Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

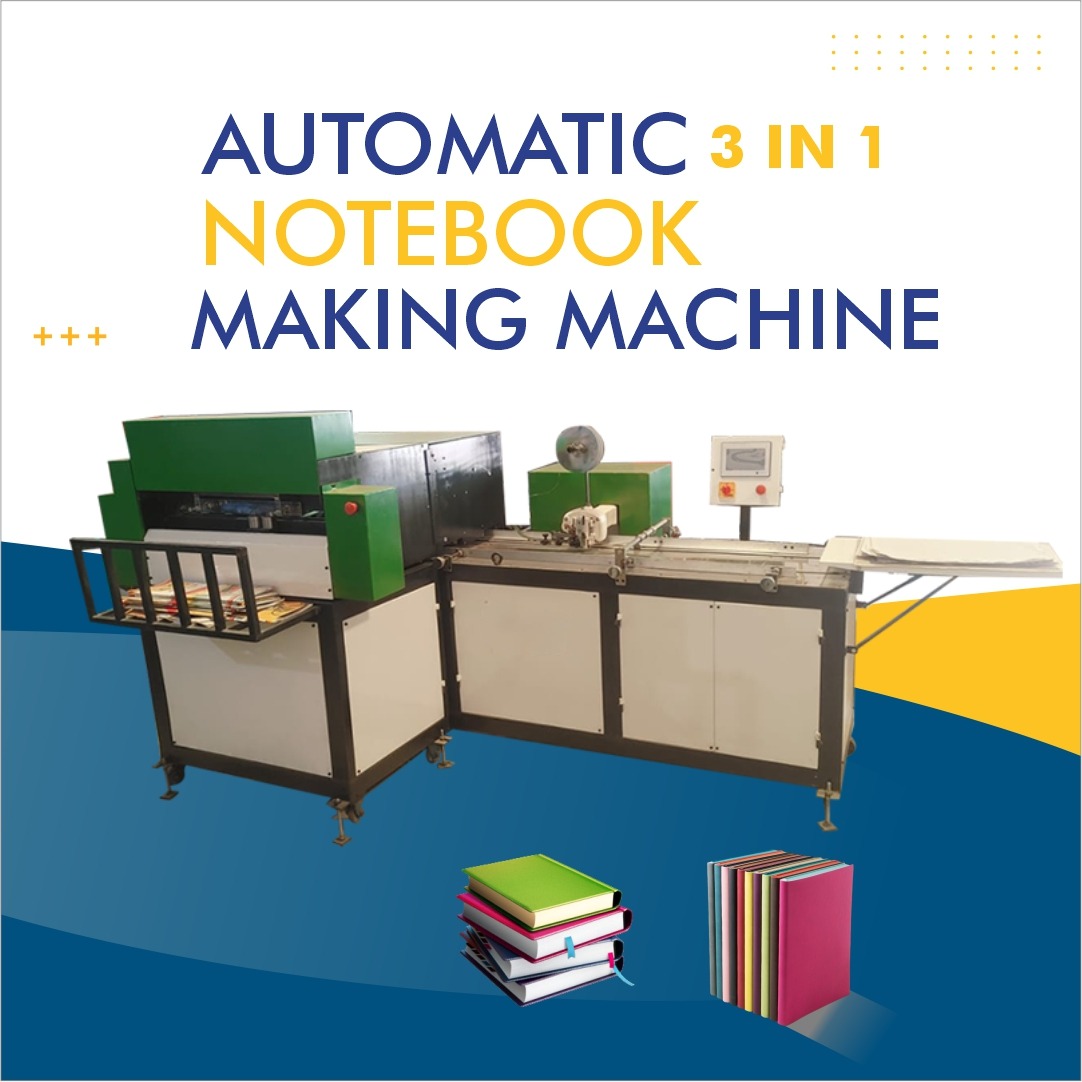

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Best Notebook Making Machine in Dawki Meghalaya | High-Performance Notebook Manufacturing Machines

Notebook Making Machine in Dawki | Meghalaya

Dawki in Meghalaya has become a growing hub for small-scale and medium-scale manufacturing businesses. Among the emerging industries, demand for the notebook making machine has risen significantly as education, stationery, and paper product markets continue to expand across Northeast India. Businesses in regions such as Dawki, Jowai, Shillong, and the surrounding Meghalaya belt are now seeking reliable machinery that supports high efficiency, low operational cost, and long-term profitability.

A notebook making machine is essential for entrepreneurs looking to start a notebook manufacturing unit, supply exercise books to schools, or expand their stationery production line. This guide explains everything you need to know about notebook making machines in Dawki Meghalaya, including types of machines, benefits, working mechanisms, and factors you should consider before purchasing.

To ensure maximum SEO value, this content includes repeated synonyms such as notebook manufacturing machine, exercise book making machine, copy making equipment, paper notebook production line, and school notebook machine throughout the article.

Why Notebook Manufacturing is Growing in Dawki Meghalaya

Dawki is strategically located near the India-Bangladesh border, making it an excellent commercial zone with easy transportation and access to raw materials. The rise of local education institutes, tourism-related businesses, and government support for small-scale industries has fueled demand for quality notebooks and stationery products.

Entrepreneurs in Dawki are increasingly investing in notebook manufacturing machines to meet local and regional demand. Whether you want to supply notebooks to schools, wholesale markets, or corporate offices, owning a high-performance notebook making machine ensures consistency, speed, and quality.

Understanding Notebook Making Machine Technology

A notebook making machine is a specialized piece of machinery designed to convert large paper reels into finished notebooks. A complete setup typically includes:

Roll to sheet cutting

Cover pressing unit

Edge squaring machine

Ruling or printing unit

Folding and stitching machine

Binding and pressing machine

Final trimming system

A modern notebook manufacturing machine integrates most of these processes into one streamlined unit. Instead of manually handling each step, operators rely on automation, saving time and improving accuracy.

Throughout Dawki Meghalaya, demand for automated and semi-automatic systems continues to grow because they increase productivity while reducing labor cost.

Types of Notebook Making Machines Available in Dawki Meghalaya

Businesses in Dawki can choose from several types of notebook machines depending on their budget and production goals. Below are the major categories:

1. Manual Notebook Making Machine

Suitable for small-scale startups. These machines require more manual effort but have lower cost. Many new entrepreneurs in Dawki begin with manual systems before expanding.

2. Semi-Automatic Notebook Making Machine

This type of notebook manufacturing machine combines automation and manual handling. It is ideal for medium-scale production.

3. Fully Automatic Notebook Making Machine

A fully automated system integrates cutting, folding, stitching, pressing, and trimming into one efficient line. Businesses that want large production volumes prefer this option in Dawki.

4. Exercise Book Making Machine

Designed to specifically produce school exercise books. This exercise book making machine is widely used by suppliers serving educational institutions.

5. Paper Notebook Production Line

A complete paper notebook production line includes multiple integrated units for uninterrupted manufacturing at industrial scale.

Each machine type offers different advantages, but all play an essential role in boosting the notebook industry in Dawki Meghalaya.

Key Components and Their Functions

1. Reel to Sheet Cutting Unit

This unit cuts large paper reels into sheets of desired notebook sizes.

2. Ruling or Printing Machine

Also referred to as a copy making equipment component, it prints lines, grids, or designs onto pages.

3. Folding and Gathering Unit

Folds sheets into notebook sections.

4. Stitching or Stapling Unit

Automatically stitches folded sheets together to form notebook blocks.

5. Binding and Cover Pressing Unit

The machine presses covers and binds them with notebook blocks to ensure durability.

6. Final Trimming Machine

Cuts the edges to give a perfect finish.

Each of these units plays an important role in ensuring smooth functioning of any school notebook machine setup.

Benefits of Investing in a Notebook Making Machine in Dawki Meghalaya

1. Local Market Advantage

Meghalaya has a strong educational ecosystem. Schools and institutions regularly require exercise books, making an exercise book making machine extremely profitable.

2. Low Raw Material Access Cost

Paper mills and distributors supply raw materials at competitive prices, especially around Guwahati and Siliguri, making Dawki an ideal location.

3. High Demand Across Borders

Proximity to Bangladesh adds export opportunities for notebooks produced by a modern notebook manufacturing machine.

4. Easy Transport and Logistics

Road connectivity from Dawki to Shillong and other parts of Meghalaya supports smooth transport of stationery products.

5. Scalability and Automation

A fully automatic paper notebook production line allows companies to scale rapidly.

How Notebook Making Machines Work Step by Step

Step 1: Paper Feeding

Large reels are fed into the system.

Step 2: Cutting

Sheets are cut to specific notebook dimensions.

Step 3: Ruling or Printing

The copy making equipment prints lines or designs.

Step 4: Folding

Sheets are folded into notebook sections.

Step 5: Stitching

Stitched with durable wire or thread.

Step 6: Binding

Cover sheets are added.

Step 7: Trimming

Final trimming to make clean edges.

This step-by-step process ensures high-quality production using a reliable school notebook machine setup.

Important Factors to Consider Before Buying a Notebook Making Machine in Dawki Meghalaya

1. Production Capacity

Choose between 2,000 to 30,000 notebooks per day depending on your expected output.

2. Machine Type

Whether manual, semi-automatic, or fully automatic.

3. Budget and Features

Automatic models cost more but ensure higher speed and quality.

4. Availability of Spare Parts

Ensure local or regional access.

5. Seller Reputation

Always buy your notebook manufacturing machine from a reliable supplier with service support in Meghalaya.

6. After-Sales Support

Technician availability is crucial.

Why Dawki Meghalaya is Perfect for Starting a Notebook Manufacturing Unit

Dawki offers:

Lower operational cost

Nearby access to labor

Transport access to Shillong, Jowai, and Guwahati

Growing demand for stationery

Cross-border commercial opportunities

Investing in a notebook making machine in Dawki can help entrepreneurs establish a stable and profitable business.

Conclusion

The demand for quality stationery and exercise books continues to rise across Meghalaya and the Northeast. Entrepreneurs in Dawki can take advantage of this expanding industry by investing in a high-performance notebook making machine, whether manual, semi-automatic, or fully automatic. With a reliable notebook manufacturing machine, you gain efficiency, speed, and consistent product quality. Additional tools like an exercise book making machine, copy making equipment, and a complete paper notebook production line can help you scale further and meet regional market demand.