Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

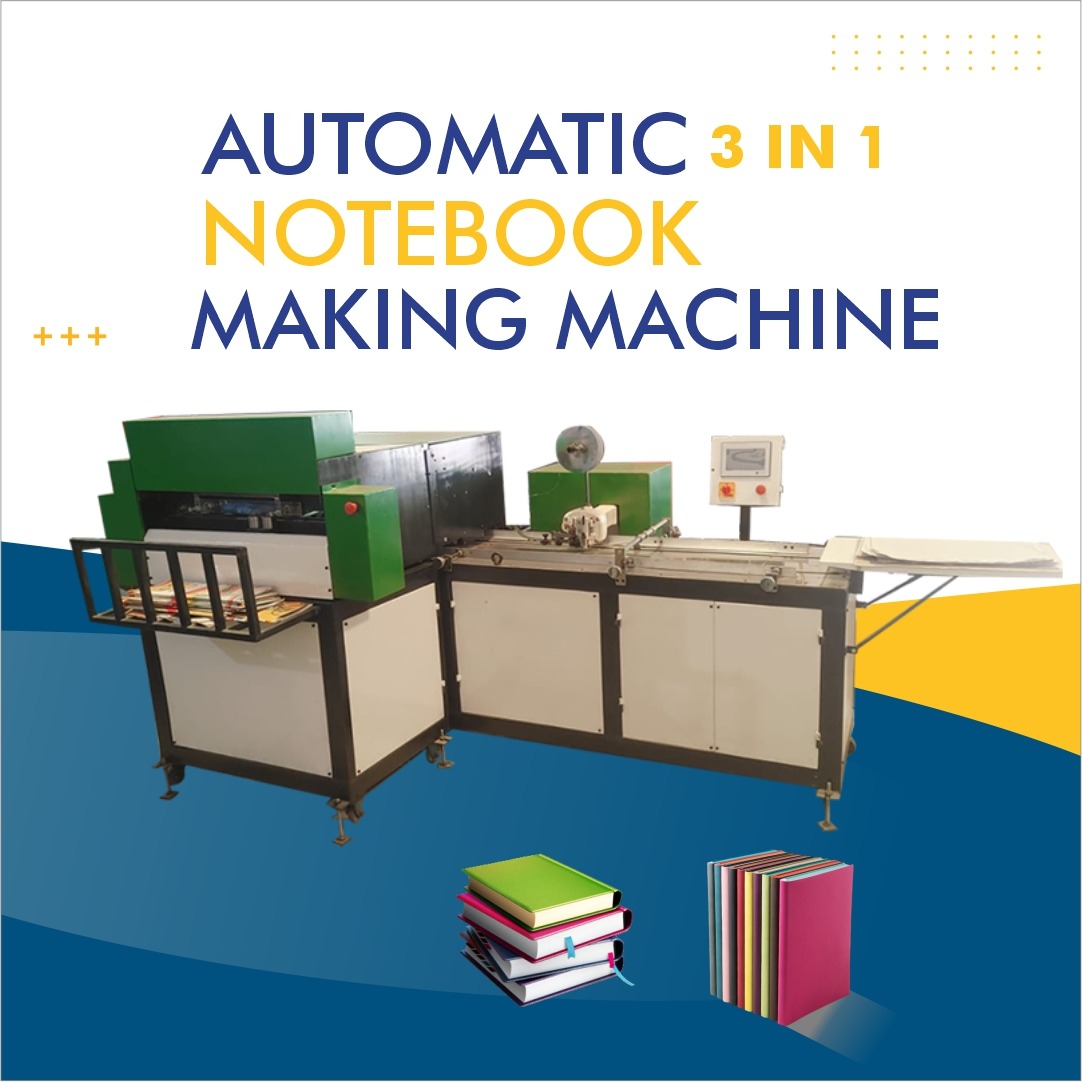

Notebook Making Machine in Vatakara Kerala | High-Efficiency Notebook Production Equipment

Notebook Making Machine in Vatakara | Kerala

Setting up a notebook manufacturing line today requires investing in a robust piece of equipment: the notebook making machine. For businesses in and around Vatakara, Kerala, selecting the right notebook making machine ensures efficient production, cost-effectiveness, and scalability. In this article we’ll explore what a notebook making machine is, the benefits, key features to evaluate, why Vatakara is a favourable location, and how you can maximise success with your notebook production machinery.

In the text that follows, the term notebook making machine (and its synonyms: notebook production machine, notebook manufacturing equipment, notebook making equipment, notebook machine) will recur multiple times to support clarity and SEO.

What is a Notebook Making Machine?

A notebook making machine is the core equipment used in the production of notebooks – combining processes such as paper cutting, folding, stitching (or binding), trimming and finishing into a streamlined workflow. Whether you are producing simple exercise notebooks, school-notebooks or premium journals, the notebook making machine enables high output with consistent quality.

The notebook production machine typically includes subsystems for:

-

Cutting paper sheets or block to size

-

Folding or collating sheets

-

Stitching or binding the folded sheets (centre stitch, side stitch, wire-oscillating etc)

-

Trimming edges to final format

-

Cover attaching and finishing

For instance, one manufacturer lists notebook making machines capable of 3,000 pcs/day for a manual setup, up to 9,000-10,000/day for fully automatic models. sbsmachine.com+2guptamachinary.com+2

Another describes a model with “multi-head wire booking stitching … servo-driven” automation. Endurance Machinery

Therefore, when you investigate notebook manufacturing equipment for your facility in Vatakara, the term “notebook making machine” encompasses this full production line or key segments thereof.

Why Choose a Notebook Making Machine for Your Business in Vatakara, Kerala

1. Strategic Location

Vatakara, in the northern part of Kerala, provides logistical advantages: proximity to ports, access to raw materials (paper, board, covers) in South India, skilled labour pool and competitive overheads compared to metropolitan regions. Setting up a notebook manufacturing line here can offer cost benefits.

2. Growing Demand

Stationery products like notebooks remain in demand in India with increasing enrolments, educational initiatives, and demand for customised notebooks. Investing in a notebook production machine enables you to capitalise on this demand by producing in-house rather than outsourcing.

3. Local Support and Maintenance

Given that many notebook making machines are manufactured in India (for example, models described as “Made in India” by several makers) shkimachinery.com+1 you can benefit from faster parts availability, local service engineers, and lower maintenance costs.

4. Scalability and Cost Efficiency

By selecting the right notebook machine (manual, semi-automatic or automatic), you can scale your production as your business grows. A semi-automatic notebook making machine can be a good entry point; later you can upgrade to a fully automatic notebook production machine with higher capacity.

Key Features to Look For in a Notebook Making Machine

When evaluating a notebook making machine, make sure you inspect the following features and attributes:

A. Production Capacity

-

What is the output per hour/day? For example: some machines claim 650 pcs/hr or 1,000-1,500 pcs/hr. guptamachinary.com+1

-

Choose a capacity aligned with your business plan: low-volume commercial notebooks vs large-volume educational notebooks.

B. Automation Level

-

Manual machines require more hand-work and labour.

-

Semi-automatic machines reduce manual steps but still rely on operators.

-

Fully automatic machines integrate cutting, folding, stitching, trimming and finishing in one line. For example: one line offering multi-head wire booking stitching with servo automation. Endurance Machinery

-

The notebook making machine you choose will influence labour cost, output consistency and return on investment.

C. Versatility & Format Sizes

-

Does the machine support different notebook sizes (A4, A5, custom)?

-

What is the maximum thickness of the notebook block? Some machines specify “maximum notebook thickness 20 mm” or similar. guptamachinary.com

-

Ability to handle different binding types (centre stitch, side wire, perfect bind) adds flexibility to your notebook production machine.

D. Quality & Precision

-

Accuracy in cutting, alignment, stitching ensures the finished notebook meets standards.

-

Look for features like servo drives, precision guides, stable frames.

-

Example: “pin to pin accuracy for centre stitch” in an automatic model. Endurance Machinery

E. Robust Build & After-Sales Support

-

Construction from robust materials (MS, mild steel, stainless steel) to ensure durability. guptamachinary.com+1

-

Availability of spare parts, local service engineers, training for operation and maintenance.

F. Energy, Maintenance & Cost of Ownership

-

Check power requirements (single phase vs three phase, voltage).

-

Check maintenance schedule, wear parts, tool change times.

-

Evaluate total cost: purchase + installation + operator training + servicing + parts over lifespan.

How to Select the Right Notebook Making Machine for Your Facility

Here is a step-by-step guide tailored for a business in Vatakara, Kerala, aiming to install a notebook making machine.

Step 1: Define Business Plan & Volume

-

Estimate how many notebooks per day/week you plan to produce.

-

Determine target formats and product mix (for example: school/college notebooks, customised corporate notebooks, export).

-

Based on these, decide capacity of notebook production machine (for example: 500-1,000 notebooks/hour, or 3,000-6,000/day).

Step 2: Decide Automation Level

-

For startup, a semi-automatic notebook making machine may suffice and reduce capital cost.

-

For larger scale, fully automatic notebook making machine offers higher throughput and labour savings.

-

Balance between investment cost vs labour/space savings and output.

Step 3: Evaluate Suppliers & Machinery Specifications

-

Request detailed spec sheets: production capacity, size formats, thickness capacity, machine dimensions, power specs, automation components.

-

Visit demonstrations or ask for video of the notebook making machine in operation.

-

Confirm availability of spare parts, service support in Kerala region.

Step 4: Site Planning in Vatakara

-

Ensure adequate floor space, power supply (phase, voltage), ventilation, handling of raw materials (paper, board) and finished notebooks.

-

Plan material handling lines: feeding paper rolls or sheets, stacking, finished product stacking.

-

Consider local labour availability and training for machine operators/maintenance staff.

Step 5: Installation, Commissioning & Training

-

Choose a supplier who will install the notebook making machine onsite, commission it and train your operators.

-

Ensure you receive documentation: user manuals, maintenance schedules, spare parts list.

-

Plan for regular preventive maintenance to ensure the notebook production machine runs at optimum performance.

Step 6: Monitor Output & Quality

-

After installation, track key metrics: throughput (notebooks/hour/day), scrap rate, machine downtime, maintenance cost.

-

Use these to measure return on investment and optimise operations of the notebook making machine.

Benefits of Installing a Notebook Making Machine in Vatakara, Kerala

Increased Control & Flexibility

With your own notebook production machine, you control everything: design, format, paper quality, binding type, production schedule. You are not reliant on external notebook manufacturers who may impose lead-times or minimum volumes. This contrasts with outsourcing notebook manufacturing.

Cost Savings in the Long Term

While the initial cost of the notebook making machine may be substantial, owning your equipment removes repeated outsourcing cost. Over time, your cost per notebook drops, improving margins.

Faster Turnaround & Customisation

Having a notebook manufacturing equipment onsite allows quicker reaction to market demand, ability to customise notebooks (branding, formats, covers) and faster delivery to clients. This is a competitive advantage in stationery markets.

Employment & Local Advantage

Setting up a notebook machine operation in Vatakara provides employment, local value-addition and potentially benefits from local policies or logistics cost advantages. Proximity to Kerala’s paper/board supply chain helps reduce inbound transport cost.

Scalability

As your business grows, you can add or upgrade notebook making machines (for example adding a second line, or shifting from semi-automatic to fully automatic) thereby scaling production in line with demand.

Challenges to Be Aware Of

Capital Investment

A notebook making machine, especially semi-automatic or automatic, involves significant capital cost. For instance, one automatic notebook making machine is described as costing around Rs. 1,000,000 in one listing. kolkatamachineryimportexport.com You must ensure your business plan covers this investment.

Raw Material Supply & Costs

Your notebook machine will require reliable supply of paper sheets/rolls, boards, cover material, binding wire or staples. Fluctuations in paper price or supply disruptions can impact cost and operation.

Skilled Labour & Maintenance

Even the best notebook making machine requires skilled operators and maintenance staff. Availability of trained personnel in Vatakara region must be planned. Also, maintenance downtime impacts productivity.

Technology Obsolescence

As demand grows or formats change (e.g., more custom notebooks, different binding methods), you may find your notebook manufacturing equipment becomes less optimal. Plan for upgrade paths when selecting your machine.

Quality Control

With your own notebook production machine, responsibility for quality falls on you entirely: consistent cut, stitch, trim and finish. Ensure robust quality control processes are in place.

Why Invest in a Notebook Making Machine in Kerala Now

-

Kerala’s literacy rate and educational infrastructure create steady demand for notebooks; local manufacturing helps serve this demand efficiently.

-

The “Made in India” notebook machine options from Indian manufacturers mean good compatibility with local requirements and support. For example, machine makers advertise models made in India specifically for notebook production. shkimachinery.com+1

-

With increasing focus on localisation and cost-efficient manufacturing, having the notebook production equipment in Vatakara gives you an operational base in the South.

Example Use Case: Startup Notebook Manufacturing Unit in Vatakara

Imagine you are launching a notebook manufacturing business in Vatakara. You decide your target is 5,000 notebooks per day. You analyse a semi-automatic notebook making machine capable of ~5,000-6,000 pcs/day. Namibind+1

You procure the machine, install it, arrange paper and cover supply from nearby suppliers in Kerala/Tamil Nadu, hire two operators and one maintenance technician, and you begin producing branded notebooks for schools and offices.

Within a few months you observe:

-

Lower cost per notebook compared to outsourcing

-

Ability to customise formats and orders

-

Faster lead-time to customers in Kerala and neighbouring states

-

Capacity to expand by adding another line.

This case demonstrates how a notebook making machine can transform your business from service-ordering to full manufacturing.

Conclusion

Selecting the right notebook making machine is a strategic decision with long-term implications for your business. Whether you are just starting out or expanding production, investing in a reliable, efficient notebook production machine in Vatakara, Kerala positions you well to serve local and regional stationery demands.

You should carefully evaluate capacity, automation level, format versatility, supplier support and total cost of ownership of the notebook manufacturing equipment. With proper planning, installation and operation, your notebook making machine will become the backbone of your manufacturing operation.