Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

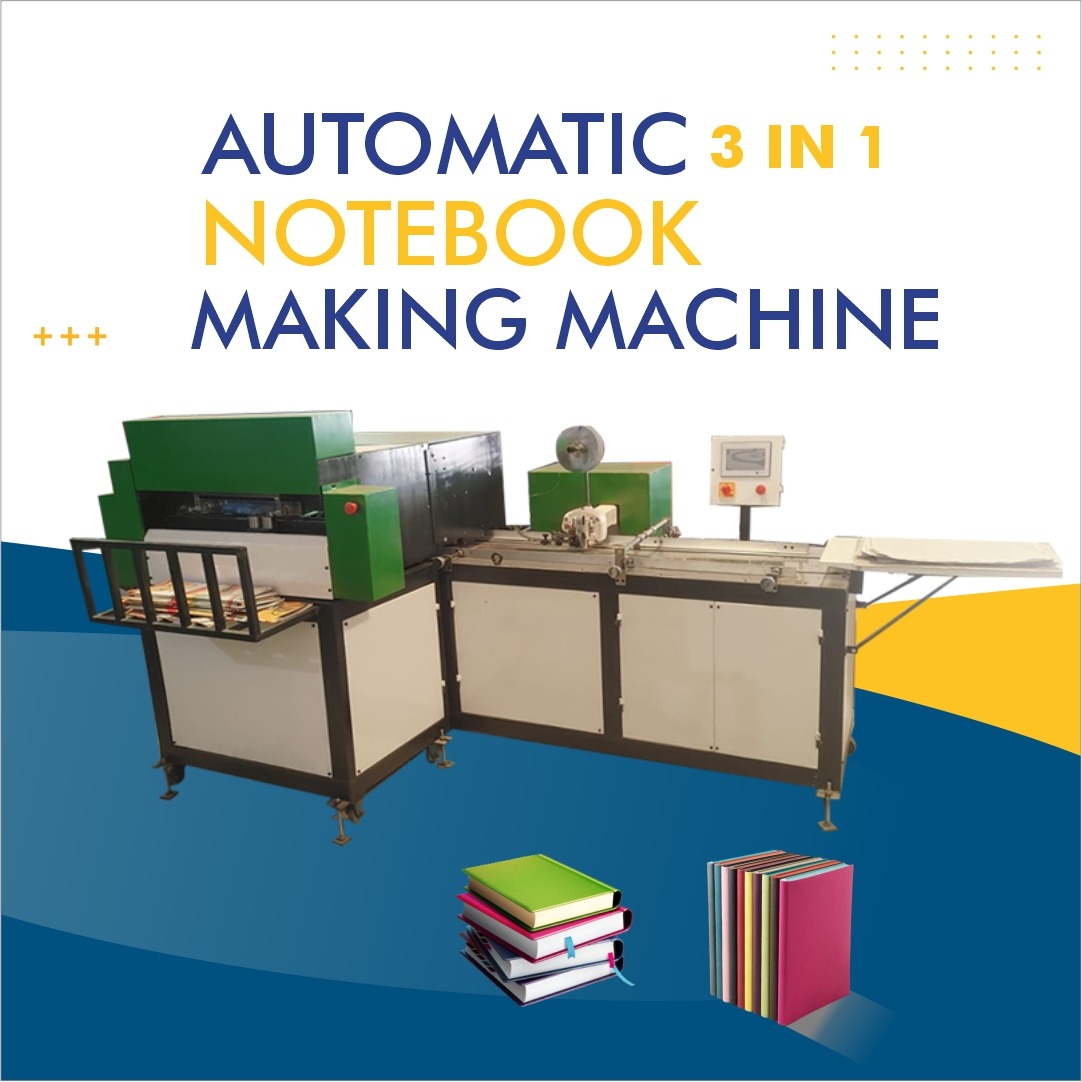

Notebook Making Machine in Chhindwara Madhya Pradesh | High‐Efficiency Notebook Manufacturing Machinery

Notebook Making Machine in Chhindwara | Madhya Pradesh

If you are planning to set up or upgrade a notebook manufacturing unit in Chhindwara, Madhya Pradesh, investing in a high‐performance notebook making machine is a critical decision. The right notebook making machine will not only enhance productivity but also reduce waste and improve quality. In this detailed article, we cover everything you need to know—from machine types and features to production capacity, benefits, and key selection criteria—tailored for the region of Chhindwara.

Why Choose a Notebook Making Machine in Chhindwara, Madhya Pradesh

Chhindwara, situated in Madhya Pradesh, enjoys several advantages for setting up a notebook manufacturing business. The state offers relatively easy access to raw materials, power supply and a labour pool familiar with manufacturing processes. Having a local machine supplier or customisation facility nearby can significantly reduce lead time and transportation costs.

By choosing a notebook manufacturing machine here, you benefit from shorter delivery times, local support and easier maintenance. Moreover, locating near your market or distribution network in central India helps reduce logistics costs for finished notebooks.

What Is a Notebook Making Machine?

A notebook making machine is a specialised industrial machine designed to produce notebooks at scale by automating several key steps: cutting raw sheets, folding, stitching or binding, edge squaring, cover lamination or binding, trimming and finishing. Some models handle manual operations; others are semi‐automatic or fully automatic. For example, one fully automatic model offers multi‐head stitching, folding and edge squaring in one line. Endurance Machinery+2sbsmachine.com+2

These machines transform stacks of sheets into finished notebooks ready for packaging and distribution. Choosing the right equipment depends on your target daily output, size of notebook, number of pages, binding type and finishing quality.

Key Features and Specifications to Consider

When selecting a notebook manufacturing machine, keep the following features in mind:

1. Automation Grade

Machines come in manual, semi‐automatic and fully automatic versions. Manual machines require more operator intervention; semi‐automatic reduces labour; fully automatic offers highest throughput. For example: one machine provides production of 9,000–10,000 pieces/day in automatic mode. sbsmachine.com+1

2. Production Capacity

You need to match capacity with your business plan. Typical capacities: 3,000 pieces/day for manual/semi‐automatic; 5,000+ or even 9,000–10,000 pieces/day for fully automatic. sbsmachine.com+1

3. Size and Binding Capabilities

Notebooks vary in size, thickness and binding type. Ensure the machine supports the notebook format you intend (A4, A5, etc.), page count, binding (wire, thread, glue) and cover materials. For example, one machine supports thickness 8mm and book length up to 30″. Endurance Machinery

4. Material & Build Quality

Frame material (mild steel, stainless steel), tooling precision, quality of stitching heads and folding units matter for long‐term durability and low maintenance. kesyainternational.com

5. Power and Utility Requirements

Check voltage, phase (single/three), power consumption (kW) and footprint. For example, an automatic machine required 5 HP power and three‐phase supply. shkimachinery.com

6. After‐Sales Service & Local Support

Since you are based in Chhindwara, access to service technicians, spare parts and installation support is vital. Choosing a supplier with regional presence ensures timely maintenance and minimal downtime.

Benefits of Investing in a Notebook Manufacturing Machine

High Productivity

Automated machines dramatically increase output. With reduced manual intervention you can meet large order volumes and shrink lead times.

Consistent Quality

Precision mechanisms ensure uniform stitching, folding and trimming across thousands of units. This results in better finished notebooks with fewer defects.

Cost‐Efficiency

By automating, you lower labour cost per unit and reduce wastage of raw material. Over time your return on investment improves.

Flexibility

Modern machines allow different notebook sizes, page counts and binding types. This flexibility helps you cater to varying customer demands and niche markets.

Scalability

Starting with a smaller machine you can scale up by adding modules or upgrading to automatic versions as business grows. For example, beginning with a semi‐automatic machine (3,000/day) and later upgrading to 10,000/day capacity. asveng.com

Notebook Manufacturing Process Overview

Here is a typical workflow when using a notebook making machine:

-

Raw sheet feeding – Bulk sheets (paper and cover) are loaded.

-

Cutting/Trimming – Sheets are trimmed to correct size.

-

Ruling/Pre‐printing (optional) – Lines or designs are printed.

-

Folding/Collating – Sheets are folded and assembled in sequence.

-

Stitching/Binding – With wire or thread; in some machines glue binding is also possible.

-

Edge Squaring/Trimming – Ensures clean edges and uniform thickness. Endurance Machinery+1

-

Cover Binding/Lamination – Cover material is affixed.

-

Finishing & Packaging – Final quality check, counting and packing notebooks for dispatch.

By integrating all these stages into one line (in automatic machines), you save time, reduce handling and control quality better.

Why Chhindwara Is a Strategic Location

Setting up the notebook manufacturing unit in Chhindwara gives you several locale advantages:

-

Central India connectivity enables distribution across Madhya Pradesh, Maharashtra, Chhattisgarh and adjoining states with reduced logistics lead‐time.

-

Availability of labour and smaller industrial land cost compared to metro zones.

-

Potential to tap into local markets, school demand and regional supply chains for stationery products.

With a robust notebook making machine installed locally, you can supply to schools, colleges, corporate offices and retail chains across the region.

Choosing the Right Supplier & Machine for Chhindwara

Here are some practical tips for selecting your supplier and machine:

-

Visit live machine demo or request video to assess build quality, output, ease of changeover for different sizes.

-

Check machine footprint and ensure your factory site in Chhindwara offers required space and infrastructure (power, ventilation, operator access).

-

Ask about spare parts availability locally or regionally so downtime is minimized.

-

Determine training and commissioning support – operator training ensures your workforce can run the machine effectively.

-

Compare total cost of ownership – initial price is just one part; consider maintenance, consumables, electricity, and eventual upgrade path.

-

Check compatibility with your notebook formats – if you intend multiple sizes or binding types, ensure the machine supports that flexibility.

-

Plan for scalability – select a machine that allows future expansion or add‐on modules as your production volume grows in Chhindwara or beyond.

Investment & Return Considerations

While specific machine costs vary widely depending on capacity and automation grade, some indicative values from Indian manufacturers:

-

Manual/semi‐automatic machines (3,000/day capacity) are often in the range of a few lakhs of rupees. shkimachinery.com+1

-

Fully automatic machines (5,000+ pieces/day or 9,000–10,000/day) can cost significantly more. sbsmachine.com

To estimate ROI:

-

Calculate your expected daily output × unit manufacturing cost × selling price.

-

Deduct machine depreciation, labour, utilities, raw materials and maintenance to arrive at profit margin.

-

With a high‐efficiency machine, lower per‐unit cost enables competitive pricing or higher margin.

Given the stationery market in Madhya Pradesh and nearby states, a well‐configured notebook production line in Chhindwara can capture significant demand—especially for educational notebooks, corporate diaries and customized notebooks.

Challenges & How to Overcome Them

Raw Material Quality & Supply

Ensure you have steady supply of good paper stock, cover material and binding wire or glue. Fluctuations in raw material price can affect margin. Mitigate by forging relationships with reliable suppliers and buying in bulk.

Maintenance & Skilled Operators

Machines with advanced features require skilled operators and regular maintenance. For Chhindwara setup, invest in operator training and schedule preventive maintenance.

Market Competition

Notebook manufacturing has competition from large units and imports. To compete, focus on quality, timely delivery, customization and local service. A good machine helps deliver consistent quality and quicker turnaround.

Space and Utility Constraints

Fully automatic machines may require significant space and three‐phase power supply. Ensure your factory site in Chhindwara meets those requirements before purchasing.

Why This Is the Right Time

With increased emphasis on education, stationery demand is rising, especially in tier‐II and tier‐III cities. Setting up a notebook manufacturing line now positions you ahead of demand growth. Moreover, locating in central India (Chhindwara) reduces logistics cost to major markets.

Investing in a modern notebook making machine equips you to meet both current demand and future expansion. It also allows customization (e.g., college‐ruled, graph notebooks, diaries) which gives you an edge over generic imports.

Conclusion

Selecting the right notebook manufacturing machine in Chhindwara, Madhya Pradesh is a strategic decision that can determine your success in the stationery industry. Focus on capacity, automation grade, build quality, supplier support and scalability. A well‐chosen machine will lead to higher productivity, better quality, lower cost per unit and significant ROI.

If you are ready to proceed, assess your production target, budget, notebook formats and factory site. Then choose a machine supplier who understands the regional dynamics of Chhindwara and offers local support. With the right notebook production equipment, you can establish a robust notebook manufacturing business in central India.