Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

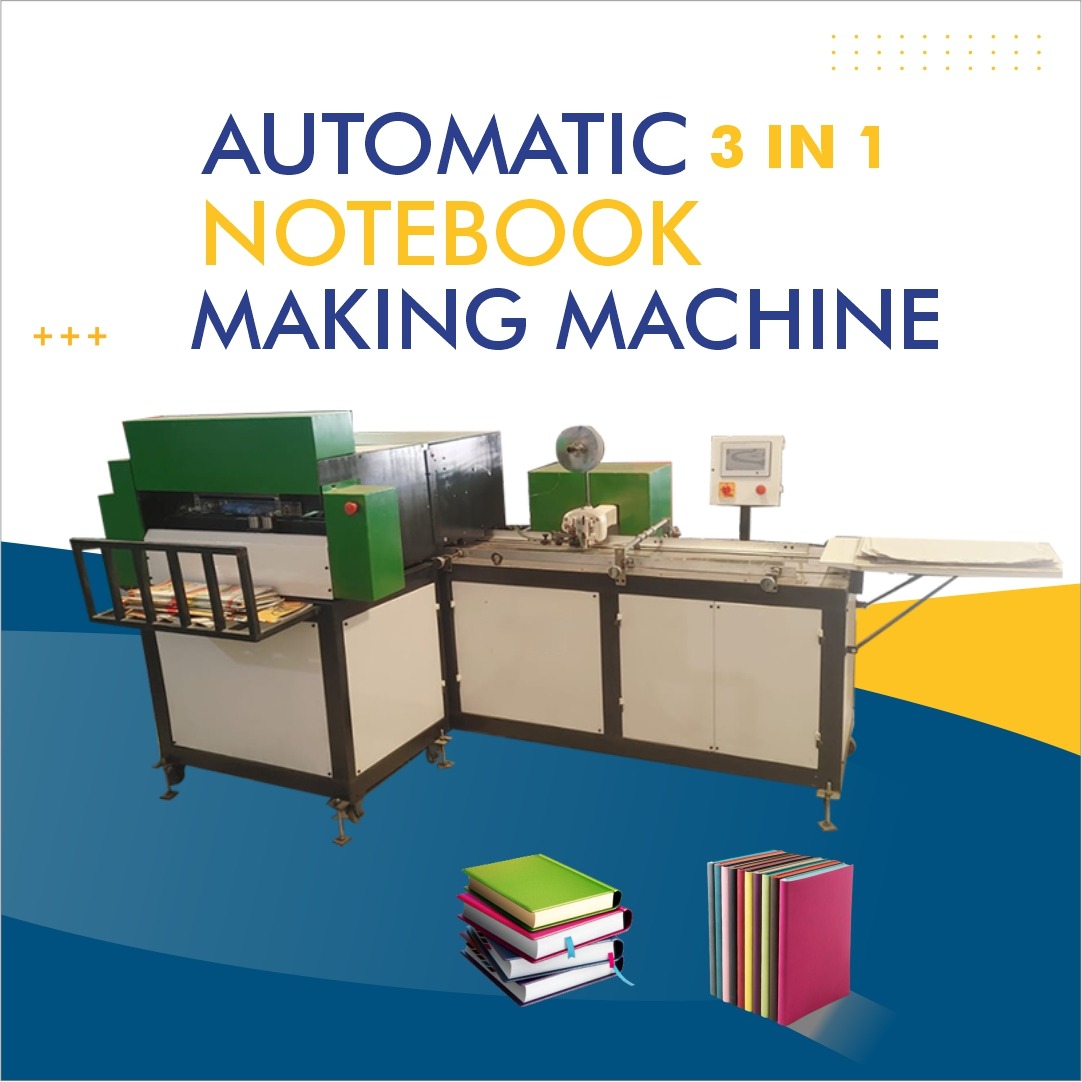

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Nelamangala Town Karnataka | High-Capacity Notebook Production Equipment

Notebook Making Machine in Nelamangala Town | Karnataka

In the expanding educational stationery market of India, investing in a robust notebook making machine presents a strong opportunity. Whether you are setting up a small-scale notebook production unit or upgrading your existing facility, choosing the right notebook production equipment in the right location—such as Nelamangala Town, Karnataka—is crucial. A reliable notebook making machine ensures consistent output, cost-efficiency, and production scalability.

This detailed guide covers everything you need to know: from what a notebook making machine is, its benefits, types (automatic, semi-automatic, manual), how to choose one, why Nelamangala Town is a good location in Karnataka, and key considerations for setup and operation of notebook manufacturing equipment.

Throughout this article the term notebook making machine will be used together with its synonyms to improve search visibility: notebook production equipment, notebook manufacturing machine, notebook machine, automatic notebook making machine, etc.

What is a Notebook Making Machine?

A notebook making machine is industrial equipment designed to manufacture notebooks at scale. It handles operations such as cutting paper sheets, folding, stitching or binding, cover lamination, edge squaring, trimming, and finishing. These machines streamline multiple production steps, improving output, quality, and turnaround time compared to manual processes.

For example, one model of automatic notebook making machine offers features such as multi-head wire stitching, folding mechanism, edge squaring, and PLC control for high precision. endurancemachinery.com+1 Other types include semi-automatic and manual setups. shkimachinery.com+1

Benefits of Investing in a Notebook Making Machine

When you choose the right notebook production equipment for your facility, you unlock several meaningful benefits:

-

High production capacity – Modern machines are capable of producing thousands of notebooks per day. For instance, a manual or semi-automatic notebook making machine setup might produce ~3,000 pieces/day. sbsmachine.com+1

-

Improved consistency & quality – Automated operations such as folding and stitching ensure uniform notebooks with professional finish, reducing rejects and wastage.

-

Labour cost savings – With mechanised processes, you require fewer hands for key steps, improving cost-efficiency, especially for high-volume production.

-

Scalability – As your business grows, you can scale by adding higher capacity machines (semi or fully automatic) or multiple units. For example, fully automatic setups produce 9,000-10,000 notebooks/day in some models. sbsmachine.com+1

-

Better turnaround time – Machines speed up batch production, making it easier to meet seasonal demand (e.g., new academic year) and manage large orders.

Types of Notebook Making Machines

The main categories of notebook manufacturing machine are: manual, semi-automatic, and fully automatic. Each has its pros and cons.

-

Manual notebook making machine: Requires more human intervention (cutting, folding, stitching). Lower cost entry point, suitable for small-scale production. Example: some manual setups produce ~3,000/day. sbsmachine.com+1

-

Semi-automatic notebook making machine: Certain operations are automated (e.g., stitching, folding), while others are manual. Balanced investment, good for mid-scale production. Example: a machine listed at capacity 3,000 pieces/8 hrs. shkimachinery.com

-

Fully automatic notebook making machine: Minimal manual intervention; highly automated line handles multiple tasks continuously. Best for large-scale production. For instance, a fully automatic machine using servo control & edge squaring with capacity up to 800 books/hour or 9,000-10,000/day. endurancemachinery.com+1

Why Choose Nelamangala Town Karnataka for Notebook Production?

Selecting a strategic location like Nelamangala Town in Karnataka offers tangible advantages for setting up notebook manufacturing with the right machine. Here are some reasons:

-

Industrial connectivity: Nelamangala is located near Bengaluru and benefits from good transport links, which makes logistics of raw materials (paper, covers, binding supplies) and dispatch to markets easier.

-

Lower operational cost: Compared to metropolitan areas, production units in smaller towns may have lower land, labour, and overhead costs, improving overall profitability.

-

Access to skilled labour: With educational institutions and nearby urban centres, staffing for machine operation, maintenance, and production supervision is feasible.

-

Growing stationery market in India: With rising literacy, education expansion, and increasing demand for notebooks (school, college, corporate), being located in Karnataka gives you good regional access to southern and western Indian markets.

-

Support infrastructure: With mechanical and machine-tool industries present in Karnataka, sourcing service, spare parts, and maintenance for notebook making machines becomes easier.

Selecting the Right Notebook Making Machine for Your Requirements

To make an informed investment in notebook production equipment, evaluate the following parameters:

-

Production capacity / Output: Estimate daily/weekly demand. If you need 3,000 notebooks/day, a semi-automatic or manual machine may suffice. For higher volume (5,000-10,000/day), go for fully automatic. For example a machine with 9,000-10,000/day capacity is already available. sbsmachine.com+1

-

Automation grade: Choose between manual, semi, and fully automatic based on budget, labour availability, and production targets.

-

Machine material & build: Ensure body & machine material (e.g., MS or mild steel) are robust to withstand continuous use. shkimachinery.com

-

Machine functions: Does the machine incorporate wire stitching, folding, edge squaring, trimming, lamination? Fully automatic lines include multiple integrated modules. For example, one machine includes multi-head wire stitching, folding, edge squaring and PLC control. endurancemachinery.com

-

Power & space requirements: Machines vary in size, phase (single or three), power consumption. E.g., fully automatic machine weight 900kg, 5 HP power. endurancemachinery.com

-

After-sales service & spare parts: It’s critical to choose a supplier who offers training, spare parts, service support.

-

Cost & Return on Investment: Calculate machine cost, installation, raw material cost, labour cost and estimate how many notebooks you need to sell for payback.

-

Compliance & Safety: Ensure the machine meets safety standards and your facility has appropriate safety measures (guards, electrical compliance, operator training).

-

Material compatibility: The machine should accept the size of paper, cover material, thickness of notebook you plan to manufacture.

Setup Considerations for Your Notebook Production Unit in Nelamangala Town

Once you procure the notebook making machine and set up your production unit, several practical factors will impact success:

-

Facility layout: Allocate proper floor space for the machine, raw material storage (paper, covers), finished goods storage, dispatch area, and service access.

-

Power infrastructure: Ensure stable three-phase supply if required, with proper earthing and safety switches.

-

Material supply chain: Establish supply relationships for paper reels/sheets, cover boards, binding wire, lamination film if used, packaging materials. Reliable supply ensures smooth production.

-

Quality control system: Set up checkpoints for raw paper quality, cover finishing, binding strength, final trimming to maintain consistency. Machines help reduce variability but human oversight remains important.

-

Operator training: Train your technicians and operators on setup, machine changeover, maintenance, defect troubleshooting. This improves machine uptime and reduces wastage.

-

Maintenance schedule: Regular maintenance of machine parts (stitching heads, folding unit, trimming blades) to avoid breakdowns. Having spare parts in inventory in Nelamangala will reduce downtime.

-

Packaging and dispatch: After manufacturing notebooks, you’ll need to pack them (shrink wrap, bundle) and dispatch. Location near Bengaluru helps logistic advantage.

-

Marketing & sales plan: Decide your target markets—schools, colleges, corporate notepads, customised notebooks. Establish sales channels (local distributors, online, direct supply to institutions).

-

Regulatory compliance: Ensure you are registered under appropriate business entity, have GST registration, and comply with local industrial regulations for manufacturing units in Karnataka.

Business Case Example for Notebook Manufacturing

Let’s assume you set up a semi-automatic notebook making machine in Nelamangala Town:

-

Machine capacity: ~3,000 notebooks/day (based on sources) shkimachinery.com+1

-

Working days: 25 days/month → 75,000 notebooks/month

-

Cost factors: machine amortisation, raw materials, labour, utilities, maintenance

-

Revenue: if you sell each notebook at a margin after material cost, the business can scale quickly.

With proper procurement of the right notebook making machine (using the synonyms: notebook production equipment, notebook manufacturing machine), you can capture opportunities in the educational stationery sector.

Key Benefits of Choosing a Local Supplier or Setting Up Near Nelamangala

Given the importance of after-sales service and proximity, setting your production in Nelamangala Town, Karnataka, offers practical benefits:

-

Closer access to suppliers and technical service providers for notebook machines in Karnataka.

-

Reduced logistics cost for inbound raw materials and outbound finished notebooks to south/west India markets.

-

Availability of manpower and local support infrastructure.

-

Potential for expansion as the stationery demand grows regionally.

Choosing Synonyms/Keywords Strategy

In this content we have repeatedly used the main keyword notebook making machine, along with synonyms: notebook production equipment, notebook manufacturing machine, notebook machine and variations like automatic notebook making machine, semi automatic notebook making machine to ensure search engines capture relevant traffic. The listing of multiple synonyms strengthens SEO relevance without keyword stuffing.

Summary

In summary, setting up a notebook manufacturing business in Nelamangala Town, Karnataka with the right machine—whether manual, semi-automatic or fully automatic—can be a strong strategic move. The key is selecting a high quality notebook making machine that meets your capacity needs, ensuring the facility is properly set up with suppliers, workforce, maintenance infrastructure, and marketing channels. By leveraging a central location like Nelamangala, you benefit from logistics efficiency and regional support. Use this guide to evaluate your options, narrow down the right notebook production equipment, and build a sustainable notebook manufacturing business.

By integrating the keywords and synonyms throughout this text we aim to ensure your content is well-optimized for search engines while providing valuable and detailed information for prospective buyers of notebook making machines.