Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

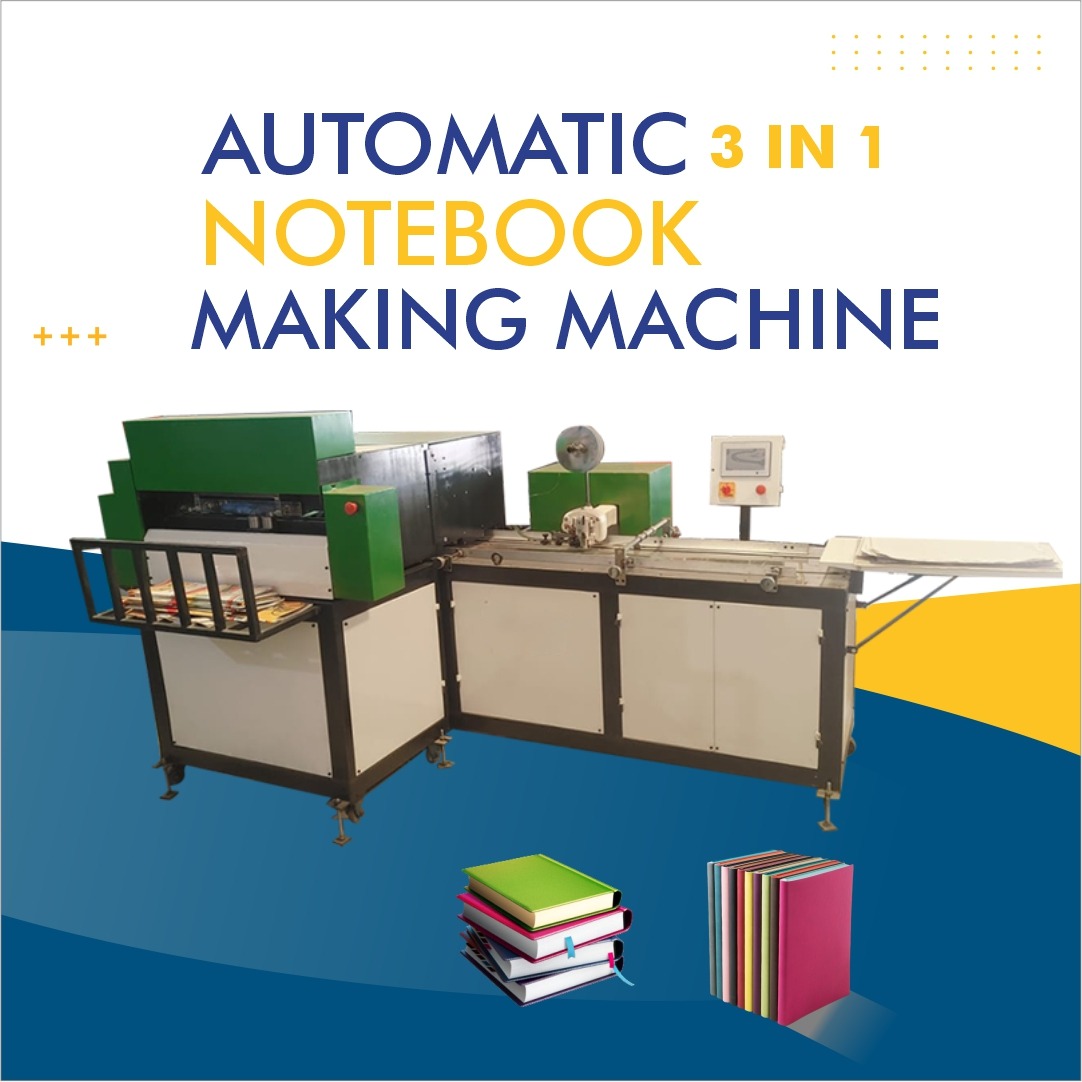

Notebook Making Machine Manufacturer in Aluva Kerala – High Efficiency Production Line

Notebook Making Machine in Aluva | Kerala

If you are looking to invest in a notebook making machine, you have arrived at the right place. Based in Aluva, Kerala, we specialise in supplying robust, high-efficiency notebook production machinery tailored for your notebook manufacturing needs. Our notebook making machine line addresses every stage of the notebook manufacturing process — from cutting and folding to stitching and edge-squaring. Whether you are a startup notebook manufacturer or an established production house looking to upgrade your equipment, our solutions are designed to deliver reliable performance, high output, and reduced downtime.

In this comprehensive write-up we will walk through: (1) the importance and benefits of choosing the right notebook making machine; (2) the key features and specification considerations; (3) how our Aluva, Kerala based facility supports you with after-sales service and local presence; (4) different types of notebook making machines (automatic, semi-automatic, manual) and how to select the right one; (5) tips for planning your notebook production line and optimising output; and (6) why choosing a machine locally in Kerala (Aluva) gives you logistical and service advantages. Throughout, we will frequently use the term notebook making machine and its synonyms (notebook production line, notebook manufacturing machine, notebook binding machine, notebook stitching machine) so you can see how we refer to the equipment.

Why a Notebook Making Machine is a Smart Investment

A notebook making machine automates many of the labour-intensive steps involved in producing notebooks, which include paper cutting, folding, stitching/binding, trimming and squaring. For example, one manufacturer describes a fully automatic notebook making machine as: “multi-head wire booking stitching, folding, edge squaring, PLC base control” with high speed output. Endurance Machinery+2kesyainternational.com+2

By installing a modern notebook manufacturing machine in your facility you benefit from:

-

Higher production throughput – machines capable of producing thousands of books per hour or several thousands per day. sbsmachine.com+2Namibind+2

-

Consistent quality – precise cutting, stitching and trimming ensures each notebook meets the required standard with minimal rejects.

-

Reduced labor costs – automation lowers dependence on manual labour and minimises operator-dependent variability.

-

Scalability – as demand for notebooks increases (for schools, offices, diaries etc.), your notebook production line can scale by upgrading the machine or running multiple units.

-

Local support & downtime reduction – having service and spare parts available locally (in Aluva / Kerala) means quicker turnaround and less production loss.

Key Features & Specifications of a Notebook Making Machine

When selecting a notebook making machine, it is vital to compare key features and ensure they match your production requirements. Below are the essential specification elements for a notebook manufacturing machine:

1. Production Capacity

Look at how many notebooks per hour or per day the machine can produce. For instance, a manual setup might produce 3,000 pieces per day. sbsmachine.com A “3-in-1” automatic machine may achieve 1,500-2,000 books/hour. Namibind

2. Automation Grade

The machine might be manual, semi-automatic, or fully automatic. Manual machines require more operator involvement; automatic ones integrate functions like folding, stitching, trimming in one line. sbsmachine.com+1

3. Machine Material & Build Quality

Durability matters. Machines built from high quality steel, with reliable mechanical and electrical components, yield longer service life and less maintenance. One machine description states “Heavy-duty construction for long-term…” when offering notebook making machine. kesyainternational.com

4. Size Range & Flexibility

Your notebook sizes (length, width, thickness) should be supported. Some machines handle notebooks of varying widths and thicknesses. Endurance Machinery

5. Key Functional Units

Important modules include:

-

Paper cutting and trimming unit

-

Folding/or collating unit

-

Stitching/binding module

-

Edge squaring or trimming unit

-

Control panel/PLC for automation

For example: “multi-head wire booking stitching, folding, edge squaring” is listed. Endurance Machinery

6. Electrical/Power Requirements

Check voltage, phases, power consumption etc. For example, some machines run at 220 V or 380 V, three phase. smallmediumbusinessindia.com+1

7. After-Sales Support & Spare Parts

Regular maintenance, availability of replacement parts, local service support are critical to minimise downtime and ensure your notebook making machine stays in production.

Choosing the Right Notebook Making Machine for Your Business in Aluva, Kerala

Since you are based in Aluva, Kerala (or considering setting up in the region), here are some tailored considerations for choosing your notebook manufacturing equipment.

Location and Logistics

Being in Aluva means you are well-positioned to receive machinery, spare parts and service quickly, especially if the supplier has local or regional presence in Kerala. Reduced freight cost and faster support are advantages.

Scale of Business

-

If you are starting small, a semi-automatic or entry-level machine may suffice — e.g., manual notebook making machine with capacity ~3,000 pieces/day. sbsmachine.com

-

If you anticipate large volume production (schools, diaries, export), go for a fully automatic notebook production line with higher capacity (e.g., 1,500–2,000 books/hour). Namibind

Product Variation

If you intend to produce notebooks of different sizes, thicknesses or formats, select a machine with flexibility in adjustments (size, thickness, stitching gap) and supported by PLC controls for program storage. Namibind

Service & Training

Make sure your supplier offers installation, operator training, periodic maintenance, and spare parts availability in Kerala. Having local service in Aluva or nearby centres is a significant benefit.

Operating Cost and ROI

Analyse power consumption, material waste, operator hours, maintenance cost, and estimate the time to recover your investment via increased production and reduced labour cost. The right notebook manufacturing machine should have quick pay-back period if utilised well.

Installation & Operational Tips for Your Notebook Production Line

-

Layout Planning: Set aside proper floor area, material flow (paper in → finished notebooks out), safety zones, and ensure electrical-air supply if needed (some machines require compressor). For instance one machine required compressor. Endurance Machinery

-

Power Supply: Check phase, voltage stability, grounding. Avoid power fluctuations that can damage control electronics.

-

Operator Training: Even the best notebook making machine benefits from trained operators who can optimise speed, minimise waste, and conduct preventive checks.

-

Material Quality: Use good quality paper, wire (for stitching), covers and binding materials. Poor input leads to higher waste or machine breakdowns.

-

Maintenance Schedule: Regular cleaning, lubrication (some machines have lubrication pump) and inspection extend machine life. Namibind

-

Quality Control: Inspect finished notebooks for stitching integrity, trimming uniformity, squaring of edges, correct thickness. Automated units help but operator oversight is still crucial.

-

Expansion Planning: If demand increases, you may add a second line or upgrade to a higher capacity notebook production line. It helps to ensure your initial setup has expansion space and capability.

Why Choose Us in Aluva, Kerala for Your Notebook Making Machine Needs

-

Local Presence: Being located in Aluva means easier logistics, quick delivery and service compared to distant suppliers.

-

Tailored Solutions: We understand local market needs in Kerala (schools, offices, export) and can advise on the right notebook manufacturing machine configuration for your budget and production scale.

-

Comprehensive Support: From machine installation, commissioning, operator training to spare-parts backup, we cover all stages of your notebook production line setup.

-

Competitive Pricing: With local operations and less import burden, our notebook making machines deliver value for money.

-

Commitment to Quality: We emphasise durable machines, optimal uptime and future-ready design so your investment in a notebook production line pays dividends.

Summary

Investing in a high-quality notebook making machine (and by extension a well-designed notebook production line) is a strategic decision. For manufacturers situated in Aluva, Kerala, the advantages of local support, logistics and service are considerable. Whether you are launching a small-scale notebook making setup or scaling up to large volume production, paying attention to machine specifications, automation grade, material quality and operational support will determine your success.

Choosing the right notebook manufacturing machine means you gain higher throughput, consistent quality, lower labour cost and scalability. Having the right partner in Aluva, Kerala ensures smooth installation, prompt service and minimal downtime — all critical for notebook production success.

Should you require detailed machine models, pricing, floor plan recommendations or service contracts for your notebook making machine set-up in Aluva, we would be happy to assist you further.