Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

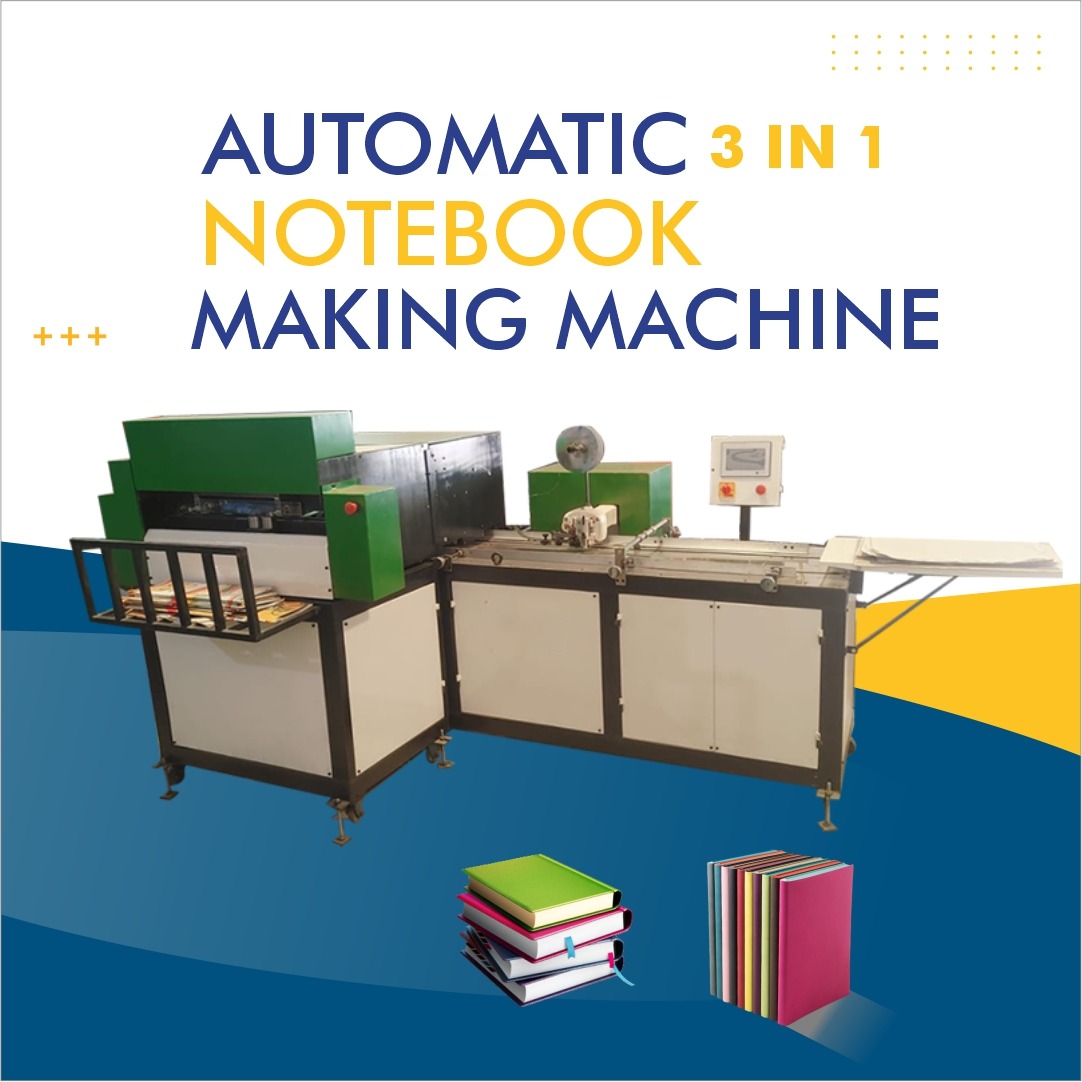

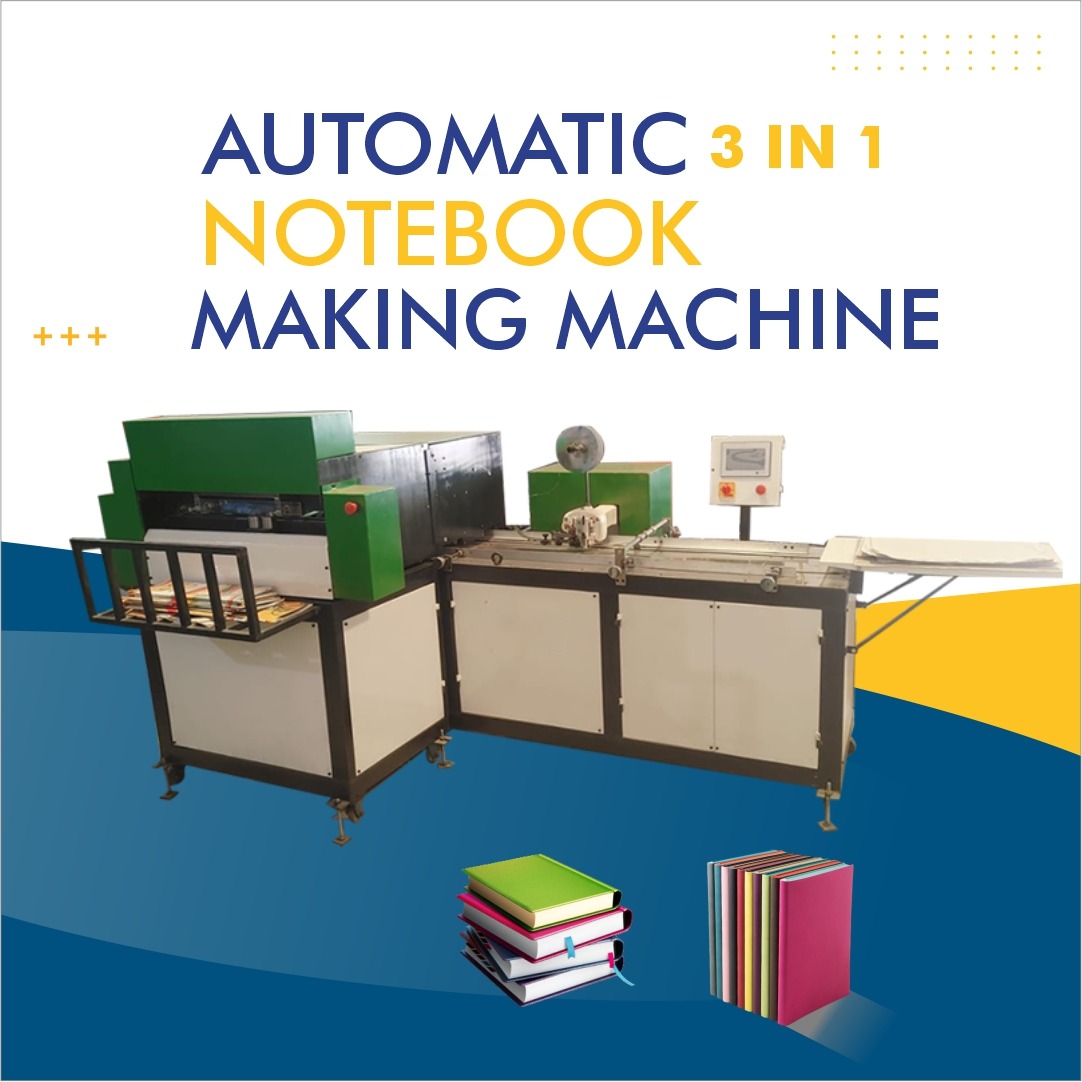

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Kottayam Kerala · High-Efficiency Notebook Production Equipment

Notebook Making Machine in Kottayam | Kerala

If you are looking to establish or expand a notebook manufacturing facility in Kerala, particularly in the Kottayam region, investing in a dedicated notebook making machine can make all the difference. A high-quality notebook making machine ensures efficient production of exercise books, registers, diaries and notebooks with consistent quality, lower labour cost and faster turnaround. In this article we will explore the key factors you should consider when selecting a notebook making machine, the advantages of locating operations in Kottayam Kerala, features of modern machines, installation and service aspects, and how you can optimise production. Throughout we will repeatedly emphasise the term notebook making machine (and synonyms) so as to reinforce its importance and help your SEO.

Why Choose Kottayam, Kerala for Notebook Manufacturing

Kottayam has several advantages as a location for manufacturing notebook production equipment and running a notebook manufacturing business:

-

Strategic location & connectivity: Kottayam lies in central Kerala with access to road and rail networks for transporting raw paper, binding materials, and finished notebooks to major markets in Kerala, Tamil Nadu and beyond.

-

Availability of skilled labour and paper-industry support: The region benefits from a tradition of printing, publishing and stationery manufacturing, which means you can source auxiliary services and labour more easily.

-

Lower operating costs: Compared to North Indian locations, manufacturing in Kerala (including Kottayam) can offer competitive labour and utility costs, particularly for a notebook making machine line.

-

Urban-rural balance: Setting up in the Kottayam district means you can benefit from an industrial estate or warehousing zone while keeping proximity to towns and support services.

-

Local market: There is robust demand for notebooks and stationery products in Kerala and the neighbouring states. A notebook making machine located in Kottayam gives you a faster supply chain for local schools, colleges, offices and retail outlets.

What is a Notebook Making Machine?

A notebook making machine (also referred to as notebook production machine or notebook manufacturing equipment) is a specialised piece of industrial equipment designed to convert raw paper sheets into finished notebooks. The process generally involves several steps: paper cutting/ruling, folding or gathering sheets, stitching or binding, trimming, squaring of edges, attaching covers, and finally delivery of finished notebooks. kesyainternational.com+2sikandarmachines.com+2

Different models may offer automatic vs semi-automatic operation, vary production capacity, support different notebook sizes/thicknesses, and include additional finishing modules (e.g., wire stitching, edge squaring). For example, one fully automatic machine offers multi-head wire stitching, folding, edge squaring and PLCbased control with speeds up to 800 books/hour. endurancemachinery.com

Key Features to Look For

When selecting a notebook making machine in Kottayam (or anywhere), pay attention to the following features:

-

Production capacity: How many notebooks per hour can it produce? Machines may range from a few thousand pieces/hour to high-speed lines producing > 8,000 pieces/hour. Toolsvilla+1

-

Automation level: Fully automatic machines reduce manual intervention (sheet stacking, folding, trimming, binding) whereas semi-automatic require more operator input. Decide based on your workforce and investment.

-

Notebook size & thickness flexibility: The machine should support the size formats you plan (e.g., A4, 32-page, 64-page, etc) and maximum thickness of notebooks. endurancemachinery.com+1

-

Stitching / binding method: Machines may use wire stitching, sewing, perfect binding. Wire / multi-head stitching is common for exercise notebooks. endurancemachinery.com

-

Cutting and edge squaring: A good machine will cut sheets accurately and square the edges of finished notebooks for a neat appearance. smallmediumbusinessindia.com+1

-

Durability & serviceability: The machine material (e.g., mild steel frame), the brand of components, local service availability, spare parts access — all matter for long-term operation. kesyainternational.com+1

-

Ease of operation & changeover: If you plan to make notebooks of different sizes or page-counts, the machine should allow quick adjustments or program saving. namibind.com

-

Energy and utility requirements: Check power supply, phase (single/three phase), compressed air if required, footprint, and waste management for your facility in Kerala.

-

Cost/return considerations: Initial investment, running costs (electricity, labour, maintenance), and expected return based on your target production and local market.

-

Local regulatory or import issues: If you are importing a machine, consider customs, GST, local installation, and after-sales support in Kerala.

Benefits of Installing a Notebook Making Machine

Installing a dedicated notebook making machine brings multiple advantages:

-

Increased production efficiency: The machine automates many manual steps, reduces errors, and speeds up throughput compared to manual assembly.

-

Consistent quality: With accurate cutting, stitching and finishing, the finished notebooks have uniform appearance and quality — important for branding and bulk supply.

-

Cost-effectiveness: Over time, the reduced labour/time per notebook and higher output can deliver lower per-unit cost and better profitability.

-

Flexibility for sizes/types: You can cater to different segments– school notebooks, premium registers, diaries – by adjusting the machine or by adding modules.

-

Competitive edge in local market: In the Kottayam/ Kerala region, supplying quickly and with better quality gives you an advantage versus distant suppliers.

-

Scalability: Starting with an entry-level machine, you can scale up production or add additional lines as demand grows.

Typical Use Case: From Raw Paper to Finished Notebook

Here’s how a typical notebook production workflow using a notebook making machine looks:

-

Paper & cover material preparation: Raw sheets (for inside pages) and cover stock are prepared, with requisite paper quality (gsm), ruling/printing done externally or in-house.

-

Feeding/cutting/ruling: The machine or pre-processing unit cuts the sheets to size (say A4 or A5), applies ruling if required, and stacks them. Some machines incorporate ruler units.

-

Folding/gathering: The sheets are folded or gathered to form signatures or sets of pages as per notebook page-counts.

-

Stitching / binding: The notebook stack is stitched (wire / multi-head) or bound through other means. The machine must maintain alignment and accuracy.

-

Edge squaring / trimming: The stack of sheets plus cover is squared and trimmed so that edges are flush and the notebook looks neat and professional.

-

Cover attachment: The cover is attached – wraparound covers, laminated covers or printed covers may be used. Some machines handle the cover feed; others require separate process.

-

Finishing and delivery: The finished notebook is collected, counted, packaged (if required) and prepared for dispatch to customers or warehouse.

-

Quality check: Inspection for page count, stitching quality, accurate trim, and cover alignment.

By using a high-quality notebook making machine you streamline many of these steps, reduce manual bottlenecks, ensure faster lead times and consistent supply to your customers in Kerala and beyond.

Selecting the Right Size & Type for Your Operation in Kottayam

When you decide to set up in Kottayam, consider the following scenario-based guidance:

-

Small scale / startup: If you are beginning with moderate volumes (say a few thousand notebooks daily) you might choose a semi-automatic notebook making machine with lower capacity. This keeps the initial investment manageable, while enabling you to build market presence in the Kottayam region.

-

Medium scale growth: If you anticipate supplying schools, colleges, offices across Kerala or Tamil Nadu, look for a mid-level automatic machine with capacity around 3,000-5,000 pieces/hour.

-

Large scale / mass production: For supplying pan-India or for large contracts, invest in a high-speed automatic notebook making machine (8,000+ pieces/hour capacity) with full line assembly, minimal manual steps, fast changeover, robust service support.

-

Size diversification: If you plan to produce different notebook sizes (A4, A5, luxury diaries, etc), pick a machine with size flexibility and quick changeover features.

-

Space & utilities: Ensure your facility in Kottayam has adequate floor area, strong power supply (three phase if required), ventilation, and space for raw materials, machine access, maintenance zone.

-

Service network: Given your location in Kerala, ensure the supplier or manufacturer offers installation, local technician support, spare parts supply, and training for operators. This minimises downtime.

Supplier & After-Sales Considerations

When you purchase your notebook making machine for Kottayam, pay attention to:

-

Manufacturer reputation & references: Choose a maker or dealer with proven installations in Indian conditions. For example, many machines in India cite production capacities and support. smallmediumbusinessindia.com+1

-

Training & commissioning: Ensure that the supplier provides installation, operator training, and commissioning at your site in Kottayam.

-

Spare parts & maintenance: Confirm availability of critical spares (motors, PLC controller modules, stitching heads, knives) and local servicing in Kerala.

-

Warranty & service contracts: Understand warranty terms, annual maintenance contracts, downtime commitments.

-

Local adaptation: The machine should be suitable for local power supply (220-380 V, three phase), local ambient conditions (humidity, dust), and local operator skill-levels.

-

Documentation & drawings: Ensure you receive operator manuals, maintenance schedules, safe operation guidelines, spare parts lists.

-

Upgradability: Choose a machine with scope for future expansion or automation (e.g., automatic cover feeding, packaging integration) so your notebook making capacity can scale.

-

Delivery & installation timeline: In the case of importing or ordering custom units, factor in lead time, shipping to Kerala, installation, testing and training.

-

Support for local regulations: Ensure that all electrical and mechanical safety standards are met for your Kerala location, and that local taxes/clearances (GST, import duties if any) are managed.

Cost & Return on Investment (ROI) in Notebook Manufacturing

Investing in a notebook making machine is a capital decision best justified by expected returns. Here are some guidelines:

-

Initial investment: The cost of a notebook making machine varies widely depending on capacity, automation, features and brand. For instance, one listing noted a price in India for a fully automatic notebook making machine. endurancemachinery.com+1

-

Operating costs: Labour (machine operators, material handlers), power, maintenance, raw materials (paper, cover), binding wire or glue, packaging.

-

Unit cost calculation: Estimate cost per notebook by dividing total cost (fixed + variable) by number of notebooks produced.

-

Break-even volume: Determine how many notebooks you must sell per month to recover the machine cost over a target period (e.g., 2-3 years).

-

Pricing & market: In Kerala and neighbouring markets, research what notebooks are being sold for (wholesale & retail) and calculate whether your per-unit cost allows margin.

-

Quality premium / differentiation: If your machine enables better finishing, you may sell premium notebooks at higher margins.

-

Capacity utilisation: The machine is only profitable if you run it at a good utilisation rate — idle machinery still incurs costs. Locating in Kottayam gives you access to local demand and lowers logistics cost, improving utilisation.

-

Lifecycle and depreciation: Consider machine life (typically many years), potential for upgrade or resale, and depreciation for accounting purposes.

By carefully modelling these factors specific to your business (location Kottayam, raw material costs, local labour, electricity tariff), you can estimate whether investing in a notebook making machine is financially sound.

Challenges & Risk Mitigation

Manufacturing notebooks using a notebook making machine involves some challenges; being aware helps you plan:

-

Raw material fluctuations: Paper prices and cover stock costs may vary. Secure reliable suppliers and maintain buffer stock.

-

Machine downtime: Breakdowns reduce output and can affect commitments. Mitigate by preventative maintenance, spares stock, skilled operators.

-

Demand variability: Demand for notebooks may be seasonal (e.g., start of school term). Ensure you have order pipeline and manage inventory accordingly.

-

Quality control: Even with automatic machines, operator input, material quality and set-up matter. Invest in quality control systems.

-

Skill availability: In some regions, sourcing trained operators or maintenance technicians may be a constraint. Plan for training.

-

Energy & utilities: In some locations power supply may be unstable; consider stabilisers or UPS for sensitive electronics like PLCs.

-

Competition & pricing pressure: Local stationery manufacturers may compete on price. Focus on quality, faster delivery, local service advantage.

-

Compliance & environment: Waste paper trimming and binding process may generate scrap; implement proper disposal or recycling to meet regulatory or environmental expectations.

By proactively addressing these risks you ensure smoother operations of your notebook making facility in Kottayam.

Why Your Business in Kottayam Needs the Notebook Making Machine

If your business is based in Kottayam and you are seeking to produce notebooks either for retail, school supply, corporate gifts or custom printed notebooks, here is why you should install a notebook making machine:

-

Local responsiveness: Being based in Kottayam, you can respond faster to nearby schools, colleges or corporate clients with short lead-time notebooks.

-

Lower logistics cost: Reduced transport cost of finished notebooks into Kerala markets, and easier returns/fault handling.

-

Brand and service advantage: You can emphasise local service, quick turnaround, regional presence, which competitors outside the region cannot match.

-

Scalability into nearby states: Once you ramp up capacity, you can supply markets in Tamil Nadu, Karnataka, Andhra etc, using your notebook making machine as core asset.

-

Flexible product offerings: With the right machine you can produce standard school notebooks, premium diaries, custom branded notebook sets, diversifying revenue streams.

-

Better ROI: Shorter supply chains, lower lead time, local sourcing of materials and labour help increase profitability and faster pay-back of the machine investment.

Thus a notebook making machine acts not just as equipment but as a strategic enabler for notebook manufacturing business in and around Kottayam, Kerala.

Summary and Next Steps

To summarise:

-

A notebook making machine is central to efficient notebook manufacturing — cutting, folding, stitching/binding, trimming and finishing.

-

Locating your operations in Kottayam, Kerala offers strategic advantages such as local demand, connectivity, skilled labour and cost benefits.

-

When selecting a notebook making machine, evaluate production capacity, automation level, size flexibility, binding method, durability, serviceability and cost.

-

Ensure good supplier support, warranty, spare parts availability, local training and suitability for Kerala conditions.

-

Analyse cost/return carefully, model production volumes, demand, pricing, utilisation, and scalability.

-

Address risks like material price fluctuations, machine downtime, demand changes, workforce skill gaps and compliance.

-

With the right machine and strategy, you can establish a competitive notebook manufacturing business in Kottayam, leveraging local advantage and scaling up over time.

Next steps: You should create a detailed specification sheet for the notebook making machine you need (target volume, notebook sizes, binding style, automation level), then request quotes from reliable manufacturers, check after-sales support in Kerala, budget for installation in Kottayam, and project your first year output and profitability. Let us know if you’d like assistance in finding suppliers in India, machine comparison, or cost modelling for your notebook manufacturing facility.