Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

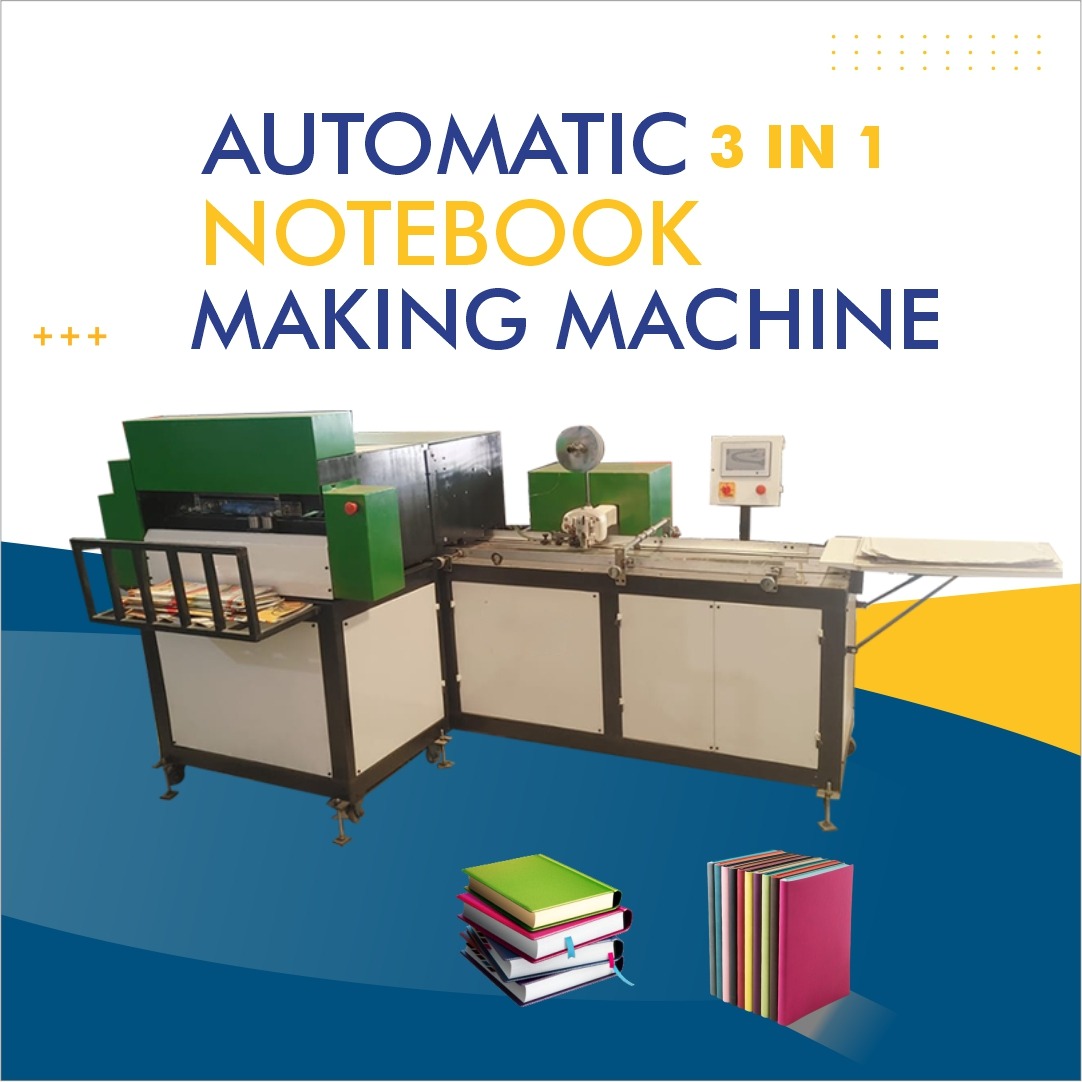

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Srirangapatna Karnataka – High Efficiency Production Equipment

Notebook Making Machine in Srirangapatna | Karnataka

In today's stationery manufacturing industry, investing in the right production equipment can make all the difference. A robust notebook making machine streamlines operations, increases output, ensures consistent quality and enables manufacturers to meet rising demand for notebooks, exercise books and writing pads. If you are located in or around Srirangapatna, Karnataka, this is your guide to understanding the features, benefits and selection criteria for a notebook making machine — including the various synonyms for the product such as notebook production equipment, notebook manufacturing machine, exercise book machine etc.

What is a Notebook Making Machine?

A notebook making machine refers to industrial equipment designed to manufacture notebooks: this includes cutting paper, folding, stitching, binding, trimming and edge-squaring. These machines come in manual, semi-automatic and fully automatic variants. For example, one machine manufacturer lists a manual setup machine with production capacity 3,000 pieces/day. sbsmachine.com+2Justdial+2 Another lists semi-automatic machines with 3,000 pieces/8 hrs capacity. shkimachinery.com+1

The process of notebook manufacturing includes:

-

Paper cutting and trimming to size

-

Page folding and assembly

-

Stitching or binding (wire, thread or glue)

-

Edge squaring or trimming for clean finish

-

Cover attachment and finishing

The notebook making machine essentially integrates several of these steps into one (or multiple linked) units to reduce manual labour and improve consistency.

Why Choose a Notebook Making Machine in Srirangapatna, Karnataka?

Choosing a machine locally in the Srirangapatna region offers several advantages:

-

Proximity to suppliers and service centres: Having a supplier located nearby means faster delivery, easier installation, and quicker after-sales service.

-

Cost-effective logistics: Transporting heavy machinery can be expensive; choosing a local supplier reduces freight and handling costs.

-

Ease of maintenance and support: Local accessibility ensures that any downtime can be addressed swiftly — key when notebook production is a revenue driver for your business.

-

Regional demand advantage: Karnataka (and southern India more broadly) has a significant stationery manufacturing ecosystem; having the right equipment in place positions you well to serve regional markets and beyond.

-

Tailored solutions: Suppliers in the region understand local manufacturing contexts (power supply norms, workforce skill levels, service infrastructure) and can offer machines suited to your operational conditions.

Key Features & Specifications to Consider

When evaluating a notebook making machine, pay attention to the following features:

Production Capacity

-

Manual machines: lower throughput, higher operator involvement. For instance, one machine listed in India is manual with capacity ~3,000 per day. sbsmachine.com+1

-

Semi-automatic machines: moderate throughput, less labour, good balance. Example: semi-automatic with capacity 3,000 pieces/8 hrs. shkimachinery.com+1

-

Fully automatic machines: high throughput, minimal manual intervention. One example: capacity 1,000-1,500 pieces/hour or above. kolkatamachineryimportexport.com

Choose capacity based on your current production target, future growth, and staffing levels.

Automation Grade

-

Manual: All or most operations done by hand; lowest cost, highest labour requirement.

-

Semi-automatic: Some operations automated (e.g., cutting or stitching) but still some manual steps.

-

Fully automatic: End-to-end automation from feeding to finishing; suitable for large scale production.

Machine Construction & Materials

Quality machines are made of durable materials (mild steel, cast iron frames) and have components designed for heavy duty operation. For instance, a machine listing states “Machine Material: Mild Steel; Body Material: MS”. shkimachinery.com+1 Ensure good build quality, reliable brand, spare parts availability.

Power & Electrical Requirements

Check voltage, phase (single or three), power consumption (kW), and ensure compatibility with your factory setup. For example, some machines list 220 V / 3-phase. sbsmachine.com+1

Flexibility & Customisation

Look for the ability to produce different notebook sizes, thicknesses (page counts), binding types, finishes (edge squaring, trimming). One machine description mentions it is suitable for up to 192 page notebooks. Sikandar Machines

Maintenance & After-Sales Service

Be sure the supplier provides training, spare parts, service support and possibly installation. A machine may have excellent specs but if servicing is difficult it could lead to downtime. Local servicing is a plus especially in Srirangapatna / Karnataka.

Footprint & Layout

Consider the physical space (floor area, height) required, and ensure it fits into your manufacturing facility. Also consider material flow (paper in, binding out) and operator access. As machine size increases (especially fully automatic), space becomes a key factor.

Cost & Return on Investment (ROI)

Initial cost is only part of the story. Consider running costs (labour savings, material waste reduction, downtime), production throughput, yield quality and potential for higher margin products (premium notebooks) to evaluate ROI. Indian market intelligence indicates that manual machines start lower, while fully automatic can cost significantly more. Justdial+1

Benefits of Installing a Notebook Making Machine

Investing in the right notebook making machine offers multiple benefits for your stationery manufacturing business:

-

Higher productivity: With automation, you can produce more notebooks in less time with fewer manual steps.

-

Cost savings: Lower labour cost per unit, less waste from trimming, mis-cuts or manual errors.

-

Consistent quality: Uniform cutting, binding, trimming and finishing lead to better-looking products, fewer defects, fewer rejections.

-

Scalability: With capacity built in, you can meet growing demand and explore new markets (schools, offices, exports) without major incremental investment.

-

Product diversification: Many machines allow switching between sizes, page counts, binding styles—so you can produce exercise books, spiral notebooks, softcover notebooks, etc.

-

Competitive advantage: Being able to offer lower cost, faster lead-time, good finish gives you an edge in the stationery market.

-

Improved manufacturing workflow: One integrated machine reduces manual hand-offs, reduces intermediate storage, simplifies layout.

In a region like Srirangapatna and the broader Karnataka manufacturing belt, having such equipment placed properly means you can target regional demand, reduce turnaround time, and build reputation for quality.

How to Select the Right Machine for Your Needs

Here is a structured approach to selecting the right notebook making machine:

-

Define your output requirement

Consider how many notebooks you plan to produce per day or per shift. Are you producing for local schools, offices, export? For example, if targeting 2,000-5,000 notebooks/day, a semi-automatic machine might suffice. If planning 10,000+ units/day, a fully automatic machine becomes relevant. -

Determine product mix and flexibility

What size notebooks? What page counts? What binding style (stitching, glue, spiral)? Will you want to vary sizes and designs? Choose a machine that supports your product mix. -

Evaluate budget versus ROI

Decide your budget. Balance initial cost with production capacity, savings from automation, increased revenue. Always check total cost of ownership (maintenance, power, spare parts). -

Check supplier credentials

Choose suppliers with good reputation, local service network (ideally in or near Karnataka), and proven machines. Review case studies, ask for references. -

Check technical specs and compatibility

Ensure the machine fits your power supply (voltage, phase), factory space (floor area, height), material supply (paper in, finished product out). Also check for spare parts availability locally. -

Consider future growth

Select a machine with room to grow: higher capacity, additional features, ability to upgrade. This ensures you don’t outgrow the machine in a short period. -

Service and maintenance planning

Ask for training, documentation, spare part list, annual maintenance schedule, warranty terms. Consider location of nearest service centre and logistics for spare parts. -

Layout & installation

Plan the layout in your factory: raw paper storage, machine feed, finishing, packing. Ensure material flow is efficient, and have operators trained.

Use-Case: Notebook Manufacturing in Srirangapatna

If you are based in Srirangapatna, Karnataka and planning to enter or expand into notebook manufacturing with a notebook making machine, here is a plausible use-case to illustrate how things might play out:

-

You set up a manufacturing unit with a semi-automatic notebook making machine capable of 3,000 pieces per 8-hour shift.

-

You supply to local schools and offices in Karnataka, Tamil Nadu, Andhra Pradesh, leveraging proximity for fast delivery.

-

You choose a machine supplier offering installation, training and after-sales service in Karnataka (or with quick logistics to reach Srirangapatna).

-

With automation you reduce labour cost per notebook, improve finish quality, reduce waste. This allows you to price competitively and secure larger contracts.

-

Over time, as orders grow, you consider upgrading to a fully automatic machine with higher capacity (e.g., 1,000 + pieces/hour) so you can also target export orders or national distribution. kolkatamachineryimportexport.com+1

-

You ensure your factory layout is optimised: raw paper storage, cutting section, stitching/binding section, finishing & packing. You also invest in logistics close-by to ensure fast turnaround for local customers.

-

Marketing touts your ability to produce high-quality notebooks, fast delivery, local manufacturing in Karnataka — giving you an edge over import-only manufacturers.

Common Questions & Clarifications

Q1. What types of notebooks can be made using such machines?

You can make regular exercise book notebooks, ruled notebooks, soft cover notebooks, possibly spiral bound (depending on machine), and various sizes (A4, A5, custom) depending on machine flexibility.

Q2. What is the difference between semi-automatic and fully automatic notebook making machines?

Semi-automatic machines require some manual intervention (e.g., feeding paper or changing settings) whereas fully automatic machines handle most steps automatically (feeding, stitching/binding, trimming, finishing). Fully automatic machines therefore have higher throughput and fewer operator requirements. kolkatamachineryimportexport.com+1

Q3. Is it feasible for a small manufacturing unit to buy one?

Yes — a manual or semi-automatic notebook making machine is feasible for a smaller scale setup. If you currently produce fewer units or have limited budget, start with a semi-automatic machine and scale later. Check Indian listings: manual/ semi machines are available in a lower cost range. Justdial+1

Q4. What is the space requirement?

This depends heavily on machine size and capacity. Larger fully automatic machines may require substantial floor space and height clearance. You should ask the supplier for dimensions, and ensure your factory has room for the machine plus material handling space, operator access and maintenance access.

Q5. What about maintenance and spare parts?

Since notebook making machines involve mechanical motion (cutting, stitching, binding), regular maintenance is key. Check for availability of spare parts in your region (Karnataka / South India), and whether supplier offers service contracts. Factory uptime is important for profitability.

Q6. What binding types are supported?

Machines may support stitching (thread or wire), glue binding, edge squaring, trimming. Depending on your product line (exercise books, premium notebooks, spiral notebooks) you may need the appropriate binding mechanism. Some machines are described as “notebook making machine” inclusive of folding, stitching and edge squaring. Sikandar Machines+1

Summary & Recommendation

Selecting the right notebook making machine for your manufacturing unit in Srirangapatna, Karnataka is a strategic decision. Focus on the following winning elements:

-

Right capacity that matches your market demand

-

Appropriate automation grade (manual / semi / full) matching budget and workforce

-

Durable build, good supplier support, local serviceability

-

Flexibility in notebook size, binding style and finish quality

-

Efficient factory layout and logistics for delivery

-

ROI evaluation factoring in labour savings, waste reduction, quality improvement

By doing so, you position your stationery manufacturing business to leverage the growing demand for notebooks in India. In a region like Srirangapatna, with proximity to markets in Karnataka and South India, and with a well-selected notebook making machine, you can build a competitive edge: faster lead-time, reliable supply, consistent quality, and cost-efficiency