Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

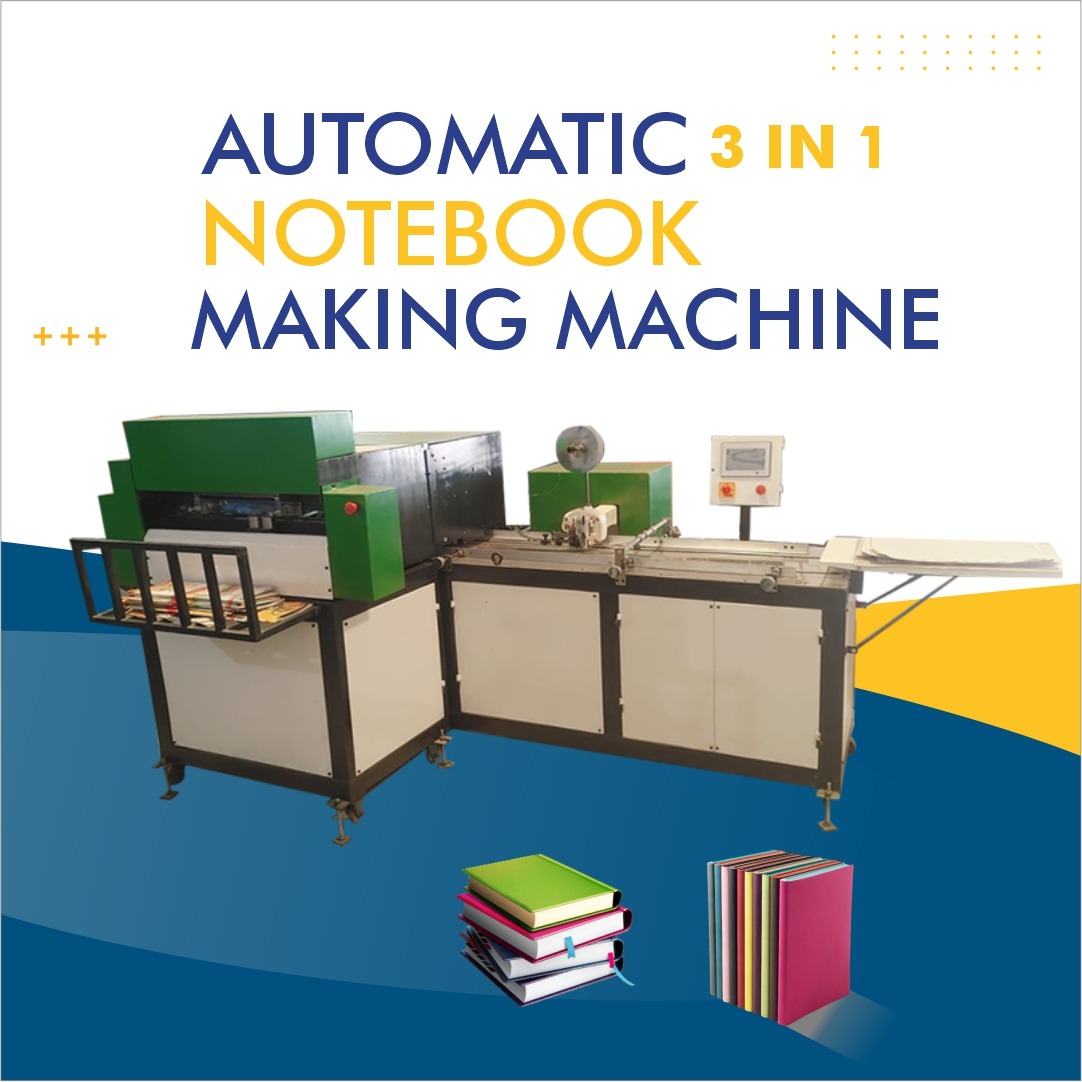

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

High-Quality Notebook Making Machine in Wangoi, Manipur | Automatic Notebook Production Solutions

Notebook Making Machine in Wangoi | Manipur

The demand for high-quality notebooks is consistently rising across India, especially in educational regions such as Manipur. Among the growing commercial hubs, Wangoi in Manipur has become an emerging location for small and medium-scale manufacturing units. One of the most profitable manufacturing setups in this region is the Notebook Making Machine business. Whether you are planning to start a new stationery production unit or expand an existing one, selecting the right notebook making machine, also known as an exercise book machine, copy book manufacturing machine, stationery notebook production machine, paper notebook fabrication machine, or a fully automated notebook production line, plays a significant role in determining productivity, quality, and profitability.

This comprehensive guide provides detailed insights into notebook manufacturing machinery, production processes, components, features, profitability, and why Wangoi Manipur is a suitable location for setting up your notebook production business.

Why Notebook Manufacturing Has High Demand in Wangoi Manipur

Wangoi is developing rapidly in terms of educational infrastructure, coaching centres, private schools, and stationery consumption. The increasing student population and local printing businesses create continuous demand for notebooks. Because of this, establishing a manufacturing unit with a notebook making machine, also referred to as an exercise book machine or notebook production line, becomes a strategic and profitable decision.

Key advantages of setting up a notebook unit in Wangoi Manipur include:

-

Proximity to local markets and distributors

-

Access to labour at reasonable rates

-

Easy availability of raw materials such as paper and covers

-

Low competition compared to mainland industrial regions

-

Opportunity for local and regional supply

Types of Notebook Making Machines Available

Depending on the scale of production and investment budget, different types of machines are available. All machines fall under categories such as:

1. Manual Notebook Making Machine

Ideal for beginners who want to start small.

Although a manual machine works slower, it is still useful for local-level notebook supply.

2. Semi-Automatic Notebook Making Machine

A balance between cost and performance.

This machine provides good speed, stable performance, and reduced labour requirement.

It is also popular as a paper notebook fabrication machine or copy book manufacturing machine among medium-scale units.

3. Fully Automatic Notebook Production Line

A complete end-to-end solution where cutting, stitching, folding, pressing, and final trimming are automated.

This type of system is often called a stationery notebook production machine or automatic notebook machine.

The fully automatic notebook production line is ideal for large-scale manufacturers planning to supply not only in Wangoi Manipur but across the Northeast and the Indian market.

Key Features of a High-Quality Notebook Making Machine

When selecting machinery for your notebook manufacturing unit in Wangoi Manipur, ensure the machine offers:

1. High Production Speed

The machine should be capable of producing thousands of notebooks per day.

A reliable exercise book machine helps meet bulk orders from schools, wholesalers, and distributors.

2. Multi-Size Compatibility

The machine must support:

-

A4 size notebooks

-

Long books

-

Registers

-

Graph books

-

Practical notebooks

3. Strong Build Quality

Choose machines built with durable steel and precision components to ensure long-lasting performance and minimal maintenance.

4. Energy Efficiency

Modern systems consume less power, making them ideal for regions like Wangoi Manipur where industrial electricity cost control is important.

5. Automated Binding and Cutting

Automatic:

-

Cutting

-

Folding

-

Stitching

-

Cover pressing

These features improve notebook quality and reduce errors.

6. Safety Features

The best notebook making machines include:

-

Emergency stop button

-

Safety covers

-

Motor overload protection

Such safety features protect both workers and equipment.

How the Notebook Production Process Works

A notebook production line or paper notebook fabrication machine follows a structured workflow. Below is the step-by-step sequence:

1. Paper Cutting

Large paper reels or sheets are cut to notebook size using precision cutters.

2. Folding

Sheets are folded uniformly using the exercise book machine.

3. Stitching

The folded sheets are moved to the stitching section where strong wire stitching binds them together.

4. Cover Placement

Covers are placed manually or automatically depending on the machine type.

5. Pressing

A pressing unit compresses the notebook for proper alignment.

6. Final Cutting / Trimming

The three edges are trimmed perfectly for a smooth finish.

7. Packing

Finished notebooks are packed and ready for distribution across Wangoi Manipur and nearby markets.

Raw Materials Needed for Notebook Manufacturing

To operate a copy book manufacturing machine or notebook production machinery, you will need:

-

Inner paper (white/ruled)

-

Cover sheets (printed)

-

Stitching wire

-

Binding materials

-

Packaging material

-

Printing ink (if printing covers in-house)

All these materials are easily available from distributors in Manipur, Assam, and other northeastern states.

Profitability of Notebook Manufacturing in Wangoi Manipur

Notebook production is one of the most profitable small manufacturing businesses due to:

1. High Market Demand

Schools, colleges, coaching institutes, and offices need notebooks throughout the year.

2. Low Competition

In regions like Wangoi Manipur, there are fewer large-scale stationery manufacturers.

3. Attractive Margin

Manufacturers often enjoy margins of 20 percent to 40 percent depending on size and quality.

4. Side Product Opportunities

With the same stationery notebook production machine, you can also produce:

-

Registers

-

Long books

-

Journals

-

Practical note copies

This increases revenue without additional heavy investment.

Why Choose a Notebook Making Machine for Wangoi Manipur

Some strong reasons include:

-

Transport cost savings by producing locally

-

Opportunity to supply to schools directly

-

Ability to expand production easily

-

Suitable for government tender supply

-

Job creation for local youth

A high-quality notebook making machine, whether it is an exercise book machine, automatic notebook machine, or paper notebook fabrication machine, ensures consistent quality output.

Maintenance Tips

To keep your notebook production line performing well:

-

Clean the machine regularly

-

Lubricate moving parts

-

Check the stitching unit daily

-

Inspect cutting blades for sharpness

-

Follow the manufacturer’s operational guidelines

-

Replace worn parts promptly

Proper maintenance ensures that your machine runs smoothly and reduces downtime.

Conclusion

Investing in a Notebook Making Machine in Wangoi Manipur is a strategic business move due to the continuous demand for quality notebooks, low market competition, and strong profit margins. Whether you choose a manual system or a fully automated notebook production line, the right machinery will help you produce high-quality notebooks efficiently.

By using advanced technology like an exercise book machine, copy book manufacturing machine, stationery notebook production machine, and paper notebook fabrication machine, manufacturers in Wangoi Manipur can supply to local, regional, and national markets with confidence.

If you are looking for durable, high-performance, and cost-effective notebook making machinery, choosing the right equipment is the first step toward building a successful notebook manufacturing business in Wangoi Manipur.