Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

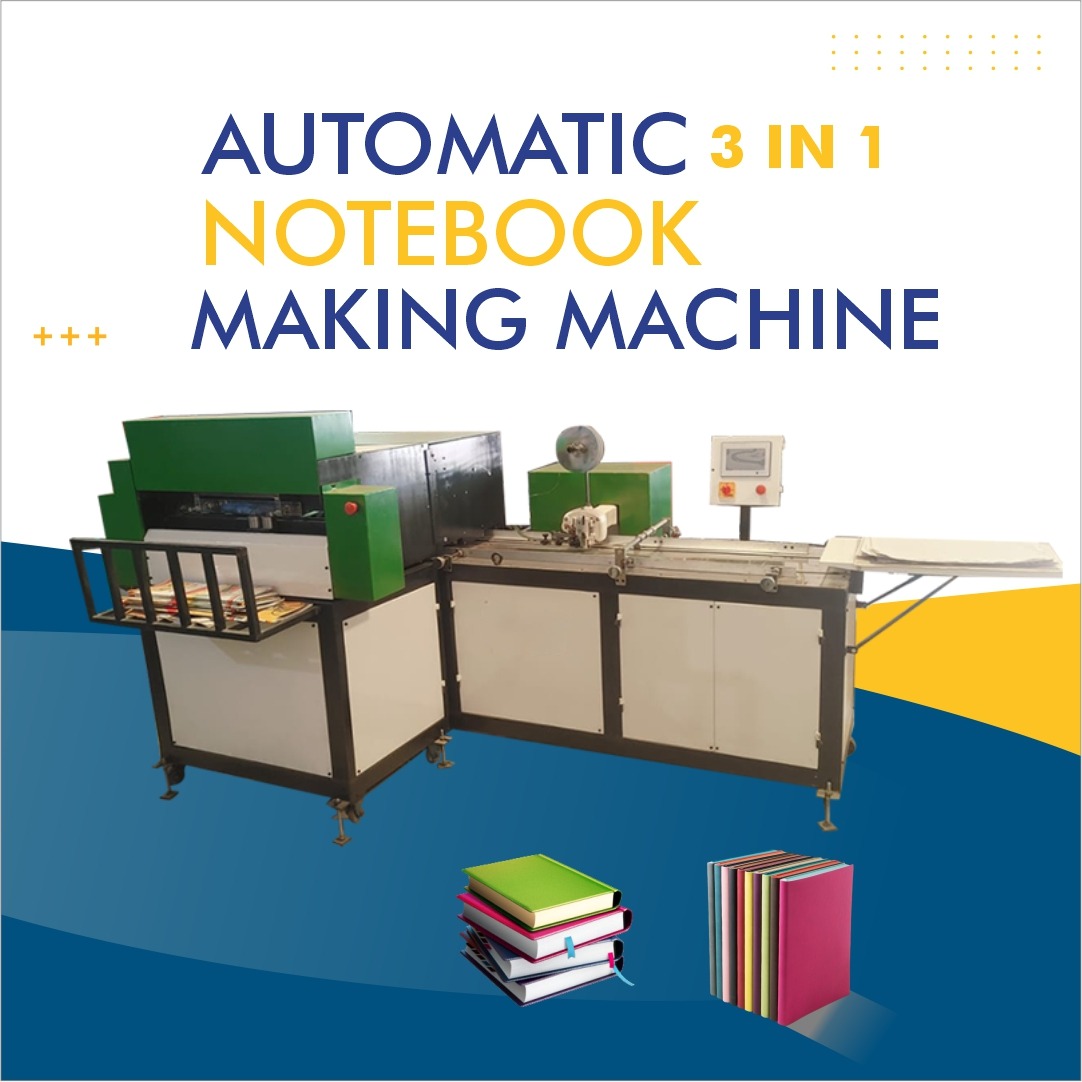

Notebook Making Machine Manufacturer in Chincholi Karnataka – High Efficiency Notebook Production Plant

Notebook Making Machine in Chincholi | Karnataka

If you are planning to establish or expand a notebook-manufacturing facility in or around Chincholi, Karnataka, investing in a high-quality notebook making machine is a strategic decision. Whether you aim to produce exercise books, spiral-bound notebooks, stitched pads or customized printed notebooks for schools and corporates, the right machine can dramatically influence your productivity, costs, and product quality. This article explores the features, benefits, selection criteria, and business advantages of a notebook making machine in Chincholi Karnataka.

In this content we will use our main keyword “notebook making machine” and a set of synonyms five times throughout: notebook production equipment, exercise book machine, book binding machine, automatic notebook line, stationery manufacturing machine.

Why Choose a Notebook Making Machine for Your Facility

The modern stationery market demands large volumes, fast turnaround, and consistent quality. A notebook making machine brings automation, precision, and repeatability.

Key advantages include:

-

Increased productivity: A dedicated notebook production equipment can process cutting, folding, stitching, binding and trimming in an integrated line, rather than manual or semi-manual workflows. cn-koten.com+2Laghu Udyog Bharat+2

-

Reduced labour costs: With automation, fewer operators are needed, reducing labour overhead and human errors. cn-koten.com+1

-

Improved quality and consistency: A book binding machine ensures each product meets the same size, binding, finish and appearance — essential when you supply schools or corporates. safireguna.com+1

-

Flexibility for different formats: A good automatic notebook line allows you to switch between sizes (A4, A5, custom), binding styles (wire, stitched, perfect bound) and covers (paper, laminated). Endurance Machinery

-

Better return on investment (ROI): Although the initial cost is higher than manual methods, the savings in time, waste reduction and scale make the stationery manufacturing machine worth it in the medium to long term. safireguna.com+1

Understanding Notebook Making Machine Features

When selecting a notebook manufacturing machine (or “notebook making machine”), you should carefully evaluate key features. Below are crucial parameters and how they impact your operations in Chincholi Karnataka.

1. Production capacity

The throughput you require depends on your market demand. Some machines offer hundreds of notebooks per hour, while high-end lines offer thousands. For example, one automated notebook line cited a production rate up to 800 books/hour with specific dimensions. Endurance Machinery

2. Automation level

Machines range from semi-automatic to fully automatic. A fully automatic notebook production equipment handles raw paper feeding, cutting, folding, stitching, trimming and stacking with minimal operator intervention. Higher automation = higher cost, but also higher throughput and lower labour cost. cn-koten.com

3. Material compatibility

Check that the machine supports the paper sizes, thicknesses, cover stocks and binding types you plan to use. If you want to produce exercise books, spiral notebooks, hard-cover notebooks or promotional notebooks you’ll need flexibility in the equipment. kesyainternational.com+1

4. Ease of operation & maintenance

A good machine should have user-friendly controls, quick changeover between formats, and accessible maintenance. Minimising downtime is critical in a facility in Chincholi Karnataka where resources and service may be more limited. cn-koten.com

5. Footprint & power requirements

Evaluate the physical size of the machine, the factory space you have in Chincholi, and power supply requirements (voltage, compressor, etc.). Some machines may require heavy power draw or compressed air. Endurance Machinery

6. After-sales service & spare parts

In a location like Chincholi Karnataka, support is essential. Choose a supplier with strong service network, spare parts availability and good reputation. This is a hallmark of a reliable stationery manufacturing machine investment. safireguna.com+1

Benefits of Installing the Machine in Chincholi Karnataka

There are specific advantages to basing your notebook production facility in Chincholi Karnataka and using the right machine.

-

Cost-effective location: Chincholi Karnataka may offer lower land/rent, labour and utility costs compared to metro regions, improving your competitive edge.

-

Regional logistics access: Proximity to Karnataka’s educational institutions, stationery markets and export corridors can help you scale distribution.

-

Local workforce: With basic training, local operators can manage the machine, especially if you invest in a simplified automatic notebook line.

-

Scalability: With a flexible notebook making machine, you can begin modestly and expand as demand grows, using the extra capacity later for new formats or value-added products.

-

Versatile product offerings: Use a single machine to produce standard notebooks, premium designer notebooks, customized corporate notebooks or branded stationery – which broadens your market reach and revenue sources.

Use Cases & Applications

Here are common applications for a notebook making machine:

-

Production of school exercise books (ruled, plain, graph) in bulk.

-

Corporate notebooks with customised covers and branding for events, promotions or internal use.

-

Premium spiral or hard-cover notebooks for retail stationery shops.

-

Bulk contract notebooks for institutions, publishers or exporters.

-

Seasonal products such as diaries, planners or themed notebooks.

Tips for Choosing and Implementing Your Machine

To ensure success, follow these practical steps:

-

Assess your target output volume, notebook types and formats for your Chincholi Karnataka facility.

-

Negotiate with multiple suppliers, focusing on those who provide robust automatic notebook line equipment and good service.

-

Visit demonstration units or existing users to evaluate performance, ease of changeover and real output.

-

Plan your factory layout: allocate sufficient space, power, raw material storage, finished goods area and operator station.

-

Train your staff in machine operation, maintenance, troubleshooting and changeover between formats.

-

Stock essential spare parts locally or ensure timely shipping from supplier, to minimise downtime.

-

Monitor your yield, waste, downtime and output regularly; strive for continuous improvement.

-

Consider expansion options: when selecting the machine, check whether the manufacturer offers modular upgrades or higher-capacity models.

-

Maintain rigorous quality checks: ensure your notebooks meet size specifications, binding security, finish standards and consistency. This helps preserve reputation and renew orders.

-

Leverage the machine flexibility: once you have the notebook making machine, explore value-added variants (branded covers, foil stamping, spiral binding, hard cover) to increase margins.

Addressing Common Challenges

Even with the best equipment, certain challenges may arise – but forewarned is forearmed.

-

Raw material variation: Variations in paper thickness, cover stock or binding wire may affect output quality. Ensure consistent supply of quality raw materials.

-

Operator skill gap: Although modern machines are automated, the human element still matters. Train operators to handle setup, change-over and minor issues.

-

Maintenance downtime: Scheduled preventive maintenance reduces breakdowns. In a location like Chincholi Karnataka, a breakdown can severely impact timelines.

-

Product mix changeover delays: If your business model includes multiple notebook formats, plan changeovers carefully and aim for quick changeover features.

-

Market fluctuation: Demand for stationery can vary seasonally (school cycles, corporate orders). Use your notebook production equipment’s flexibility to adapt to different product lines during slower periods.

-

Space and utility constraints: Ensure your facility in Chincholi Karnataka can support machine footprint, power requirements, ventilation and raw/final storage logistics.

Why Partner With Us for Your Notebook Making Machine in Chincholi Karnataka

By choosing us as your partner in establishing or upgrading your notebook manufacturing line in Chincholi Karnataka, you gain:

-

Access to high-quality notebook making machine models built for Indian conditions.

-

Local installation support, training and maintenance planning tailored for your facility.

-

Advice on machine selection, plant layout, workflow optimisation and raw material sourcing to maximise ROI.

-

Scalable solutions that allow you to start with essential requirements and grow into more advanced stationery manufacturing machine setups.

-

Commitment to quality, minimal downtime and continuous performance monitoring to ensure your notebook production equipment delivers as expected.

Conclusion

In today’s competitive stationery market, the choice of equipment can make or break your business. A robust notebook making machine offers you the productivity, quality consistency and flexibility that manual methods simply cannot match. When located in a business-friendly area like Chincholi Karnataka, this investment becomes even more attractive — lower costs, strong distribution opportunities and local workforce support.

By carefully assessing your output needs, machine features, after-sales support and factory readiness, you can set up a notebook manufacturing facility that is both efficient and future-proof. Whether you aim to produce bulk school exercise books, premium corporate notebooks or custom stationery lines, the right notebook production equipment will empower your business to succeed.

Make a strategic decision today: invest in the right notebook making machine, optimise your stationery manufacturing machine setup, and build your notebook business in Chincholi Karnataka with confidence and precision.