Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

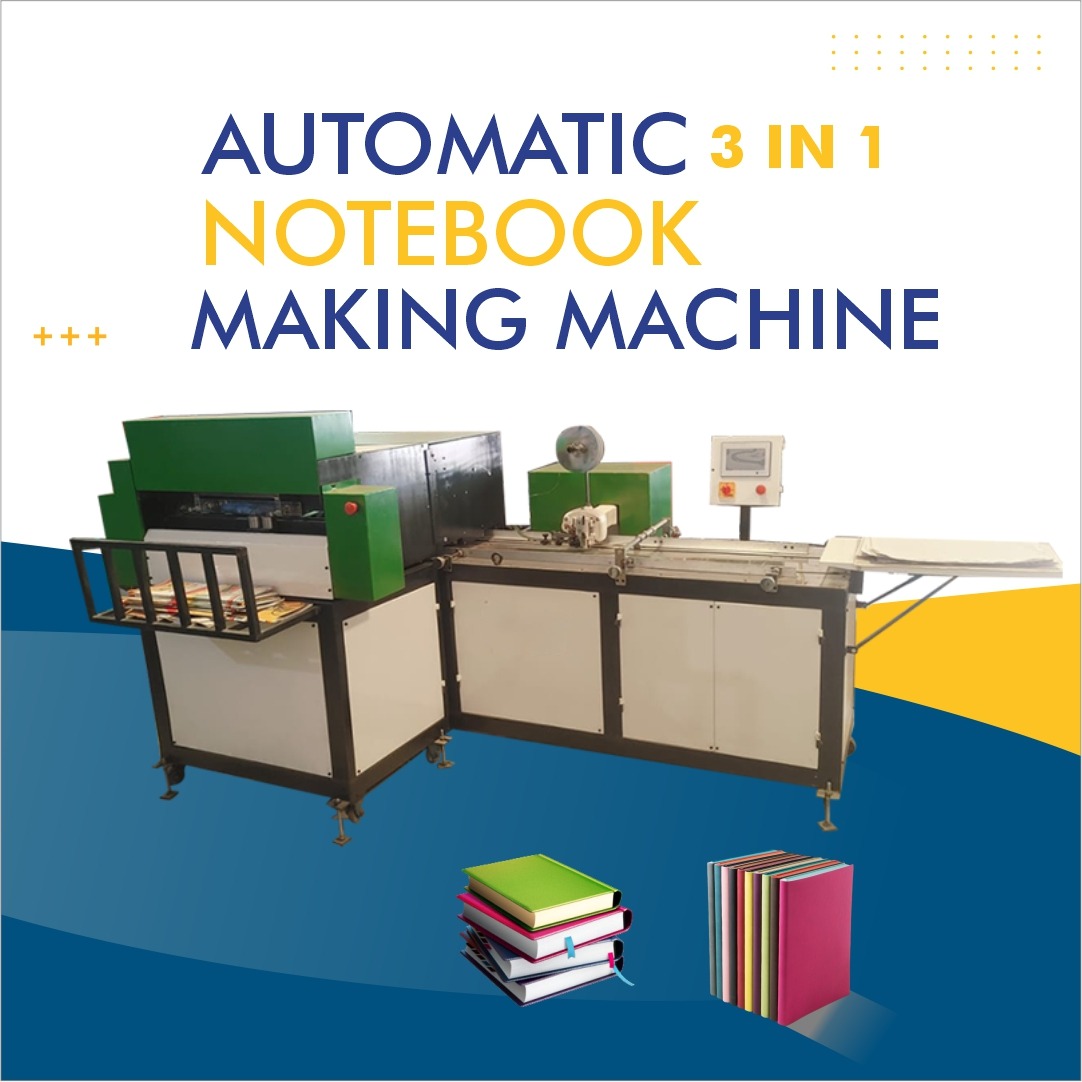

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Alappuzha Kerala | High Capacity Notebook Production Equipment

Notebook Making Machine in Alappuzha | Kerala

In today’s competitive manufacturing environment, investing in a high-performance notebook making machine is essential for any producer aiming to scale operations and maintain quality. Based in Alappuzha, Kerala, you have access to advanced notebook manufacturing equipment that can handle everything from single-sheet gathering to folding, stitching, trimming and finished book blocks. Whether you’re launching a new notebook production line or upgrading an existing one, understanding the features, benefits and operational considerations of a notebook making machine will help you make the right choice.

In this comprehensive guide we will explore: what a notebook making machine is, key specifications and types of machines, advantages of choosing a local supplier in Alappuzha/Kerala, how to select the right machine, installation and maintenance tips, potential production metrics, and how this investment can drive your notebook manufacturing business forward. The term notebook making machine is repeated here and in various synonymous forms (notebook production machine, notebook manufacturing equipment, notebook making machinery) to ensure clarity and optimisation.

What is a Notebook Making Machine?

A notebook making machine is an industrial equipment designed to automate and streamline the production of notebooks (exercise books, registers, school copies). The machine typically performs several processes in one line: gathering of inner sheets, folding or collating, stapling or stitching (if wire-stitched), trimming of edges, gluing (for soft cover or adhesive binding), cover feeding and final finishing.

Synonyms for this equipment include “notebook production machine”, “notebook manufacturing equipment”, “notebook making machinery”.

For example, manufacturers in Kerala list models described as “automatic notebook making stitching-folding-edge squaring machine”. printekengineers.in+2ExportersIndia+2

Other models are semi-automatic or manual, depending on production capacity and budget. ExportersIndia+1

Types & Specifications of Notebook Making Machines

When selecting a notebook making machine, several specifications and types matter:

1. Automation Level

-

Manual: Requires significant operator involvement; typically lower speed and capacity.

-

Semi-automatic: Some operations (folding, trimming) automated, others manual; moderate production capacity.

-

Automatic: Fully automated lines from sheet feeding to finished product; high production capacity. For instance, a machine listed has production capacity up to 2,500 pcs/hr. printekengineers.in+1

2. Production Capacity

Capacity is often specified in pcs/hour (pieces per hour). For example, one model shows 1,500 pcs/hr for stitching-folding-edge squaring machine. printekengineers.in

Another source lists machines up to 5,000 pcs/hr. aajjo.com+1

Choosing a machine with the right capacity helps align with your production needs and ensures cost‐effectiveness.

3. Material & Construction

Machine frames and body materials may include stainless steel, mild steel, cast iron, etc. Robust construction ensures durability, minimal maintenance and longer lifespan. ExportersIndia+1

4. Size & Notebook Format Compatibility

Machines may support different notebook sizes (A4, A5, king size) and variable thicknesses. For example: one machine supports spine thickness min-max 5-70 mm. printekengineers.in

Flexibility in size means you can produce a variety of notebook formats without needing multiple machines.

5. Phase, Motor Power & Electrical Specifications

Important for installation in Kerala: power supply (single-phase vs three-phase), motor kW/HP ratings. Example: motor power 4 HP, three phase. printekengineers.in

6. Additional Features

-

Edge squaring, trimming, gluing, cover feeding, counting & collecting systems.

-

Adjustability: notebook size, thickness, speed.

-

After-sales support, spare parts, warranty.

Advantages of Locating Your Equipment in Alappuzha, Kerala

Choosing to locate or source your notebook making machine in or around Alappuzha, Kerala, offers several benefits:

-

Proximity to Suppliers & Manufacturers in Kerala: Kerala has manufacturers of notebook making machines, which means you may gain local access to machines for inspection, quicker installation or servicing. For example, companies in Thiruvananthapuram and Thrissur list notebook making machines. printekengineers.in+2aajjo.com+2

-

Reduced Logistics Cost & Time: Sourcing from within the state or adjoining regions means less transport cost, faster delivery and ease of installation.

-

After-Sales & Service Support: Local manufacturers are better positioned to provide timely service, spare parts, maintenance in Kerala.

-

Regional Labour Availability: Skilled staff for operation and maintenance of equipment may be more readily available in local industrial zones.

-

Strategic Location for Supply Chain: Alappuzha has port and transportation connectivity that may help in sourcing raw materials (paper, cover stock) and shipping finished notebooks.

By leveraging these location advantages, your notebook manufacturing business can gain operational efficiency and cost savings.

How to Choose the Right Notebook Making Machine for Your Business

Here is a step-by-step guide to selecting the right notebook making machine tailored for your manufacturing unit in Alappuzha:

Step 1: Determine Your Production Requirements

-

Estimate monthly/yearly output (number of notebooks).

-

Determine format types: sizes, thickness, binding type (stitching, gluing).

-

Consider future growth: select a machine with capacity slightly above current need.

Step 2: Choose Automation Level vs Budget

-

If starting small, a semi-automatic notebook making machine may suffice.

-

For high-volume production (1000 + pcs/hr), an automatic machine is more cost effective per unit.

Remember synonyms: notebook manufacturing equipment, notebook production machine.

Step 3: Evaluate Machine Specifications

-

Capacity (pcs/hr)

-

Sizes supported (A4, A5 etc)

-

Binding/finishing options (stitching, gluing)

-

Material and build quality

-

Electrical specs matching your facility (voltage, phase)

-

Adjustability and versatility for different notebook formats.

Step 4: Supplier Evaluation

-

Choose a reputed supplier with proven track record, good reviews. For instance, platforms listing notebook making machines in Kerala highlight reliability and service. aajjo.com+1

-

Check for after-sales service: spare parts, maintenance, warranty.

-

Ask for demonstration, factory visit if possible.

Step 5: Installation & Facility Requirements

-

Ensure your location (Alappuzha) has infrastructure: power supply, floor space, ventilation.

-

Plan for installation, commissioning and operator training.

-

Align with supplier’s installation timeline and service guarantee.

Step 6: Cost & Return on Investment (ROI)

-

Compare capital cost vs expected output.

-

Compute cost per notebook production, raw material cost, labour cost.

-

A high-capacity machine may have higher upfront cost but lower per-unit cost.

Features & Benefits of Notebook Making Machines

Here are some of the principal benefits and features you should focus on, using the keywords for emphasis:

• High Production Output

With a robust notebook making machine you can achieve production of 1,000 – 5,000 notebooks per hour. This high throughput helps reduce unit cost and meet large orders.

• Versatility in Formats

A modern notebook production machine supports multiple sizes, thicknesses and cover types. You can switch between formats quickly, enabling product diversity.

• Improved Quality & Finish

Machines provide consistent stitching/folding/trimming/gluing, which ensures professional-looking notebooks. This improves your brand image and customer satisfaction.

• Reduced Labour & Errors

Automated operations such as sheet feeding, trimming and squaring reduce manual intervention, lower error rates and improve efficiency.

• Long-Term Cost Savings

Although the initial investment is significant, the long-term savings via lower labour, faster production and higher yield can deliver a strong return on investment.

• Local Support & Maintenance

With local suppliers in Kerala, you benefit from shorter service times, easier spare part procurement and local expertise for maintenance – essential for continuous operation.

Considerations for Installation & Operation

When installing a notebook manufacturing equipment (i.e., notebook making machine) in Alappuzha, keep these operational considerations in mind:

-

Power supply and phase: Verify your facility supports the machine’s power needs (single vs three-phase).

-

Floor space and foundation: The machine may be heavy and require foundations, space for material feed and output.

-

Operator training: Machine operation and safety training must be provided.

-

Maintenance schedule: Preventive maintenance ensures less downtime; check manufacturer’s recommended service intervals.

-

Spare parts availability: Ensure the supplier has spare parts stock and service network in Kerala.

-

Dust and waste management: Notebook production generates paper waste and dust; plan for waste disposal and housekeeping.

-

Safety and compliance: Ensure machine meets relevant safety standards and your facility adheres to local regulations.

Case Example & Application in Kerala

As per listings, a Kerala-based manufacturer offers automatic notebook making stitching-folding-edge squaring machine with capacity ~1,500 pcs/hr, motor power 4 HP, three phase. printekengineers.in

Another listing shows machines targeting up to 5,000 pcs/hr capacity in India. aajjo.com

For a notebook production unit in Alappuzha, you could choose a machine in the 2,000 pcs/hr capacity range initially and scale up later. With local service and proximity to suppliers, this becomes a feasible setup.

Why This Investment Makes Sense in Alappuzha Kerala

-

The KNOWN manufacturing cluster and skilled workforce in Kerala make it feasible to operate a notebook manufacturing unit.

-

Sourcing an efficient notebook making machine means you can serve schools, institutions, local markets and export clients.

-

With the growth of education and stationery demand in India, a well-equipped manufacturing line in Kerala will be well positioned.

-

The local supplier ecosystem in Kerala ensures you are not solely dependent on far-away manufacturers.

In other words, by installing a capable notebook making machine in Alappuzha, you set up a competitive manufacturing unit that can deliver quality notebooks, reduce turnaround time, manage costs and build strong client relationships.

Conclusion

Investing in the right notebook making machine (aka notebook production machine, notebook manufacturing equipment) in Alappuzha, Kerala is a strategic decision that can transform your notebook manufacturing business. By carefully assessing your production needs, choosing the proper automation level, evaluating key specifications, and aligning with a reliable local supplier, you position yourself for growth and efficiency. With the local benefits of Kerala’s manufacturing ecosystem, you can leverage faster delivery, service support and skilled labour.

As you embark on selecting your notebook making machinery, keep in mind the long-term benefits: higher output, lower unit cost, improved quality and greater flexibility. The keywords used here — notebook making machine, notebook production machine, automatic notebook making machine, etc. — all reflect the core equipment you need to focus on.