Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

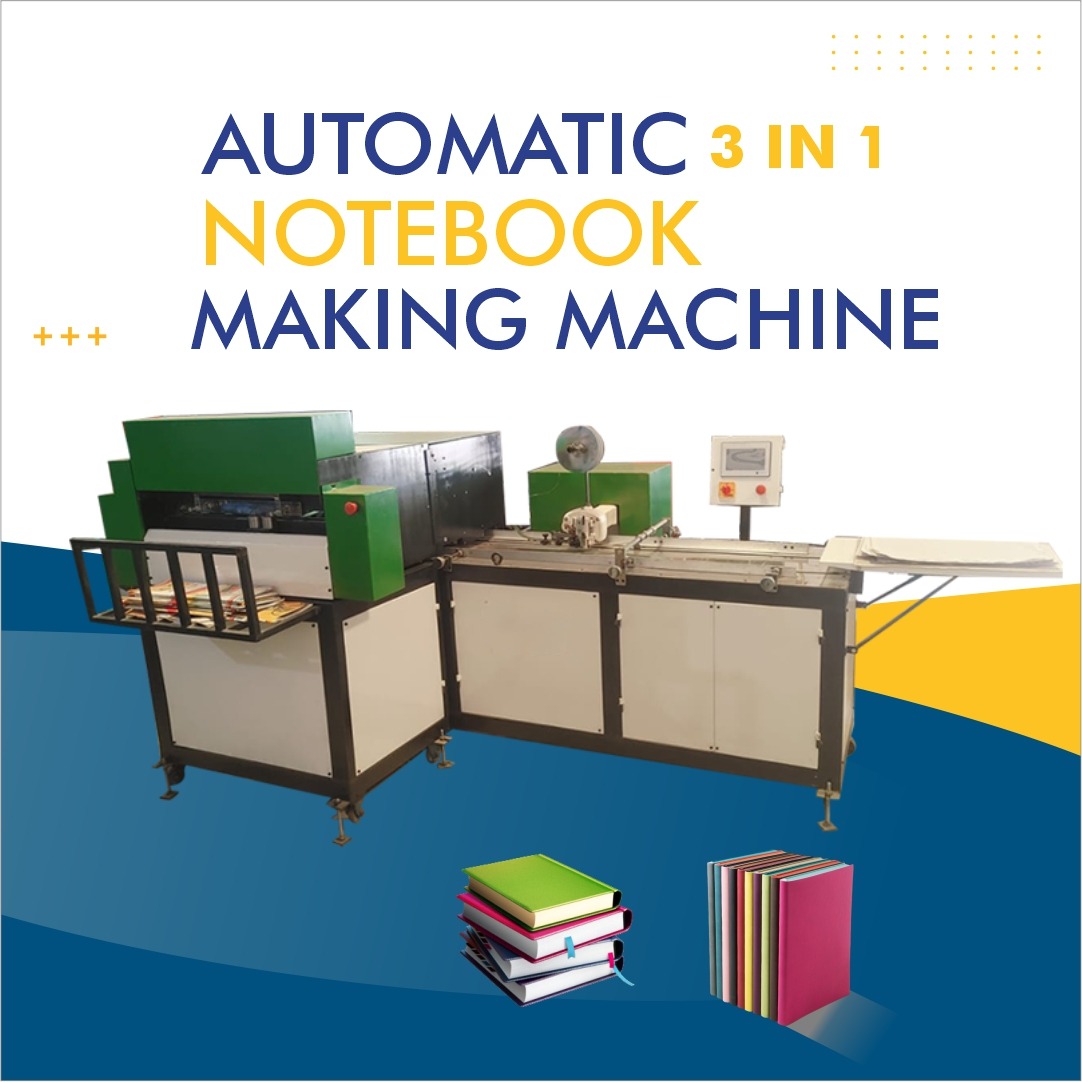

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Best Notebook Making Machine in Lungphunlian Mizoram | High-Quality Paper Notebook Manufacturing Equipment

Notebook Making Machine in Lungphunlian | Mizoram

The demand for high-quality notebooks in the educational, corporate, and commercial sectors continues to rise across India. Mizoram, especially places like Lungphunlian, is witnessing rapid growth in the paper stationery market. As a result, many local entrepreneurs and manufacturers are investing in a Notebook Making Machine to start or expand their business. This detailed guide covers everything you need to know about notebook manufacturing in Lungphunlian, including the machine types, features, setup requirements, profitability, and why investing in this machinery is beneficial.

A Notebook Making Machine is a professional paper converting machine, equipment, unit, system, and apparatus designed for converting large paper reels into finished notebooks of different sizes and formats. Whether you want to manufacture school notebooks, long books, registers, diaries, or customized paper stationery, the right notebook production equipment can help you achieve consistent quality with high output.

Why Notebook Making Machines Are in Demand in Lungphunlian Mizoram

Lungphunlian and surrounding regions in Mizoram rely heavily on notebooks for schools, colleges, government offices, and private institutions. Due to limited large-scale notebook production within the state, most notebooks are imported from other states. This increases cost and delivery time for local buyers. By setting up a local notebook manufacturing machine, equipment, unit, system, or apparatus, entrepreneurs can supply products at competitive prices.

Key reasons for high demand include:

-

Growing number of educational institutions

-

Increase in government stationery consumption

-

Rising business documentation needs

-

Opportunity for customized notebook branding

-

Reduced transportation cost when manufactured locally

Types of Notebook Making Machines Available in Lungphunlian

Manufacturers and suppliers offer various models of Notebook Making Machines depending on production scale:

1. Manual Notebook Making Machine

Best for beginners and small-scale production.

Key features include low investment cost, simple operation, and basic output. Although manual machines, equipment, units, systems, or apparatuses require more labor, they are ideal for new entrepreneurs.

2. Semi-Automatic Notebook Making Machine

Suitable for medium-scale notebook manufacturers.

These machines combine mechanical and electrical components to enhance speed while keeping costs moderate.

3. Fully Automatic Notebook Making Machine

Best for large commercial notebook production.

Fully automatic notebook manufacturing equipment performs stitching, ruling, cutting, pasting, and finishing with minimal human involvement. These machines, units, systems, equipment, and apparatuses offer the highest efficiency and quality.

Features of a High-Quality Notebook Making Machine

A premium Notebook Making Machine for Lungphunlian Mizoram typically includes:

-

Automatic ruling and printing

-

Precision cutting technology

-

Adjustable notebook sizes

-

Robust stitching or binding mechanism

-

Durable steel frame

-

Low power consumption

-

Consistent, high-quality finishing

-

Long operational life with minimal maintenance

Such machines, equipment, units, systems, and apparatuses ensure long-term reliability for notebook businesses.

Raw Materials Required for Notebook Manufacturing

To produce notebooks using your Notebook Making Machine, you will need:

-

Paper reels or sheets

-

Cardboard covers

-

Gum and adhesives

-

Binding tapes or wires

-

Printing ink

-

Labels and packaging materials

All these materials are readily available in nearby markets or from suppliers in Mizoram and neighbouring states.

Step-by-Step Notebook Manufacturing Process

A typical notebook production cycle includes the following stages:

1. Paper Cutting

Large paper reels are cut to desired sizes using the cutting machine, equipment, unit, system, or apparatus.

2. Ruling/Printing

Ruling patterns (single line, double line, graph lines) are printed using a ruling machine.

3. Folding

Paper sheets are folded precisely to form notebook sections.

4. Gathering and Stitching

The folded pages are aligned and stitched using a heavy-duty stitching machine, equipment, unit, system, or apparatus.

5. Cover Pasting

The outer cover is attached, giving the notebook structure and design.

6. Final Cutting & Trimming

Extra edges are trimmed to give a clean finish.

7. Packaging and Bundling

Finished notebooks are packed and ready for market delivery.

Investment and Machinery Cost in Lungphunlian Mizoram

The price of a Notebook Making Machine depends on automation level:

-

Manual notebook making machine: Low investment

-

Semi-automatic notebook making machine: Medium investment

-

Fully automatic notebook making machine: Higher investment, but best quality

Local distributors in Mizoram often provide installation support, training, and maintenance packages.

Profitability of Notebook Manufacturing Business

Setting up a notebook production machine, equipment, unit, system, or apparatus in Lungphunlian can generate significant profits. With growing demand and low competition, manufacturers can secure bulk orders from:

-

Schools

-

Bookstores

-

Government departments

-

Local wholesalers

-

Corporate offices

Profit margins increase when buying raw materials in bulk and using efficient machinery.

Benefits of Buying a Notebook Making Machine in Lungphunlian Mizoram

-

Easy availability of local labour

-

Increasing stationery demand

-

Opportunity for local branding

-

Lower shipping and material costs

-

Quick supply to nearby markets

-

High return on investment

A notebook production machine, equipment, unit, system, or apparatus ensures maximum output with minimum effort.

Conclusion

Investing in a Notebook Making Machine in Lungphunlian Mizoram is one of the best opportunities for entrepreneurs looking to enter the stationery manufacturing sector. With rising demand for notebooks and limited local competition, the business offers excellent growth potential. Whether you choose a manual, semi-automatic, or fully automatic model, the right machine, equipment, unit, system, or apparatus can help you produce high-quality notebooks consistently and profitably.