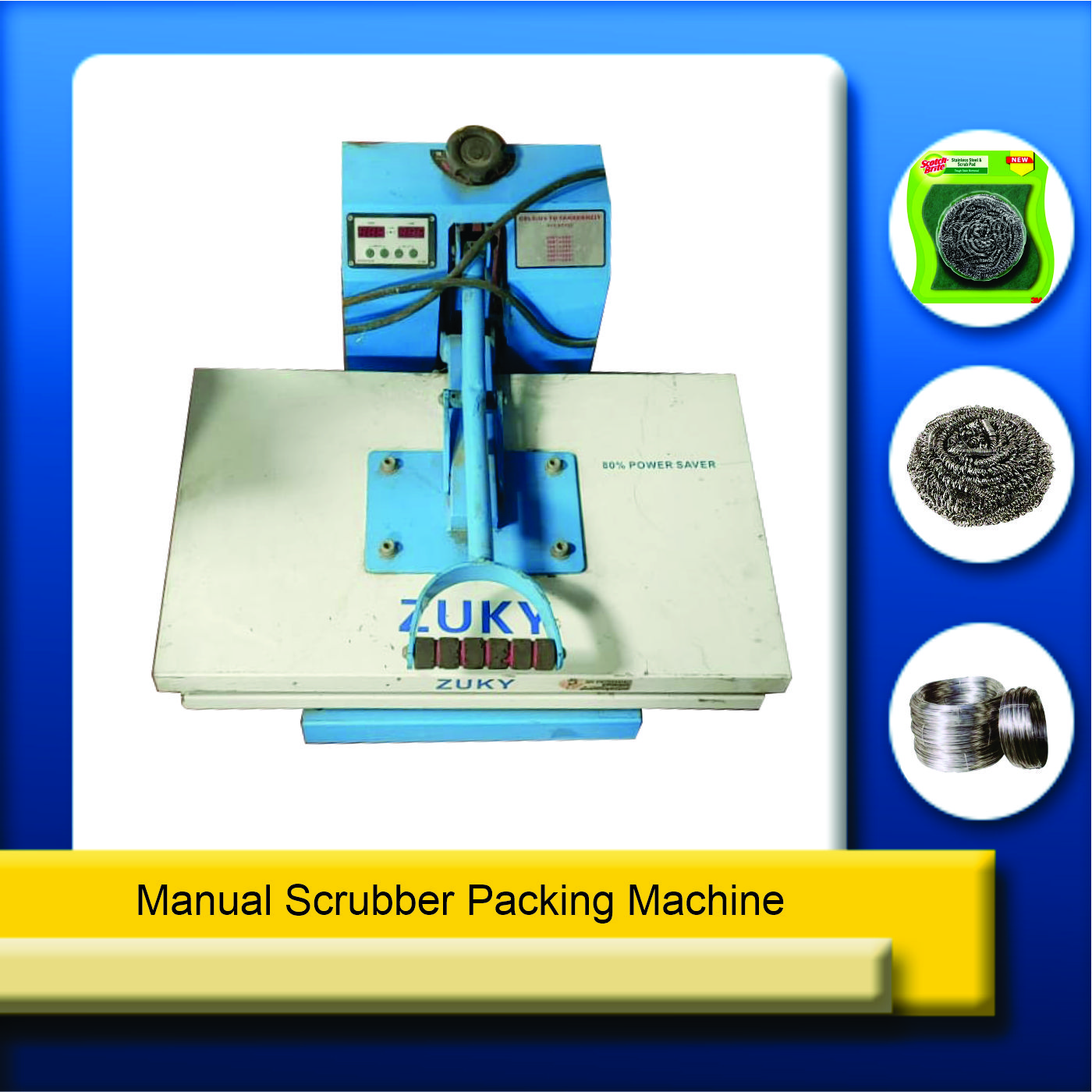

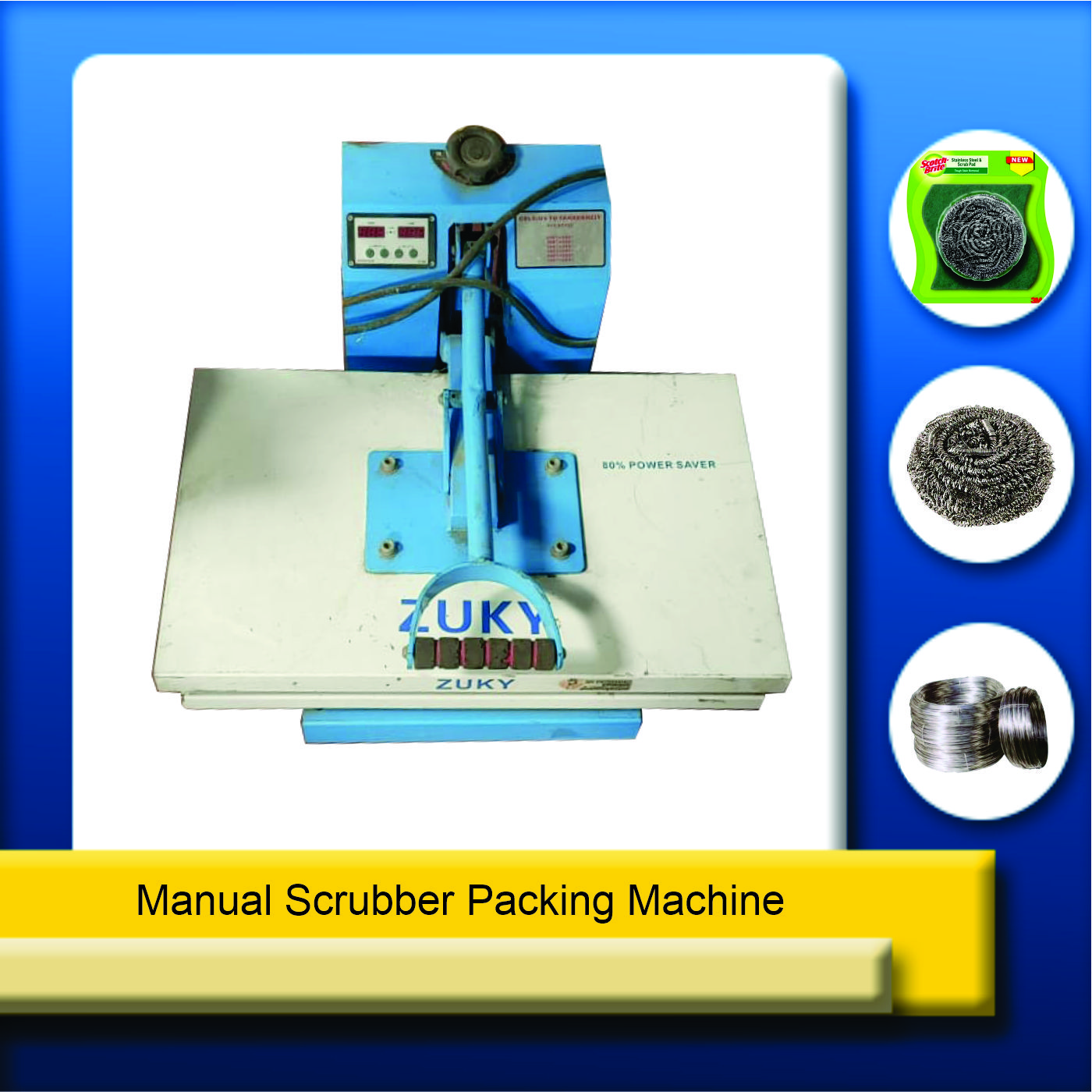

Scrubber Packing Machine

Price: ₹90000

In today’s competitive cleaning and hygiene industry, product presentation and packaging quality play a vital role in brand success. Whether it is household scrubbers, industrial cleaning pads, or specialty scrubbers used in commercial kitchens, packaging directly affects shelf life, customer perception, and logistics efficiency. A Scrubber Packing Machine is designed to meet these exact needs by offering speed, accuracy, hygiene, and consistency in packaging.

A scrubber packing machine is a specialized packaging solution used to pack scrubbers into pouches, packets, or wraps with precision and uniformity. These machines are widely used by manufacturers of kitchen scrubbers, steel scrubbers, plastic scrubbers, foam-based scrubbers, and other cleaning accessories. With the growing demand for automation and standardized packaging, businesses are shifting from manual packing methods to advanced automatic and semi-automatic scrubber packing machines.

What is a Scrubber Packing Machine?

A Scrubber Packing Machine is an industrial packaging machine engineered to pack scrubbers efficiently using heat sealing, flow wrapping, or pouch sealing technology. It automates the entire packaging process, including feeding, positioning, sealing, cutting, and batch output. This ensures uniform packaging, reduced material wastage, and enhanced productivity.

Unlike manual packing, which is time-consuming and inconsistent, scrubber packing machines offer a streamlined solution suitable for small-scale units as well as large manufacturing plants.

Why Packaging Matters in Scrubber Manufacturing

Scrubbers are daily-use cleaning products, and their packaging must be:

Hygienic and dust-free

Visually attractive for retail display

Strong enough to protect product shape

Easy to store, transport, and stack

Poor packaging can lead to deformation, contamination, and loss of customer trust. A high-quality scrubber packing machine ensures that each product is sealed properly and presented professionally.

Types of Scrubber Packing Machines

Depending on production requirements and scrubber type, different configurations are available:

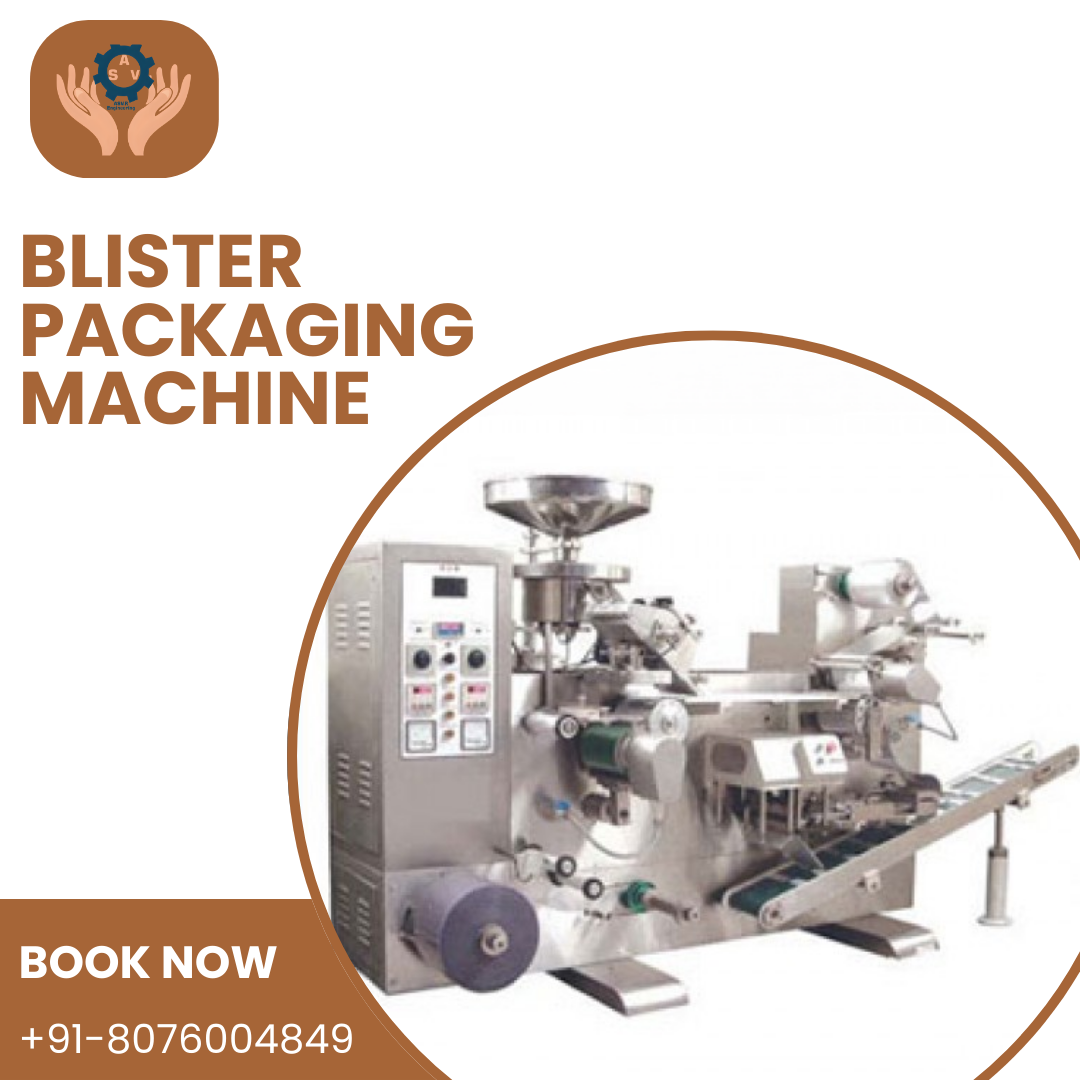

1. Automatic Scrubber Packing Machine

Ideal for high-volume production units, this machine operates with minimal human intervention. It offers high speed, precise sealing, and consistent output quality.

2. Semi-Automatic Scrubber Packing Machine

Best suited for small to medium businesses, this machine balances cost-effectiveness and productivity. Some manual input is required, while sealing and cutting remain automated.

3. Flow Wrap Scrubber Packing Machine

Used for single scrubbers or bundled scrubbers, flow wrapping provides tight, attractive, and moisture-resistant packaging.

4. Pouch Packing Machine for Scrubbers

This machine packs scrubbers into pre-formed or form-fill-seal pouches, making it ideal for retail markets.

Key Features of a Scrubber Packing Machine

A modern scrubber packing machine is built with advanced features to ensure long-term performance and ease of operation:

Robust MS/SS body construction

High-quality sealing jaws for leak-proof packing

Adjustable speed control system

User-friendly control panel

Low power consumption

Consistent pouch size and sealing quality

Minimal maintenance requirement

Compatibility with various packaging materials

These features make the machine suitable for continuous industrial use with reliable output.

Advantages of Using a Scrubber Packing Machine

Investing in a scrubber packing machine brings multiple business benefits:

Increased Productivity

Automation significantly increases output compared to manual packing, allowing manufacturers to meet market demand efficiently.

Cost Efficiency

Reduced labor dependency and minimized material wastage result in lower operational costs over time.

Improved Packaging Quality

Uniform sealing and professional presentation enhance product appeal and brand value.

Hygienic Packaging

Machines operate in a controlled environment, ensuring cleaner and safer packaging.

Scalability

As business demand grows, machines can be upgraded or integrated into a complete packing line.

Industries That Use Scrubber Packing Machines

Scrubber packing machines are widely used across various sectors, including:

Household cleaning product manufacturing

Industrial cleaning equipment suppliers

FMCG companies

Export-oriented scrubber manufacturers

Commercial kitchen cleaning product units

Their versatility makes them suitable for both domestic and international markets.

Packaging Materials Used

Scrubber packing machines support a wide range of packaging materials such as:

LDPE films

HDPE films

Laminated pouches

Printed packaging rolls

Food-grade plastic films

The choice of material depends on branding, durability, and market positioning.

Quality & Durability

A high-quality scrubber packing machine is designed for continuous operation under industrial conditions. Precision-engineered components, heavy-duty frames, and reliable sealing mechanisms ensure long service life with minimal downtime. Proper quality control during manufacturing ensures consistent machine performance and accurate packaging results.

Maintenance & Ease of Operation

Modern scrubber packing machines are designed with simplicity in mind. Routine maintenance includes cleaning sealing jaws, checking electrical connections, and lubricating moving parts. Easy accessibility to components ensures quick servicing and minimal production interruption.

Why Choose a Trusted Manufacturer

Selecting the right manufacturer is crucial for long-term success. A reliable manufacturer ensures:

High-quality machine construction

Timely delivery

Technical support and spare parts availability

Customization based on production needs

Competitive pricing

Working with experienced professionals guarantees that the machine meets both current and future business requirements.

About ASVR Engineering

ASVR Engineering is a trusted name in industrial packaging and automation solutions. The company is known for manufacturing and supplying reliable, high-performance packing machines designed for Indian and global markets. With a strong focus on quality, innovation, and customer satisfaction, ASVR Engineering delivers machines that meet industry standards and client expectations.

Their scrubber packing machines are engineered using advanced technology, ensuring durability, accuracy, and efficiency for long-term industrial use.

Applications & Market Demand

With increasing awareness of hygiene and cleanliness, the demand for scrubbers and cleaning products is growing rapidly. Retail chains, supermarkets, and online marketplaces require well-packed products that are easy to store and visually appealing. Scrubber packing machines help manufacturers keep up with this demand while maintaining consistent quality.

Customization Options

Depending on customer requirements, scrubber packing machines can be customized in terms of:

Packing speed

Pouch size

Film type compatibility

Automation level

Branding and printing alignment

Customization ensures that the machine perfectly aligns with production goals.

Conclusion

A Scrubber Packing Machine is not just a piece of equipment; it is a strategic investment for businesses aiming to grow in the cleaning products industry. From improved efficiency and reduced costs to professional packaging and enhanced brand value, the benefits are substantial. Whether you are a startup or an established manufacturer, choosing the right scrubber packing machine can significantly impact your operational success.

For reliable performance, durable construction, and expert support, investing in a quality scrubber packing machine from an experienced manufacturer is the smartest move for long-term growth.

Contact Information

📞 Call Now:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

In today’s competitive cleaning and hygiene industry, product presentation and packaging quality play a vital role in brand success. Whether it is household scrubbers, industrial cleaning pads, or specialty scrubbers used in commercial kitchens, packaging directly affects shelf life, customer perception, and logistics efficiency. A Scrubber Packing Machine is designed to meet these exact needs by offering speed, accuracy, hygiene, and consistency in packaging.

A scrubber packing machine is a specialized packaging solution used to pack scrubbers into pouches, packets, or wraps with precision and uniformity. These machines are widely used by manufacturers of kitchen scrubbers, steel scrubbers, plastic scrubbers, foam-based scrubbers, and other cleaning accessories. With the growing demand for automation and standardized packaging, businesses are shifting from manual packing methods to advanced automatic and semi-automatic scrubber packing machines.

What is a Scrubber Packing Machine?

A Scrubber Packing Machine is an industrial packaging machine engineered to pack scrubbers efficiently using heat sealing, flow wrapping, or pouch sealing technology. It automates the entire packaging process, including feeding, positioning, sealing, cutting, and batch output. This ensures uniform packaging, reduced material wastage, and enhanced productivity.

Unlike manual packing, which is time-consuming and inconsistent, scrubber packing machines offer a streamlined solution suitable for small-scale units as well as large manufacturing plants.

Why Packaging Matters in Scrubber Manufacturing

Scrubbers are daily-use cleaning products, and their packaging must be:

Hygienic and dust-free

Visually attractive for retail display

Strong enough to protect product shape

Easy to store, transport, and stack

Poor packaging can lead to deformation, contamination, and loss of customer trust. A high-quality scrubber packing machine ensures that each product is sealed properly and presented professionally.

Types of Scrubber Packing Machines

Depending on production requirements and scrubber type, different configurations are available:

1. Automatic Scrubber Packing Machine

Ideal for high-volume production units, this machine operates with minimal human intervention. It offers high speed, precise sealing, and consistent output quality.

2. Semi-Automatic Scrubber Packing Machine

Best suited for small to medium businesses, this machine balances cost-effectiveness and productivity. Some manual input is required, while sealing and cutting remain automated.

3. Flow Wrap Scrubber Packing Machine

Used for single scrubbers or bundled scrubbers, flow wrapping provides tight, attractive, and moisture-resistant packaging.

4. Pouch Packing Machine for Scrubbers

This machine packs scrubbers into pre-formed or form-fill-seal pouches, making it ideal for retail markets.

Key Features of a Scrubber Packing Machine

A modern scrubber packing machine is built with advanced features to ensure long-term performance and ease of operation:

Robust MS/SS body construction

High-quality sealing jaws for leak-proof packing

Adjustable speed control system

User-friendly control panel

Low power consumption

Consistent pouch size and sealing quality

Minimal maintenance requirement

Compatibility with various packaging materials

These features make the machine suitable for continuous industrial use with reliable output.

Advantages of Using a Scrubber Packing Machine

Investing in a scrubber packing machine brings multiple business benefits:

Increased Productivity

Automation significantly increases output compared to manual packing, allowing manufacturers to meet market demand efficiently.

Cost Efficiency

Reduced labor dependency and minimized material wastage result in lower operational costs over time.

Improved Packaging Quality

Uniform sealing and professional presentation enhance product appeal and brand value.

Hygienic Packaging

Machines operate in a controlled environment, ensuring cleaner and safer packaging.

Scalability

As business demand grows, machines can be upgraded or integrated into a complete packing line.

Industries That Use Scrubber Packing Machines

Scrubber packing machines are widely used across various sectors, including:

Household cleaning product manufacturing

Industrial cleaning equipment suppliers

FMCG companies

Export-oriented scrubber manufacturers

Commercial kitchen cleaning product units

Their versatility makes them suitable for both domestic and international markets.

Packaging Materials Used

Scrubber packing machines support a wide range of packaging materials such as:

LDPE films

HDPE films

Laminated pouches

Printed packaging rolls

Food-grade plastic films

The choice of material depends on branding, durability, and market positioning.

Quality & Durability

A high-quality scrubber packing machine is designed for continuous operation under industrial conditions. Precision-engineered components, heavy-duty frames, and reliable sealing mechanisms ensure long service life with minimal downtime. Proper quality control during manufacturing ensures consistent machine performance and accurate packaging results.

Maintenance & Ease of Operation

Modern scrubber packing machines are designed with simplicity in mind. Routine maintenance includes cleaning sealing jaws, checking electrical connections, and lubricating moving parts. Easy accessibility to components ensures quick servicing and minimal production interruption.

Why Choose a Trusted Manufacturer

Selecting the right manufacturer is crucial for long-term success. A reliable manufacturer ensures:

High-quality machine construction

Timely delivery

Technical support and spare parts availability

Customization based on production needs

Competitive pricing

Working with experienced professionals guarantees that the machine meets both current and future business requirements.

About ASVR Engineering

ASVR Engineering is a trusted name in industrial packaging and automation solutions. The company is known for manufacturing and supplying reliable, high-performance packing machines designed for Indian and global markets. With a strong focus on quality, innovation, and customer satisfaction, ASVR Engineering delivers machines that meet industry standards and client expectations.

Their scrubber packing machines are engineered using advanced technology, ensuring durability, accuracy, and efficiency for long-term industrial use.

Applications & Market Demand

With increasing awareness of hygiene and cleanliness, the demand for scrubbers and cleaning products is growing rapidly. Retail chains, supermarkets, and online marketplaces require well-packed products that are easy to store and visually appealing. Scrubber packing machines help manufacturers keep up with this demand while maintaining consistent quality.

Customization Options

Depending on customer requirements, scrubber packing machines can be customized in terms of:

Packing speed

Pouch size

Film type compatibility

Automation level

Branding and printing alignment

Customization ensures that the machine perfectly aligns with production goals.

Conclusion

A Scrubber Packing Machine is not just a piece of equipment; it is a strategic investment for businesses aiming to grow in the cleaning products industry. From improved efficiency and reduced costs to professional packaging and enhanced brand value, the benefits are substantial. Whether you are a startup or an established manufacturer, choosing the right scrubber packing machine can significantly impact your operational success.

For reliable performance, durable construction, and expert support, investing in a quality scrubber packing machine from an experienced manufacturer is the smartest move for long-term growth.

Contact Information

📞 Call Now:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Buy Now

(8).jpg)

(8).jpg)

(8).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)