Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

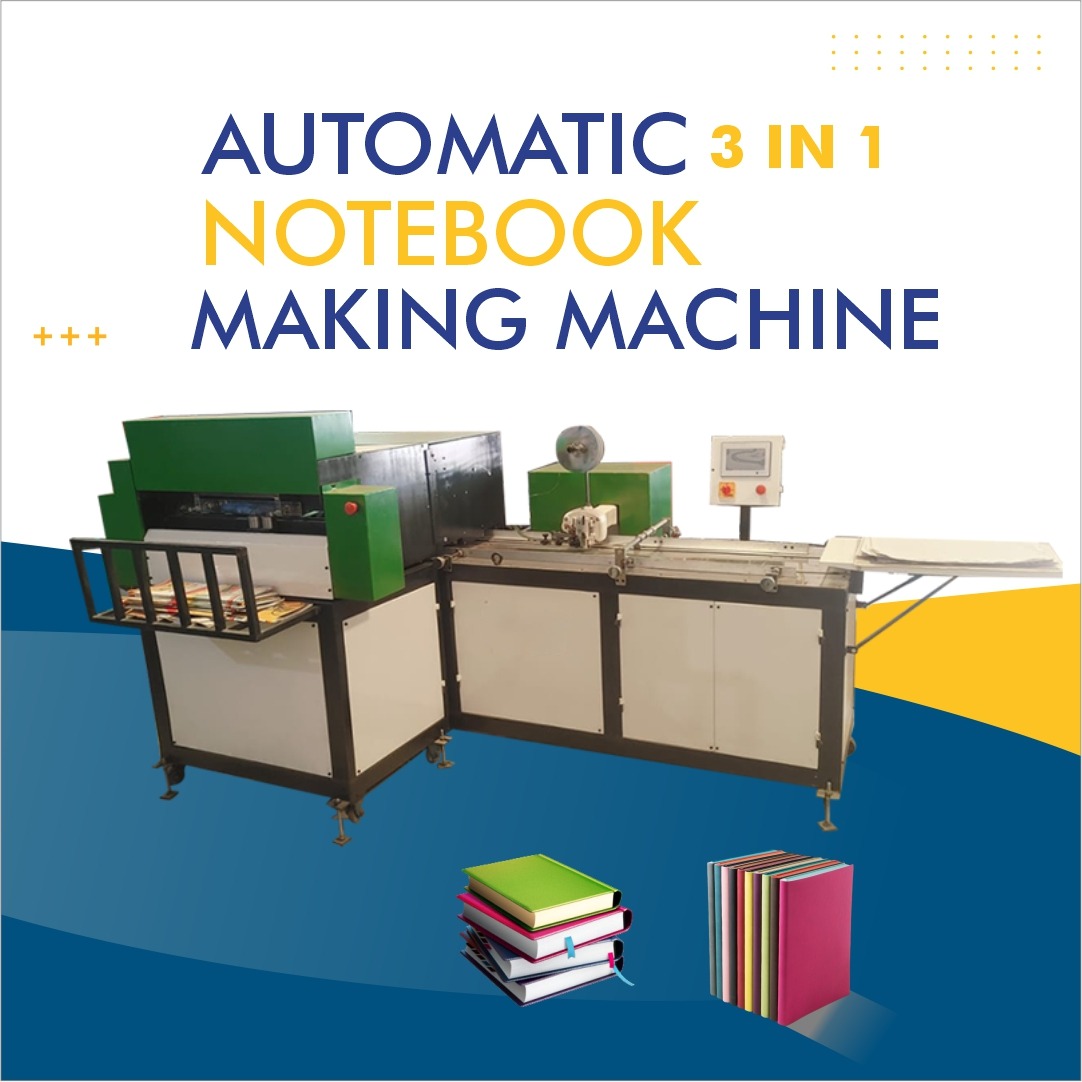

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Ratlam Madhya Pradesh – High-Quality Stationery Production Equipment

Notebook Making Machine in Ratlam | Madhya Pradesh

If you’re planning to set up or upgrade your stationery manufacturing unit in Ratlam, Madhya Pradesh, investing in the right notebook making machine is crucial. Whether you want to manufacture exercise notebooks, spiral bound notebooks or stitched notebooks, this guide will walk you through everything—from types of machines and key features to local supply, benefits and how to choose the right equipment.

What is a notebook making machine?

A notebook making machine is equipment designed to produce notebooks in batch or continuous production. This includes feeding the paper, cutting or trimming, folding, stitching or binding, and sometimes cover mounting and finishing. The machine automates or semi-automates the processes that would otherwise be manual, increasing speed, consistency and productivity.

For example, one manual full-set notebook making machine model from Indian manufacturer shows daily output of approx. 3,000 pieces per day. sbsmachine.com

There are also fully automatic lines that integrate multiple functions—cutting, stitching, folding—into a single production line. endurancemachinery.com+1

Why choose Ratlam, Madhya Pradesh as your location?

Ratlam and its surrounding region in Madhya Pradesh are increasingly active in the machinery and stationery manufacturing sector.

-

You’ll find local dealers and suppliers of notebook making machines listed for Ratlam. aajjo.com+1

-

Being locally based reduces logistics costs and allows easier service, spare parts and maintenance.

-

Being in a region with stationery manufacturing presence means supporting vendors and knowledge networks.

Types of notebook making machines (and their capacities)

Here are typical categories of notebook making machines you can consider:

-

Manual notebook making machine – Basic equipment where many operations are manually fed or assisted, suited for smaller operations or start-ups.

-

Example: A manual set with capacity of ~3,000 per day. sbsmachine.com+1

-

Lower investment, simpler controls, but more labour involvement.

-

-

Semi-automatic notebook making machine – Key operations such as cutting, folding or stitching are automated, but some manual feeding, cover mounting or finishing still done by operator.

-

Example: Machines listed at “semi automatic notebook making machine” category. shkimachinery.com+1

-

Good balance between cost and output.

-

-

Fully automatic notebook making machine – All major operations automated: paper feed, cutting, stitching/binding, trimming, cover loading, stacking. Minimal manual intervention.

-

Example: Fully automatic lines with high output (thousands per hour) and servo control for precision. endurancemachinery.com+1

-

Higher investment, but much higher throughput and lower labour cost per unit.

-

Key features & specifications to evaluate

When choosing a notebook making machine in Ratlam (or anywhere), ensure you check these crucial features:

-

Production capacity: How many notebooks per hour or per shift. For example one machine advertises 3,000 pieces per 8 hr. shkimachinery.com+1

-

Automation grade: Manual, semi or fully automatic. More automation reduces manual labour, but increases capital cost.

-

Machine material and build: Materials like MS (mild steel) or stainless steel, quality of construction. sbsmachine.com

-

Power requirements: Voltage (220 V/380 V), phase (single/three phase), motor ratings. Important for your plant setup. shkimachinery.com

-

Flexibility: Ability to produce different notebook sizes, types (spiral, stitched, exercise), thicknesses.

-

Support & service: Availability of spare parts, local service technician, installation support. Being in Ratlam helps local support.

-

Footprint & installation: How much space the machine needs, and whether you require foundation or special setup.

-

Safety and operator ergonomics: Safety features, ease of use, minimal waste.

Benefits of investing in a quality notebook making machine

-

Improved productivity: Automating steps means you can produce far more notebooks in a given time compared to manual methods.

-

Consistent quality: Machines give consistent cuts, binding, finishing, which ensures your notebook product meets quality standards and attracts better market acceptance.

-

Reduced labour cost: While manual machines require more hands, semi/automatic machines reduce operator count or shift labour into higher-value tasks.

-

Scalability: You can scale up production as demand grows—especially useful if you cater to schools, institutional buyers or export markets.

-

Competitive advantage: Having efficient machines helps you respond faster, maintain competitive pricing, and handle large orders.

Market opportunities for notebook making in Ratlam region

-

The demand for stationery products such as exercise books, spiral notebooks, stitched copies remains strong in India due to schools, colleges, corporate gifting, customized notebooks.

-

A local presence in Ratlam gives you proximity to raw material suppliers (paper, board, cover stock), logistics and regional markets in Madhya Pradesh and nearby states.

-

With a good machine setup, you can cater to regional institutional orders, uniforms, and customized notebooks for clubs, educational institutes, etc.

How to select the right machine for your needs

Here is a suggested step-by-step process:

-

Define your target output and product mix: How many notebooks per day/week? What types (exercise book, spiral, stitched)? What sizes and thicknesses?

-

Assess your budget and plant capacity: How much capital can you allocate? What electric supply and space is available in your Ratlam facility?

-

Compare machine types: Based on your output requirement, decide if manual/semi or fully automatic machine is optimal.

-

Check local suppliers: In Ratlam, you can explore local manufacturers and dealers listed for notebook making machines. aajjo.com+1

-

Evaluate technical specifications & service: Visit the machine, see a demo if possible; check for ease of maintenance, spare parts availability, local technician support.

-

Factor in operational cost: Not just machine cost, but labour, power, raw materials, maintenance.

-

Plan for future growth: Choose a machine that allows you to expand output or switch to varied notebook types to grow market share.

Common FAQs about notebook making machines

-

What capacity do I need for a start-up?

If you are starting, a manual or semi‐automatic machine producing a few thousand notebooks/day may suffice. Gradually upgrade as demand grows. -

Can I produce different sizes and types on one machine?

Many modern machines allow flexibility in size and thickness, but check with the manufacturer for changeover time, tooling costs and limitations. -

What is the typical investment range?

According to product listings, manual machines start at significantly lower cost; semi and fully automatic machines cost substantially more. For example, one listing shows price range for notebook making machines from ~1.35 lakh to ~13.50 lakh depending on automation level. swayamrojgarinds.co.in -

How quickly can I recover the investment?

That depends on your production volume, product pricing, demand, raw material cost and operational efficiency. But higher output machines reduce per-unit cost, improving margins.

Why our offering stands out in Ratlam

At our facility in Ratlam, Madhya Pradesh, we focus exclusively on supplying reliable notebook production equipment that meets modern standards. Some of our differentiators include:

-

Local presence ensures quick installation, training and after-sales support for your notebook making machine.

-

Machines suited for the region’s power, space and labour conditions.

-

Competitive pricing considering the Ratlam industrial region’s supplier ecosystem.

-

Ability to customise machine size, capacity and notebook types to align with your target market.

-

Strong focus on durability and maintenance, so your notebook manufacturing machine remains productive for years.

Conclusion

Choosing the right notebook making machine for your Ratlam-based plant in Madhya Pradesh is a strategic decision. With the right machine, you’ll gain productivity, quality and competitive advantage. Whether you opt for a manual machine to start small or invest in a high-capacity fully automatic line, ensure the specifications, service, flexibility and future-proofing are aligned with your business goals.