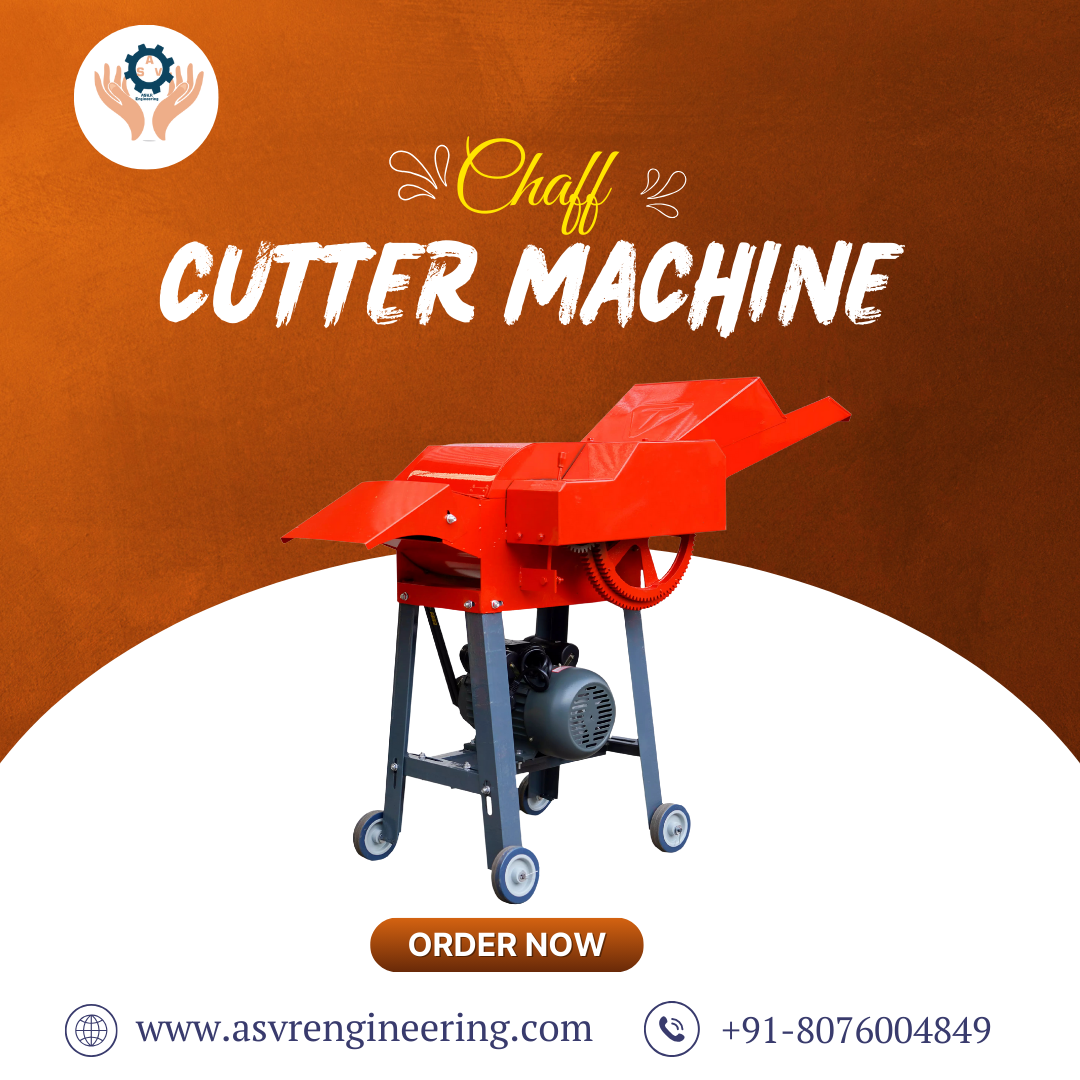

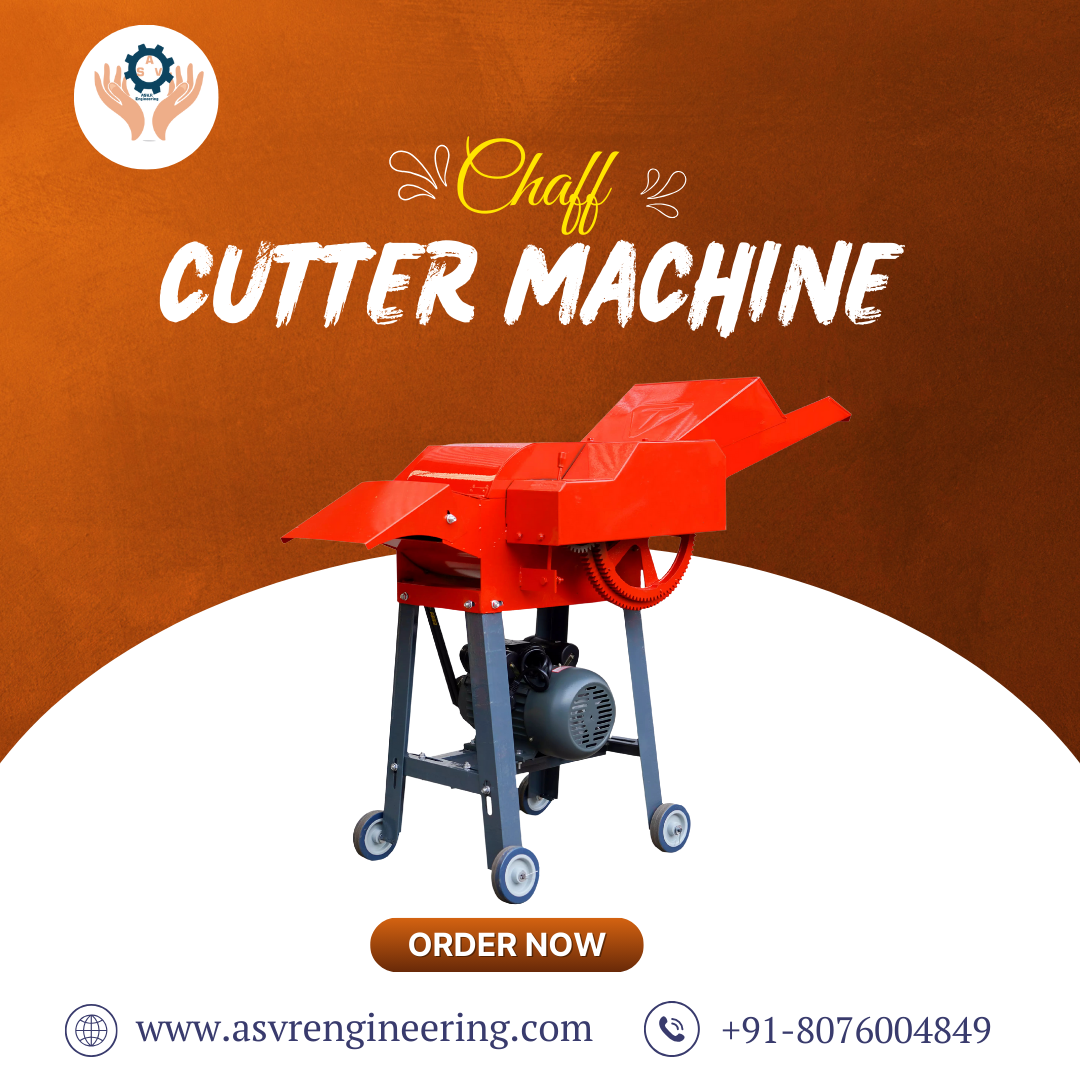

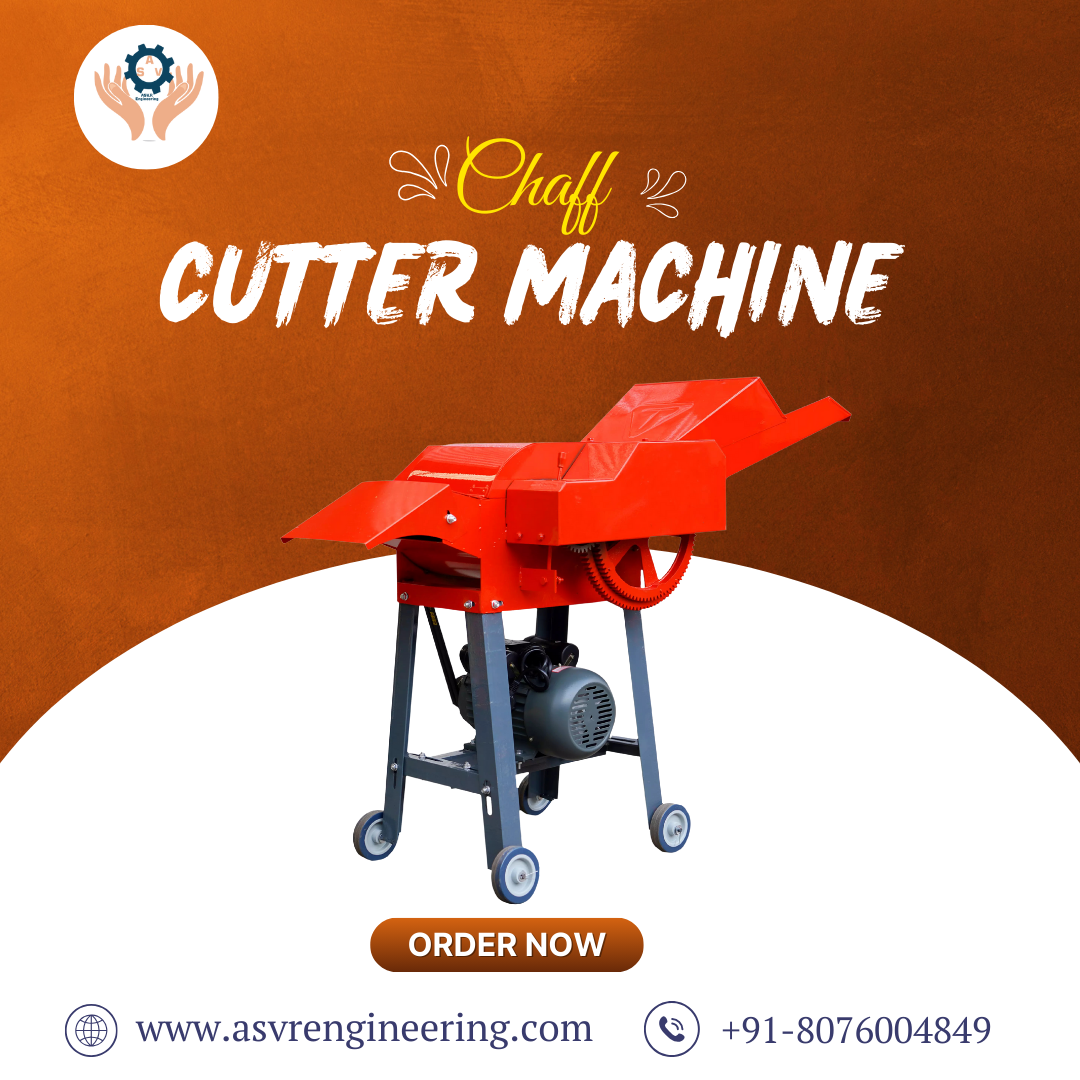

Chaff Cutter Machine

Price: ₹20000

A Chaff Cutter Machine plays a vital role in modern agriculture and dairy farming. It is designed to cut hay, straw, grass, maize stalks, sugarcane tops, and other fodder into small pieces, making it easier for animals to chew, digest, and absorb nutrients efficiently. In today’s time, where productivity and cost-effectiveness matter the most, a good quality chaff cutter machine is no longer an option—it is a necessity.

Indian farmers and dairy owners have been using chaff cutters for decades, but with advancements in technology, today’s machines are safer, stronger, and more efficient than traditional models. Whether you are running a small dairy farm or a large commercial cattle operation, investing in the right chaff cutter machine directly impacts animal health, milk production, and overall profitability.

What is a Chaff Cutter Machine?

A chaff cutter machine is an agricultural equipment used to chop fodder into uniform pieces. These chopped fodder pieces are easier for cattle to consume and help reduce wastage. The machine can be operated manually, electrically, or through tractor power, depending on the model and requirement.

By using a chaff cutter, farmers can:

-

Improve feed utilization

-

Reduce fodder wastage

-

Save time and labor

-

Increase milk yield

-

Maintain better animal health

Importance of Chaff Cutter Machine in Dairy Farming

One of the biggest challenges in dairy farming is managing fodder efficiently. Feeding uncut or poorly cut fodder often results in wastage and uneven nutrition intake. A chaff cutter machine ensures consistent fodder size, leading to better digestion and improved milk productivity.

Key benefits include:

-

Better digestion: Smaller fodder pieces are easier to chew

-

Reduced wastage: Animals consume more, waste less

-

Time saving: Quick fodder preparation

-

Cost efficiency: Lower fodder loss means lower expenses

For dairy farmers aiming for long-term sustainability, a chaff cutter machine is a smart investment.

Types of Chaff Cutter Machines

1. Manual Chaff Cutter Machine

Manual chaff cutters are ideal for small farmers or households with limited cattle. These machines are affordable, easy to maintain, and operate without electricity. Though they require manual effort, they are reliable in areas with limited power supply.

2. Electric Chaff Cutter Machine

Electric chaff cutters are widely used in medium to large dairy farms. These machines are faster, more efficient, and require less physical effort. With sharp blades and strong motors, electric chaff cutters deliver consistent output with minimal downtime.

3. Tractor Operated Chaff Cutter

Designed for large-scale operations, tractor-driven chaff cutters handle heavy workloads with ease. They are suitable for commercial farms where large quantities of fodder need to be processed daily.

Key Features of a High-Quality Chaff Cutter Machine

When choosing a chaff cutter machine, quality and durability should be top priorities. A well-designed machine offers long service life and consistent performance.

Important features include:

-

Heavy-duty steel body

-

High-grade cutting blades

-

Smooth feeding mechanism

-

Low maintenance design

-

Safety covers and guards

-

High output capacity

A strong build ensures the machine can handle both green and dry fodder without frequent breakdowns.

Applications of Chaff Cutter Machine

A chaff cutter machine is widely used across different agricultural and farming sectors:

-

Dairy farms

-

Poultry feed preparation

-

Cattle farms

-

Goat and sheep farming

-

Agricultural research centers

-

Commercial fodder suppliers

It can process:

-

Green grass

-

Dry straw

-

Wheat straw

-

Paddy straw

-

Sugarcane tops

-

Maize stalks

Why Choose a Quality Chaff Cutter Machine?

Many farmers make the mistake of choosing low-cost machines that compromise on material quality. While they may seem affordable initially, frequent repairs and breakdowns increase long-term costs.

A premium chaff cutter machine ensures:

-

Long operational life

-

Consistent cutting size

-

Lower maintenance cost

-

Better safety for operators

-

Higher fodder output

Choosing the right manufacturer is just as important as choosing the right machine.

Chaff Cutter Machine Manufacturing Standards

A trusted manufacturer follows strict quality control measures during production. From raw material selection to final testing, every stage is monitored to ensure durability and performance.

Standard manufacturing practices include:

-

Precision blade alignment

-

Load testing before dispatch

-

Quality-checked motors and bearings

-

Rust-resistant paint coating

-

Proper balancing for vibration-free operation

These standards guarantee reliable performance even in demanding conditions.

Safety Measures in Chaff Cutter Machines

Modern chaff cutter machines are designed with user safety in mind. Protective covers, blade guards, and stable bases minimize the risk of accidents.

Basic safety practices:

-

Never feed fodder by hand directly

-

Use safety covers at all times

-

Keep children away from the machine

-

Regularly check blade sharpness

-

Ensure proper grounding for electric models

Safety awareness ensures smooth and accident-free operation.

Maintenance Tips for Long Life

Proper maintenance significantly increases the lifespan of a chaff cutter machine.

Simple maintenance tips:

-

Clean the machine after daily use

-

Lubricate moving parts regularly

-

Sharpen or replace blades when needed

-

Check belt tension and motor alignment

-

Store in a dry, covered area

Regular care keeps the machine efficient and reduces unexpected downtime.

Chaff Cutter Machine Price in India

The price of a chaff cutter machine in India depends on several factors:

-

Type (manual, electric, tractor-driven)

-

Motor capacity

-

Blade quality

-

Output capacity

-

Build material

Manual models are the most economical, while electric and tractor-operated machines fall in a higher price range due to advanced features and higher productivity.

For accurate pricing and model selection, direct consultation with the manufacturer is always recommended.

Why Buy Directly from the Manufacturer?

Buying directly from the manufacturer offers several advantages:

-

Competitive pricing

-

Customization options

-

Genuine spare parts availability

-

Technical support

-

After-sales service

Direct manufacturers also provide better guidance in choosing the right model based on your usage needs.

Why ASVR Engineering for Chaff Cutter Machine?

ASVR Engineering is a trusted name in agricultural machinery manufacturing. With years of industry experience, the company focuses on quality, durability, and customer satisfaction.

Reasons to choose ASVR Engineering:

-

Robust and durable machine design

-

High-performance cutting efficiency

-

Tested and quality-approved products

-

Competitive pricing

-

Reliable after-sales support

Every chaff cutter machine is manufactured keeping Indian farming conditions in mind.

Technical Support & Customer Assistance

Customer satisfaction does not end with product delivery. Proper guidance, installation support, and maintenance advice play a crucial role in long-term performance.

ASVR Engineering ensures:

-

Prompt customer support

-

Easy availability of spare parts

-

Expert technical guidance

-

Quick response to service queries

Conclusion

A Chaff Cutter Machine is an essential agricultural tool that improves fodder management, enhances animal health, and boosts overall farm productivity. Choosing the right machine from a trusted manufacturer ensures long-term benefits and reliable performance.

Whether you are a small farmer or running a commercial dairy farm, investing in a quality chaff cutter machine is a step toward smarter and more profitable farming.

Contact Information

📞 Call Us:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Buy Now