Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

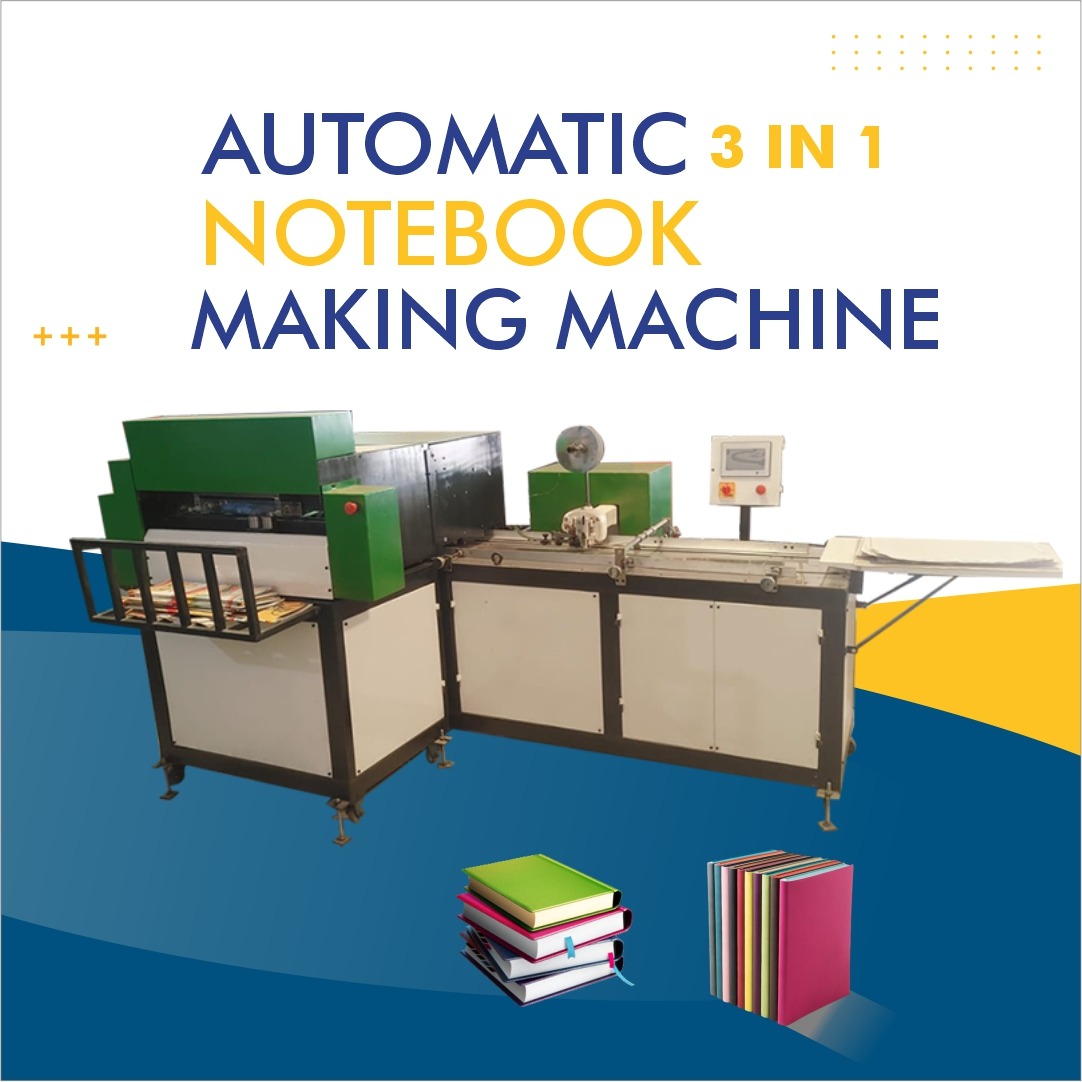

High-Performance Notebook Making Machine in Ungma, Nagaland | Automatic Notebook Manufacturing Solutions

Notebook Making Machine in Ungma - Nagaland

The demand for Notebook Making Machines in Ungma, Nagaland has seen substantial growth in recent years. As the educational sector expands and the need for school stationery continues to rise, businesses, printing units, and new entrepreneurs are actively establishing notebook production units across the region. Ungma, being one of the fastest-growing areas in Nagaland, offers excellent opportunities for setting up a notebook manufacturing business. To support this growth, high-quality and automated Notebook Making Machines have become essential.

In this guide, we will cover everything about Notebook Making Machines, including machine features, benefits, types, business scope, technical details, manufacturing process, investment opportunities, and why Ungma, Nagaland is a strategic location for this industry.

Additionally, throughout the content, the following synonyms (5) for Notebook Making Machine are used repeatedly:

notebook manufacturing machine, exercise book making machine, paper notebook machine, automatic notebook machine, and notebook production line.

1. Understanding the Notebook Making Machine

A Notebook Making Machine is industrial equipment designed to produce notebooks of various sizes, page counts, and binding styles. The modern notebook manufacturing machine ensures high accuracy, smooth cutting, perfect ruling, and consistent binding quality. Whether for school use, college use, office supply, or commercial stationery, this machinery offers flexibility in production.

The exercise book making machine performs tasks such as cutting paper, folding sheets, stitching, pressing, binding, and trimming. With advanced automation technology, manufacturers in Ungma, Nagaland can produce large volumes of notebooks with reduced manual labor and minimum operational cost. Many units also integrate ruling, cover printing, UV coating, lamination, and trimming, making the paper notebook machine a complete production solution.

2. Demand for Notebook Production in Ungma, Nagaland

Ungma is emerging as a significant center for educational supply businesses. With several schools, coaching centers, government institutions, and private institutions increasing in number, the need for high-quality notebooks is rising. Instead of depending on supplies from other states, many local businesses now prefer to establish their own units equipped with an automatic notebook machine.

Why Ungma is a Good Location

-

Growing education sector

-

Low competition in local notebook production

-

Easy distribution across Mokokchung district

-

Availability of skilled but affordable workforce

-

Low transportation cost for local demand

Because of these benefits, many entrepreneurs plan to install a high-speed notebook production line in Ungma to meet regional needs.

3. Types of Notebook Making Machines

When planning to start a notebook manufacturing unit in Ungma, Nagaland, it is important to understand the different types of machines available. Each machine type serves a specific production capacity and scale.

A. Manual Notebook Making Machines

-

Low cost

-

Suitable for small production

-

Higher labor requirement

B. Semi-Automatic Notebook Manufacturing Machines

-

Moderate speed

-

Better accuracy

-

Ideal for small to medium businesses

C. Fully Automatic Notebook Production Line

-

High production capacity

-

Minimum manual involvement

-

Suitable for large factories and commercial operations

These machines also include variants such as:

-

Automatic ruling machine

-

Notebook cutting machine

-

Notebook stitching machine

-

Spiral notebook making machine

-

Hardbound book manufacturing line

Choosing the right machine depends on your budget, production goals, and distribution network in Ungma.

4. Key Features of a High-Quality Notebook Manufacturing Machine

A modern Notebook Making Machine comes with upgraded features that boost productivity while maintaining premium notebook quality. Some of the major features include:

-

High-speed sheet cutting and folding

-

Accurate ruling and margin printing

-

Auto cover feeding and binding

-

Sturdy heavy-duty frame

-

Smooth and precise trimming operation

-

Energy-efficient motors and components

-

Low noise and vibration design

-

Safety sensors to reduce risk

-

Easy to operate control panel

These features ensure that the exercise book making machine delivers consistent output every day.

5. Notebook Manufacturing Process Using the Machine

To operate a paper notebook machine smoothly in Ungma, Nagaland, understanding the production process is crucial.

Step 1: Paper Sheet Cutting

Large paper reels or sheets are cut into notebook-size pages.

Step 2: Ruling / Printing

Lines, margins, grids, and designs are printed using a ruling machine.

Step 3: Folding

The sheets are folded to create notebook sections.

Step 4: Stitching or Binding

Binding can be done using:

-

Center stitching

-

Spiral binding

-

Perfect binding

-

Hard cover binding

Step 5: Cover Placement

Covers are printed and laminated before assembly.

Step 6: Pressing

The notebook is pressed for a neat finish.

Step 7: Edge Cutting / Trimming

A trimming machine shapes the notebook edges perfectly.

Step 8: Packaging

Final notebooks are packed and distributed across Ungma and other nearby markets.

Throughout this process, the automatic notebook machine helps reduce wastage, increase efficiency, and improve quality.

6. Investment and Profit Potential in Ungma, Nagaland

Setting up a notebook manufacturing machine unit in Ungma involves several cost elements but offers impressive profit margins. Investment varies based on automation level, brand, and production size.

Estimated Cost Breakdown

-

Semi-automatic notebook production line: Moderate investment

-

Fully automatic notebook manufacturing machine: Higher investment

-

Raw materials (paper, ink, cover sheets)

-

Labor charges

-

Electricity and maintenance

-

Packaging and transport

Profit Margin

Notebook manufacturing usually delivers 20%–35% profit, making it a highly attractive business for Ungma entrepreneurs. Because demand remains steady year-round, businesses can expect reliable revenue.

7. Benefits of Installing a Notebook Making Machine in Ungma

-

Local supply advantage

-

Fast delivery to nearby schools and markets

-

Reduced dependency on suppliers from other states

-

Custom notebook production for institutions

-

High demand with recurring orders

The notebook manufacturing machine offers long-term stability and growth potential in the Nagaland market.

8. Choosing the Right Notebook Production Line: Key Considerations

Before purchasing a notebook production line, consider:

-

Production capacity needed

-

Type of notebook required (spiral, stitched, hardbound)

-

Machine automation level

-

After-sales service availability

-

Spare part compatibility

-

Warranty and technical support

This ensures long-term reliability for your exercise book making machine.

9. Conclusion

The Notebook Making Machine in Ungma, Nagaland is not only a business opportunity but a long-term investment for entrepreneurs and manufacturers. With increasing demand for quality stationery, educational materials, and customized notebooks, installing a paper notebook machine, notebook production line, or automatic notebook machine can deliver high profits and stable business growth.

Ungma’s strategic location, growing population, educational expansion, and minimal competition make it a prime location to start a notebook production business. By selecting the right machinery, understanding market needs, and operating efficiently, you can establish a highly successful and sustainable notebook manufacturing unit.