Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

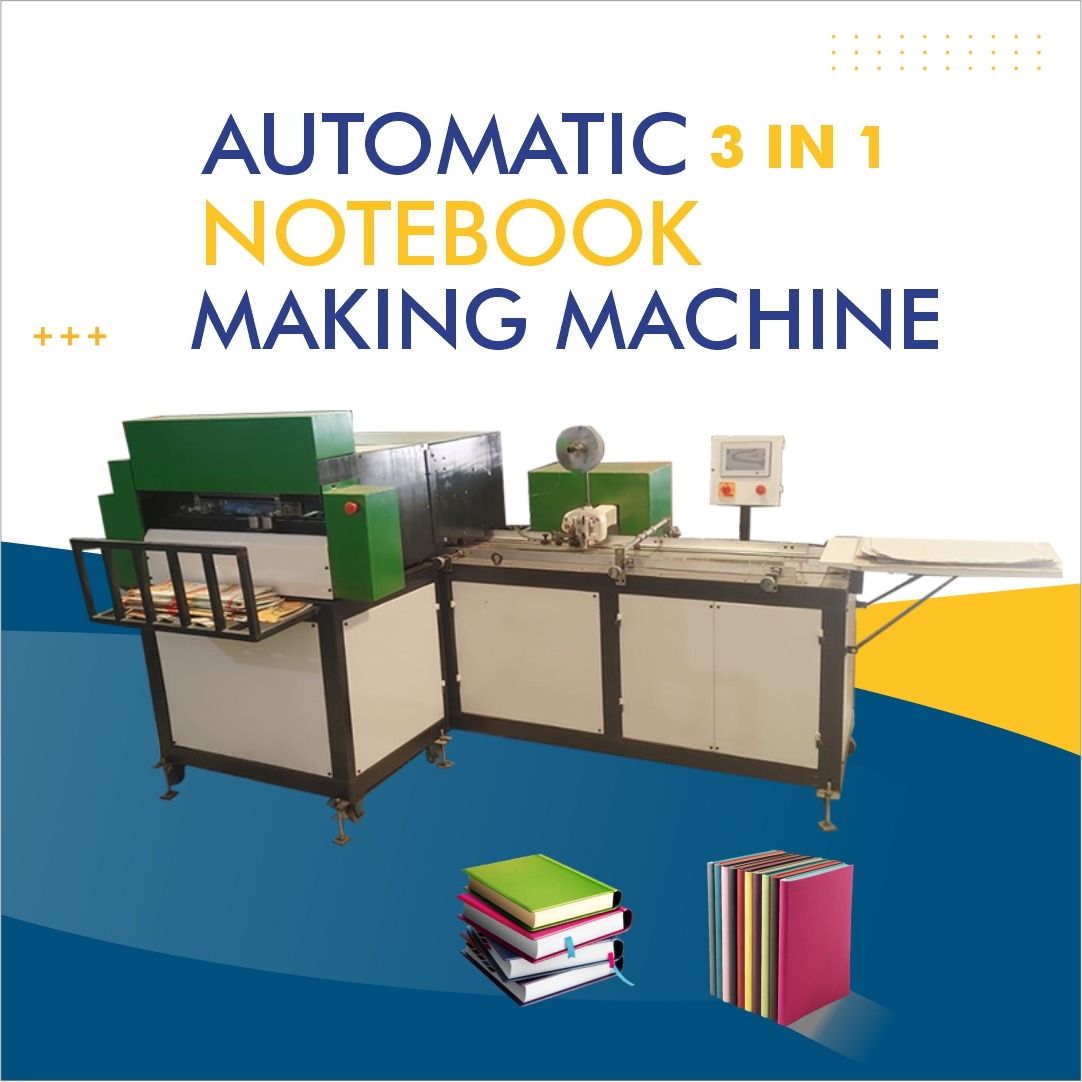

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

High-Quality Notebook Making Machine in Khawhai Mizoram – Affordable Exercise Book Manufacturing Solutions

Notebook Making Machine in Khawhai | Mizoram

If you are planning to start or upgrade a notebook manufacturing business in Khawhai, Mizoram, choosing the right notebook making machine is the most important decision. The growing demand for high-quality notebooks, exercise books, and stationery products in the Northeast has encouraged many new entrepreneurs to invest in reliable notebook production technology. A high-performance notebook making machine not only increases productivity but also ensures consistent quality, faster turnaround time, and higher profit margins.

In Khawhai and nearby areas of Mizoram, educational institutions, government offices, private organizations, and local businesses create a constant demand for notebooks of different sizes and formats. This makes notebook manufacturing an excellent long-term business opportunity. To meet this growing demand, industries today rely on advanced machinery such as the exercise book making machine, copy making machine, stationery book making equipment, notebook production machine, and paper notebook manufacturing machine. All these terms represent different variants or synonyms of the same essential technology used in notebook production.

Why Notebook Manufacturing is Growing in Khawhai, Mizoram

Khawhai is gradually becoming a hub for small and medium manufacturing units due to improving connectivity, supportive government schemes, and rising local consumption. Notebook manufacturing is especially promising because:

1. Evergreen Local Demand

Schools, colleges, training centers, coaching classes, offices, and government departments continuously require notebooks. This ensures stable business throughout the year.

2. Easy Availability of Raw Materials

Raw materials like paper reels, covers, binding materials, and stitching wires are easily accessible from nearby markets in Aizawl, Silchar, and Guwahati.

3. Low Competition in Local Market

Compared to large cities, Khawhai has fewer notebook manufacturers. This gives new businesses an excellent opportunity to establish themselves.

4. Suitable for Small and Large Entrepreneurs

Whether someone wants to start a small-scale unit or a fully automated notebook manufacturing plant, options are available within every budget range.

What is a Notebook Making Machine?

A notebook making machine is a production system designed to manufacture various types of notebooks. These machines can perform multiple processes such as ruling, cutting, stitching, pressing, folding, cover pasting, and edge trimming.

Synonyms used repeatedly in this article include:

-

Exercise book making machine

-

Copy making machine

-

Notebook production machine

-

Stationery book making equipment

-

Paper notebook manufacturing machine

These synonyms refer to machines that perform similar manufacturing functions with slight variations depending on the model and features.

Types of Notebook Making Machines Available in Khawhai, Mizoram

To start a notebook manufacturing unit, understanding the different types of machinery is essential.

1. Manual Notebook Making Machines

Suitable for small beginners with limited budget.

Pros: Low investment, easy to operate.

Cons: Lower production capacity.

2. Semi-Automatic Notebook Making Machines

A balanced option for medium-scale manufacturers.

Pros: Good speed, moderate pricing, better accuracy.

Cons: Requires some manual intervention.

3. Fully Automatic Notebook Production Machines

Ideal for large units aiming for high output.

Pros: High speed, precision, minimal labor, excellent finishing.

Cons: Higher investment.

These machines fall under broader categories like exercise book making machine and copy making machine, widely preferred in medium to large production facilities.

Key Features to Look for in Notebook Making Machines

Choosing the right machinery is essential for long-term success. Important features include:

1. High Production Capacity

Depending on requirements, choose a machine capable of producing between 2,000 to 30,000 notebooks per day.

2. Multiple Function Integration

Advanced notebook production machines combine several operations into one:

-

Ruling

-

Folding

-

Stitching

-

Cover insertion

-

Pressing

-

Trimming

This saves time, manpower, and operational cost.

3. Durability and Robust Frame

Machines made with high-grade steel ensure long life and consistent performance even under heavy workloads.

4. Low Maintenance Requirement

Select models that offer easy servicing, low downtime, and affordable spare parts.

5. Energy Efficiency

Modern paper notebook manufacturing machines are designed to consume less electricity, making them cost-effective for long-term use.

Production Process Using a Notebook Making Machine

A typical notebook is produced through the following stages:

1. Ruling or Printing

Lines or grids are printed using a ruling machine or offset printer.

2. Folding

Printed sheets are folded to form notebook sections.

3. Stitching or Binding

Using copy making machine technology, pages are stitched with stainless wire or thread.

4. Cover Pasting

Covers are inserted and pasted for additional strength and durability.

5. Edge Cutting and Trimming

Hydraulic cutting machines ensure perfect notebook dimensions.

6. Final Pressing and Packaging

Pressing machines provide a clean and professional look before packaging.

A good stationery book making equipment setup ensures that all these steps can be executed smoothly and efficiently.

Investment Required for Notebook Manufacturing in Khawhai, Mizoram

Investment depends on production scale:

Small-Scale Unit

-

Manual machines

-

Investment: Low to moderate

-

Capacity: 3000–6000 notebooks/day

Medium-Scale Unit

-

Semi-automatic machines

-

Investment: Moderate to high

-

Capacity: 10,000–20,000 notebooks/day

Large-Scale Commercial Unit

-

Fully automatic notebook production machines

-

Investment: High

-

Capacity: 30,000+ notebooks/day

Raw material cost, electricity, labor, and packaging further determine your total operational budget.

Why Businesses in Khawhai Prefer Modern Notebook Making Machines

1. Higher Productivity

Advanced machines complete multiple processes simultaneously.

2. Superior Notebook Quality

Perfect stitching, accurate cuts, strong binding, and smooth finishing help compete against imported notebooks.

3. Low Labor Requirement

Automatic systems reduce dependence on manual labor.

4. Faster Return on Investment

Growing demand ensures quick sales and faster recovery of investment.

5. Easy Availability of Spare Parts

Most machine manufacturers supply nationwide, making maintenance convenient.

How to Choose the Right Supplier in Mizoram

When selecting a supplier for notebook making machine setups, consider:

-

Experience in manufacturing stationery machinery

-

After-sales support

-

Availability of installation and training

-

Spare parts accessibility

-

Warranty period

-

Machine demo availability

Trustworthy suppliers can guide you in selecting the ideal combination of exercise book making machine, copy making machine, and paper notebook manufacturing machine to suit your production needs.

Conclusion

Starting a notebook manufacturing unit in Khawhai, Mizoram is an excellent business opportunity with low competition and high market demand. A dependable notebook making machine ensures smooth production, consistent quality, and long-term profitability. Whether you choose a manual unit or a fully automatic notebook production machine, the growing demand for stationery products will support steady business growth.

By selecting the right exercise book making machine, copy making machine, and stationery book making equipment, entrepreneurs can transform their manufacturing operations into a profitable venture that serves the educational and commercial needs of Mizoram.