Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

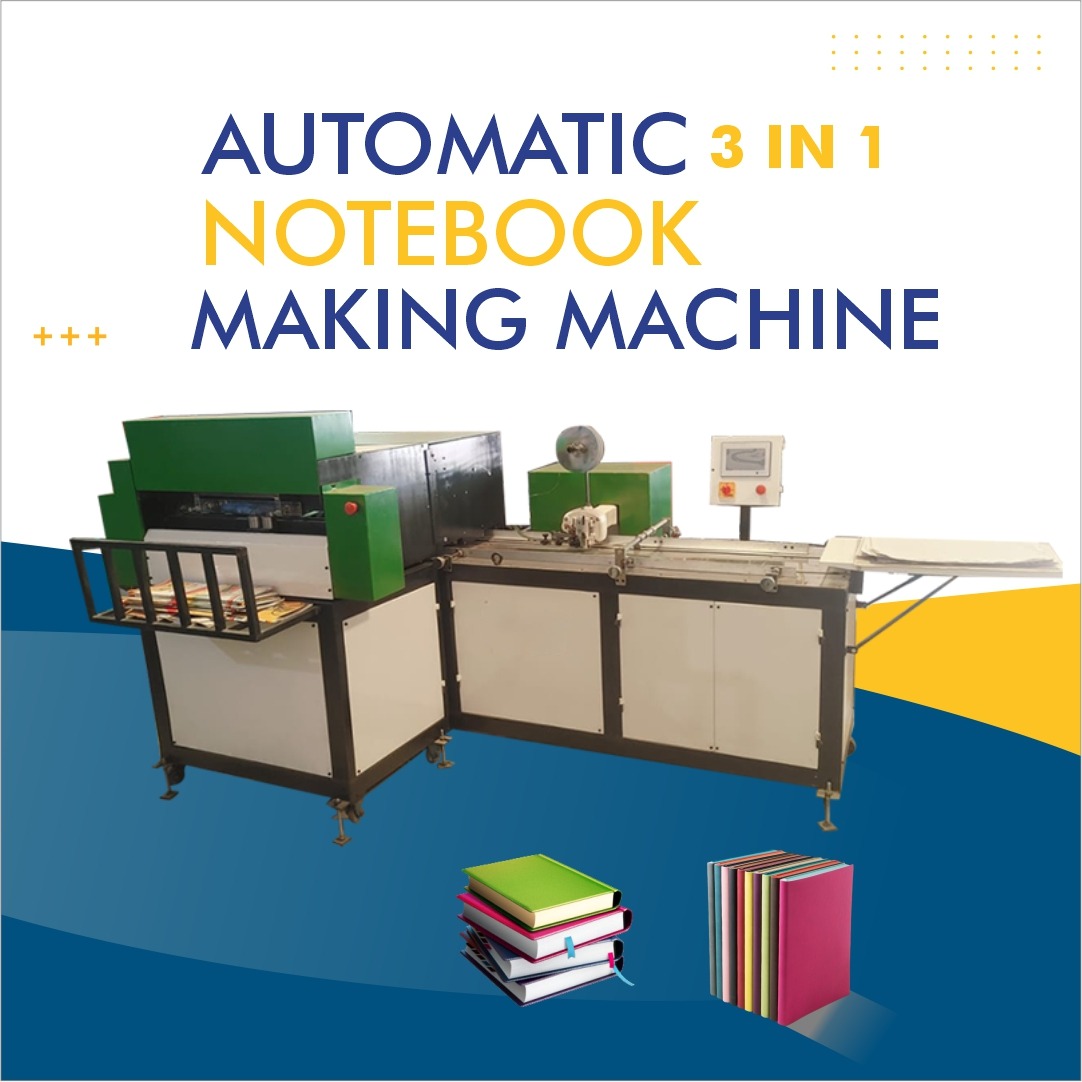

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Idukki Kerala | High-Efficiency Notebook Production Equipment

Notebook Making Machine in Idukki | Kerala

Setting up a profitable notebook manufacturing unit begins with choosing the right notebook making machine. From the heart of Kerala in Idukki, entrepreneurs and printing houses are exploring opportunities to utilise advanced notebook production equipment for school books, exercise books, registers and more. Whether you are planning a small‐scale setup or a full-fledged production line, the right notebook manufacturing equipment lays the foundation for consistent quality and efficient output.

In this article, we will dive deep into what a notebook making machine is, the features to look for, how it supports notebook production, why locating in Idukki, Kerala matters, what kinds of machines are available (manual, semi-automatic, automatic), cost and ROI considerations, installation and maintenance tips, as well as how one can make the most of this investment. We will ensure to repeat our key term and synonyms several times (for example: notebook making machine, notebook production machine, notebook manufacturing equipment) to help you with search engine visibility.

What is a Notebook Making Machine?

A notebook making machine is specialised equipment designed to manufacture notebooks and exercise books. The machine integrates several stages of production: cutting paper sheets, folding, stitching or binding (as per choice), edge trimming, cover application and packaging. In essence, notebook production machine equals the industrial setup that converts raw paper and covers into finished notebooks ready for shipment.

These machines fall under the broader category of notebook manufacturing equipment, and they are available in manual, semi-automatic or fully automatic varieties. For example, one manufacturer offers a manual notebook making machine full-setup that produces about 3,000 pieces per day. sbsmachine.com+2Namibind+2 Another lists fully automatic notebook making machines capable of 1,000-1,500 pieces per hour. kolkatamachineryimportexport.com+1

Why Choose a Notebook Making Machine in Idukki, Kerala?

1. Strategic location advantages

Idukki, Kerala offers key benefits for setting up manufacturing, including access to regional labour, relatively lower land or factory lease costs compared to metropolitan hubs, and proximity to southern India markets. Having a notebook manufacturing equipment production line here allows you to serve schools, institutions and stationery markets in Kerala, Tamil Nadu and beyond with shorter logistics.

2. Growing demand for notebooks

The stationery market in India continues to see demand for notebooks and exercise books. With rising education levels and school enrolments, production capacity becomes critical. A notebook production machine enables you to scale supply to meet market needs.

3. Local workforce and infrastructure

Kerala has a strong educational infrastructure and a workforce capable of operating manufacturing lines with proper training. For a notebook machine setup, you can access labour, logistic links (roads, possibly power supply), and integration with paper suppliers in southern India.

Types of Notebook Making Machines & Features

Let’s break down how notebook production machine equipment varies:

Manual Notebook Making Machine

-

These are more suited for smaller production volumes or start-ups.

-

Example: A manual notebook making machine full setup (Model SBS NB-01) with capacity ~3,000 notebooks per day. sbsmachine.com

-

Pros: lower investment cost, simpler maintenance, easier to operate.

-

Cons: labour-intensive, slower output, less suitable for large-scale production.

Semi-Automatic Notebook Making Machine

-

Mid-level equipment — more mechanised but still needs some manual intervention.

-

Example: A semi-automatic notebook making machine “36” with capacity production ~4,000-7,000 per day. asveng.com+1

-

Features: automatic cutting, folding, some stitching, trimming.

-

Pros: good balance of cost and output, higher productivity, moderate labour requirement.

-

Cons: still manual oversight required, not fully “set-and-forget”.

Fully Automatic Notebook Making Machine

-

Highest end in terms of automation and output.

-

Example: Fully automatic notebook making machine with capacity of 1,000-1,500 pcs/hr (or 4,000+ pcs/day) as per one supplier. kolkatamachineryimportexport.com+1

-

Features: servo driven folding, automatic stitching/binding, trimming, stacking, packaging integrated.

-

Pros: high throughput, consistent quality, lower labour cost per unit.

-

Cons: highest investment, more complex maintenance, requires skilled operators and stable power supply.

Key Features to Evaluate in Notebook Making Machine

When selecting a notebook making machine for your Idukki facility, consider these features:

-

Production capacity: How many notebooks per hour/day can the machine handle? For example, some machines produce 3,000/day; others 1,000+ per hour.

-

Automation level: Is it manual, semi-automatic or automatic? Your budget and scale will influence this decision.

-

Machine material & build quality: Machines made of MS (mild steel) or stainless steel are common. Durability matters. sbsmachine.com+1

-

Paper size and thickness handling: Can the machine handle different notebook sizes (A4, A5, custom)? What maximum thickness of notebook (number of pages) can be processed?

-

Power requirement: Check voltage, phase (single or three phase) and power consumption. For remote locations or smaller factories, simpler machines with lower power requirement are preferable. shkimachinery.com+1

-

Binding type and finishing: Does it include stitching, glue binding, perfect binding, edge trimming? Some machines integrate multiple functions. Endurance Machinery

-

Maintenance & service support: Availability of spare parts, technical service in the region, ease of maintenance.

-

Footprint and space requirement: The size, weight of machine (some weigh 800-1200 kg or more). sbsmachine.com

-

Quality of finished notebooks: Equally important is that the notebooks produced are neat, aligned, stitched well and visually acceptable. The machine should support consistent quality.

Investment & Cost Considerations

Understanding the investment involved is essential. Here are the typical ranges and considerations:

-

Entry-level manual machines might cost a few lakhs of rupees (for Indian context).

-

Semi-automatic machines often cost several lakhs to tens of lakhs depending on capacity and features.

-

Fully automatic machines might run into many lakhs or crores depending on output and complexity (as per Indian supplier listings).

-

Example: A manufacturer lists their fully automatic notebook making machine with capacity up to 4,000 + pcs/day. kolkatamachineryimportexport.com+1

-

Besides machine cost, factor in: space (factory/ shed), power supply (single phase vs three phase), operator training, raw materials (paper, board, covers), consumables (stitching wire or glue), finishing and packaging, maintenance and servicing.

ROI & Benefits of Using a Notebook Production Machine

Using a high-quality notebook making machine can yield multiple benefits:

-

Increased productivity: Automating steps reduces labour time, increases output per shift.

-

Reduced per-unit cost: Higher throughput lowers cost per notebook, increasing margins.

-

Better quality control: Mechanised processes produce consistent notebooks, less wastage.

-

Scalability: You can scale up production as market demand grows.

-

Competitive edge in Kerala / South India: By placing facility in Idukki, you can serve local schools, institutions and stationery markets with shorter lead times, possibly lower logistic cost.

-

Diversification: Capability to produce different notebook sizes, custom covers, registers, exercise books opens more business avenues.

Why Idukki, Kerala is a Suitable Base

-

Regional demand: Kerala has a high literacy rate and strong demand for quality stationery. Setting up a notebook manufacturing line here positions you to serve local markets.

-

Lower overheads: Land, utilities and labour in Idukki may be more cost-effective compared to metro areas.

-

Access to raw materials: Paper mills and board producers in South India supply raw materials; proximity reduces logistics cost.

-

State support & incentives: While specific incentives need local verification, many states in India encourage manufacturing units to locate in less saturated districts — you should check Kerala’s industrial policy and benefits for Idukki.

-

Connectivity: Though Idukki is more rural, access to major roads and transport to major cities (Kochi, Cochin, etc.) allow distribution to larger markets.

Installation, Operation & Maintenance Tips

To maximise the value of your notebook production machine, consider the following best practices:

-

Site preparation: Ensure the factory floor is level, with required power (single/three phase), safety provisions, lighting and ventilation.

-

Operator training: Skilled operators help maintain machine efficiency, reduce downtime, minimise defects and wastage.

-

Maintenance schedule: Regular lubrication, cleaning, inspections of moving parts, replacement of worn components increases machine life and avoids production losses.

-

Raw material quality control: Use good quality paper, covers and binding materials. Sub-par materials lead to rejection, wastage and reputation damage.

-

Production planning: Match machine capacity to demand. For example, if you have a machine capable of 4,000 notebooks/day, ensure you have market orders or storage for that capacity.

-

Waste reduction: Monitor rejects, edge trimming wastage, mis-stitching etc. A well-set machine minimises waste.

-

Power backup: Especially in semi-automatic or automatic machines, stable power supply is critical. In areas prone to outages, consider generator backup or UPS for critical components.

-

Spare parts inventory: Keep common spare parts (belts, wires, cutting blades, screws) available to minimise downtime.

Product Variants & Customisation Opportunities

With notebook making equipment, you can customise and diversify your product offerings:

-

Different notebook sizes: A4, A5, square, bespoke sizes for schools or corporate gift notebooks.

-

Cover styles: Hard cover, soft cover, laminated covers, printed covers.

-

Binding methods: Stitching, spiral, glue binding, perfect binding (depending on machine capacity or additional equipment).

-

Special pages: Ruled, plain, grid, customised layouts for schools, colleges, coaching institutes.

-

Bulk production for clients: Schools or brands may require bulk orders, custom branding — a robust notebook production machine enables you to take such contracts.

-

Complementary products: Registers, diaries, exercise books, writing pads, which you can manufacture using the same or slightly modified equipment.

Risk Factors & Mitigation

No business is without risk; here are common risks and ways to mitigate them for notebook manufacturing setup:

-

Demand fluctuations: Stationery demand may vary with academic cycles. Mitigation: maintain diversified product range, sell to multiple segments (schools, colleges, corporate).

-

Raw material price volatility: Paper or cover board cost may fluctuate. Mitigation: tie-up with reliable suppliers, negotiate bulk rates, maintain buffer stock.

-

Maintenance delays / downtime: Machine breakdown leads to lost production. Mitigation: schedule preventive maintenance, keep spare parts, have trained technicians.

-

Power supply issues: Especially in semi or full automatic machines, inconsistent power can damage electronics or stop production. Mitigation: power backup, stabilisers, surge protection.

-

Quality control lapses: Poor finished product leads to rejection and loss of reputation. Mitigation: implement quality checks at each stage, train labour, maintain machine calibration.

-

Competition & pricing pressure: Many players in stationery manufacturing. Mitigation: differentiate via quality, speed, custom offerings, timely delivery, after-sales service.

Steps to Acquire and Deploy Your Notebook Production Machine in Idukki

-

Define your production capacity: Based on market research in Idukki/Kerala region, decide how many notebooks per day you intend to produce.

-

Select machine type: Choose manual, semi-automatic or automatic notebook making machine depending on budget, scale and market.

-

Source supplier/manufacturer: Compare machines from reliable manufacturers (for example those listed in India). Check specifications and demo if possible. shkimachinery.com+2sbsmachine.com+2

-

Arrange finances & budget: Include machine cost, installation, space prep, raw materials, labour, utilities, packaging, marketing.

-

Prepare site in Idukki: Ensure factory/ shed, power, water, access, workforce are ready.

-

Install machine and test runs: Set up and conduct test production runs, check alignment, stitching, trimming, finishing.

-

Train workforce: Operators, supervisors and maintenance staff should be trained.

-

Start production and quality control: Begin production, monitor output, rejects, machine performance.

-

Sales & marketing: Leverage location in Kerala to target local educational institutions, bookstores, stationery chains. Emphasise timely delivery, customisation.

-

Scale up and diversify: Once stable, you may expand capacity, add another notebook production machine line, produce registers or other stationery.

Conclusion

Investing in a high-quality notebook making machine in Idukki, Kerala can be a strategic move for entrepreneurs looking to serve the stationery market with efficiency and quality. By selecting the right machine—manual, semi-automatic or automatic—you can balance cost, capacity and output. The key is to select notebook manufacturing equipment that aligns with your production goals, ensure solid installation, train your team, maintain quality, and leverage the regional advantages of Kerala.

With the right approach, you can build a profitable notebook production business, diversifying into exercise books, registers and writing pads. The notebook machine becomes the heart of your production and, with proper planning, it yields sustained benefits.