Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

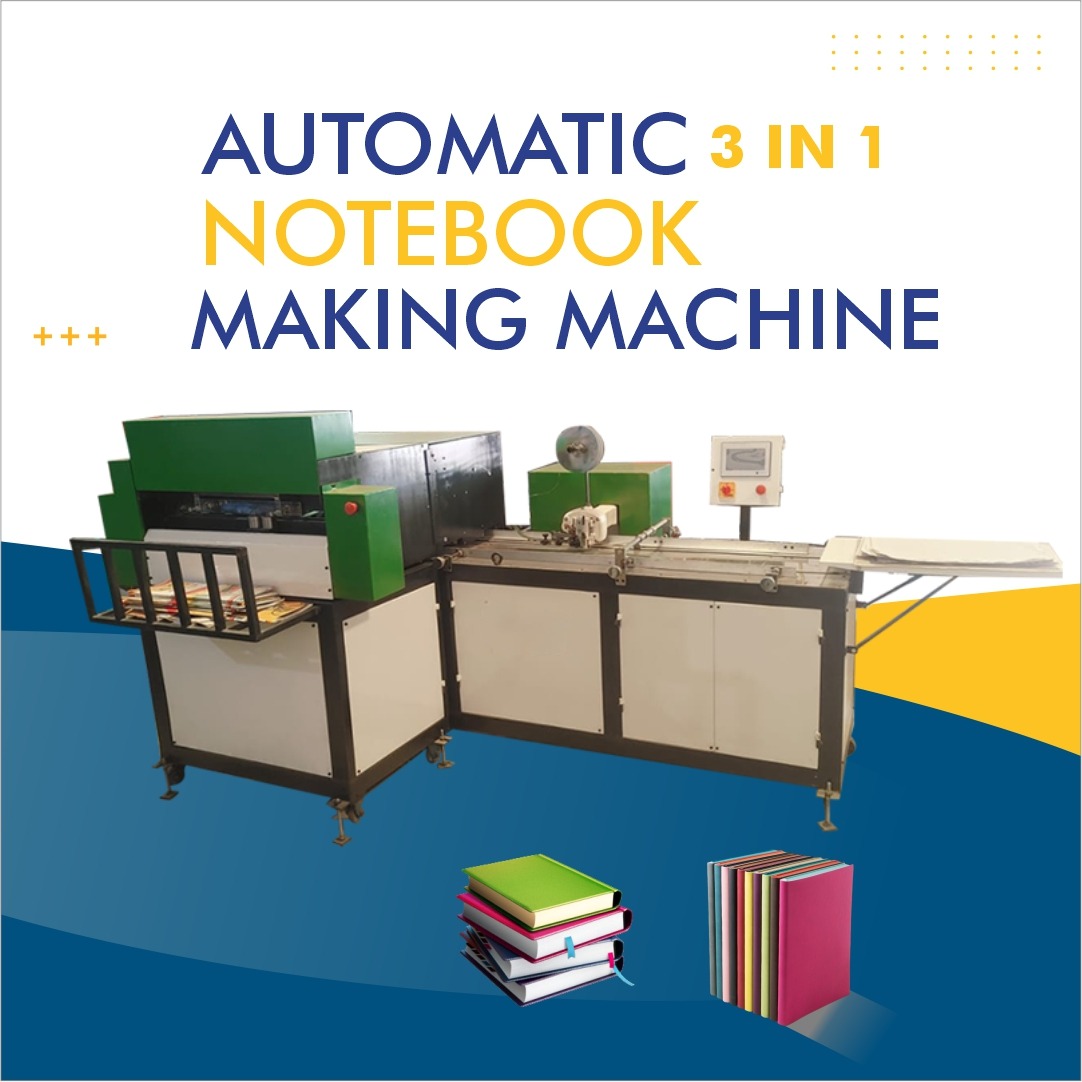

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Khargone Madhya Pradesh – High Capacity Notebook Production Equipment

Notebook Making Machine in Khargone | Madhya Pradesh

Setting up or scaling a notebook production unit demands robust, reliable machinery that can meet varying levels of output, quality demands and automation. A notebook making machine allows you to streamline processes such as cutting, stitching, binding and trimming, enabling efficient production of notebooks at large volumes. When you establish your manufacturing facility in the thriving industrial environment of Khargone in the state of Madhya Pradesh, you benefit from both strategic location and industrial support infrastructure. In this article, we will explore how to select the right notebook making machine, what to consider, and why Khargone is a favourable location for your notebook manufacturing project.

Throughout this content, we repeat synonyms of our main keyword such as notebook manufacturing machine, notebook production equipment, notebook production machine, notebook production line, notebook making machine in order to improve relevance.

Why Choose Khargone, Madhya Pradesh for Notebook Production

Industrial Infrastructure & Location

Khargone district is located in the south-west border of Madhya Pradesh and covers an area of over 8,000 sq km. DCMSME+2Khargone District+2 According to the district economy profile, there are approximately 13,779 small-scale industries and 14 medium and large-scale industries in the district. Khargone District The state government is actively developing new industrial areas and expanding land banks for industry promotion. KNN India+1

Strategic Advantages

-

Proximity to major road routes and connectivity for logistics. DCMSME+1

-

Industrial belts such as Nimrani, Badwah, Padli and Bhikangaon are already established within the district, providing support ecosystem for manufacturing. Khargone District+1

-

The government’s attention to developing industrial zones means easier allotment of land, faster clearance and better infrastructure. The Times of India+1

Implications for Notebook Production

When you set up a notebook manufacturing machine line in Khargone, you benefit from:

-

Lower logistics costs to raw-material suppliers and markets.

-

Access to labour, utilities and industrial facilities in a growing manufacturing region.

-

Possibility to scale up production owing to availability of industrial land.

Thus selecting Khargone as your base for notebook manufacturing makes strategic sense if you are investing in a notebook production equipment line.

Understanding Notebook Making Machine – Key Features

What is a Notebook Making Machine?

A notebook making machine (sometimes called notebook manufacturing machine or notebook production equipment) is designed to perform one or more steps in the notebook production process. Typical functions include:

-

Sheet cutting and trimming

-

Stacking and collating of inner pages

-

Cover printing/lamination (optional)

-

Binding/stitching (e.g., saddle-stitch, centre-stitch)

-

Edge-squaring and trimming of finished notebook

Various manufacturers emphasize manual, semi-automatic or fully‐automatic machines depending on capacity and investment. For example, a manufacturer lists capacities from ~3,000 notebooks per day to up to 9,000-10,000 per day for fully automatic models. sbsmachine.com+2guptamachinary.com+2

Capacity and Automation Levels

-

Manual / semi automatic notebook production machine: Suitable for smaller operations, lower investment. Example: capacity 3,000 /day. sbsmachine.com+1

-

Fully automatic notebook production line / notebook making machine: Higher investment but large throughput (e.g., 9,000-10,000 notebooks/day). sbsmachine.com+1

-

The right capacity depends on your target notebook volume, workstation space, labour cost and ROI.

Material Quality & Construction

When choosing your notebook making machine, consider:

-

Body material: Mild steel or MS construction is common. asveng.com+1

-

Machine weight and footprint: Higher capacity means larger size and weight (e.g., 1,300-1,400 kg for certain models). sbsmachine.com

-

Power requirement: For example 2 kW for smaller units. sbsmachine.com

-

Ability to handle different notebook sizes, page counts, thicknesses (e.g., maximum thickness 20 mm). guptamachinary.com

Flexibility and Plant Layout

-

Does the machine support various notebook sizes (A4, A5, custom sizes)?

-

Is the machine modular and upgradable?

-

What is the workflow: raw sheet → cutting → stitching → trimming → finished product?

Design your plant layout around the notebook production line to optimise flow and reduce material handling.

Selecting the Right Notebook Making Machine in Khargone

Step-by-Step Considerations

-

Estimate your production target

-

How many notebooks per day/week?

-

Will you target different sizes/forms (spiral, binding style, cover types)?

-

This sets whether you need a semi-automatic notebook production machine or a fully automatic notebook making machine.

-

-

Assess available space & utilities

-

The machine footprint including feeder, binding, trimming sections.

-

Availability of power supply, ventilation, material storage.

-

Since you’re in Khargone industrial belt, ensure your site has ready utilities.

-

-

Quality and brand selection

-

Choose the machine vendor with track record in “notebook making machine / notebook manufacturing machine / notebook production line”.

-

E.g., one vendor lists a broad range of notebook making machines and notebook making plant. shkimachinery.com

-

-

After-sales support & spare parts

-

Maintenance of notebook making machine is critical for consistent output.

-

Ensure vendor can supply replacement parts, training for local staff.

-

-

Budget & ROI analysis

-

Compare machine cost + installation + training vs expected output & market price of notebooks.

-

Higher automation means higher cost but lower labour and faster production.

-

-

Compliance & local advantages

-

In Khargone industrial area you may receive state incentives or easier clearance.

-

Align your notebook production equipment setup with local regulations and industrial layout plans.

-

Why Investing Here Makes Sense

-

Installing a dedicated notebook production equipment line in Khargone leverages the industrial ecosystem, available land and the growing infrastructure.

-

By choosing the right notebook making machine, you gain competitive advantage in cost, quality and output.

-

You also build the capacity to scale up if demand grows for notebooks (education sector, custom notebooks, corporate orders) using reliable notebook production machinery.

Benefits of Installing a Notebook Making Machine in Khargone

Operational Benefits

-

High production capacity: With a notebook production machine of suitable automation, you can achieve thousands of notebooks per day.

-

Consistent quality: Machines ensure accurate cutting, stitching and trimming which manual processes may struggle with.

-

Reduced labour cost and waste: Automation streamlines workflow and reduces errors in notebook production line.

-

Scalability: Once operation is set up, you can scale up by adding additional units or shifting to higher capacity notebook making machine.

Strategic Benefits (Khargone Location)

-

Access to industrial land and support infrastructure in Khargone district’s industrial belts. The Times of India+1

-

Lower logistics costs for raw materials (paper, boards, binding materials) and for distributing finished notebooks to markets across Madhya Pradesh and neighbouring states.

-

Potential for government‐backed incentives as area develops for manufacturing.

-

Availability of labour and local workforce, training institutes in Khargone district (engineering colleges, polytechnics) aid staffing. Khargone District

Typical Specification Examples of Notebook Making Machines

Here are some benchmark figures to guide you when you evaluate suppliers:

-

Production capacity 3,000 notebooks/day for manual/semi automatic notebook production equipment. sbsmachine.com+1

-

Fully automatic notebook production machine up to 9,000-10,000 notebooks/day. sbsmachine.com

-

Maximum notebook thickness ~20 mm for high-capacity machines. guptamachinary.com

-

Machine material steel (MS/mild steel), power requirement from ~2 kW for smaller units. sbsmachine.com+1

These figures help set your expectations and specify requirements when discussing with machine vendors.

Integrating a Notebook Making Machine into Your Production Plant

Workflow Integration

-

Raw material (paper sheets, covers) → cutting/trim station → collating/stitching station → cover binding station → trimming/edge-squaring → finished notebook stacking.

-

The notebook manufacturing machine should ideally integrate multiple steps or allow sequential stations to minimise manual handling.

-

Layout your factory floor for smooth material flow, minimal backtracking, and safe operator access.

Factory Setup in Khargone

-

Choose a plot in industrial belt (e.g., Nimrani, Badwah, Bhikangaon) where utilities (power, water, logistics) are available.

-

Undertake power load assessment for the notebook making machine and auxiliary equipment (like paper storage, finishing machines).

-

Ensure dust control, ventilation and worker ergonomics for handling paper and binding materials.

Quality Control & Finishing

-

Monitor cut accuracy, stitch consistency, cover alignment.

-

Use trimming/edge squaring equipment in line with the notebook production equipment to ensure finished product quality.

-

Inspect finished notebooks for thickness uniformity, binding strength, cover adhesion.

Maintenance & Spare Parts

-

Regular cleaning and lubrication of moving parts of the notebook making machine.

-

Keep critical spare parts (e.g., cutting blades, stitching wire, bindings) in inventory to avoid downtime.

-

Work with machine vendor to schedule preventive maintenance to maintain consistent notebook production output.

Why Your Investment Will Pay Off

-

The demand for notebooks remains steady (education sector, corporate gift notebooks, custom branded notebooks).

-

With a robust notebook production machine, you reduce per-unit cost through higher throughput and lower waste.

-

Location advantage in Khargone enables you to serve regional markets in Madhya Pradesh, Maharashtra border, and central India.

-

By scaling capacity using notebook manufacturing machine lines, you capture business growth and new product variations (spiral, hardcover, customised).

-

Over time, you build manufacturing competence and can leverage the notebook making machine equipment to diversify into related stationery production (registers, diaries, notebooks with custom covers).

Conclusion

Investing in the right notebook making machine (or notebook manufacturing machine / notebook production equipment) is a critical decision for any notebook production business. When combined with the strategic location of Khargone in Madhya Pradesh, favourable industrial infrastructure and growth potential, your facility is well-positioned to succeed. By carefully selecting your machine (capacity, automation level, vendor support), planning your plant layout, and aligning operations with market demand, you gain a competitive edge in notebook production.