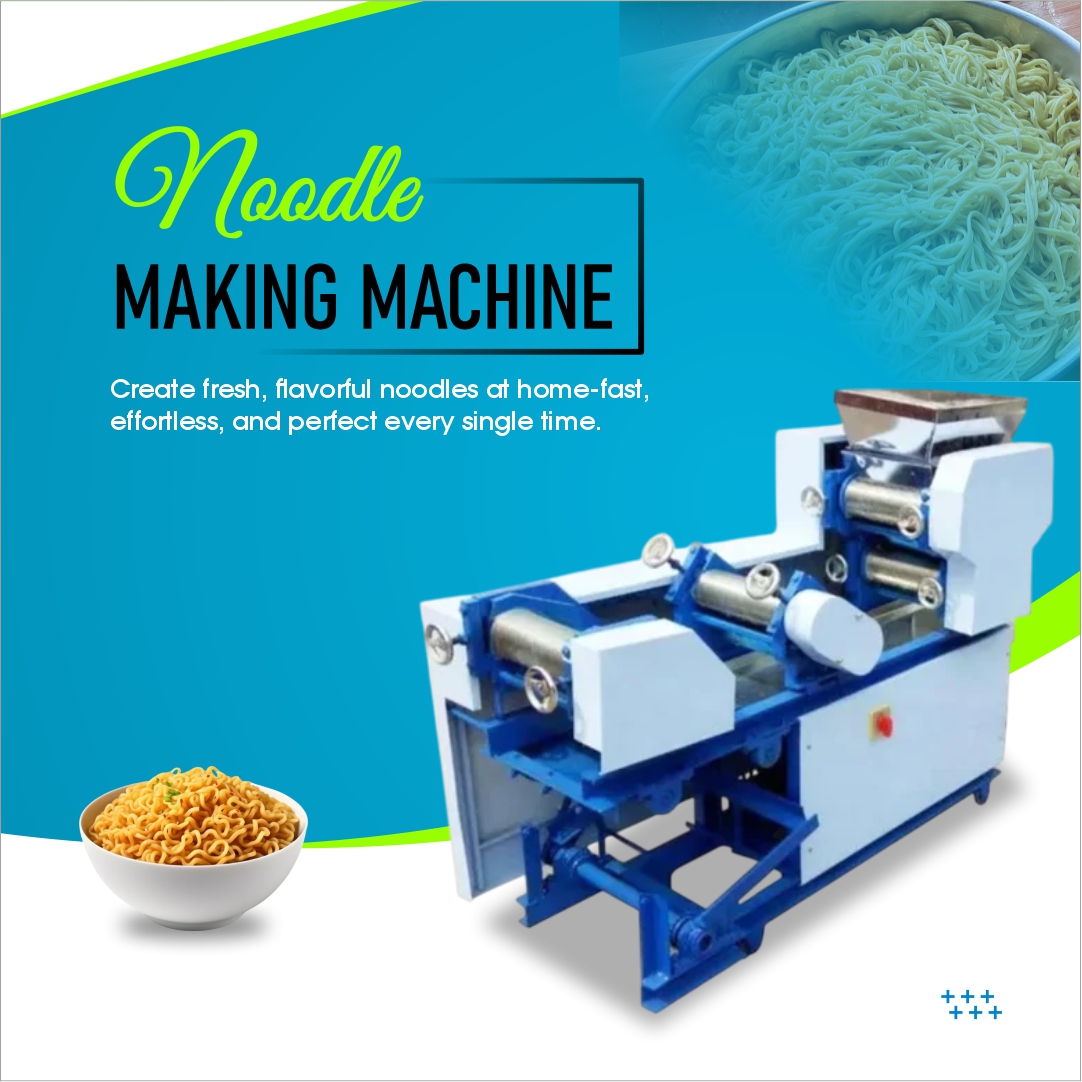

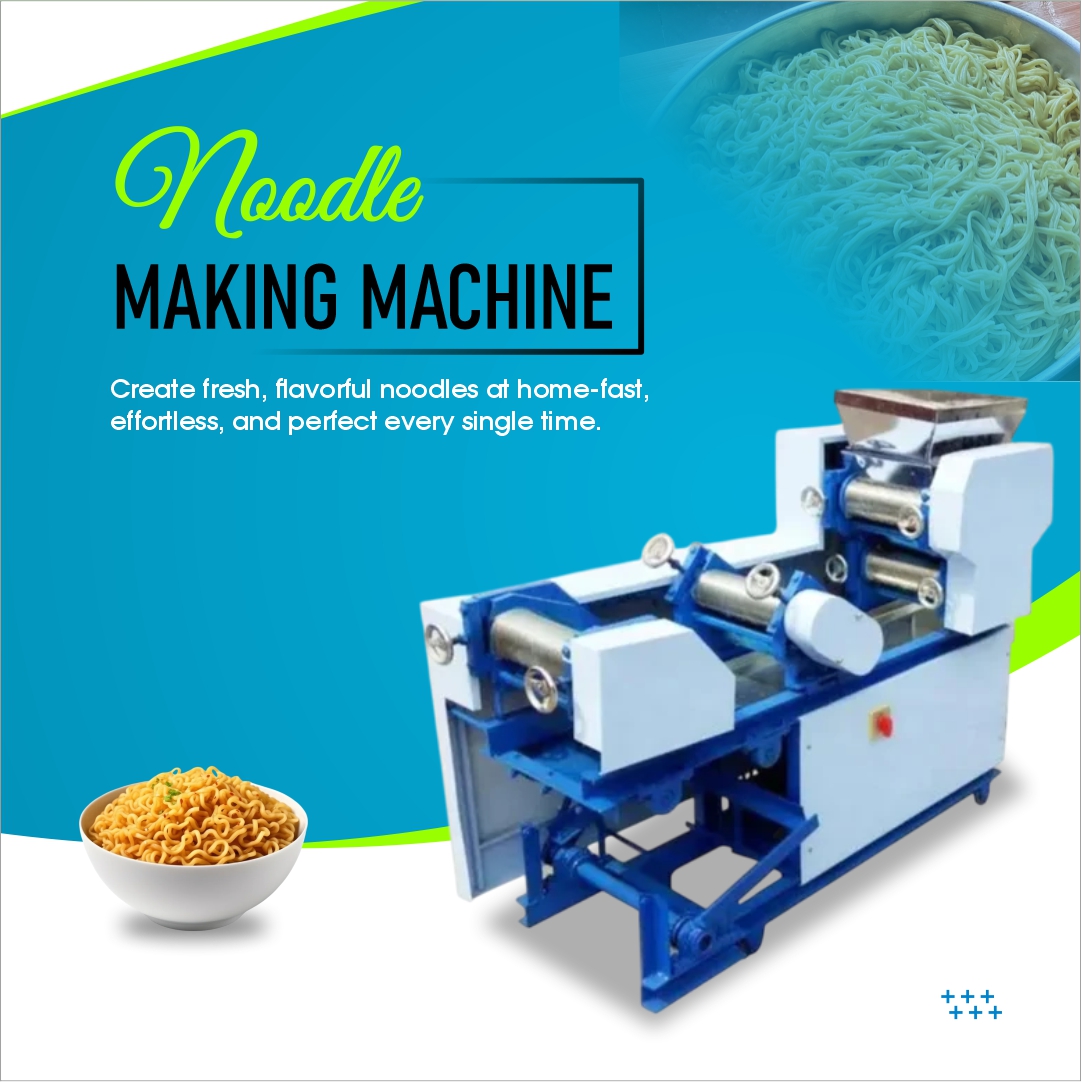

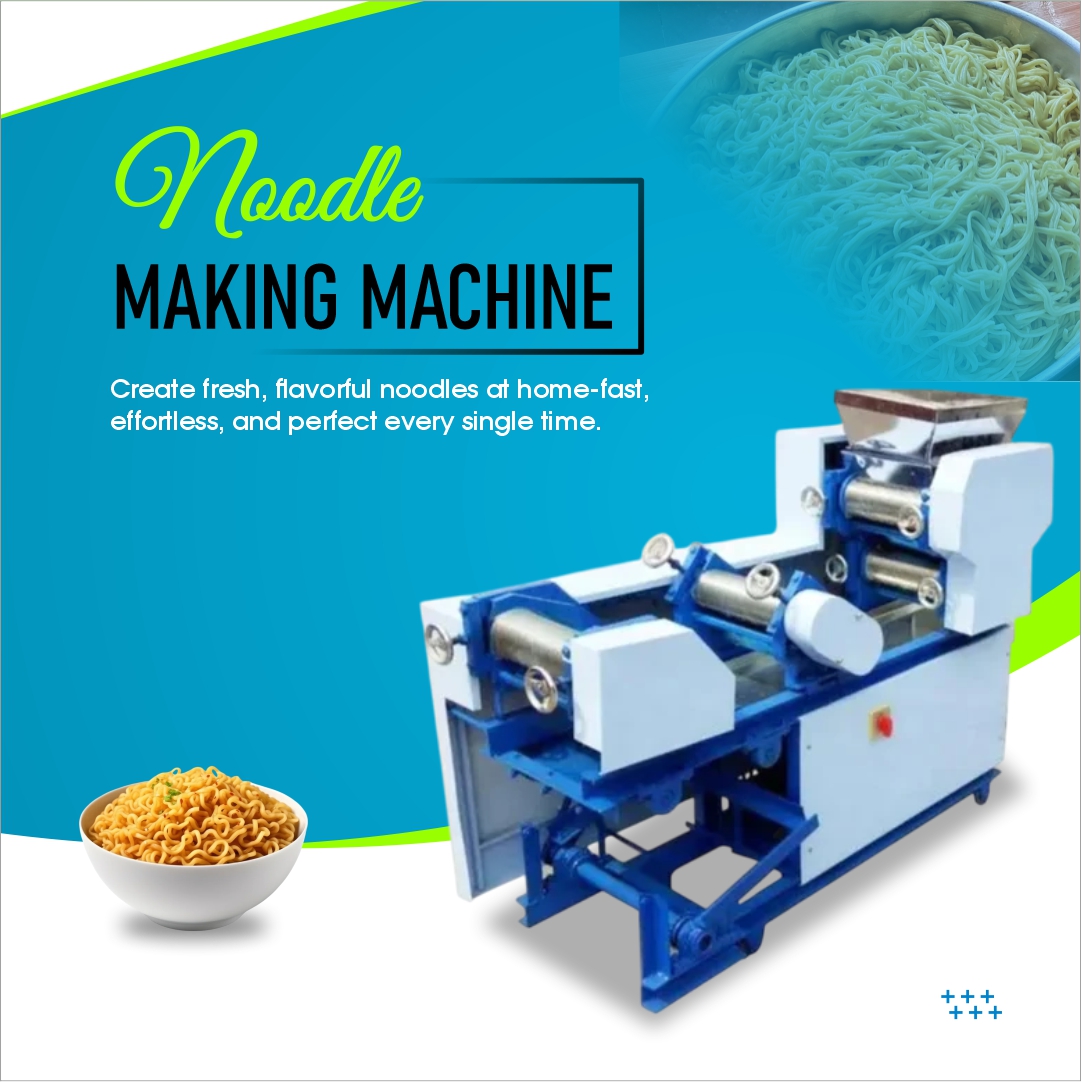

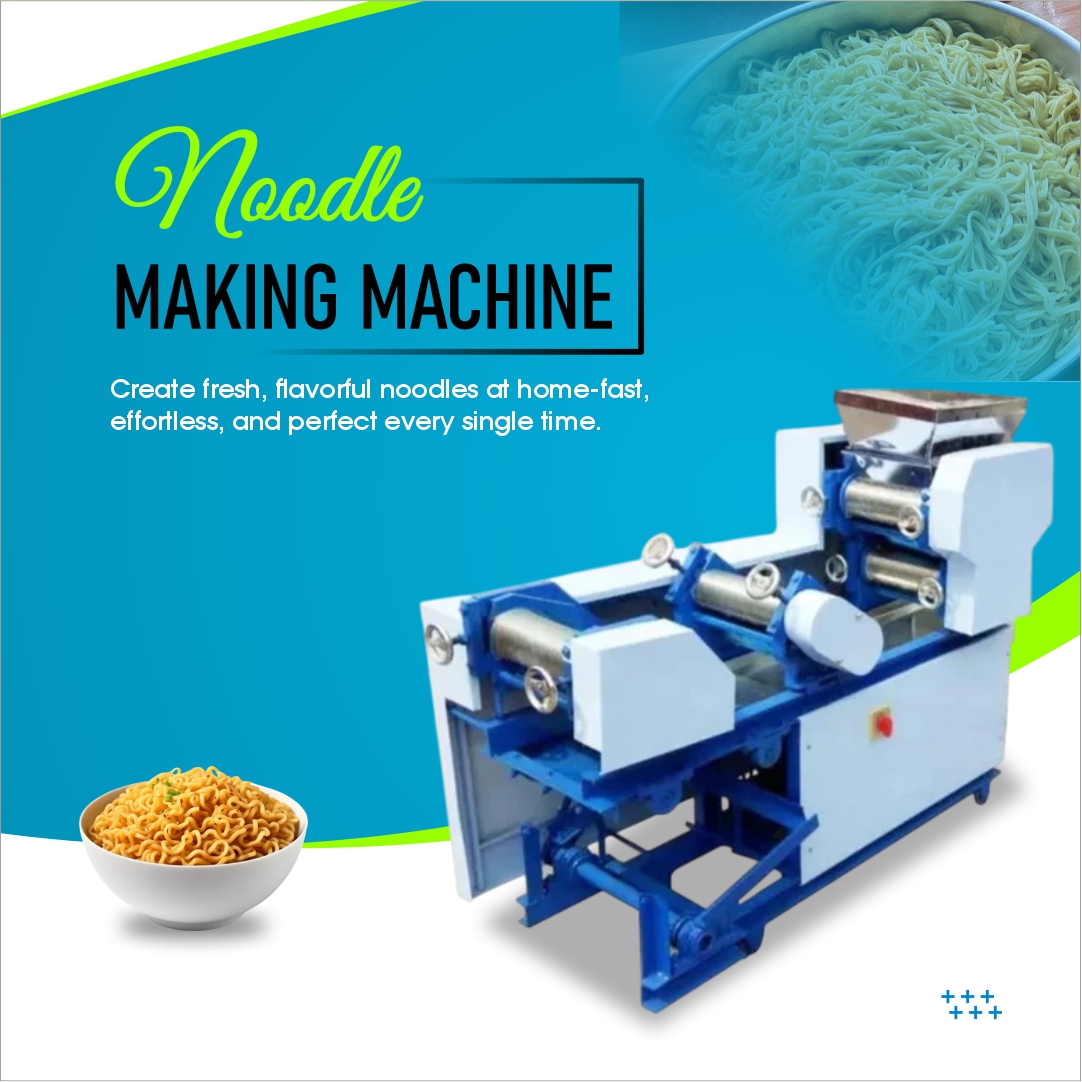

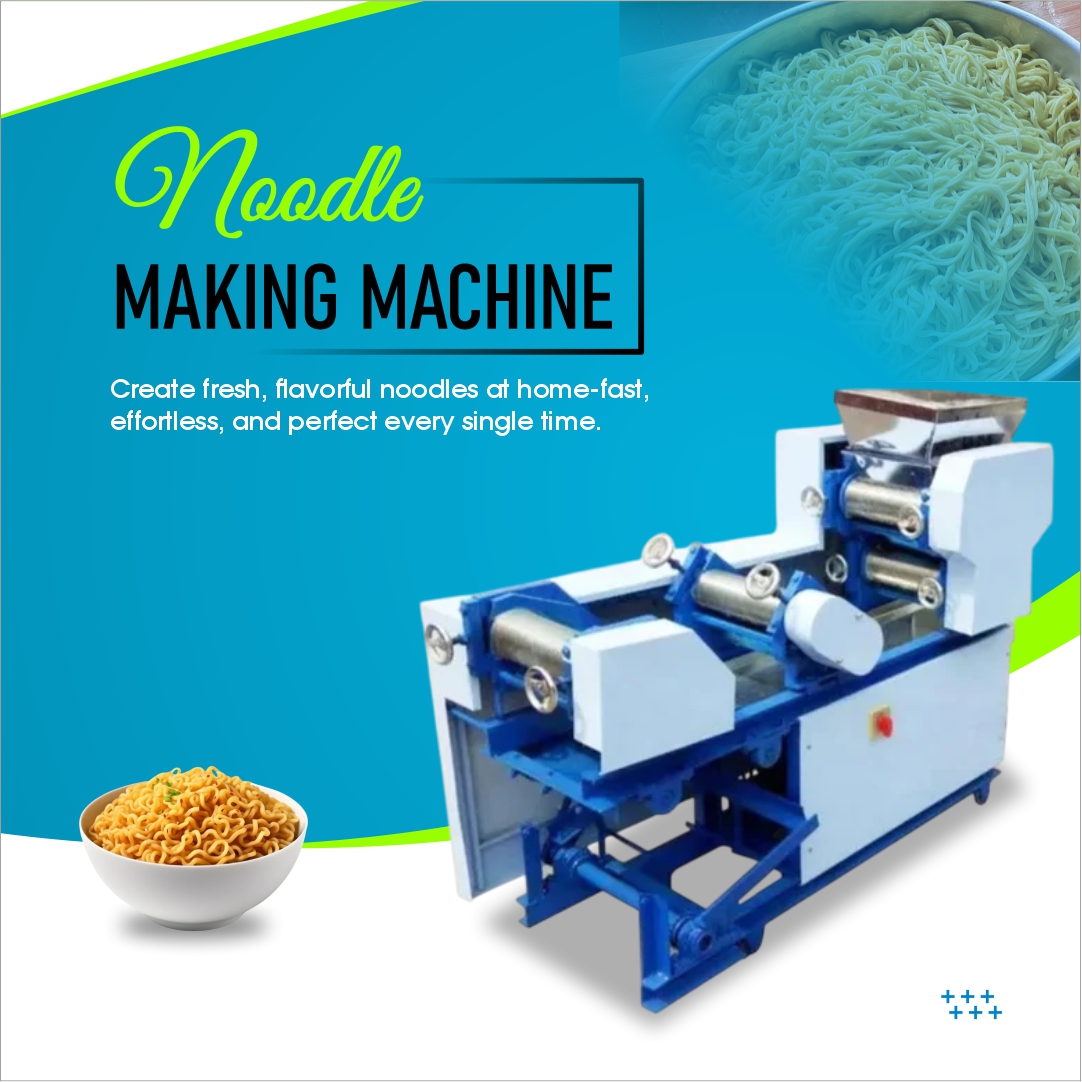

Noodle Making Machine Wholesalers Supplying Advanced, Energy-Efficient Processing Equipment

Price: ₹78000

The global and Indian food processing industry has witnessed tremendous growth over the past decade, and noodles have emerged as one of the most consumed convenience foods across all age groups. From instant noodles and wheat noodles to rice noodles and specialty varieties, the demand continues to rise due to busy lifestyles, urbanization, and changing food habits. To meet this ever-increasing demand, manufacturers require robust, efficient, and scalable production solutions. This is where professional noodle making machine wholesalers play a vital role by supplying advanced, energy-efficient processing equipment designed for consistent quality and high output.

At ASVR Engineering, we understand that noodle manufacturing is not just about machines—it is about precision, hygiene, productivity, and long-term operational savings. As a trusted wholesaler and supplier, we provide modern noodle making machines that are engineered to deliver reliable performance while minimizing energy consumption and production downtime.

Understanding the Noodle Manufacturing Process

Before choosing the right noodle making machine, it is important to understand the complete production process. Noodle manufacturing involves several critical stages, each of which must be carefully controlled to ensure uniform texture, taste, and shelf life.

The process typically begins with flour mixing, where wheat flour, rice flour, or other ingredients are blended with water and additives to form a consistent dough. This dough is then rested to allow proper gluten development. After resting, the dough passes through rolling and sheeting units, where it is flattened to the desired thickness. The sheeted dough is then cut into strands using precision cutters to achieve uniform noodle size.

Depending on the product type, noodles may be steamed, boiled, or dried. For instant noodles, frying or hot air drying is used to remove moisture and increase shelf life. Each of these stages requires specialized equipment that works in perfect synchronization. As experienced noodle making machine wholesalers, we supply complete processing lines as well as individual machines to suit diverse production requirements.

Advanced Noodle Making Machines for Modern Production Units

Modern noodle making machines are far more advanced than traditional systems. Today’s equipment integrates automation, digital controls, and energy-efficient components to improve productivity and reduce operational costs. At ASVR Engineering, our machines are designed with a focus on performance, durability, and ease of maintenance.

Our advanced noodle making machines are built using high-grade stainless steel to ensure hygiene and corrosion resistance. Automated control panels allow operators to monitor temperature, speed, and pressure parameters with precision. This not only improves product consistency but also reduces dependency on manual labor.

Energy efficiency is another major advantage of modern noodle processing equipment. Our machines are engineered to optimize power consumption without compromising output capacity. This makes them ideal for manufacturers who want to scale production while keeping electricity costs under control.

Energy-Efficient Processing Equipment: A Smart Business Investment

In today’s competitive market, energy efficiency is no longer optional—it is a necessity. Rising electricity costs directly impact profit margins, especially in high-volume food processing units. Choosing energy-efficient noodle making machines helps manufacturers achieve long-term savings while supporting sustainable manufacturing practices.

The machines supplied by ASVR Engineering are designed with optimized motors, advanced heating systems, and intelligent automation. These features ensure that energy is used only where required, reducing wastage and improving overall efficiency. Heat recovery systems and insulated chambers further contribute to lower power consumption.

By investing in energy-efficient noodle processing equipment, manufacturers can reduce their carbon footprint, comply with environmental regulations, and enhance their brand image as responsible food producers.

Types of Noodle Making Machines Supplied by Wholesalers

As leading noodle making machine wholesalers, we cater to a wide range of production needs. Different manufacturers require different capacities and configurations based on their target market and product range. Some of the commonly supplied machines include:

Automatic noodle making machines designed for large-scale production with minimal human intervention. These machines are ideal for instant noodle manufacturers and large food processing units.

Semi-automatic noodle machines suitable for medium-scale operations, offering a balance between automation and manual control.

Manual noodle making machines for small businesses, startups, and restaurants that require lower output but consistent quality.

Complete noodle production lines that integrate mixing, sheeting, cutting, steaming, drying, and packaging systems into a seamless workflow.

Each machine is customized to meet specific requirements related to capacity, noodle type, and available floor space.

Importance of Machine Quality and Build Standards

The quality of a noodle making machine directly affects product consistency, operational reliability, and maintenance costs. Low-quality machines may appear cost-effective initially, but they often result in frequent breakdowns, inconsistent output, and higher long-term expenses.

At ASVR Engineering, we follow strict quality control standards during manufacturing and sourcing. All machines are tested for performance, safety, and durability before dispatch. Components are selected from trusted vendors to ensure long service life and minimal downtime.

Food-grade materials, precision engineering, and robust construction ensure that our machines perform efficiently even under continuous operation. This commitment to quality has helped us earn the trust of clients across India.

Customization and Technical Support for Manufacturers

Every noodle manufacturing unit is unique. Factors such as raw material type, production capacity, space availability, and budget vary from one business to another. As experienced wholesalers, we offer customized solutions tailored to individual needs.

Our technical team works closely with clients to understand their production goals and recommend suitable machinery. We also provide installation guidance, operator training, and after-sales support to ensure smooth operation.

Prompt technical assistance and easy availability of spare parts further enhance machine reliability. This comprehensive support approach helps manufacturers focus on production and business growth without worrying about equipment issues.

Applications Across Diverse Market Segments

Noodle making machines supplied by ASVR Engineering are used across a wide range of applications. Instant noodle manufacturers rely on high-speed automated lines to meet mass-market demand. Regional noodle producers use semi-automatic systems to cater to local tastes and preferences.

Hotels, restaurants, and catering businesses benefit from compact noodle machines that deliver fresh noodles on demand. Export-oriented units prefer advanced processing equipment that meets international quality and hygiene standards.

This versatility makes our machines suitable for startups, established brands, and expanding enterprises alike.

Why Choose ASVR Engineering as Your Noodle Making Machine Wholesaler?

Choosing the right wholesaler is just as important as selecting the right machine. ASVR Engineering stands out due to its commitment to quality, transparency, and customer satisfaction.

We combine industry knowledge with engineering expertise to deliver machines that perform reliably in real-world production environments. Our focus on energy efficiency helps clients achieve cost savings and sustainable growth.

With competitive pricing, timely delivery, and dedicated support, we have built long-term relationships with food processing businesses across the country.

Future Trends in Noodle Processing Equipment

The future of noodle manufacturing lies in automation, digital monitoring, and sustainable production. Smart machines with IoT integration allow manufacturers to track performance, predict maintenance needs, and optimize output in real time.

Energy-efficient designs will continue to evolve, incorporating renewable energy compatibility and advanced insulation technologies. As consumer preferences shift toward healthier and specialty noodles, machines will also adapt to handle diverse ingredients and formulations.

ASVR Engineering remains committed to staying ahead of these trends, continuously upgrading its product range to meet future industry demands.

Conclusion: Building a Profitable Noodle Manufacturing Business

Investing in high-quality, energy-efficient noodle making machines is a crucial step toward building a successful and sustainable food processing business. Reliable machinery ensures consistent product quality, higher productivity, and reduced operational costs.

As trusted noodle making machine wholesalers, ASVR Engineering is dedicated to supplying advanced processing equipment that empowers manufacturers to grow with confidence. Whether you are starting a new unit or upgrading an existing facility, our solutions are designed to support your journey toward long-term success.

For detailed product information, pricing, and expert consultation, connect with us today.

Contact Details

Company: ASVR Engineering

Phone: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Buy Now