Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

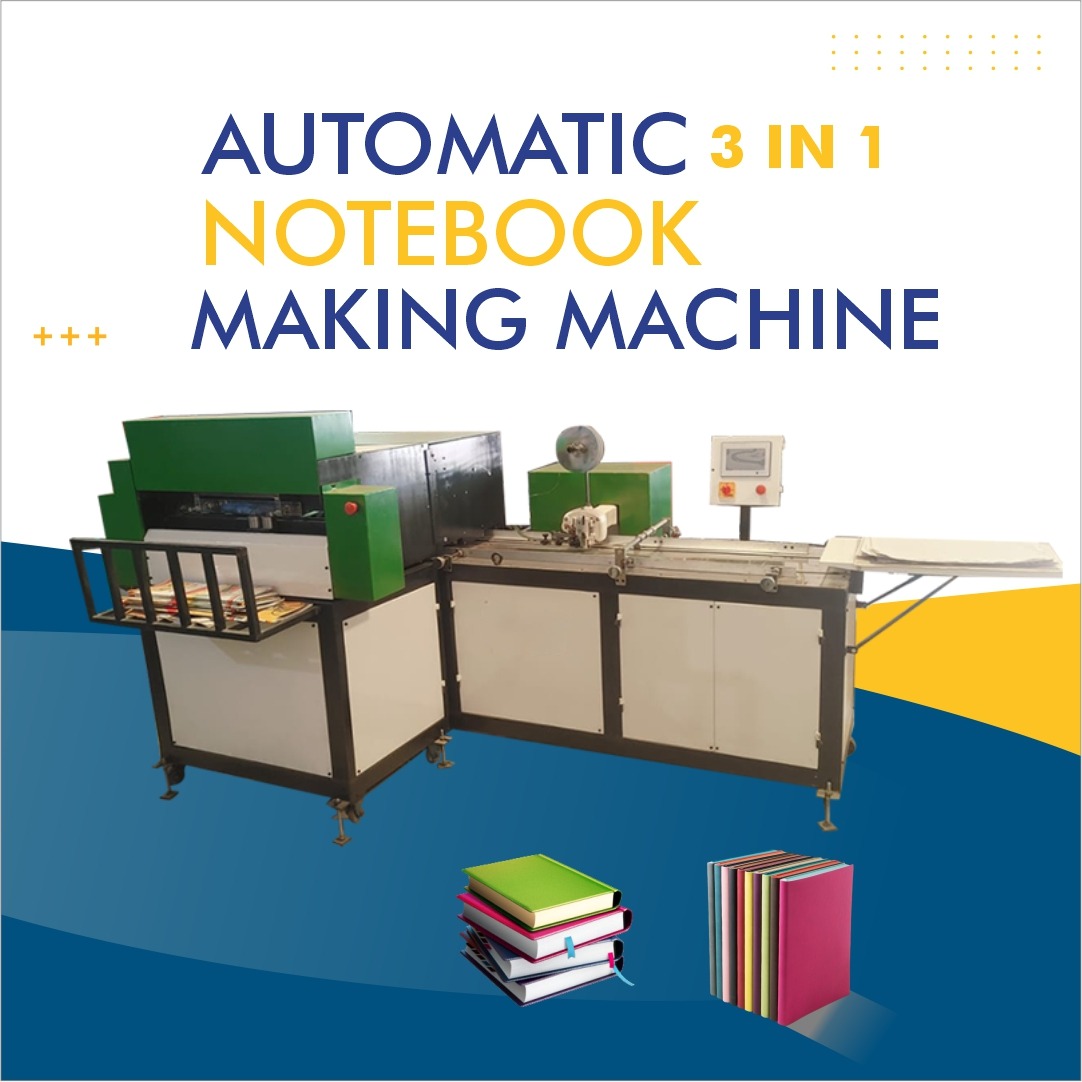

Buy High-Quality Notebook Making Machine in Mysuru, Karnataka

Notebook Making Machine in Mysuru | Karnataka

If you are in the market for a notebook making machine in Mysuru, Karnataka, you have come to the right place. In today’s competitive stationery and educational supplies industry, having a reliable and efficient notebook production system is crucial for ensuring timely output and consistent quality. Notebook making machines are the backbone of any notebook manufacturing business, whether small-scale or industrial. In this guide, we will cover everything you need to know about purchasing, using, and maintaining these machines, along with industry insights, types, and benefits.

What is a Notebook Making Machine?

A notebook making machine is an automated or semi-automated system designed to produce notebooks efficiently. It streamlines the entire process, from cutting paper to binding, and even finishing the notebooks with covers. These machines can handle various sizes, paper thicknesses, and binding types, making them versatile for different requirements.

Synonyms used in the context: notebook production machine, paper binding machine, stationery machine, school notebook machine, industrial notebook machine.

Types of Notebook Making Machines

1. Automatic Notebook Making Machine

The automatic notebook making machine is ideal for high-volume production. It combines multiple processes like paper feeding, cutting, folding, stitching, and cover attachment in a single operation.

Features:

-

High-speed production

-

Minimal human intervention

-

Consistent notebook quality

-

Energy-efficient operation

2. Semi-Automatic Notebook Making Machine

For small-scale businesses or startups, a semi-automatic notebook making machine offers cost-effective solutions. While some processes require manual input, these machines still increase production efficiency compared to fully manual methods.

3. School Notebook Machine

The school notebook machine is designed for producing standard-size notebooks used in schools and colleges. It focuses on efficiency, accuracy, and durability to meet educational standards.

4. Industrial Notebook Machine

The industrial notebook machine caters to large-scale production units, including factories producing thousands of notebooks per day. These machines are robust, fully automated, and capable of producing notebooks in bulk without compromising quality.

Benefits of Investing in a Notebook Making Machine

-

High Efficiency – A notebook production machine can produce hundreds of notebooks per hour, saving time and labor.

-

Consistent Quality – Automation ensures uniform cutting, binding, and finishing, reducing errors.

-

Cost-Effective – Though the initial investment might seem high, these machines reduce labor costs and material wastage in the long run.

-

Versatility – Modern machines support different notebook sizes, paper thickness, and binding methods.

-

Durability – Machines designed for industrial use offer long-term reliability, ensuring continuous operations.

Key Features to Look for in a Notebook Making Machine

When choosing a notebook making machine in Mysuru, Karnataka, consider the following features:

-

Speed – Check the production capacity per hour.

-

Paper Handling – Ensure the machine can handle multiple paper sizes and thicknesses.

-

Binding Options – Choose between stapling, spiral binding, or glue binding depending on your business needs.

-

Automation Level – Fully automatic machines are ideal for large-scale operations, while semi-automatic ones suit smaller businesses.

-

Maintenance – Look for machines with easy maintenance and readily available spare parts.

How to Maintain Your Notebook Making Machine

Proper maintenance ensures long-term performance and reduces downtime. Here are some tips:

-

Regular Cleaning – Keep the machine free from dust and paper residue.

-

Lubrication – Regularly oil moving parts to prevent wear and tear.

-

Check Alignment – Ensure paper guides, cutters, and stitching parts are properly aligned.

-

Routine Inspection – Inspect electrical components, belts, and gears for damage.

-

Use Genuine Spare Parts – Always replace worn-out parts with manufacturer-approved components.

Why Mysuru, Karnataka is a Good Market for Notebook Making Machines

Mysuru, Karnataka, has a thriving educational sector, small industries, and stationery markets. This makes it an ideal location for notebook manufacturing businesses. With growing demand from schools, colleges, and offices, investing in a notebook making machine here guarantees a consistent customer base and business growth.

Tips for Choosing the Right Notebook Making Machine Supplier

Selecting the right supplier is critical to ensure quality, warranty, and post-sales support. Here’s what to consider:

-

Experience – Choose a supplier with a proven track record in Mysuru.

-

Customer Support – Ensure they provide installation, training, and maintenance services.

-

Machine Quality – Check reviews and visit showrooms if possible to assess machine performance.

-

After-Sales Service – Reliable suppliers provide spare parts and technical support when needed.

Frequently Asked Questions

Q1: What is the average cost of a notebook making machine in Mysuru?

The cost varies depending on the machine type, automation level, and production capacity. Semi-automatic machines start from moderate investment, while fully automatic industrial machines are priced higher.

Q2: Can I produce different sizes of notebooks with one machine?

Yes, most modern machines offer versatility in handling multiple sizes and paper thicknesses.

Q3: How long does it take to set up a notebook making machine?

Setup typically ranges from a few hours to a full day depending on the complexity and automation level of the machine.

Q4: Is training provided for operating the machine?

Reliable suppliers usually provide comprehensive training to ensure operators can run the machine efficiently and safely.

Conclusion

Investing in a notebook making machine in Mysuru, Karnataka, is a smart decision for businesses looking to scale their notebook production. Whether you are a small-scale entrepreneur or an industrial manufacturer, choosing the right machine ensures efficiency, consistency, and long-term profitability. By focusing on quality, automation, and maintenance, your notebook production process can achieve higher output and meet growing market demands.