Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

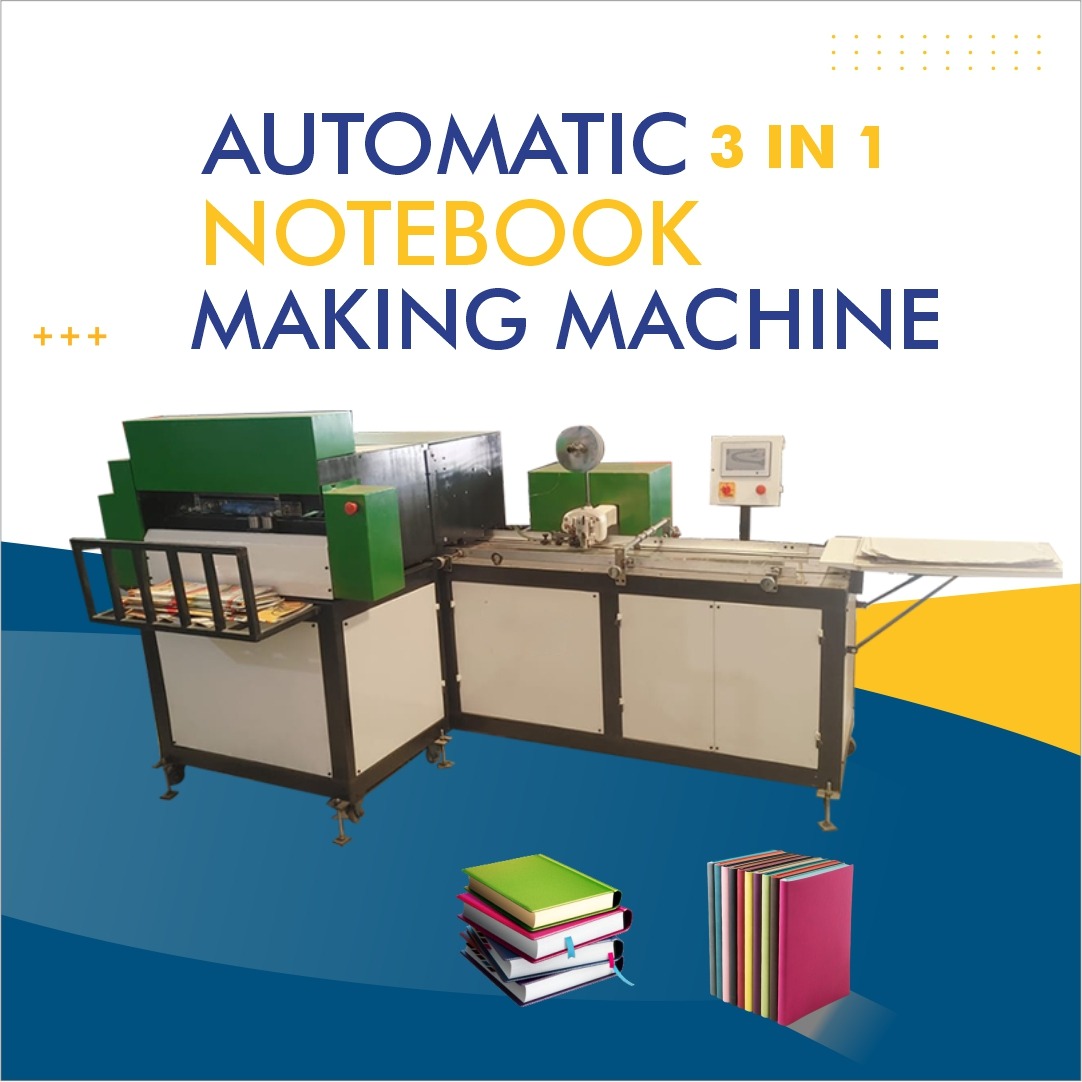

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Maddur, Karnataka – High-Capacity Notebook Making Machine Supplier

Notebook Making Machine in Maddur | Karnataka

If you are setting up or expanding your notebook production facility in Maddur (Karnataka), selecting the right notebook making machine is key to ensuring efficient output, high quality and competitive costs. In this comprehensive guide we’ll explore everything you need to know about notebook making machines: their types, features, benefits, selection criteria, maintenance, and how being based in Maddur, Karnataka gives you strategic advantages.

Throughout this content we use the keywords “notebook making machine”, “notebook manufacturing equipment”, “exercise book making machine”, “register making machine”, “semi automatic notebook machine”, “automatic notebook making line”, “notebook production machine India”, and “notebook machine manufacturer”. Variants and synonyms such as “notebook production equipment”, “notebook manufacturing machine”, “book-making machine for notebooks”, “exercise-book machine”, and “register production line” are also used for better coverage.

What is a Notebook Making Machine?

A notebook making machine is industrial equipment designed to automate or semi-automate the process of producing notebooks (exercise books, registers, writing pads). It takes raw materials such as paper sheets, cover boards, and binding materials and processes them through cutting, folding, stitching or glue binding, trimming, squaring and finishing to yield a finished notebook.

For example, one provider lists models of notebook making machine with production capacities of up to 3,000 pieces per day and automation grade “Manual” or “Semi-Automatic”. sbsmachine.com+1 Another manufacturer shows fully automatic notebook making machines with capacities of several hundred pieces per hour. guptamachinary.com+2endurancemachinery.com+2

In summary, a notebook making machine is the backbone of any notebook manufacturing equipment setup, enabling consistent production, higher throughput, better quality and reduced labour cost.

Why Choose Maddur, Karnataka for Notebook Machine Manufacturer

Locating your notebook manufacturing equipment or production in Maddur (Karnataka) offers several strategic advantages:

-

Central South India Location – Maddur lies within Karnataka, offering good connectivity to paper suppliers (from Karnataka, Tamil Nadu), printing services (in Bengaluru, Mysore), and logistics to major markets.

-

Lower Costs – Compared to large metros, locating in Maddur may reduce land, labour and overhead costs, improving the return on investment of your notebook making machine and related manufacturing plant.

-

Skilled Workforce – Karnataka has a growing manufacturing and machine-tools ecosystem; you can access technicians and machine maintenance talent for your notebook production machine line.

-

Supplier Proximity – Many notebook making machine manufacturers in India supply to Karnataka; easier service visits, spare parts inventory, and quicker lead-times.

-

Growth Potential – With demand rising for educational stationery in India, having a manufacturing base in Karnataka allows you to service regional markets efficiently.

Therefore, when you search for a notebook machine manufacturer or supplier of notebook making equipment in India, highlighting “Maddur, Karnataka” as your location signals to suppliers the logistics and support region you’re targeting.

Types of Notebook Making Machines & Equipment

When planning your notebook manufacturing equipment, you will encounter various machine types. Choosing the right combination can determine your efficiency, capacity and cost-effectiveness.

1. Manual Notebook Making Machine

These machines involve significant manual intervention and are suitable for small-scale production or startups. As one example: a manual notebook making machine full setup (brand SBS NB-01) offers production capacity of 3,000 per day, automation grade manual, power required 2 kW. sbsmachine.com

Pros: Lower cost, simpler maintenance, suitable for moderate runs.

Cons: Higher labour cost, slower production, more skill required.

2. Semi-Automatic Notebook Machine

These machines automate some processes (e.g., paper cutting or stitching) while others remain manual. For example, a semi-automatic notebook making machine with capacity of 3,000 pieces per 8 hrs is listed by one manufacturer. shkimachinery.com+1

Pros: Good balance of cost vs productivity, suitable for medium volume manufacturing.

Cons: Still requires operator oversight; not fully plug-and-play.

3. Fully Automatic Notebook Making Line

This comprises a complete production line with automated feeding, cutting, folding, stitching/gluing, trimming, squaring, and stacking — enabling large scale production. For example, a manufacturer claims servo-powered automatic notebook making machine includes multi-head wire stitching, folding, edge squaring, PLC control. endurancemachinery.com

Pros: Highest throughput, lowest per-unit labour cost, consistent quality.

Cons: High capital investment, needs more space and maintenance discipline.

4. Auxiliary Equipment

Besides the core notebook making machine, you will need supporting equipment, such as paper cutting machines, cover trimming machines, stitching machines, squaring machines, packing lines. These complement the notebook production machine to complete your notebook manufacturing equipment set. shkimachinery.com+1

Key Features to Consider in a Notebook Making Machine

When evaluating notebook manufacturing equipment for your plant in Maddur or elsewhere, make sure you assess these features:

-

Production Capacity: How many pieces per hour or per day can the machine deliver. For instance, some models offer 500 pcs/hr, 800 pcs/hr, or over 2,000 pcs/hr. guptamachinary.com+2endurancemachinery.com+2

-

Automation Grade: Manual, semi-automatic or fully automatic. Your choice depends on budget, space, labour availability, product variety.

-

Material Compatibility: Does the machine handle different cover materials, paper weights, thicknesses of notebooks? For example, a model says max notebook thickness 20 mm. guptamachinary.com

-

Machine Build Quality: Consider the body material (mild steel, stainless steel), frame rigidity, brand reputation, service availability. sbsmachine.com+1

-

Energy & Power Requirements: For example, one machine requires 2 kW, others 7 kW, single phase or three phase. sbsmachine.com+1

-

Footprint & Layout: The machine line may require significant floor space, good ventilation, material handling systems.

-

After-sales Service & Spare Parts: With a plant in Karnataka, ensure the manufacturer supplies service engineers and parts locally or regionally.

-

Product Flexibility: Ability to switch sizes, formats (A4, A5, custom), binding types (wire, glue, saddle stitch) to adapt product range.

-

Cost & ROI: Capital cost, running cost, labour savings, maintenance cost all feed into return on investment.

-

Quality Output: Consistent binding, squaring, trimming, minimal rejects. A good notebook making machine ensures high finished product quality.

Benefits of Investing in a Quality Notebook Making Machine

Here are the key advantages you unlock when you select the right notebook manufacturing equipment and notebook making machine:

-

Increased Production Efficiency: Automation reduces manual steps, speeds up output, and lowers labour cost. For example, fully automatic lines can deliver hundreds to thousands of notebooks per hour. guptamachinary.com+1

-

Improved Product Quality: Consistent cutting, stitching and binding ensures fewer defects, better finish, reduced wastage.

-

Scalability: As your business grows, you can upgrade from manual to semi-automatic to automatic equipment, adding capacity without fundamental redesign.

-

Cost-Effectiveness: Over time the higher throughput and lower labour cost deliver better unit economics.

-

Flexibility in Product Range: With good equipment you can offer a variety of notebook formats, cover types, sizes, finishes—meeting diverse customer demands.

-

Competitive Edge: In the stationery manufacturing market in India, being able to deliver high-quality notebooks at lower cost gives you a market advantage.

Setting Up Notebook Production in Maddur – Checklist

To successfully implement your notebook manufacturing equipment and machine line in Maddur, Karnataka, follow this practical checklist:

-

Site & Infrastructure

-

Choose a facility with adequate floor space, power supply (single phase/three phase), ventilation, dust control.

-

Ensure logistics access (transport of raw material — paper, cover board; dispatch of finished notebooks to markets).

-

Setup material handling areas (raw stock, work-in-process, finished stock).

-

-

Machine Selection & Layout

-

Based on your target volume pick manual, semi or fully automatic notebook making machine.

-

Plan the layout for the notebook manufacturing equipment: raw feeding → cutting → stitching/glue binding → trimming/squaring → packing.

-

Ensure adherence to safety, ease of maintenance and cleaning.

-

-

Power & Utility

-

Check machine power requirements (voltage, phase, kW). Some require three phase, 220-240 V or 380 V. shkimachinery.com+1

-

Install appropriate transformers or backup if necessary in Karnataka region.

-

Ensure compressed air, dust extraction and water (if required) are provisioned.

-

-

Raw Material Procurement

-

Secure paper sheets, cover boards, stitching wire or glue, binding materials.

-

Establish reliable suppliers nearby to Karnataka to reduce transit cost and lead time.

-

-

Labour & Training

-

Hire operators and maintenance staff; train them on notebook making machine operation, safety, quality checks.

-

Implement standard operating procedures for machine start-up, shutdown, maintenance.

-

-

Quality Control & Finishing

-

Set checkpoints for cover finish, binding strength, trimming accuracy, squaring of notebooks.

-

Invest in QC tools (micrometers, finishing tables, stacking systems).

-

-

Maintenance & Spare Parts

-

Maintain a log for machine uptime, service intervals, wear parts (blades, stitching heads, conveyors).

-

Stock critical consumables/spare parts locally in Karnataka region to reduce downtime.

-

-

Production Planning & Logistics

-

Plan runs based on demand for different notebook sizes and formats.

-

Coordinate dispatch to regional markets (Karnataka, Andhra, Tamil Nadu, Maharashtra) to optimize distribution.

-

-

Costing & ROI Monitoring

-

Monitor unit cost of production, scrap/waste levels, labour cost, utilities.

-

Compare to benchmarks to ensure profitability of your notebook manufacturing equipment investment.

-

Case Example: Typical Machine Specification

To illustrate, here’s an example specification from a semi or fully automatic notebook making machine:

-

Production capacity: 500 pcs/hour up to 2,400 pcs/hour depending on model. guptamachinary.com+1

-

Automation Grade: Fully Automatic, Semi-Automatic or Manual.

-

Material: Machine body made of MS (mild steel) or stainless steel. sbsmachine.com

-

Max notebook thickness: 20 mm (for a given model). guptamachinary.com

-

Voltage: 220 V (single phase) or 380 V (three phase) depending on size. shkimachinery.com

-

Additional features: Folding, stitching, edge squaring, PLC control (in high-end machines). endurancemachinery.com

When you approach suppliers or manufacturers for notebook making machine quotes, compare these spec points carefully.

Choosing a Manufacturer in India

Since you are based near Maddur, Karnataka, you will be seeking a machine manufacturer or supplier in India. Here are criteria to help you choose the right notebook machine manufacturer:

-

Experience & Reputation: Look for manufacturers with a track record in notebook manufacturing equipment, good client references.

-

Customization Ability: Ability to adjust the machine for your target notebook size, thickness, binding style, production volume.

-

Spare Parts & Service Network: Local or regional service support (especially in Karnataka / South India) is vital for machine uptime.

-

Training & Commissioning: The manufacturer should provide installation supervision, operator training, initial setup support.

-

Technical Documentation: Provide manuals, maintenance guidelines, spare part list.

-

Cost & Warranty: Transparent pricing, warranty period, after-sales support.

-

Upgradability: Option to upgrade machine automation or add modules as business grows.

Given the data above, you can shortlist a few suppliers & compare their offerings for notebook manufacturing equipment and notebook making machine lines.

ROI & Business Case for Notebook Production

Let’s outline how investing in the right notebook making machine and manufacturing equipment can translate into business results:

-

Reduced Labour Cost: A fully automatic notebook line reduces the need for manual operators per shift, thereby lowering wage cost per piece.

-

Higher Throughput: More notebooks produced per hour means you can meet larger orders or reduce lead time, giving you competitive advantage.

-

Lower Rejection & Waste: Better precision in cutting, binding, trimming reduces material wastage and improves margins.

-

Product Diversification: With good equipment you can make a variety of formats (exercise books, registers, specialty notebooks) and command higher price points.

-

Faster Break-Even: While capital cost is higher for automatic machines, the faster throughput and lower operational cost mean the payback period shortens.

-

Competitive Market Access: Based in Karnataka, you can serve South India markets with lower logistics cost and faster fulfilment.

Therefore, selecting the right notebook manufacturing equipment and notebook making machine is not just a cost centre — it becomes a strategic asset for your stationery business in Maddur and beyond.

Common Challenges & How to Address Them

When implementing a notebook manufacturing equipment line, you may face the following challenges:

-

Machine Downtime: Due to maintenance or lack of spare parts. Solution: Keep critical spares locally, schedule preventive maintenance, train operators.

-

Raw Material Variability: Paper/cover board thickness may vary leading to binding issues. Solution: Establish quality checks for incoming materials and calibrate the machine accordingly.

-

Operator Skill Gap: Even automated machines need skilled operators for setup and adjustments. Solution: Include training in vendor contract, maintain SOPs.

-

Space & Utilities Constraint: Fully automatic lines require space, proper power and ventilation. Solution: Plan plant layout early, ensure power backup or dedicated lines.

-

Market Demand Fluctuation: If notebooks demand drops, machine utilisation may suffer. Solution: Maintain product flexibility (different formats), pursue contract orders for schools, institutions.

-

Quality Defects: e.g., mis-stitched notebooks, unsquared edges, cover peeling. Solution: QC stations at critical stages, periodic machine checks and adjustment.

By anticipating these issues and incorporating mitigation strategies from the start, you ensure that your notebook manufacturing equipment investment yields the best results.

Why We Emphasize Keywords

For SEO effectiveness on your website (for example if you sell or supply notebook making machines in India or Karnataka), using keywords such as “notebook making machine”, “notebook manufacturing equipment”, “exercise book making machine”, etc., ensures your content targets search queries your potential customers use. Repeating relevant synonyms (e.g., “notebook production machine”, “notebook machine manufacturer”, “register making machine”) in a natural, non-spammy way helps search engine indexing while preserving readability.

Conclusion

If you are looking to establish or upgrade your notebook production facility in Maddur, Karnataka, investing in a high-quality notebook making machine and the associated notebook manufacturing equipment is a foundational step. The benefits—from increased throughput to improved quality, lower costs and scalability—make this decision strategic for long-term success.

By carefully selecting between manual, semi-automatic or fully automatic notebook production lines; assessing key features like capacity, automation grade, material compatibility, power requirements and service support; and ensuring solid planning for plant layout, raw material supply, operator training and maintenance — you can build a resilient and profitable notebook manufacturing business.

Should you need help shortlisting manufacturers, comparing machine models, assessing costs or planning implementation specific to Madhur/Maddur region (Karnataka), I’d be happy to assist further.