Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

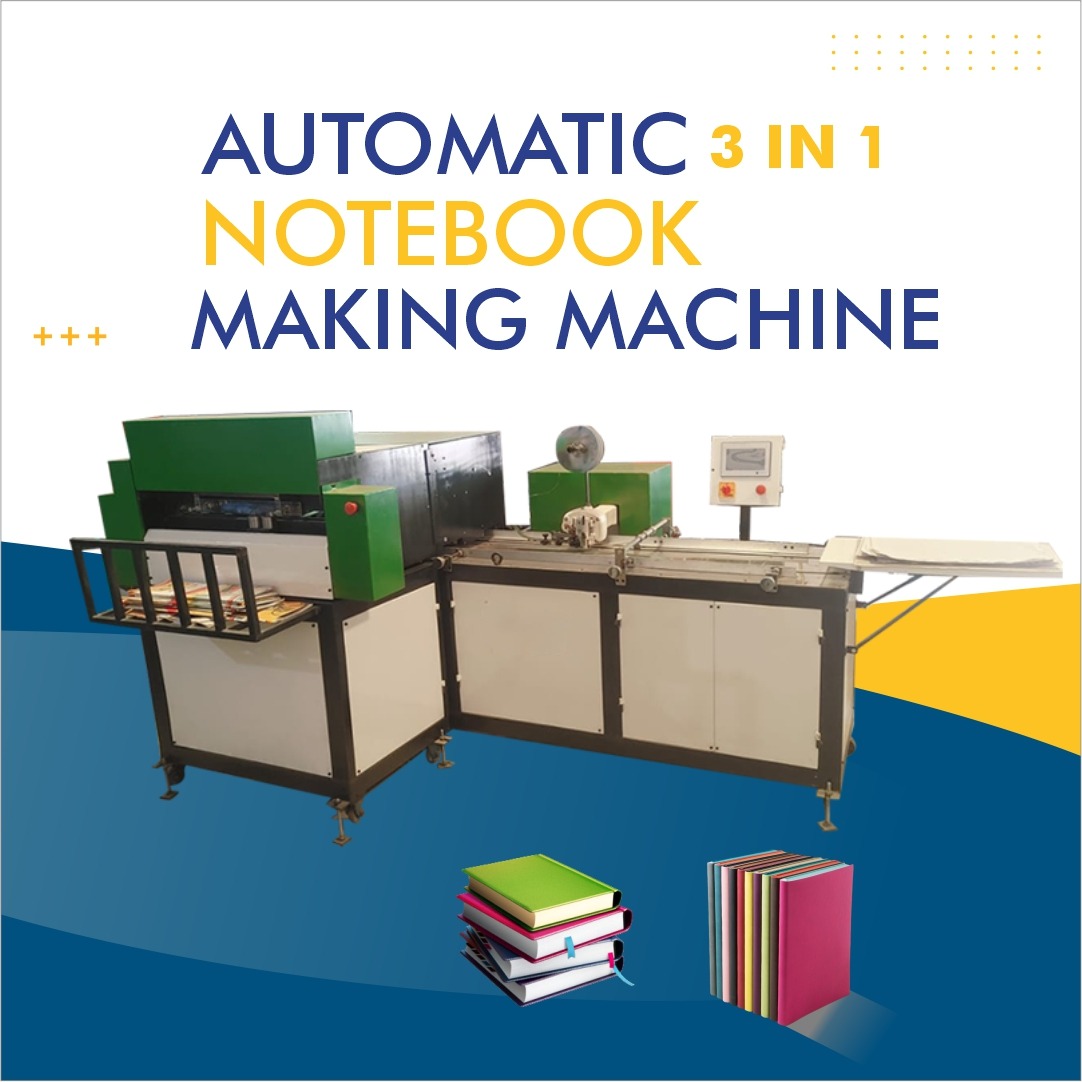

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Anekal Karnataka | High Capacity Notebook Production Equipment

Notebook Making Machine in Anekal | Karnataka

Setting up or upgrading a notebook manufacturing unit in Anekal, Karnataka requires choosing the right notebook making machine. Whether you are just starting a small-scale operation or scaling up to large volumes, selecting the proper machine is critical for efficiency, cost control, and quality. In this article we will explore the key considerations, machine types, technical specifications, advantages, local factors in Anekal, and how to evaluate suppliers. We will use multiple synonyms of our focus keyword (notebook making machine) throughout to reinforce relevance and clarity.

Why Invest in a Notebook Production Equipment?

Investing in reliable notebook production equipment (i.e., a notebook making machine) offers several benefits:

-

Higher production capacity: Modern machines can produce hundreds to thousands of notebooks per hour, improving throughput significantly. For example, some units are rated at 500 pcs/hour up to 2,400 pcs/hour. guptamachinary.com

-

Consistency and quality: Using a dedicated notebook manufacturing machine ensures standard dimensions, precise binding, and better finishes — leading to more professional notebooks.

-

Cost-efficiency: While the initial investment for a notebook making equipment may be significant, the operational cost per notebook goes down as volume increases and manual labour reduces.

-

Scalable operations: As demand grows, you can upgrade from a semi-automatic machine to an automatic notebook machine (notebook production line) without complete rebuild of your facility. For example, a fully automatic machine may include multiple functions in one line such as stitching, folding and edge-squaring. endurancemachinery.com

-

Competitive edge: With efficient notebook production equipment, you can reduce time-to-market, offer custom formats, and respond faster to changing market demands.

Understanding the Types of Notebook Making Machines

When selecting your machine, you will come across different categories. Here's a breakdown of the main types of notebook manufacturing machines:

| Type | Description | Best For |

|---|---|---|

| Manual notebook making machine | Basic setup, primarily manual operations (cutting, folding, stitching) with machine-assistance. Lower cost but labour intensive. According to one source, manual setups still exist at production capacity ~3,000 per day. sbsmachine.com | Very small scale operations or start-ups with low volumes |

| Semi-automatic notebook making machine | Some processes automated (e.g., feeding, trimming), while others still manual. Balanced cost vs productivity. e.g., 3,000 pieces per 8 hours. shkimachinery.com | Medium-scale production; businesses expecting mid-volume growth |

| Fully automatic notebook making machine | High-end equipment: automated feeding, stitching, folding, trimming, binding, edge-squaring. High throughput, low labour. Example: machine with 1,000-1,500 pcs/hr capacity. sbsmachine.com+2guptamachinary.com+2 | Large-scale manufacturing, high-volume orders, industrial setups |

Key Technical Specifications to Consider

When you evaluate a notebook making machine (notebook production equipment), keep these specs top of mind:

-

Production capacity: How many notebooks per hour/day? Higher capacity allows you to meet more demand. For instance, one machine claims 1,000-1,500 pcs/hr. sbsmachine.com

-

Automation grade: Is it manual, semi-automatic or fully automatic? Automation grade affects labour cost, space, and capital investment.

-

Material and build quality: Machine material (MS, mild steel, stainless steel) and build rigidity affect durability and maintenance. For example: machine body MS, machine weight 800–1200 kg. sbsmachine.com

-

Power requirement & utility: Check voltage, phase (single/three), power consumption (kW), and utility infrastructure in your location.

-

Size and format capability: What notebook sizes and thicknesses can the machine handle? For example, thickness up to 20 mm. guptamachinary.com

-

Flexibility & upgrade options: Can it be upgraded later? Does supplier provide modules?

-

After-sales support & parts availability: Especially important in Karnataka and around Anekal — local or regional support is a plus.

-

Space & infrastructure: Fully automatic machines require more floor-space, stronger foundations, and may need special utilities (air-compressor, etc).

-

Maintenance & ease of operation: Simpler machines may be easier to maintain but slower; highly automated machines require skilled operators and maintenance staff.

Specific Advantages of Installing Such Equipment in Anekal, Karnataka

Setting up your notebook production line in or around Anekal (Karnataka) presents several location-specific advantages:

-

Industrial zone infrastructure: Anekal is part of the Bangalore metropolitan region and has access to industrial parks, logistic connectivity, and utilities — beneficial when installing machine and setting up production.

-

Proximity to suppliers and markets: Being near Bengaluru means easier access to machine manufacturers, spare parts, servicing, and raw material suppliers (paper, covers, binding supplies).

-

Skilled manpower availability: The region has a workforce used to manufacturing jobs, which eases staffing for operating the notebook production equipment.

-

Cost-effective logistics: Transport to nearby markets, schools, stationery distributors in Karnataka and neighbouring states can be faster and cost-effective, making the investment in a good notebook manufacturing machine more viable.

-

Growth potential: The demand for notebooks (school, college, corporate) remains stable, especially in the Indian sub-continent. Having robust notebook making equipment means you can scale as regional demand rises.

-

Government schemes & incentives: Karnataka offers industrial incentives in certain zones which may help in purchasing large equipment and setting up manufacturing units.

How to Evaluate Suppliers & Choose the Right Notebook Machine in Anekal

When you approach suppliers for a notebook production machine, follow these steps:

-

Short-list reputable suppliers: Look for Indian manufacturers with proven track record, and ask for references. For example, some machines are clearly listed with capacity, brand, specifications. Namibind+1

-

Check demonstration & trials: Ask for machine demonstration or visit an operational setup. Understand how the notebook making machine (or notebook manufacturing machine) performs in real scenarios.

-

Clarify scope of supply: Some machines are just the core machine (cutting + binding), others are full line (cutting, stitching, folding, trimming). Confirm what is included.

-

Warranty & after-sales service: Ensure the supplier provides warranty, spare parts, and local service in or near Anekal / Bengaluru region.

-

Training and commissioning: Ask whether the supplier provides on-site commissioning, training of operators, documentation.

-

Cost vs ROI calculation: Estimate how much output you will get (notebooks per day) and what revenue that can generate. Then compare with machine cost + installation + operational cost to estimate payback period.

-

Space & infrastructure check: Ensure your factory site in Anekal has required power, floor load, ventilation, and space for the notebook making equipment.

-

Flexibility for future upgrades: If you start small (semi-automatic machine), ensure you can eventually upgrade to automatic notebook machine (notebook making equipment) when demand grows.

-

Local regulations & compliance: Ensure your unit complies with Karnataka’s regulations for manufacturing, waste handling, power connections, etc.

-

Material supply chain alignment: Make sure you have reliable supply of paper, covers, binding materials, and that your notebook production machine is compatible with the materials you intend to use (size, thickness, cover stock).

Example Machine Specifications & What They Imply

Here are some example data points to help you benchmark:

-

A manual notebook making machine full-set: production capacity ~3,000 per day, body material MS, power required 2 kW. sbsmachine.com

-

A semi-automatic notebook making machine: capacity ~3,000 pieces/8 hours, voltage 380 V. shkimachinery.com

-

A high-end automatic notebook making machine: capacity up to 2,400 pcs/hour (from one manufacturer). guptamachinary.com

From this you can infer: if you want to produce, say, 2,000 notebooks per day, a manual or semi-automatic machine may suffice. If you want 10,000+ per day, you will need an automatic notebook making equipment and corresponding investment.

Return on Investment (ROI) Considerations

To estimate ROI:

-

Determine your target output: e.g., 4,000 notebooks/day

-

Estimate selling price per notebook (depending on size, cover quality)

-

Compute daily revenue = output × price

-

Subtract operating costs: raw materials (paper, covers, binding), labour, utilities, maintenance

-

Capital cost: machine cost + installation + training + infrastructure modifications

-

Then estimate pay-back period = capital cost / (daily profit)

By choosing a suitable notebook manufacturing machine size now (based on likely growth), you ensure you don’t over-invest too early nor under-invest and lose business due to capacity constraints.

Why Choose A Notebook Making Machine Now in Anekal Region

-

Demand for stationery and notebooks remains robust, especially in education-driven markets like Karnataka and across India.

-

Local manufacturing in Anekal gives you shorter supply chains, control over quality, faster turnaround.

-

With a good notebook production equipment, you can cater to local schools, colleges, wholesale distributors, customizing formats (ruled, plain, spiral, stitched) and compete effectively.

-

Setting up now positions you for future growth whether you scale regional or national.

-

The advantage of local manufacturing is quicker iteration, faster product development, and better margin than relying purely on imports.

Potential Challenges and How to Mitigate

-

Machine downtime or service issues: Choose a supplier with local service, train on maintenance, keep spare parts in stock.

-

Material quality variation: Make sure your machine is compatible with the quality of paper/covers you use; conduct trials.

-

Power fluctuations: In many industrial zones, power stability may be an issue—plan for stabilizers or UPS if needed.

-

Operator skill level: For semi/fully automatic machines, hire or train operators; initial training is vital.

-

Space and layout constraints: Plan your production line layout properly in your Anekal site to accommodate machine, material flow, waste management.

-

Market competition: Having a high capacity notebook making machine is an advantage, but you must still manage cost, quality, delivery, and differentiation (custom covers, niche formats) to compete.

Summary & Recommendation

If you are looking to purchase a notebook making machine in Anekal, Karnataka, here is a suggested roadmap:

-

Define your production target (e.g., notebooks per day/month).

-

Choose automation level accordingly (manual → semi-automatic → automatic).

-

Short-list 2-3 suppliers, evaluate their machine specs, service support, cost.

-

Prepare your factory site for the machine (power, space, raw material input & output, waste management).

-

Budget for the machine cost + installation + commissioning + training.

-

Perform a financial model (cost vs expected revenue) and evaluate payback period.

-

Make the purchase, ensure installation and training, and then monitor production, quality, maintenance.

-

Plan for future scale-up: ensure your machine can be upgraded or you can add machines when demand grows.

With careful planning and investment in the right notebook production equipment (notebook manufacturing machine), you can establish a high-quality, efficient notebook manufacturing operation from your Anekal base, serving Karnataka and beyond.