Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

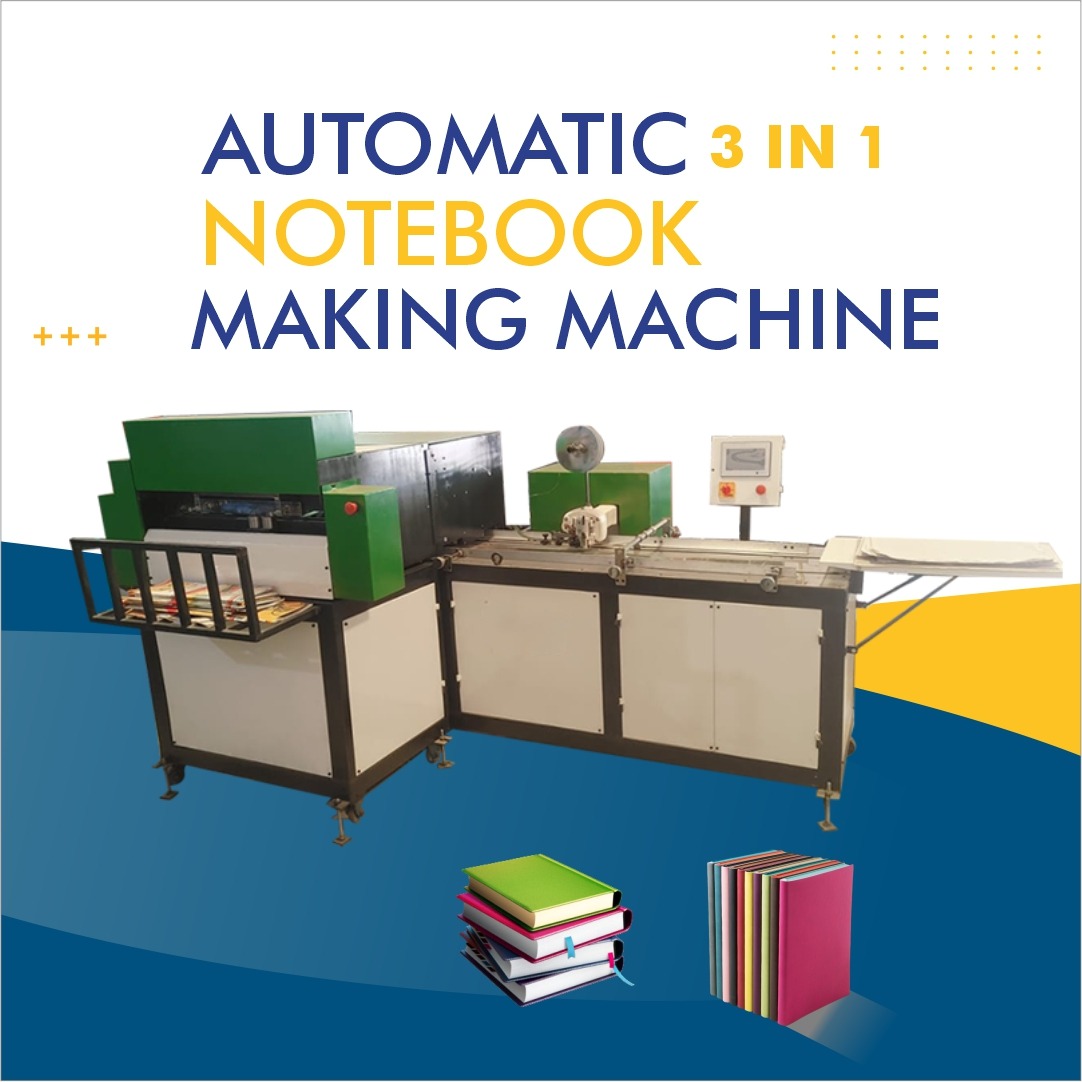

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer & Supplier – Sangli Miraj, Maharashtra

Notebook Making Machine Supplier in Sangli Miraj | Maharashtra

In the growing stationary and printing industry of Maharashtra, a notebook making machine plays a vital role in boosting productivity, improving quality, and reducing manual labour. Sangli-Miraj, known for its emerging industrial and engineering base, is now home to manufacturers and suppliers of precision notebook making machines. If you are planning to set up or upgrade your notebook production line in Sangli Miraj (or anywhere in Maharashtra), it is essential to understand the key features, types, benefits, cost factors, and after-sales service available locally.

In this comprehensive guide, you will learn:

-

What is a notebook making machine

-

Types and specifications

-

Why Sangli-Miraj / Maharashtra is a good location for sourcing

-

Cost & pricing considerations

-

Buying guide & maintenance

-

Frequently asked questions

We also include repeated use of synonyms for search-engine visibility: notebook manufacturing machine, notebook production machine, note book production equipment, school notebook machine, notebook machine price, etc.

What Is a Notebook Making Machine?

A notebook making machine is industrial equipment used to assemble, cut, bind, stamp, and finish notebooks in bulk. It automates operations that would otherwise be done by hand—such as punching holes, folding covers, injecting glue or staples, trimming, and packaging.

Synonymous terms include:

-

notebook manufacturing machine

-

note book production machine

-

notebook production equipment

-

school notebook production line

-

automatic notebook machine

Using such a machine increases output, maintains consistent quality, and reduces labour cost per unit.

Types of Notebook Making Machines

Depending on your scale, automation level and budget, you may select one of the following types:

-

Manual / Semi-automatic Notebook Making Machine

-

Requires significant operator involvement

-

Ideal for small-scale production or prototype runs

-

Lower capital cost, more hands-on control

-

-

Automatic Notebook Making Machine

-

High speed, minimal human intervention

-

Integrated functions: feeding paper sheets, glue application, stacking, trimming, binding

-

Suitable for medium to large scale production

-

-

Heavy-Duty Notebook Making Machine

-

Built for continuous use in a factory environment

-

Rugged components, high durability

-

Useful if you plan to run multiple shifts or produce thousands of notebooks daily

-

-

School Notebook Making Machine

-

Designed to produce ruled school notebooks, exercise books, with printed ruling lines, margins, stamping, binding and packaging

-

Often configured to handle lighter weight cover paper but high volume

-

-

Custom / Modular Notebook Machine

-

Modular design allows you to upgrade or expand blocks of operation — cutting, stitching / stapling, trimming & packaging

-

Ideal if you want future-proof expansion

-

Each of these machines can also be described as a notebook manufacturing machine or notebook production equipment depending on how you search or market it.

Why Choose Sangli-Miraj (Maharashtra) for Notebook Machine Sourcing?

There are multiple advantages in sourcing notebook machines from Sangli-Miraj region:

-

Engineering & Fabrication Ecosystem: Sangli-Miraj has a growing base of small-medium engineering workshops, metal fabrication units, and mechanical component suppliers. That makes servicing, spare parts fabrication and customization easier.

-

Skilled Workforce & Local Support: Local technicians and fabricators are familiar with sheet-metal work, welding, automation retrofit, which means you can localize maintenance and repair.

-

Lower Transportation & Logistics Cost (for Maharashtra customers): If your business is in or around Pune, Mumbai, Kolhapur, Satara, Sangli or Miraj, sourcing from here reduces shipping cost and turnaround time.

-

Regulatory and Industrial Support: Maharashtra Industrial Development Corporation (MIDC) and state industrial policies often favour local manufacturing and may provide incentives, easier electricity connections, and local certifications.

-

Customization & After-Sales Proximity: Being located close to the supplier means you can request custom modifications (for paper sizes, binding仕様, trimming width) faster and get on-site support for repair or calibration.

Thus, many buyers from Maharashtra (and adjoining states) prefer notebook machine manufacturers based near Sangli-Miraj or Kolhapur belt.

Key Specifications to Consider

When evaluating a notebook machine or notebook production machine, keep these technical factors in mind:

| Specification | Why It Matters |

|---|---|

| Maximum Paper Size & Sheet Format | Determines the largest notebook size you can produce (A4, A5, custom ruling). |

| Binding Method | Stapling / stitching / perfect binding / glue binding – affects cost and durability. |

| Cutting & Trimming Accuracy | Neat edges → better finish & reduced scrap. |

| Production Speed | Measured in notebooks per hour or per minute; higher speed means more output. |

| Automation Level | Manual vs semi-automatic vs fully automatic – influences labour cost & reliability. |

| Power Requirements & Energy Efficiency | Operating voltage (e.g. 415 V 3-phase), energy consumption, safety compliance. |

| Materials Handled | Paper thickness (gsm), cover board weight, type of glue or adhesive if used. |

| Dimensions & Footprint | Floor space required in your factory. |

| Safety Features & Certifications | Emergency stop, guard doors, electrical safety standards, CE / BIS certifications if applicable. |

| After-Sales Service & Spare Parts Availability | Proximity of the manufacturer / supplier matters for quicker downtime recovery. |

Using a well-designed notebook manufacturing machine or note book production equipment meeting these criteria will ensure consistent quality, less waste, and smooth production flow.

Cost & Pricing Considerations

When you ask for a note book making machine price, the cost depends on:

-

Automation Level

Manual or semi-automatic machines cost less; fully automatic or heavy duty versions cost more due to sensors, motors, PLCs, and precise mechanical design. -

Capacity & Speed

Higher speed machines with large monthly throughput tend to cost more because motors, control systems, and robustness must scale accordingly. -

Material Handling & Add-ons

Extra modules — such as pre-printed ruling lines, hot-melt glue units, cover creasing / scoring, programmable trimming — increase price. -

Build Quality & Brand / Supplier Reputation

Machines built with industrial-grade components (gears, bearings, drives) are more reliable but cost more upfront. -

Custom Modifications

If you require special sizes, binding styles, or packaging integration, customization will add to engineering cost. -

After-Sales & Warranty

Some suppliers include spare-parts kits, warranty periods, commissioning support and training — all of which affect upfront and long-term value. -

Shipping & Installation

Even if you source locally in Sangli-Miraj, you may incur costs for installation, foundation work, civil anchoring, electrical wiring and on-site calibration.

Rough estimate (for guidance only): a semi-automatic notebook making machine in Maharashtra might cost between ₹3-5 lakh depending on specifications, while a fully automatic or heavy-duty model may range from ₹7-15 lakh or more. These figures depend on capacity, features and supplier terms.

Before you finalize a purchase, always request multiple quotations, check machine test-runs, and verify after-sales support in your area.

Buying Guide: What to Check & How to Select

Here are practical steps to purchasing the right notebook making machine:

-

Define your Requirements

-

Daily or monthly production volume

-

Notebook size(s) / format(s)

-

Binding type you prefer

-

Floor-space available

-

Budget for capital as well as running cost

-

-

Shortlist Local Manufacturers / Suppliers

-

Look for manufacturers around Sangli, Miraj, Kolhapur belt

-

Ask for demonstration or reference installations

-

Check who else is using similar equipment nearby

-

-

Request Technical Specifications & Layout Drawings

-

Get detailed drawings of machine footprint, electrical wiring plan, feed-in / output material flow

-

Ask for speed curves, accuracy tolerances, uptime / downtime statistics

-

-

Compare Quotations

-

Evaluate not just price but included accessories, spare-parts package, warranty, commissioning cost

-

Factor in training for your operators

-

-

Site Visit & Factory Audit

-

Visit the manufacturer’s workshop

-

Inspect their fabrication quality (sheet-metal welds, alignment of mechanical components, finish)

-

Ask about maintenance policies and lead time for parts

-

-

Installation & Commissioning

-

Ensure the supplier sends technicians for installation, alignment and test run at your site in Sangli-Miraj

-

Get operator training as part of the deal

-

-

Maintenance & Upkeep

-

Keep spare-parts inventory (belts, blades, electrical components)

-

Schedule preventive maintenance (lubrication, calibration, safety check)

-

Use the manufacturer’s support or local service provider

-

-

Scalability & Upgrades

-

Choose a modular notebook production machine if you foresee scaling up

-

Ask whether the machine can be upgraded to add trimming station, packaging conveyor, or automated counting

-

By following the steps above, you ensure you acquire a machine that delivers consistent performance, minimal downtime, and good return on investment.

Maintenance Tips & Operating Best Practices

To get the maximum life and performance from your notebook machine (or notebook production line), follow these best practices:

-

Operate within designed parameters: paper size, thickness, speed load

-

Keep the machine clean—remove paper debris from cutters, trimming blades or glue application areas

-

Regularly inspect and sharpen cutting blades or knives used in trimming

-

Lubricate moving parts (bearings, slide-ways) as per recommended schedule

-

Check and align feed rollers or paper feeding paths periodically

-

Monitor motor current / temperature for signs of overload

-

Train staff to shut down equipment safely in case of jams or mis-feeds

-

Maintain a log of machine hours, downtime causes, and maintenance actions

-

Replace worn spare parts proactively rather than waiting for breakdown

This ensures your notebook production equipment continues to run efficiently, with reduced breakdowns, lower scrap rate, and longer service life.

Case Example: Installing a Notebook Machine in Sangli

Imagine you run a small stationery factory in Sangli city and want to produce 10,000 ruled exercise books per day. You approach a local manufacturer of notebook making machines located near Miraj. After discussing volumes, you select a semi-automatic to automatic notebook production machine with the following features:

-

Sheet feeding capacity up to A4 size

-

Integrated stapling & trimming stations

-

Production speed ~ 600 notebooks/hour

-

Electrical requirement: 415 V three-phase industrial supply

-

Footprint 2.5 m × 1.5 m, with local installation & commissioning

Once installed, you train two operators, keep spare trimming blades in stock, and commission quarterly preventive maintenance. Within six months, the machine operates reliably, production targets are met, manual labour reduced, and cost per book falls by 25 %. You are able to expand production further by adding a second shift using the same equipment.

This illustrates how an investment in a notebook manufacturing machine in Sangli-Miraj can quickly pay off.

Frequently Asked Questions (FAQ)

Q1. What is the delivery time for a notebook making machine from Sangli-Miraj?

A: Typical delivery / fabrication plus installation time may range from 4 to 12 weeks depending on customization, capacity, and order backlog.

Q2. Can the machine handle different paper sizes?

A: Yes — most manufacturers provide adjustment settings or optional rollers / guides so you can produce A4, A5 or custom-size notebooks using the same machine.

Q3. Is training provided to operate the machine?

A: Reputable suppliers around Sangli-Miraj will offer operator training during commissioning as part of the contract.

Q4. What is the electricity requirement?

A: Usually industrial three-phase supply (e.g. 415 V), with proper circuit protection, earthing and voltage stabilisation as required under Maharashtra regulations.

Q5. What maintenance support is available locally?

A: Because the supplier is local (in or near Sangli–Miraj), you can expect faster spare-part supply, on-site maintenance visits, and lower downtime compared to sourcing from far away.

Conclusion

If you are searching for a notebook making machine or notebook production equipment in Sangli-Miraj, Maharashtra, you have significant advantages: proximity to skilled fabrication resources, lower logistics cost, and the ability to get custom upgrades and service quickly.

Before purchasing, always clarify your volume, automation level, machine capacity, speed, and maintenance support. Obtain quotations with detailed specifications and visit the manufacturer’s workshop if possible. With due diligence, you can secure a reliable notebook manufacturing machine or automatic notebook making machine that meets your production goals, minimizes costs, and enables you to scale your stationery business successfully.