Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

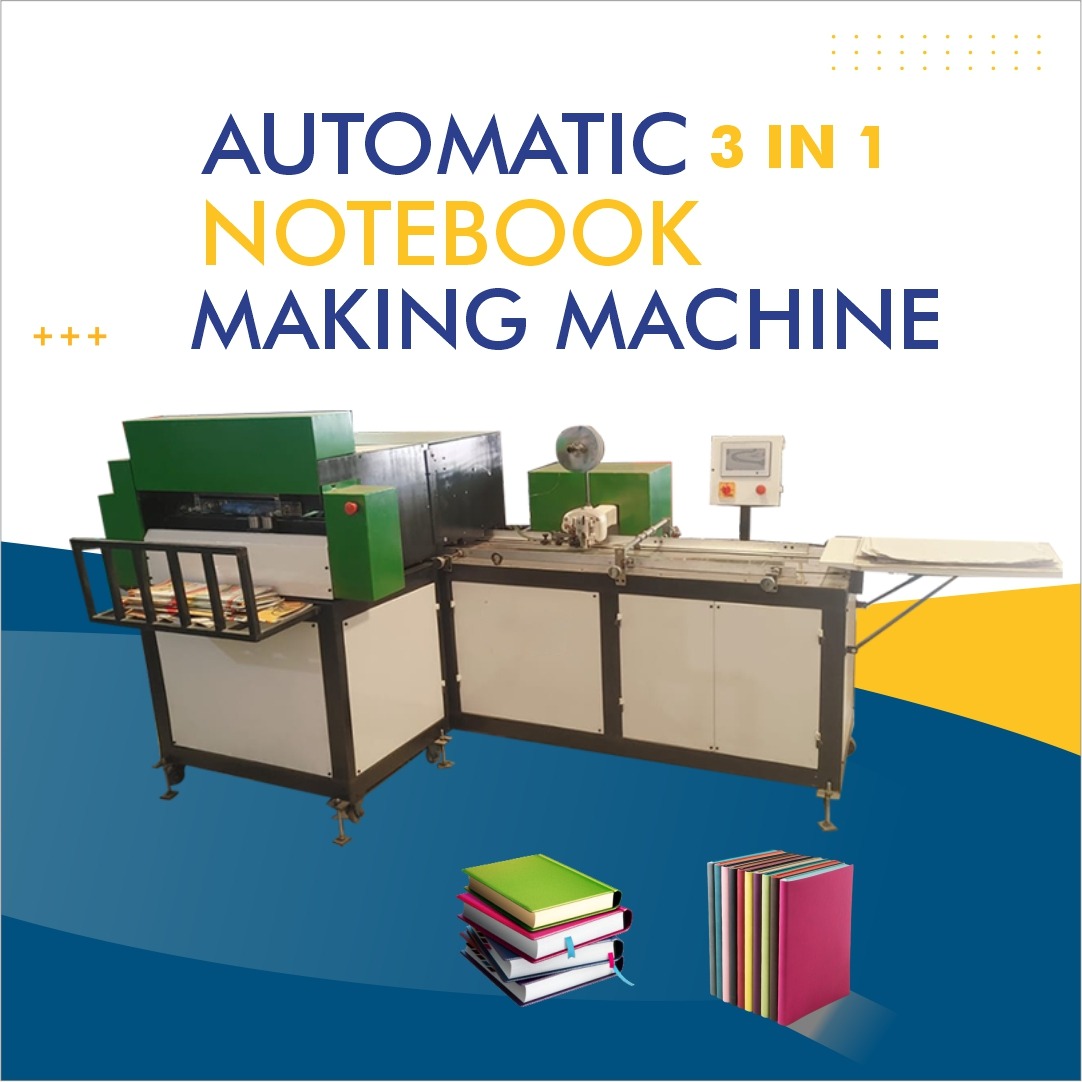

Notebook Making Machine in Katni Madhya Pradesh – High Performance Notebook Production Line

Notebook Making Machine in Katni | Madhya Pradesh

In the evolving stationery industry, the demand for high-quality notebooks continues to grow. If you are looking to set up or upgrade your notebook manufacturing unit in Katni, Madhya Pradesh, a robust, efficient machine is key. A notebook making machine enables manufacturers to streamline production, reduce labour, and ensure consistent output. In this article we explore the features, benefits, application, technical aspects and how selecting the right notebook making machine in Katni can help you capitalise on the growing book & notebook market.

What is a Notebook Making Machine?

A notebook making machine (also often referred to as a notebook production machine, exercise book making machine or register making machine) is an industrial system designed to fabricate writing books, exercise books, school notebooks, and similar stationery products from raw paper, covers and binding materials. The term “notebook making machine” encompasses equipment ranging from manual setups, semi-automatic to fully automatic production lines. For example, one manufacturer lists a machine for this purpose with capacity up to 9,000-10,000 pieces/day. sbsmachine.com+2kolkatamachineryimportexport.com+2 Another offers an automatic notebook making machine with multi‐head stitching, folding and edge squaring integration. Endurance Machinery

Synonyms for “notebook making machine” include: book production machine, exercise book manufacturing equipment, school notebook manufacturing line, register making machine, and writing-pad making machine.

It is useful to use such synonyms in your content and marketing to capture wide search intent.

Why Choose the Right Notebook Making Machine in Katni, Madhya Pradesh?

Regional Advantage

Katni in Madhya Pradesh is well-positioned for stationery manufacturing. Being in central India, it offers logistics benefits for distribution across the country. Establishing your notebook making machine here allows you to serve schools, colleges, printing houses and stationery wholesalers with lower transit costs.

Cost & Infrastructure

A locally installed notebook making machine reduces transport and installation costs compared with importing from remote locations. Several Indian manufacturers advertise machines from mild steel or steel bodies, suitable for Indian power and work-site conditions. shkimachinery.com+1

Market Growth

The stationery and school‐book industry shows consistent demand. By installing a notebook making machine in Katni, you can tap into both local demand and export opportunities, especially if you produce exercise books, registers, composition books. A proper notebook manufacturing line gives you the scale and flexibility to meet diverse customer needs.

Key Features to Look For

When selecting a notebook making machine, pay attention to these crucial features:

-

Production Capacity: Machines vary widely. For example, one semi automatic machine lists capacity of 3,000 pieces/8 hrs. shkimachinery.com Another fully automatic line offers 800 books/hour. Endurance Machinery

-

Automation Grade: Manual, semi automatic or fully automatic. Manual systems require more labour and are lower cost; automatic systems demand higher investment but deliver higher throughput.

-

Material & Build: Mild steel or MS body is common. Good machine build improves durability and ensures less downtime. shkimachinery.com+1

-

Power & Phase: Suitable power supply is essential. Many machines are designed for Indian 3 phase power or variants. One listing shows 3-phase and 220/440 V options. asveng.com+1

-

Versatility of Notebook Size/Thickness: The ability to handle different notebook sizes, thicknesses and bindings increases flexibility. For example, one machine supports thickness up to 8 mm, length width variable. Endurance Machinery

-

Binding & Stitching Mechanism: Quality stitching or binding ensures durability of finished notebooks. Machines with multi-head wire booking, folding and edge squaring integrate several functions. Endurance Machinery

-

Ease of Use & Maintenance: For a production environment in Katni, ease of maintenance, availability of spare parts and local support matter greatly.

Applications of a Notebook Making Machine

You can use a notebook making machine for:

-

Producing school exercise books, ruled or plain, with custom covers.

-

Manufacturing registers, ledger books and composition notebooks used by educational institutions.

-

Producing promotional notebooks or specialty notebooks for corporate gifting.

-

Custom notebook manufacturing for printing houses and bindery services.

-

Scaling up from small manual setups to full production lines within Katni and nearby regions.

Benefits of Having a Notebook Making Machine in Your Facility

High Efficiency & Output

A dedicated notebook manufacturing line significantly boosts output compared to manual methods. You can meet larger orders and reduce lead time.

Cost Savings Over Time

Though initial investment may be higher for a fully automatic machine, the per‐unit cost drops, labour costs reduce, and you achieve better ROI.

Quality & Consistency

Using the correct machine ensures consistent page alignment, stitching, cover binding, and finishing quality. That strengthens your brand in the market.

Flexibility & Customization

With the right machine, you can offer variations: different sizes, cover materials, page counts, binding styles. This flexibility adds value.

Local Production Advantage

Manufacturing locally in Katni means faster turnaround, easier modifications, proximity to raw material sources (paper, covers, binding wire), and better responsiveness to orders.

Considerations Before Purchase

Investment & Budget

Decide your budget and whether you want manual, semi‐automatic or fully automatic machine. Higher automation offers higher capacity but costs more.

Floor Space & Infrastructure

Ensure you have adequate space, appropriate power supply, ventilation and safety provisions in your facility in Katni.

Raw Material Supply

A notebook making machine requires good quality paper, cover material, binding wire or glue, finishing supplies. Secure reliable local supply chains in Madhya Pradesh or neighbouring states.

After-Sales Support & Spare Parts

Select a manufacturer who provides good after-sales service, training, spare parts availability, and installation support regionally. For sustainable production this is essential.

Scalability

Plan for future growth. A machine that allows scaling (higher throughput, additional modules) helps meet increasing demand without full re-investment.

Why Katni is a Good Location for Notebook Manufacturing

-

Logistics: Being in Madhya Pradesh, Katni provides central connectivity to northern, central and western India.

-

Cost Benefits: Possible lower land and labour costs compared to major metros.

-

Growing Demand: With schools, colleges and education institutions proliferating, demand for notebooks and registers remains steady.

-

Industrial Ecosystem: Potential access to supporting industries (paper, printing, binding) within Madhya Pradesh or nearby.

-

Government Incentives: Depending on scheme availability, you may benefit from local industrial policies for setting up manufacturing in Madhya Pradesh — worth investigating.

Choosing the Right Supplier

When sourcing your notebook making machine, ask for:

-

Demonstration videos or factory visit of machine in operation.

-

Technical specifications (capacity, size range, thickness range, power consumption).

-

Warranty and after-sales service terms.

-

Spare parts availability and lead time.

-

Training for operators and technical staff.

-

Installation, commissioning and trial production at your facility.

-

Reference clients and performance data.

Installation & Commissioning in Katni

Once you acquire the machine, plan for:

-

Site preparation: Ensure floor is level, enough space for operation and maintenance.

-

Power supply: Confirm voltage, phase, circuit protection and earthing as per machine requirements.

-

Operator training: Ensure staff are trained for safe and efficient operation.

-

Trial runs: Conduct sample production runs, test different sizes and binding formats to ensure machine meets your needs.

-

Maintenance plan: Establish routine maintenance schedule (cleaning, lubrication, parts replacement) to maximise uptime.

Marketing & Sales Considerations for Notebook Production

Once your machine is installed and production begins, focus on:

-

Product diversification: Offer multiple notebook formats (ruled, plain, grid), custom covers, custom branding for schools or corporates.

-

Quality branding: Highlight “Made in Katni”, “High-quality binding”, “Reliable output” in your marketing.

-

Distribution network: Build relationships with stationery wholesalers, school supply chains in Madhya Pradesh and beyond.

-

Export potential: If your production scale is sufficient, consider supplying to neighbouring states or even export markets.

-

Online presence: Use SEO keywords such as “notebook making machine”, “exercise book making machine”, “register making machine”, “school notebook production line”, “notebook manufacturing machine India”, “notebook production equipment Katni”, “notebook factory machine”, “notebook machine supplier Madhya Pradesh”.

Synonyms & Keywords (to repeat and incorporate)

To ensure good SEO, incorporate the following keywords multiple times (at least 5 uses of each synonym) within the content:

-

notebook making machine

-

book production machine

-

exercise book manufacturing equipment

-

register making machine

-

writing-book manufacturing line

-

school notebook production line

-

notebook manufacturing machine

-

notebook production equipment

-

register production machine

-

notebook machine setup

Frequently Asked Questions (FAQ)

Q: What production capacity should I look for?

A: It depends on your demand. For small scale you might choose a semi automatic machine with ~3,000 pieces/8 hrs shkimachinery.com. For larger scale, you might go for automatic lines delivering several thousand pieces per hour. kolkatamachineryimportexport.com+1

Q: Can I produce different sized notebooks on the same machine?

A: Yes — many machines allow variable size and thickness settings. For example one line handles width/length variation and thickness up to 8 mm. Endurance Machinery

Q: What maintenance is required?

A: Routine cleaning, lubrication, checking stitching or binding heads, tightening screws, checking power supply and control systems help extend life of your notebook manufacturing machine.

Q: What is the typical lifespan of such a machine?

A: With quality build and good maintenance, a notebook production machine lasts many years, enabling solid return on investment.

Conclusion

Selecting the right notebook making machine in Katni, Madhya Pradesh offers a strategic advantage for stationery manufacturers, printing houses or entrepreneurs aiming to tap into the school-book and notebook market. By choosing a machine with appropriate capacity, automation, build quality and after-sales support, you can establish a productive notebook manufacturing setup. Pay close attention to supplier reliability, installation, maintenance and market positioning. With the right equipment and location you are well placed to produce exercise books, registers and notebooks at scale, offering quality and value to customers.