Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

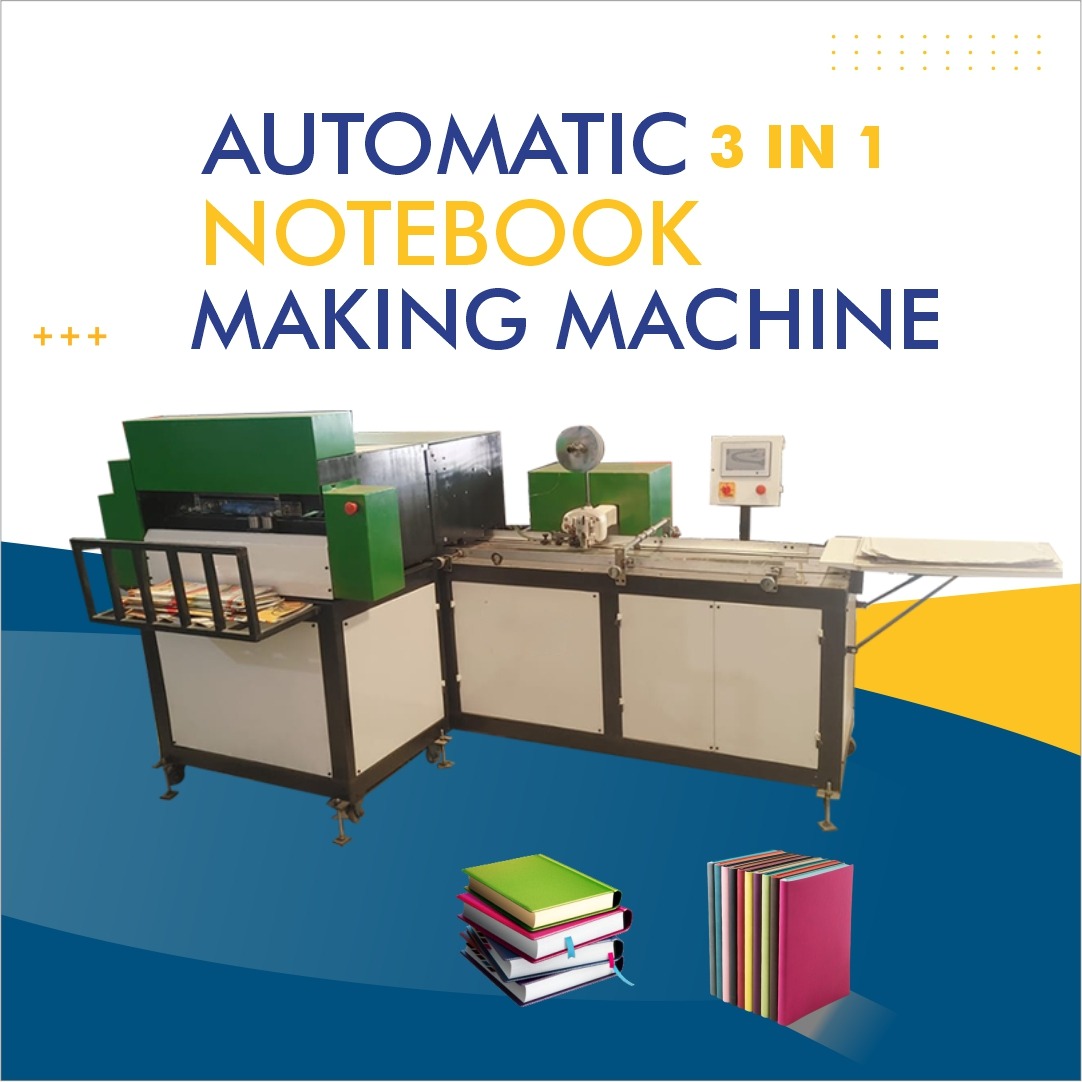

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Jabalpur Madhya Pradesh – High-Quality Notebook Production Equipment

Notebook Making Machine in Jabalpur | Madhya Pradesh

If you’re establishing or scaling a stationery manufacturing unit in Jabalpur, Madhya Pradesh, investing in a high-performance notebook making machine is a strategic move. Whether you’re producing academic notebooks, corporate journals, spiral-bound books, luxury notebooks or customised editions, the right machine will define your production capacity, quality consistency, and cost-efficiency. In this detailed guide we will cover the benefits, how to choose the right machine, technical considerations, and why locating in Jabalpur makes sense for notebook manufacturing. We will use synonyms such as “notebook production equipment”, “notebook manufacturing machine”, “notebook fabrication machine”, “journal making machine”, “binder notebook machine” throughout to reinforce relevance.

Why Choose a Notebook Making Machine

A dedicated notebook making machine (or notebook manufacturing machine) offers significant advantages over manual or semi-automatic methods:

-

Enhanced production efficiency: Modern machines automate cutting, folding, stitching or binding, trimming and cover attachment. As one source explains, “notebook-making machines offer … increased production efficiency, reduced labour costs, and improved product quality.” cn-koten.com+1

-

Consistency & quality: Precision controls ensure each notebook is uniform in size, binding, finish. For example, a full notebook production equipment solution promises “superior precision & consistency”. kesyainternational.com+1

-

Lower operational cost: By automating multiple steps in the notebook manufacturing process, you reduce material waste, labour hours, and minimise errors. Safire Machinery -+1

-

Flexibility & diversification: With the right notebook fabrication machine, you can switch sizes, binding styles (spiral, stitched, hard cover), paper types and covers – enabling you to serve different market segments. Safire Machinery -+1

-

Scalability: As demand grows (for school supplies, corporate gifting, promotional items), the notebook making equipment can scale production, helping you to keep lead time short and meet bulk orders.

-

Competitive advantage: Owning your notebook production equipment positions you as a supplier rather than a buyer of finished notebooks, giving you better margin control, quicker turnaround and better quality oversight.

Why Jabalpur, Madhya Pradesh is a Good Location

Establishing your notebook manufacturing facility in Jabalpur, Madhya Pradesh offers several strategic benefits:

-

Central location: Jabalpur is centrally located in India, offering logistics advantages to supply notebooks across northern, central and eastern India. This helps reduce freight cost and lead times.

-

Labour & infrastructure: Madhya Pradesh has reasonably priced skilled and semi-skilled labour, and Jabalpur has industrial zones and established manufacturing access.

-

Raw material access: Proximity to paper mills, binding material suppliers and packaging vendors can reduce procurement costs and improve supply chain responsiveness.

-

Growing stationery market: With increasing demand for notebooks in schools, colleges, corporate training, promotional merchandise, having a local production hub in Jabalpur gives you responsiveness and cost-advantage over import or long-distance sourcing.

-

Government support: The state government of Madhya Pradesh often provides incentives for manufacturing units, electricity concessions, subsidies or easier land allotment in industrial estates – which can lower your fixed costs.

Features to Look For When Buying a Notebook Making Machine

When selecting your notebook production equipment (aka notebook manufacturing machine or journal making machine), keep the following features and criteria in mind:

-

Production capacity / throughput

-

Look at how many notebooks per hour or per shift the machine can produce. A higher-capacity machine will cost more upfront but gives better economies when volume is large. cn-koten.com+1

-

Match capacity with your projected demand, but leave some headroom for growth.

-

-

Automation level

-

Fully automatic machines integrate feeding, cutting, folding, binding, trimming, cover attachment. Semi-automatic machines require more manual labour. The more automation, the less reliance on manual labour and fewer operator errors. armindindustries.in+1

-

Consider ease of operation, interface, change-over time when switching notebook sizes or binding types.

-

-

Binding style supported

-

Ensure the notebook machine supports the binding type you require: stitched binding, spiral binding, perfect binding, or wire binding.

-

If you plan to diversify (academics, corporate gifting, diaries) make sure the machine can switch easily between styles.

-

-

Material compatibility

-

Paper types and weights: The machine should handle various paper weights (for inner pages, covers) and different cover materials (board, cardstock, laminated).

-

Cover attachment and finish: If you are doing laminated covers, embossing, logo printing, the machine should be compatible with downstream finishing.

-

-

Footprint and layout

-

The machine size, required floor space, utilities (power, compressed air) must fit your facility in Jabalpur.

-

Consider maintenance access, operator safety, and workflow (feeding materials → binding → trimming → stacking).

-

-

Quality control and sensors

-

Modern machines include sensors to detect mis-feeds, alignment issues and defects, thereby improving yield and reducing downtime. cn-koten.com

-

A machine with built-in defect detection helps maintain uniform quality, essential for customer trust and repeat business.

-

-

After-sales support and spare parts

-

Buying from a reputable supplier with good after-sales support, technical service, local spare parts availability is important. One article emphasises “support from reliable notebook machine suppliers”. Safire Machinery -

-

In Jabalpur you’ll want a vendor who can service the machine quickly, to minimize downtime.

-

-

Cost of ownership and ROI

-

Consider not just the purchase price but maintenance cost, consumables (binders, staples, wires), electricity, labour.

-

Many sources state that automatic notebook making machines have a rapid return-on-investment when production volume increases. Medium+1

-

Calculate payback period: (Machine cost + installation + training) ÷ (incremental profit from in-house production).

-

-

Flexibility and future growth

-

Ensure the machine is not too specialized such that when your business evolves you cannot adapt it. For example, if you may move into spiral bound diaries or notebooks with custom covers, get a machine or a line that allows this flexibility.

-

Typical Workflow of Notebook Manufacturing

Here’s a summary of how a notebook production line typically works when using a notebook making machine:

-

Raw material feeding: Sheets of paper (inner pages) are loaded; cover stock is loaded.

-

Cutting and folding: The paper is cut to size, then folded or formed into signatures or stacks.

-

Binding/stitching: The signatures are stitched (thread or wire) or bound using the selected binding style.

-

Trimming and edge finishing: Edges are trimmed to precise dimension; unwanted edges removed.

-

Cover attachment: The cover is attached (either glued, stitched, or inserted) and laminating or finishing may be applied.

-

Stacking and packaging: Finished notebooks are stacked, counted, packed ready for dispatch.

-

Quality inspection: Defect detection sensors or operator checks ensure uniformity, correct binding, clean edges and cover.

As one machine maker explains: “The machine then cuts the paper to the desired size and folds it into signatures. The signatures are then stitched … the notebook is trimmed … Finally, the cover is attached to the notebook”. cn-koten.com

Each step being automated reduces manual intervention, errors, and improves speed.

Market Outlook and Business Opportunity

The stationery market, especially notebooks, remains robust in India due to educational institutions, corporate gifting, promotional merchandise, personal usage, and customised journals. Key factors to consider:

-

The rise in schools and colleges in India means steady demand for academic notebooks.

-

Corporate and promotional notebooks with company branding are increasingly popular.

-

Customised notebooks (designer covers, luxury finishes) are a growing niche.

-

Regional manufacturing (in Jabalpur) gives you advantage in lower logistics cost and faster turnaround compared to distant sourcing.

-

With your own notebook making machine, you can price competitively and respond quicker than import-based competitors.

Choosing the right notebook fabrication machine is thus a gateway into a growing, sustainable business.

Why Work with Us in Jabalpur

If you are looking to invest in a notebook making machine in Jabalpur, Madhya Pradesh, here are key reasons to partner with us:

-

Local presence: We understand the regional market, labour environment and logistical specifics of Madhya Pradesh and provide on-site evaluation and support.

-

Tailored machine selection: We help you identify the optimum notebook manufacturing machine size and specification based on your production target, binding style, budget and future growth.

-

Installation & training: We provide turnkey solutions – machine delivery, installation, operator training and initial operational support so your line begins producing notebooks quickly.

-

After-sales service: Local spare parts, maintenance support, remote troubleshooting and preventive maintenance plans ensure your machine runs smoothly.

-

Cost efficiency: By choosing a machine that matches your demand, you optimise your investment and harness the benefits of automation early.

-

Scalability: We advise on future-proof options so your notebook production equipment can adapt as you expand varieties (spiral bound, stitched, hard bound) and volumes.

How to Get Started

To proceed, follow these steps:

-

Define your production requirement: How many notebooks per day/week? What size formats? What binding types? What paper weights?

-

Visit our facility or request demonstration: See a notebook making machine in operation, understand its throughput, setup, and binding results.

-

Site survey in Jabalpur: We visit your facility to ensure floor space, power supply, material feeding path, storage, logistics are appropriate.

-

Select machine model & quotation: Based on your requirement we propose the notebook production equipment model, technical specs, lead time, installation cost.

-

Installation & training: Once machine is delivered we install, commission, and train your operators in Jabalpur to ensure smooth start.

-

Production roll-out: Begin notebook manufacturing, monitor yield, quality and output. We support you in tune-up, preventive maintenance and optimisation.

FAQ – Frequently Asked Questions

Q: What is the difference between a notebook making machine and a normal binding machine?

A: A notebook making machine or notebook manufacturing machine integrates multiple steps – cutting, folding, binding, trimming, cover attachment – in one line. A normal binding machine may only do the binding step. This full integration leads to higher throughput, better consistency and lower cost per unit. cn-koten.com+1

Q: What binding styles are possible?

A: You can choose stitched binding, spiral (wire) binding, perfect binding or hard cover depending on the model. Ensure your notebook fabrication machine supports the style you need. Safire Machinery -+1

Q: How quickly will the machine pay for itself?

A: While it depends on production volume, binding style, labour cost and market pricing, many manufacturers report rapid ROI once the machine operates at full capacity. Medium+1

Q: What size space is needed for installation?

A: It varies by model and capacity. A high-capacity machine may occupy several square meters plus space for feeding material, stacking finished notebooks, operator access and maintenance clearance.

Q: What maintenance is involved?

A: Regular maintenance includes lubrication, checking alignment, replacing cutting blades or binding staples/wires, cleaning sensors, and ensuring consistent material feeding. Choosing a vendor with local support in Jabalpur helps minimise downtime.

Conclusion

Investing in the right notebook making machine in Jabalpur, Madhya Pradesh positions you to capitalise on the growing demand for notebooks in India. By choosing a machine that offers high capacity, automation, flexibility, quality control and local service support you future‐proof your manufacturing operations. Whether you are entering the stationery business or scaling an existing line, the right notebook manufacturing machine empowers you to deliver premium notebooks, control costs, diversify your offerings and build a competitive edge.