Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

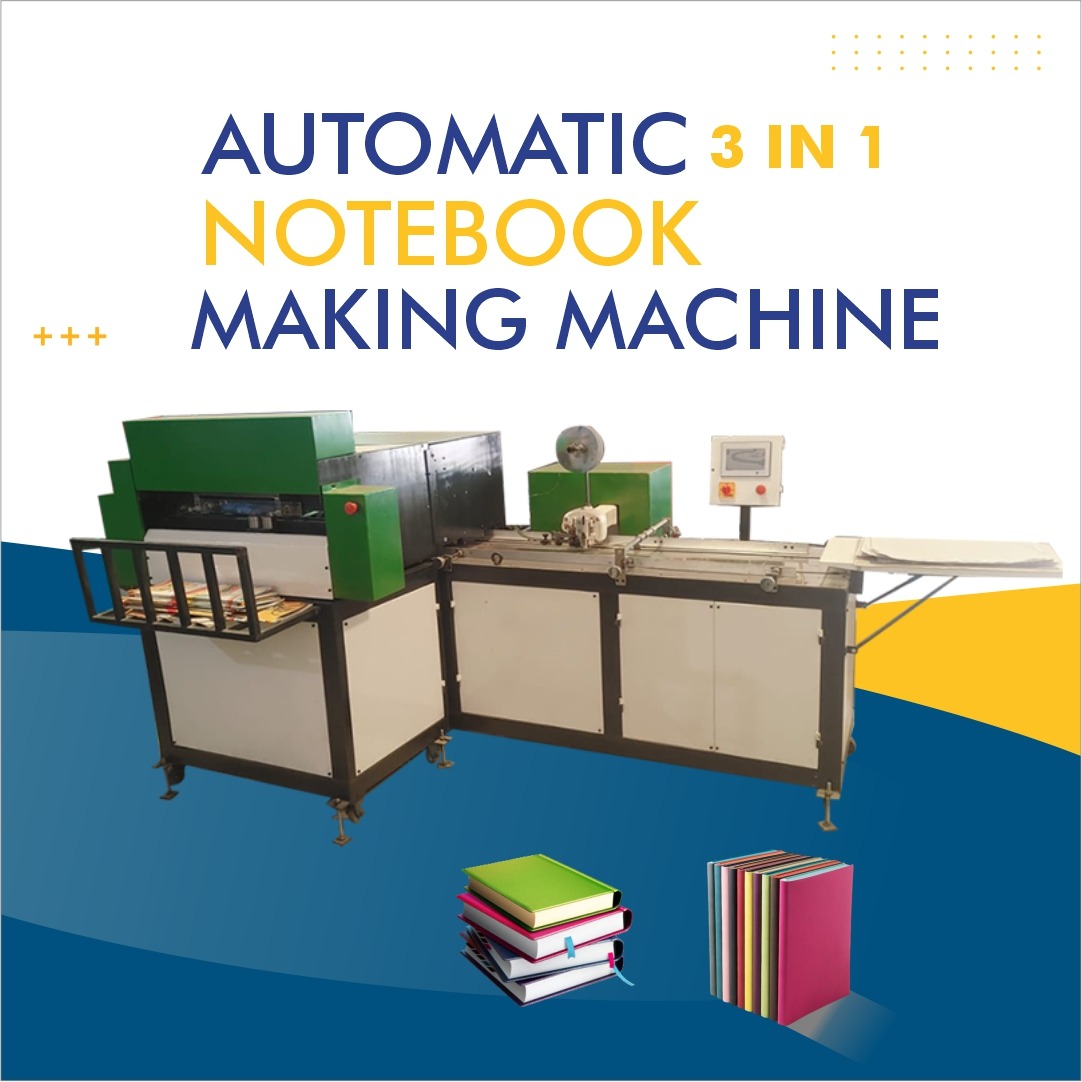

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Thrissur Kerala – High-Quality Notebook Production Equipment

Notebook Making Machine in Thrissur | Kerala

If you are in Thrissur, Kerala and seeking a specialised machine to manufacture exercise books, notebooks or writing pads, you have landed at the right place. A notebook making machine, sometimes referred to as a notebook production machine or notebook manufacturing equipment, is a key industrial asset for companies engaged in stationery production. In this comprehensive guide we will explore everything you need to know about the notebook making machine: its features, benefits, production capacity, selection criteria, setup in Thrissur, India, local service considerations, and how to optimise your investment.

What is a Notebook Making Machine?

A notebook making machine (also called notebook production machine) is a mechanical system designed to automate the conversion of raw paper sheets into finished notebooks. It typically combines several operations such as cutting, ruling, folding, stitching or binding, edge-squaring, trimming and perhaps also cover-insertion or laminating. kesyainternational.com+2smallmediumbusinessindia.com+2

In the notebook manufacturing business, especially in the stationery industry in India, this machine gives you the advantage of increased throughput, consistent quality, and less manual intervention — all of which are especially valuable when you operate from a location like Thrissur, Kerala.

Why Install a Notebook Making Machine in Thrissur, Kerala?

Thrissur is a dynamic industrial and commercial city in Kerala with good connectivity and a strong tradition of manufacturing. Setting up your notebook production line here offers several advantages:

-

Local access to skilled operators and technicians who understand machinery for stationery manufacturing.

-

Proximity to raw materials (paper stocks, cover boards, bindings etc) from within Kerala and neighbouring states.

-

Easier logistics across south India for distribution of finished notebooks.

-

Competitive cost base for labour and utilities compared to major metropolitan centres.

-

Availability of after-sales support and service for machinery in the region (seek suppliers who service Kerala).

Key Features to Look For in a Notebook Making Machine

When selecting a notebook making machine (notebook production machine, notebook manufacturing equipment), consider the following critical features:

-

Production capacity: How many notebooks per hour? Some machines list 3,000-5,000 pieces/hour for automatic types. smallmediumbusinessindia.com+1

-

Automation grade: Fully automatic versus semi-automatic or manual. A fully automatic machine reduces manual labour, speeds up production, and improves consistency. endurancemachinery.com+1

-

Size flexibility: Ability to handle different notebook sizes (length, width, thickness) and different page counts. endurancemachinery.com

-

Binding and stitching mechanism: Eg multi-head wire stitching, folding, edge-squaring. These aspects greatly affect book quality. endurancemachinery.com

-

Cutting / trimming accuracy: A machine that handles paper cutting, edge trimming or squaring well will deliver clean notebooks. smallmediumbusinessindia.com

-

Material construction & durability: Strong frame, corrosion-resistant parts, good machine life. Toolsvilla

-

After-sales service/support: Especially in Kerala, ensure spare parts availability, local technicians, and service agreements.

-

Power and utility considerations: Single or three-phase electricity supply, space requirements, operator training. sbsmachine.com

Benefits of Using a Quality Notebook Making Machine

By investing in a high-quality notebook making machine in Thrissur, you can unlock several business advantages:

-

Increased output: Higher production per shift compared to manual assembly or smaller machines.

-

Reduced labour cost: Automation reduces manual steps, thereby reducing labour overhead and errors.

-

Consistent product quality: Machines can deliver uniform stitching, trimming and alignment, leading to better notebook finish.

-

Flexibility: Many machines allow quick changeovers between sizes and formats, so you can cater to varied client demands (schools, colleges, retailers).

-

Cost-efficient manufacturing: Over time, the machine cost amortises across large volumes, improving factory productivity and profitability.

-

Competitive positioning: With reliable machinery, you can establish yourself as a serious stationery manufacturer in Kerala and beyond, supplying to schools, offices, retail chains etc.

Selecting the Right Machine Model for Your Requirements

When you are assessing suppliers and models, use a systematic approach:

-

Define your target notebook formats (sizes, page counts, covers, binding type).

-

Estimate your annual production volume and required throughput (notebooks per hour/day).

-

Consider your budget and ROI timeframe.

-

Visit machine manufacturers, ideally those with experience in stationery manufacturing in India.

-

Ask for demonstrations, test runs with your format, training for operators.

-

Check spare parts availability, local service in Kerala, warranty terms.

-

Evaluate total cost of ownership: electricity, maintenance, downtime, operator training.

-

Check space requirements, noise/ventilation, safety compliance (especially for factory in Thrissur).

-

Ensure the machine is adaptable for future growth (e.g., ability to upgrade to larger formats or higher capacity).

Installing and Operating a Notebook Making Machine in Thrissur

Once you have procured your notebook making machine, your focus shifts to installation and operation:

Installation

-

Select a dedicated area in your factory or workshop in Thrissur: ensure level flooring, adequate power supply (single/three phase as required), proper lighting and ventilation.

-

Ensure the machine is anchored correctly, with safety zones and clear access for operator and maintenance.

-

Coordinate with the supplier for mechanical installation, wiring, commissioning, and initial calibration.

-

Train operators on machine usage, safety norms, maintenance procedures.

Operation & Workflow

-

Begin with raw paper stacks: input may be ruled sheets (if you print ruling), cover materials, binding wires.

-

Machine sequence: Cutting/trimming → Folding (if required) → Stitching/binding → Edge squaring → Trimming/finishing → Packaging. Many machines combine these steps. endurancemachinery.com+1

-

Monitor throughput and waste rate: Keep track of how many notebooks per hour you achieve, how much scrap or rejects you have.

-

Maintenance: Routine cleaning, lubrication, checking blade wear, screws & fasteners, alignment. Preventive maintenance avoids unplanned downtime.

-

Quality control: Inspect finished notebooks for proper binding, square edges, correct page count, cover alignment. Uniform quality is vital for customer satisfaction and repeat business.

Cost Considerations and ROI

While machine cost varies substantially depending on capacity, automation level, brand and features, you should estimate ROI by factoring:

-

Machine purchase or lease cost.

-

Installation and commissioning costs.

-

Operational costs: electricity, operator wages, maintenance, spare parts.

-

Raw material costs: paper, covers, wires, laminates.

-

Production volume: estimate notebooks per month, per year.

-

Selling price per notebook or bundle.

-

Break-even point: how many months/years to recoup machine cost.

For example, a machine with capacity of 3,000–5,000 notebooks/hour at full automation could significantly reduce unit cost per notebook compared to manual labour, hence faster ROI in a busy factory in Thrissur.

Market Potential in Kerala and South India

Stationery consumption remains robust in India, especially in school and college segments, institutional supplies and retail consumers. Kerala’s literacy rate is high, and there is strong demand for notebooks, especially in academic seasons. By having your manufacturing base in Thrissur, you can cater to Kerala, Tamil Nadu, Karnataka and distribution via ports or road networks. With the right notebook making machine, you can position yourself as both a contract manufacturer (for other brands) and your own brand.

Maintenance, Service and Local Support in Thrissur

A crucial non-machinery factor is the after-sales service and local support. When your machine is in Thrissur:

-

Ensure the supplier has either a branch or authorised service agency in Kerala (or nearby state) so that breakdowns are addressed quickly.

-

Secure spare-parts list for wear-items (blades, stitching heads, belts, etc) and stock critical spares locally.

-

Train a local technician in basic maintenance so that you don’t face long downtime.

-

Implement a maintenance schedule: daily short checks, weekly cleaning, monthly lubrication and quarterly major service.

-

Maintain logs of machine usage, downtime, error logs—to evaluate performance and optimise uptime.

Why Choose Us (or Our Machine Offer) in Thrissur

If you are looking to purchase a notebook making machine in Thrissur, Kerala, here are key value-propositions you should seek:

-

A machine that is built for Indian manufacturing conditions (stable for varying voltage, humidity, paper quality).

-

A supplier who offers on-site installation, commissioning and operator training in your Thrissur facility.

-

A support network for spare parts and service within Kerala or South India.

-

A machine model that gives you flexibility—multiple notebook sizes, variable page counts, future-proof upgrades.

-

Transparent cost of ownership: upfront price, runtime cost, maintenance cost, expected throughput and ROI calculations.

-

Compliance with safety and industrial norms for your factory in Thrissur.

-

Good references from other stationery manufacturers who have installed similar notebook making machines.

Common Questions and Answers

Q1: What size notebooks can I make on a typical machine?

A: It depends on machine model. Some lines support lengths from ~10″ to 30″, widths ~10″ to 18″. endurancemachinery.com You must confirm with supplier regarding the particular size range you will run.

Q2: What is the production speed?

A: Speeds vary widely: some automatic machines deliver 800 books/hour in one example. endurancemachinery.com Others claim thousands of pieces per hour if size and configuration allow. smallmediumbusinessindia.com

Q3: Can I change notebook sizes quickly?

A: Many machines offer adjustable programs and quick changeovers. For example, some models allow saving settings for different notebook sizes. namibind.com

Q4: What kind of binding does it support?

A: Some machines support multi-head wire booklet stitching (wire binding) and folding and squaring. endurancemachinery.com

Q5: What about maintenance and spare parts?

A: As with any industrial machine, regular preventive maintenance is essential. Choose a supplier offering spares, local support and training for your staff in Thrissur.

Conclusion

Investing in the right notebook making machine in Thrissur, Kerala can transform your stationery manufacturing business. With the right machine you will enjoy higher throughput, consistent quality, and greater flexibility. Focus on selecting a machine that suits your size requirements, production capacity, binding type and future growth, and make sure you have strong service and support locally in Kerala. With careful planning and the right equipment you’ll be well placed to capture the stationery market across south India.