Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

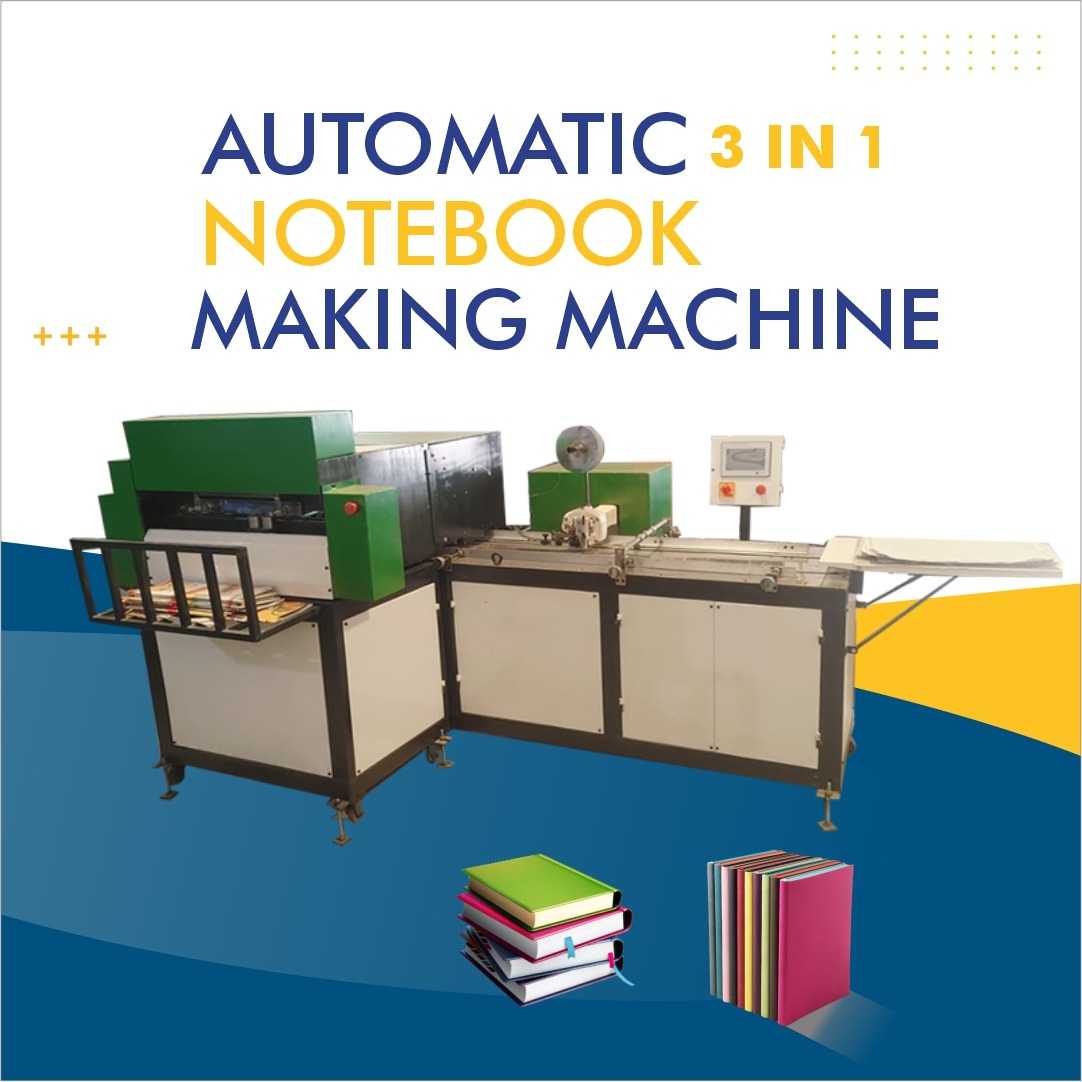

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Seoni Madhya Pradesh | High Precision Notebook Production Machinery

Notebook Making Machine in Seoni | Madhaya Pradesh

In the heart of central India, in the city of Seoni (Madhya Pradesh), there is a growing demand for efficient and reliable machinery to meet the requirements of the stationery and book-production industry. One of the critical pieces of equipment for this industry is the notebook making machine. Whether you are looking at small-scale setups or full-scale production units, a capable notebook manufacturing machine can make all the difference.

In this detailed article we will delve into everything from what a notebook making machine is, the benefits of purchasing such equipment in Seoni, the different types (manual, semi-automatic, fully automatic), technical specifications, purchase considerations, cost and ROI, maintenance tips, local support in Seoni / Madhya Pradesh, and how to evaluate vendors. We will repeat and emphasise keywords such as “notebook making machine” and “notebook manufacturing machine” (and their synonyms) so as to support SEO and help you get relevant traction online.

What is a Notebook Making Machine?

A notebook making machine (also called notebook manufacturing machine) is equipment designed to automate or semi-automate the production of notebooks – from the cutting of paper, folding, stitching or binding, edge squaring, trimming, cover attachment, to finishing. For example, one supplier lists machines with capacities of 3,000 pieces per 8 hours for semi-automatic notebook and register making machines. shkimachinery.com+1

Another manufacturer advertises an automatic notebook making machine with four functions in a single line (multi-head wire binding, folding, edge squaring, PLC control) capable of 800 books per hour. endurancemachinery.com

Thus, the notebook machine is the backbone of a notebook production unit, delivering consistent output, reducing manual error, improving finish and lowering labour cost.

Synonyms / Alternate Terms

-

notebook manufacturing machine

-

book production machine

-

notebook production machinery

-

binder machine for notebooks

-

automatic notebook machine

-

semi automatic notebook machine

These synonyms help reinforce the SEO value and capture different search phrases.

Why Set Up Notebook Making Machine Equipment in Seoni, Madhya Pradesh?

Strategic Location

Seoni is well-positioned in Madhya Pradesh which is centrally located in India. This gives logistical advantages for supplying not only local markets but also neighbouring states. Having a production facility here with a notebook manufacturing machine means access to labour, lower land costs than major metros, and connectivity.

Growing Stationery Demand

With increasing educational enrolment, stationery consumption is rising. A dedicated notebook manufacturing machine enables you to capitalise on this trend by producing exercise books, notebooks, registers, diaries, etc.

Localised Support & Services

While large metros have machine suppliers, setting up in Seoni means you can negotiate with suppliers who service Madhya Pradesh, ensure parts availability, local technician visits, and lower downtime. When you invest in a notebook making machine, reliable after-sales support is key.

Cost-Effective Startup

Starting notebook production with a semi-automatic notebook machine can be an affordable business model. For instance, machine capacity of 3,000 pcs per 8 hrs is mentioned in one listing. shkimachinery.com With proper marketing and local distribution channels, you can break even faster.

Types of Notebook Making Machines

Selecting the right type of notebook making machine depends on your production volume, budget, and product mix. Below are the typical categories:

1. Manual Notebook Making Machine

This is the entry-level machine. Manual operations dominate (paper loading, binding, trimming). Useful for small volumes or startup units. One listing describes manual notebook machine with production capacity 3,000 per day. sbsmachine.com+1

Pros: Low cost, simple operation, minimal automation.

Cons: High labour involvement, slower output, more variability.

2. Semi Automatic Notebook Making Machine

This machine automates certain steps (e.g., folding, stitching) while others remain manual. Example – production of 3,000 pcs/8 hrs. shkimachinery.com

Pros: Better output, less labour, moderate investment.

Cons: Still requires trained staff, not as fast as fully automatic.

3. Fully Automatic Notebook Making Machine

High-end machine with full automation – cutting, stitching, folding, edge squaring, cover attachment, finishing all in one line. Example: one model claims 9,000-10,000 pieces/day. sbsmachine.com+1

Pros: Very high output, consistent quality, lower per unit labour cost.

Cons: High initial investment, more complex maintenance, requires skilled operators.

Key Technical Specifications to Evaluate

When procuring a notebook production machine, focus on these critical specifications:

-

Production capacity: e.g., 3,000 pcs/day vs 9,000 pcs/day. sbsmachine.com+1

-

Automation grade: manual, semi, automatic.

-

Material quality: machine body steel/mild steel/stainless steel. Example: “Machine Material Mild Steel, Body Material MS”. asveng.com+1

-

Power requirement: voltage, phase, KW. For example, one machine requires 5 HP, voltage 420 V. shkimachinery.com

-

Book size flexibility: width, length, thickness range (pages). Example: 10-30 inch length, width 10-18 inch. endurancemachinery.com

-

Binding type: wire stitching, centre stitch, etc. In an automatic machine listing: multi-head wire binding. endurancemachinery.com

-

After-sales/parts availability: local servicing is crucial for uptime.

-

Footprint & floor-space: e.g., one machine has dimensions 192”×60”×72”. endurancemachinery.com

-

Machine brand/reliability: prefer brands with proven track record.

How to Choose the Right Notebook Making Machine for Your Business in Seoni

Assess Your Production Requirements

-

Estimate your daily/monthly output target.

-

Consider the product mix: exercise books, registers, diaries – each may require different formats.

-

Match production capacity of machine to your demand. If demand is small, a semi automatic notebook machine may suffice.

Budget & Investment

-

Manual machines cost less; automatic machines cost significantly more. For example, listings show automatic machines priced over ₹1,000,000. Tradeindia+1

-

Factor in cost of installation, power supply upgrades, operator training, maintenance.

Space & Infrastructure

-

Ensure your facility in Seoni has sufficient floor space, power supply (single/three phase), ventilation, and material storage.

-

The notebook production machine you choose should fit your plant layout and logistics flow.

Quality and Future-Proofing

-

Quality finish, minimal scraps, consistent binding are major for market competitiveness.

-

Choose a machine that can handle future expansion (higher capacity, different formats) to avoid early obsolescence.

Local Service & Parts

-

Ensure supplier provides service and spare parts in or around Madhya Pradesh/Seoni.

-

Downtime costs money, so local support is a plus.

Return on Investment (ROI) Estimation

-

Estimate cost: machine + installation + running cost.

-

Estimate output: number of notebooks per day × selling price – raw material cost – labour cost.

-

From these, estimate how many months to break even. A higher capacity notebook manufacturing machine will offer better ROI if you can utilise its capacity.

Practical Benefits of Using a Notebook Making Machine

Boosted Production & Efficiency

With a purpose-built notebook machine, you’ll see much higher throughput compared to manual assembly. For instance, fully automated machines deliver 9,000-10,000 pcs/day. sbsmachine.com+1

Consistent Quality

Automated folding, stitching and trimming result in uniform finished notebooks, which enhances your brand reputation among schools, corporates, and stationery retailers.

Labour Cost Savings

Reduction of manual labour per unit means lower per-unit cost and improved margins.

Versatility & Format Flexibility

Many machines offer adjustable format sizes, different binding styles, cover attachment, etc. This allows you to diversify product offerings (not just standard notebooks but premium ones).

Competitive Advantage

With an advanced notebook production machine, you can deliver volume, reliability, and quality — helping you stand out in a crowded stationery market.

Considerations & Challenges

Capital Investment

As noted, automatic notebook making machines demand significant investment. If your capacity utilisation is low, the pay-back may be slower.

Skilled Operation & Maintenance

Advanced machines require trained operators, preventive maintenance and may have higher downtime if neglected.

Material Supply Chain

Even with a good machine, your success depends on consistent supply of paper, covers, binding wire/threads, and finishing supplies. Establish reliable vendors.

Machine Downtime Risk

If the machine is down due to parts or service issues, production halts. Hence selecting a supplier with support in Madhya Pradesh/Seoni region is critical.

Market Demand & Sales Channel

Ensure you have a ready sales channel: schools, stationery dealers, bulk orders, corporate gifting. Production machines are helpful only if you can sell the output.

Setting Up Your Notebook Production Unit in Seoni

Choose Location & Facility

Select a site in Seoni with adequate space, power infrastructure (preferably 3-phase supply if needed), easy access for material delivery and finished goods dispatch.

Purchase & Install the Notebook Making Machine

-

Get machine quotations and compare specifications, warranty, service commitments.

-

Plan installation: machine placement, power wiring, safety guards, operator training.

-

Conduct trial runs to ensure production capacity is met.

Hire & Train Staff

Hire machine operators, helpers for loading/unloading, quality checkers. Provide training on machine operation, safety, preventive maintenance, trouble-shooting.

Raw Material Procurement

Arrange supply of paper sheets (various GSM), covers, binding wire/stitch, thread, coatings, laminates if required, trimming blades, finishing supplies.

Workflow Design

Design a workflow: paper cutting → folding → stitching/binding → trimming/edge-squaring → finishing/cover attachment → packing → dispatch. The notebook machine will handle core operations; plan for upstream and downstream tasks.

Quality Assurance

Implement quality check at incoming raw material, in the machine line (monitor binding, stitch strength, cover alignment, finishing) and final inspection. With notebook manufacturing machine in place, you can aim for low rejection rates and superior output.

Sales & Marketing

Since you are based in Seoni, target local schools, educational institutions, regional stationery markets, corporate gifting, bulk orders for training materials. Emphasise “Made in Madhya Pradesh” or “Local production in Seoni” as a selling point. Use keywords like notebook making machine / notebook manufacturing machine in your marketing materials to capture search traffic.

Case Example & Price Indicators

-

A manual notebook making machine full setup is listed by a manufacturer with capacity 3,000/day; price approx ₹1,70,000 for one model. sbsmachine.com

-

A semi-automatic notebook making machine is offered by another with capacity 3,000 pcs/8 hrs. shkimachinery.com

-

Automatic notebook making machine with advanced functions listed at regular price Rs. 1,575,000 (Approx) for Indian market. endurancemachinery.com

These figures are indicative; final cost depends on features, brand, capacity, installation. When planning your facility in Seoni, factor in such costs plus civil works, power upgrades, staff training, auxiliary equipment.

Maintenance & Operational Tips

-

Maintain a scheduled preventive maintenance plan: lubrication, checking belts/chains, ensuring alignment of stitching heads, checking cutting/trimming blades.

-

Monitor raw material quality: consistent paper GSM, straight edges, correct size. Poor material undermines machine output.

-

Train operators to monitor output, do test runs, adjust settings for different formats, and promptly fix issues like mis-stitching or cover mis-alignment.

-

Keep spare parts inventory: blades, stitching wires, belts, fuses. Especially important when using a high-capacity notebook manufacturing machine.

-

Ensure safety compliance: training, guards, emergency stop, electrical safety.

-

Analyse production data: units produced per shift, rejects, downtime. Use notebook machine metrics to identify bottlenecks (e.g., trimming might be slower than stitching).

-

Build relationships with your machine supplier for after-sales support; this is critical for keeping your notebook making machine in Seoni operating at full efficiency.

Marketing Your Notebook Production to Buyers

Since you are producing notebooks, highlighting the equipment (notebook making machine) gives credibility and allows you to emphasize volume, quality, and lead times. Use phrases like: “Produced on cutting-edge notebook manufacturing machine”, “High-volume notebook production from our Seoni facility”, “Quality guaranteed via semi automatic/automatic notebook making machine”. These help differentiate your offering.

Also consider showcasing your production facility, machine in action, sample notebooks, finishing quality. This builds trust for buyers.

Conclusion

Investing in a high-quality notebook making machine in Seoni (Madhya Pradesh) offers significant advantages: increased production capacity, consistent quality, cost savings, and competitive edge. Whether you are starting with a semi-automatic notebook production line or scaling up to a fully automatic notebook manufacturing machine, careful planning across machine selection, infrastructure, staffing, material sourcing, and market strategy is essential.