Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

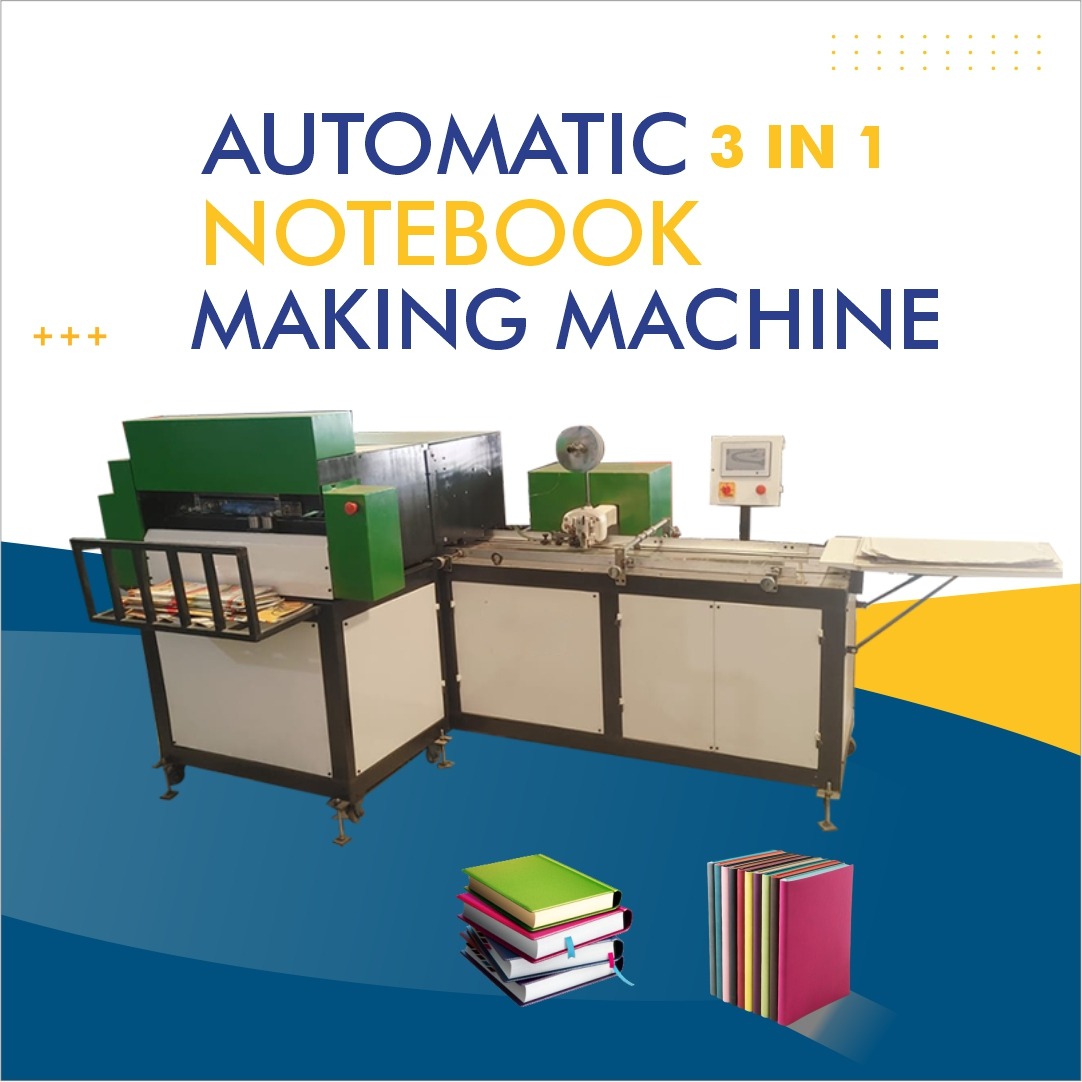

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Kanakapura | Premium Notebook Manufacturing Equipment

Notebook Making Machine in Kanakapura | karnataka

If you are planning to enter or expand in the stationery manufacturing industry, investing in a high-quality notebook making machine is one of the best decisions you can make. Especially if you are located in or near Kanakapura, Karnataka, you have the opportunity to leverage local advantages while utilising a notebook making machine to build a profitable business. In this comprehensive guide, we’ll explore everything you need to know about notebook making machines—from types and features to benefits, selection criteria and why Kanakapura is a good location for this business.

1. Introduction: Why a Notebook Making Machine?

In the stationery sector, notebooks remain one of the most basic yet essential products. The demand for notebooks is consistent—schools, colleges, coaching centres, offices and freelancers all need notebooks. A notebook making machine enables you to manufacture finished notebooks in-house rather than relying on outsourcing. This translates into improved cost control, faster turnaround and better customisation possibilities. With the right machine, you can operate at various production capacities—from modest output suited to a small business to high-speed lines suited for large scale manufacturing.

When you select the appropriate notebook making machine, you benefit from automation, precision cutting and binding, minimal wastage and the flexibility to produce different sizes and formats. For example, some machines are designed specifically for A4 size, others for A5, or for registers and exercise books. Many modern machines in India are built by local manufacturers, offering good value for money and easier servicing. shkimachinery.com+2guptamachinary.com+2

2. Types of Notebook Making Machines & Their Features

One of the first decisions you must make is the level of automation: manual, semi-automatic or fully automatic. Each has its own advantages and cost implications.

Manual Notebook Making Machine

These machines require significant operator involvement. For example, cutting, stitching or binding may all be handled manually or with minimal mechanisation. The benefit is lower initial cost, simpler setup and lower maintenance complexity. However, productivity is limited and labour costs are higher per unit.

For example, one Indian machine manufacturer lists a manual notebook making machine full setup for production capacity around 3000 pieces per day. sbsmachine.com

Semi-Automatic Notebook Making Machine

These machines represent a middle ground: certain functions (cutting, folding, stitching) are automated, but some manual steps remain. Semi-automatic machines offer improved productivity without the high investment of fully automatic lines. They are ideal for small-to-medium sized operations. According to sources, machines with capacity up to 550–650 pieces per hour are available. guptamachinary.com+1

Automatic Notebook Making Machine

Fully automatic machines manage most of the process end-to-end—feeding paper, cutting, folding, stitching or gluing, trimming, stacking. These are high-investment but allow high throughput and lower per-unit labour cost. For example, one supplier describes a machine capable of 1000-1500 pieces per hour. kolkatamachineryimportexport.com+1

3. Key Specifications & Features to Consider

When selecting a notebook making machine, you should pay attention to several important specifications and features to ensure you get what suits your business:

-

Production Capacity: Units per hour or per day. Higher capacities mean higher investment but lower cost per unit. Example: 3000 pcs/day in manual setups. sbsmachine.com

-

Automation Grade: Manual, semi-automatic or automatic. Choose based on your budget, labour availability and target output.

-

Machine Material / Build Quality: Machines made from mild steel, MS, or stainless steel, with robust construction will last longer. Example: “machine material stainless steel; automation grade semi-automatic”. guptamachinary.com

-

Voltage / Power Requirement: Machines vary in power requirement (single phase or three phase). Example: 220 V or 380 V depending. shkimachinery.com

-

Max Notebook Thickness / Size: Some machines can handle thicker notebooks or larger sizes, others are limited. Example: max thickness 20mm, notebook size A4. guptamachinary.com

-

Cutting / Stitching / Binding Quality: Precision cutting, neat stitching/folding, minimal errors. For example, one machine uses servo technology for pin-to-pin accuracy. endurancemachinery.com

-

Flexibility / Format Variation: Ability to switch sizes, designs, custom formats.

-

Service / Spare Parts / Local Support: Since you are in Karnataka (near Kanakapura), choosing a supplier with local service is a big plus.

-

Cost / ROI: Consider upfront cost, running cost, maintenance, labour savings and how long it takes to recoup your investment.

4. Why Kanakapura, Karnataka is a Good Location

Choosing the right location matters. If you are operating your notebook manufacturing business in or around Kanakapura, Karnataka, you gain several strategic advantages:

-

Proximity to Bengaluru / industrial region: Kanakapura lies in Bengaluru Rural district and is relatively close to the industrial ecosystem of Bengaluru. This means easier access to raw materials (paper, board, cover stock), logistics, skilled labour and service providers.

-

Logistics Advantage: Being in Karnataka enables access to south India markets, the Mangaluru port, and good road connectivity.

-

Lower Operating Costs: Compared to major metro zones, operating costs (land, wages, utilities) in Kanakapura may be more favourable.

-

Labour Pool: Karnataka has a skilled workforce for manufacturing. Starting with a notebook making machine, you can train staff locally.

-

Growth Potential: With rising demand for notebooks in India (schools, notebooks for coaching, corporate gifting), setting up in a well-connected region gives you room to scale.

-

Local Support Ecosystem: Several machine manufacturers and service suppliers operate in Karnataka and neighbouring states, making maintenance and spare parts easier.

5. Benefits of Investing in a Notebook Making Machine

Here are compelling benefits of purchasing a notebook making machine for your manufacturing setup:

-

Cost Efficiency: Once you invest in the machine, your per-unit cost drops significantly compared to outsourcing the notebook production. You can control margin better.

-

Quality Control: You control the entire process—from raw paper to finished notebook—which ensures consistent quality and reduces defects or returns.

-

Customisation & Flexibility: With your own machine, you can produce various formats (A4, A5, custom sizes), custom binding, covers, designs, and fulfil special orders quickly.

-

Faster Turnaround: You are not dependent on third-party vendors. With your own notebook making machine, you can respond to market demand quickly.

-

Scalability: As demand grows, you can upgrade from a semi-automatic to automatic machine or add multiple units.

-

Competitive Advantage: Having in-house capability sets you apart from competitors relying on external vendors; you can advertise faster delivery, customisation, better control, and local manufacturing in Karnataka.

6. Investment & Return Considerations

When making the investment, you must plan carefully for costs and returns. Here are some key considerations:

-

Initial Cost: Manual machines cost less but have lower capacity. Fully automatic machines cost more but have higher throughput. For example, one machine with capacity ~9000-10000 pcs/day is quoted at higher capital cost. sbsmachine.com

-

Running Costs: Electricity, labour, maintenance, consumables (covers, board, wire, stitching, glue) all impact cost per unit.

-

Labour Savings: Automating reduces labour per unit, improving profitability.

-

Utilisation Rate: Higher machine utilisation means better returns. Idle time reduces ROI.

-

Raw Material Cost & Supply: In Karnataka or near Kanakapura, ensure reliable supply of paper, binding material and cover boards, at competitive rates.

-

Market Pricing & Demand: Estimate how many notebooks you can sell, at what price, in your region. Corporate, institutional, retail markets vary.

-

Break-Even Time: Based on cost, capacity, unit margin, calculate how many units you need to manufacture and sell to cover machine cost and running cost.

-

Future Upgrades: Plan for scaling—if demand increases, you may need additional notebook making machines or automatic versions.

7. How to Select the Right Notebook Making Machine

Here is a step-by-step approach to selecting a machine:

-

Determine your production target: e.g., 1000 notebooks/day, 3000/day, or 5000/day. Choose capacity accordingly.

-

Decide automation level: If you’re starting small, a semi-automatic machine may suffice. If you anticipate large volume, go for automatic.

-

Verify machine specifications: size of notebooks, maximum thickness, material compatibility, power requirement, phase type, build material. For example, one semi-automatic machine lists capacity 550pcs/hr, MS body. guptamachinary.com

-

Supplier location and service: In Karnataka, choosing a supplier with nearby service centre helps.

-

Evaluate flexibility: Can the machine handle multiple formats, different sizes, most binding types (wire, stitched, glued)?

-

Consider maintenance & spare parts: Are parts easily available? Does the supplier provide installation and training?

-

Check references / reviews: Ask for case studies of existing users.

-

Budget & financing: Ensure you have funds for machine, installation, raw material stock, labour training, and working capital.

-

After-sales support & training: Good supplier will provide operator training and troubleshooting.

-

Location & facility readiness: Ensure your manufacturing unit near Kanakapura has adequate power supply (single phase / three phase as required), stable floor, dust-free environment if needed, raw material storage, and logistics for shipment.

8. Operating Your Notebook Manufacturing Setup with the Machine

Once you have selected and installed your notebook making machine, you need efficient operations. Here’s a breakdown:

-

Raw Material Procurement: Secure paper sheets (inside pages), cover boards, binding materials (wire, staples, glue) and packaging material.

-

Machine Setup & Calibration: Set up the machine for required notebook format (size, page count, cover design). Calibrate cutting depth, stitching depth or glue lines.

-

Production Workflow: Typically: cut pages → fold or stitch inside pages → attach cover/hard board → binding (wire/stitch/glue) → trimming/edge finishing → stacking & packaging.

-

Quality Control: Check for alignment, flawless binding, clean edges, correct page count, cover adhesion. Good quality reduces returns and enhances reputation.

-

Maintenance & Clean-up: Regular maintenance of blades, stitching heads, motors, cleaning of dust and debris helps longevity.

-

Labour Management: Even automated machines require supervised operators. Train staff in machine operation, routine maintenance, safety protocols.

-

Inventory & Supply Chain: Manage stock of raw material, schedule procurement, avoid stock-outs or overstocking.

-

Sales & Distribution: Build relationships with schools, institutions, office suppliers, stationery shops, export if viable. Since you are in Karnataka, you may also tap southern states.

-

Scaling Up: Monitor machine utilisation. If you reach capacity limits, plan for additional machine or upgrade to higher capacity model.

9. Challenges & Mitigation Strategies

No business is without challenges. Here are common ones in the notebook manufacturing business and how to address them:

-

Raw Material Price Fluctuations: Paper and board prices can vary. Mitigate by sourcing multiple suppliers, negotiating contracts, stocking strategic safety inventory.

-

Power Supply & Utilities: Machine may require stable three-phase power. Ensure your facility near Kanakapura has reliable power or consider backup.

-

Machine Downtime: Breakdown leads to lost production. Regular preventive maintenance and having spare parts helps.

-

Labour Quality: Skilled operators may be limited. Invest in training and choose machines with easier user interfaces.

-

Quality Issues / Rejections: Poor binding or mis-cut notebooks will hurt reputation. Implement stringent QC.

-

Market Competition: Notebook business is competitive. Differentiate via customisation, faster delivery, local manufacturing claims (“Made in Karnataka”), or niche formats.

-

Logistics & Distribution: Beyond production, ensure timely delivery. Being near Bengaluru helps but you must plan logistics to reach clients across south India.

-

Regulatory & Tax Considerations: Stationery manufacturing may have compliance requirements (GST, labour laws). Keep these in mind.

-

Scalability Constraints: Scaling up too fast without demand may cause under-utilisation. Use realistic demand projections.

10. Why Choose Us / Our Offerings (for Your Location)

If you are seeking a partner for notebook manufacturing equipment near Kanakapura, Karnataka, here is why working with a reputable supplier makes sense:

-

We offer a range of notebook making machines from manual to fully automatic, enabling you to choose based on budget & output.

-

Our machines are sourced from Indian manufacturers who understand local needs — robust build for Indian conditions, spare parts availability and service support. For example, Indian manufacturers offer machines with capacity 5000-6000 pieces per day. namibind.com

-

We support installation and training in the Karnataka region, so you get your operation up and running quickly.

-

Local support means quicker service turnout, lower downtime, better long-term support.

-

Our machines are designed for variable formats — you can manufacture A4, A5, exercise notebooks, registers—giving your business flexibility.

-

Cost-effective maintenance and operation help you maintain competitive pricing while preserving margins.

11. Success Stories & Market Potential

The notebook manufacturing business in India is seeing steady demand. With growth in education sector, stationery consumption remains robust. By bringing production in-house using a high capacity notebook making machine, manufacturers are able to tap into institutional orders, corporate gifting segments and retail channels.

For example, one machine manufacturer claims that a semi-automatic model can produce 7000 notebooks per day. asveng.com+1 The key is to have consistent demand, efficient operations and a machine that matches your output needs.

As you are based in Karnataka (Kanakapura region), you are well placed to serve southern Indian states, which often rely on manufactured goods from local hubs rather than distant centres. This proximity gives a competitive advantage in logistics, lead time and custom orders.

12. Frequently Asked Questions (FAQ)

Q1. What size notebooks can I produce?

A: Depending on the machine, you can produce common dimensions such as A4 (210×297 mm), A5 (148×210 mm), or custom sizes. Some machines support variable size cuts and binding formats. guptamachinary.com

Q2. How many notebooks can a typical machine produce?

A: Production capacity varies widely—manual machines may yield 3000 pieces/day; semi-automatic machines might reach 500-650 pieces per hour; high-end automatic machines can do 1000-1500 pieces/hour or more. kolkatamachineryimportexport.com+1

Q3. What is the difference between semi-automatic and automatic machines?

A: Semi-automatic machines still require manual intervention in certain steps (feeding, aligning, packaging). Automatic machines manage most steps automatically, resulting in higher productivity and lower labour cost.

Q4. What power and trade requirement should I check for?

A: Machines may require single-phase (220 V) or three-phase (380 V or 420 V) supply. Check power requirement, phase type, machine size, and ensure your facility at Kanakapura can handle this. Example: one machine spec: voltage 420 V. shkimachinery.com

Q5. What after-sales support is important?

A: Look for suppliers offering installation, operator training, spare parts availability, service centres, and prompt response. Especially since you are operating near Kanakapura, local access is important.

Q6. Is it viable to start small and upgrade later?

A: Yes. You can start with a semi-automatic machine and gradually upgrade as demand grows. Ensure your factory layout and power supply allowance permit scale-up.

Q7. What are common binding methods supported?

A: Many machines support wire-O binding, pin centre stitching, glue binding, register binding. Make sure the machine matches your target product type.

Q8. How long before I see return on investment (ROI)?

A: ROI depends on machine cost, running cost, labour savings, material cost, your pricing and utilisation. For example, if machine cost is recovered by margin per notebook × number of notebooks per day × days of operation. Detailed financial planning is advised.

13. Conclusion

Investing in a notebook making machine is a strategic move for anyone looking to enter or expand in the stationery manufacturing business. For operations based in the Kanakapura region of Karnataka, you benefit from favourable location attributes—including logistics, cost structure and skilled workforce. By selecting the right machine (manual, semi-automatic or automatic) aligned with your production targets, ensuring robust specifications and after-sales support, and executing efficient operations, you position your business for success.

The key action steps for you now:

-

Define your target production volume and format of notebooks.

-

Choose the right automation level and machine specification.

-

Assess your facility at Kanakapura (power, floor, logistics, labour).

-

Secure raw material suppliers (paper, board, binding material).

-

Choose a reliable machine supplier with local support.

-

Train your workforce, implement quality control, launch your product line.

-

Market your notebooks—retail, institutional, corporate—to fully utilise your machine capacity.

With the right approach, your notebook manufacturing venture can stand out—producing high-quality notebooks efficiently, meeting regional demand and gaining competitive advantage. You can anchor your business around the core keyword notebook making machine (and its synonyms) to ensure your website or marketing materials are SEO-optimised and discoverable by potential buyers.