Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

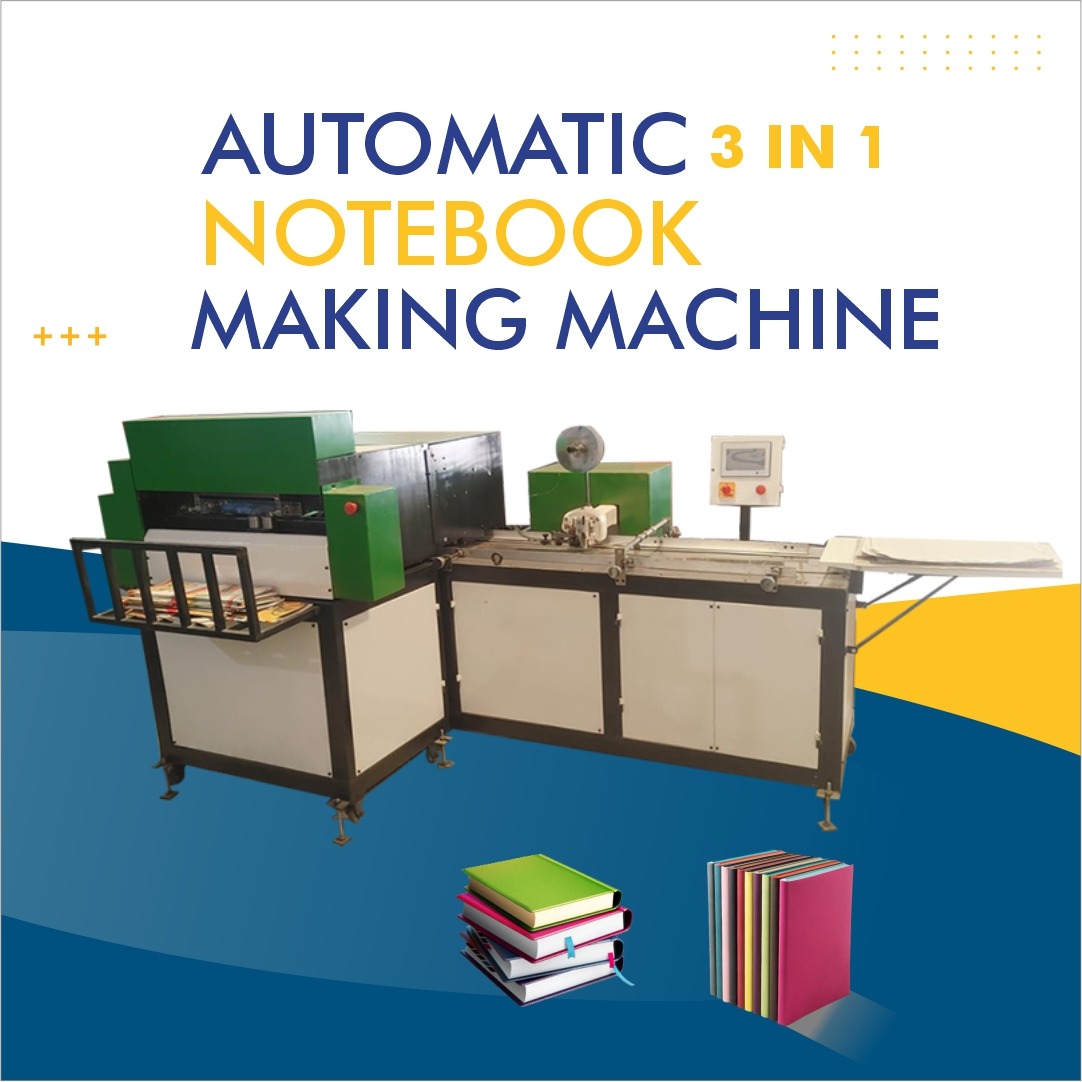

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Morena (Madhya Pradesh) – High Quality Equipment for Sale

Notebook Making Machine in Morena | Madhya Pradesh

If you are in Morena, Madhya Pradesh and planning to set up or upgrade your notebook production line, investing in a notebook making machine can bring transformative benefits to your business. In this article we will explore what a notebook making machine is, how it works, its major features, why choosing the right machine in Morena matters, what to look for, cost considerations, and how you can get started.

What is a Notebook Making Machine

A notebook making machine is a specialised piece of industrial equipment that automates the various steps required to produce notebooks or exercise books from paper raw material. It combines functions such as page cutting, folding, stitching or binding, edge squaring, trimming, and sometimes even covers and printing. According to industry descriptions, the notebook manufacturing machine is capable of handling different thicknesses, sizes and binding types. skengineer.org For instance, one specification notes a production capacity of up to 20,000 notebooks per ten hours. skengineer.org

In the context of notebook production, this machine helps the manufacturer move from manual, labour-intensive processes to a mechanised workflow, thus improving productivity, consistency and ultimately profitability.

Why Use a Notebook Making Machine

There are several compelling reasons why a notebook making machine is worth considering:

-

Increased production capacity: As seen in listings, fully automatic versions can produce thousands of notebooks per hour. smallmediumbusinessindia.com+1

-

Consistency and quality: Automated machines ensure uniform size, cut, stitch and finish – protecting the product brand and reducing waste.

-

Reduced labour cost: Over time, mechanisation replaces manual hand-labour in many steps, thereby lowering variable cost per notebook.

-

Flexibility in size and binding: Many machines allow adjustment for different notebook sizes, thicknesses, and binding styles (wire/stitch, edge square) so you can cater to varied customer orders. sikandarmachines.com+1

-

Competitive advantage: In a market such as Madhya Pradesh, having efficient equipment gives you a head-start in pricing, lead-time and product variety.

Key Features to Consider

When selecting a notebook making machine, you should evaluate a number of features and specifications to ensure you get the right fit for your business. Some of the key parameters are:

-

Production capacity: How many notebooks per hour/day the machine can handle. For example, some automatic machines claim 3,000–5,000 pieces per hour or more. smallmediumbusinessindia.com+1

-

Automation grade: Manual vs semi-automatic vs fully automatic. The more automatic the machine, typically the higher the investment but also the higher the throughput. sbsmachine.com

-

Size and thickness handling: What range of notebook sizes and thicknesses the machine can accommodate (e.g., min/max length, width, thickness). One machine listing showed thickness up to 8 mm, length 10″-30″, width 10″-18″. Endurance Machinery

-

Binding/finishing mechanism: The type of stitch or binding (wire, book stitching, fold & stitch), edge squaring, trimming, folding. sikandarmachines.com+1

-

Material and build quality: Machine material (mild steel, stainless steel), structural robustness, drive systems (servo, PLC controls) for precision. Endurance Machinery

-

Ease of operation & maintenance: User-friendly controls, ability to change sizes, minimal downtime.

-

Service and spare parts availability: Especially in a regional location like Morena, you want assured local support or at least reachable service network.

-

Electrical and space requirements: Power supply (220 V, 3-phase), floor space, operator skill. For instance one listing required 5 HP motor and weighed ~900 kg. Endurance Machinery

Why Location in Morena, Madhya Pradesh Matters

Operating from Morena in Madhya Pradesh gives you several advantages if you set up a notebook manufacturing unit and invest in a notebook making machine there:

-

Proximity to raw materials: Paper mills and stationery raw-material suppliers are accessible within central India, which can reduce transport cost.

-

Lower labour cost: Labour in more regional towns tends to be more cost-effective than in major metro areas.

-

Lower overheads: Real estate, power, and other infrastructure costs in a place like Morena may be lower compared to big industrial zones in larger cities.

-

Regional market access: You are well placed to cater to schools, institutes, and stationary distributors across Madhya Pradesh and neighbouring states like Uttar Pradesh and Rajasthan.

-

Logistics: Morena has rail/road connectivity which makes inbound supply of components and outbound distribution of finished notebooks relatively efficient.

Given these factors, selecting a high-quality notebook making machine in or for setup in Morena can provide you with a strong foundation and competitive edge in the stationery manufacturing business.

Typical Workflow of Notebook Production with the Machine

Here is a typical process you would run when you deploy a notebook making machine:

-

Paper cutting/slitting – Raw paper sheets are cut to size for pages and covers.

-

Folding – Sheets are folded into signatures or sets depending on size/thickness.

-

Stitching/Binding – The machine uses wire-booking stitching, centre stitch, or book-stitched binding. For example, multi-head wire booking stitching is one feature of advanced machines. Endurance Machinery

-

Edge squaring/trimming – After stitching, the edges are trimmed or squared off to give the notebook a clean finish. sikandarmachines.com

-

Cover application – Covers (printed or plain) are applied and may be glued or stitched depending on machine capability.

-

Final inspection & packaging – Notebooks are inspected, counted, stacked, and prepared for shipment or sale.

Throughout this workflow, the notebook making machine automates or supports many of the key steps, thereby reducing manual handling and improving output consistency.

Investment & Cost Considerations

When budgeting and planning for a notebook making machine, especially for a setup in Morena, consider the following cost elements:

-

Machine cost: The upfront equipment cost will vary hugely depending on automation level, size, brand and features. Some manual or semi-automatic machines are available at lower cost (e.g., small sets) while fully automatic ones with high throughput will cost more. sbsmachine.com+1

-

Installation & commissioning: Setup, training of operators, alignment and tuning of machine.

-

Power & infrastructure: You must ensure stable power supply (often 3-phase), adequate floor space, ventilation, and maybe foundation if heavy machine.

-

Raw material cost: Paper, covers, binding wires, ink if you print, etc.

-

Labour cost: Even though machine reduces labour, you will still need operators, maintenance staff, supervisors and packaging helpers.

-

Maintenance & spare parts: Machine downtime can impact production, so budget for regular servicing and availability of spares (especially important for units in Morena – ensure vendor supplies these).

-

Working capital: For raw materials, inventory, finished stock until sale.

-

Logistics: Inbound and outbound transport costs – although being in central India may reduce some of these.

-

Return on Investment (ROI): Estimate how many notebooks you need to sell at what margin to recover your investment. Higher automation and capacity means faster ROI but higher upfront cost.

Selecting the Right Supplier & Machine for Morena

Here are some practical tips for choosing the correct notebook making machine and supplier when you are operating in Morena:

-

Visit the supplier’s demo unit or ask for video demonstration of the machine in operation to see output quality, speed, changeover times.

-

Check local references: Ask other notebook manufacturers (if any in Madhya Pradesh) about machine reliability, service support, spare parts availability.

-

Spare parts availability regionally: Ensure the supplier supplies spares in your area or has a distributor network near Madhya Pradesh.

-

After-sale support: Installation, training of your team, trouble-shooting support should be included.

-

Machine adaptability: Choose a machine that allows for future scalability – ability to handle different sizes, thickness, binding styles as your business grows.

-

Energy consumption: In areas where power stability may vary, machines with lower power requirements or protections against voltage fluctuations are important.

-

Space and layout planning: Since physical footprint matters, map out your factory layout in Morena for smooth material flow (raw → processing → finished).

-

Budget vs capacity trade-off: If you are starting smaller, a semi-automatic machine may suffice; but if you plan growth, consider fully automatic options.

-

Lead time and delivery: Ensure the machine can be shipped to Morena in a timely manner and installation is feasible regionally.

Challenges & How to Overcome Them

Every manufacturing initiative has its own set of challenges. Here are a few you might face when deploying a notebook making machine in Morena, and how to mitigate them:

-

Power fluctuations or outages: Install stabilisers, backup power (UPS or generator) to ensure the machine does not suffer damage or stoppages.

-

Operator training and supervision: Even automated machines require skilled supervision. Allocate time for training your workforce.

-

Raw material quality variability: Paper or cover materials of inconsistent quality may affect output quality – work with reliable suppliers and perform incoming QC.

-

Maintenance downtime: Schedule preventive maintenance to avoid surprise breakdowns; keep critical spares stocked locally.

-

Logistics and supply chain delays: In case raw materials or spare parts need transport beyond local area, establish buffer inventory and multiple supplier sources.

-

Market diversification: Notebooks are a competitive market; ensure you have sales channels and diversify product sizes/types to manage risk.

Growth Opportunities & Scaling Up

Once you have the notebook making machine up and running in Morena, you can think about scaling and diversifying:

-

Expand product range: produce exercise books, registers, spiral notebooks, hard-covered notebooks (if machine supports).

-

Offer custom sizes or binding styles to schools, coaching institutes, corporate gifting.

-

Export or supply to neighbouring states – Madhya Pradesh, Uttar Pradesh, Rajasthan, etc.

-

Integrate printing or pre-printing unit upstream so you can offer printed covers and papers.

-

Automate packaging downstream to further enhance efficiency.

Why Choose Our Notebook Making Machine Solution in Morena

For businesses in Morena who are serious about notebook manufacturing, we offer a tailored solution:

-

Machines selected for central-India conditions (reliable build, local support)

-

Assistance in layout planning for your workshop in Morena

-

Guidance on raw-material sourcing & logistics within Madhya Pradesh

-

Support in commissioning, training and maintenance scheduling

-

Flexible financing or leasing options (if applicable) to suit initial capital budgets

By investing in a high-quality notebook making machine now you set yourself up for long-term competitive strength, cost-control, quality consistency and business growth.

Conclusion

if you are operating in or around Morena in Madhya Pradesh and aiming to enter or expand your notebook manufacturing operations, choosing the right notebook making machine is a strategic decision. From capacity and automation to build quality, supplier support and logistics, all factors matter. With the right machine you can achieve strong production throughput, consistent notebook quality, and cost-effective operations – positioning your business for success in the competitive stationery market.