Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

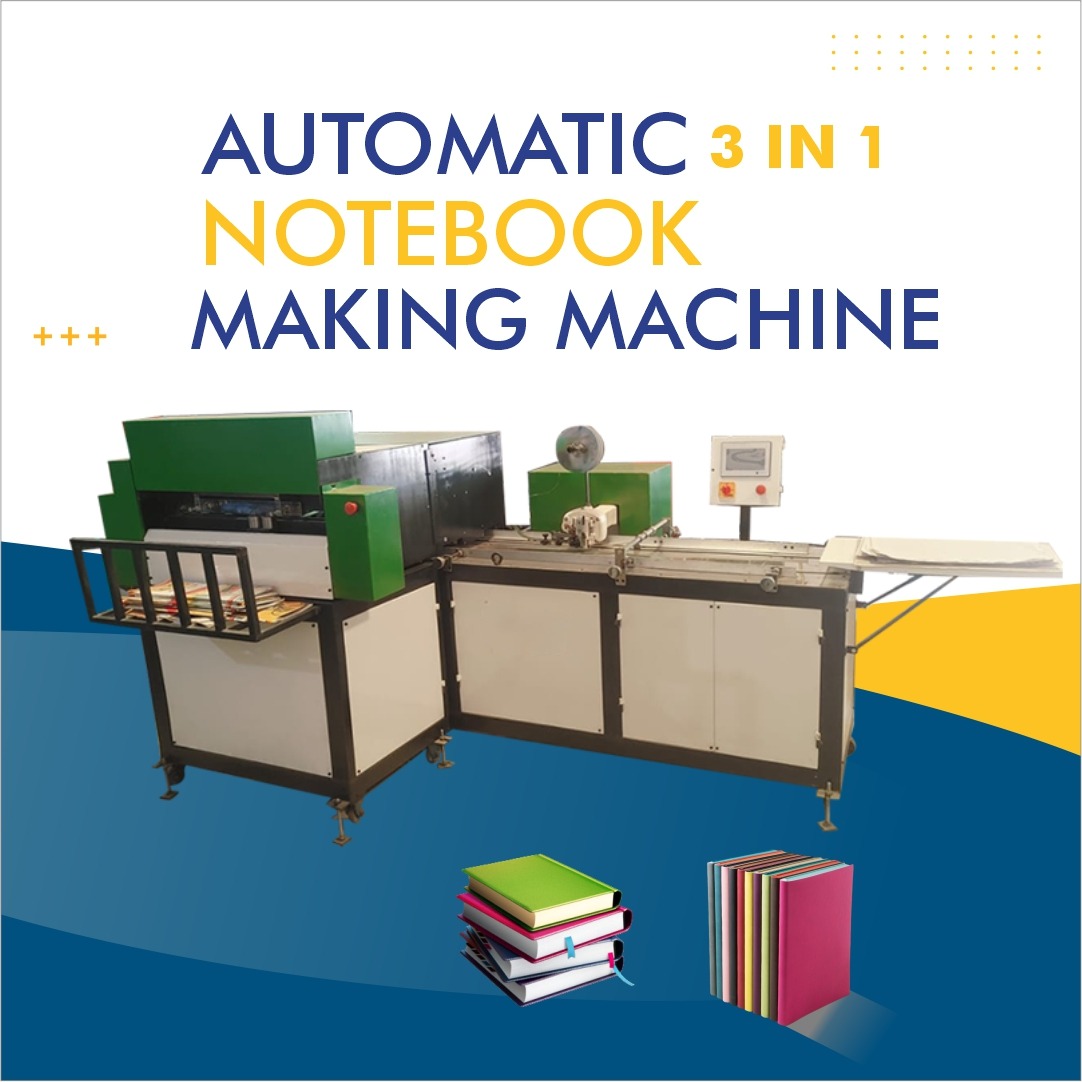

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Hussainabad Jharkhand | High-Quality Equipment

Notebook Making Machine in Hussainabad | Jharkhand

If you are searching for a high-performance Notebook Making Machine in Hussainabad, Jharkhand, your search ends here. Whether you are setting up a small-scale notebook manufacturing shop or upgrading your existing binding line, choosing the right notebook production equipment is critical for product quality, production speed, and return on investment. This page gives you a comprehensive guide to selecting, installing, and maintaining a notebook making machine — especially tailored for businesses in Hussainabad and nearby districts of Jharkhand.

Why Choose Local Supplier in Hussainabad, Jharkhand?

-

Proximity and responsiveness: A supplier located near Hussainabad can offer timely installation, commissioning, and after-sales service.

-

Customisation: Local machine builders familiar with local standards (voltage, sizes, raw-material availability) can design notebook production equipment customised to your needs.

-

Cost-saving: Reduced freight cost and local support help you save on shipping and import overheads.

-

Regulatory compliance: Local vendors are more aware of Jharkhand or Indian manufacturing regulations, which simplifies certifications, safety compliance, and statutory inspections for your book binding machine or binding equipment.

What Is a Notebook Making Machine?

A notebook making machine combines several mechanical and electrical subsystems to convert raw materials (paper sheets, card covers, adhesives, staples, wire-rings, threads) into finished notebooks. These machines may include processes such as cutting, folding, creasing, stacking, binding (stapling or glue), punching, and trimming. The notebook manufacturing machine may be manual, semi-automatic or fully automatic based on capacity and budget.

Synonyms for notebook making machine include notebook production equipment, book binding machine, paper binding machine, and binding equipment.

Key Components & Features

When evaluating a notebook making machine, consider these key features:

-

Cutting unit

Precision cutter to cut paper and covers to correct sizes. Adjustable blade clearance for different thickness. -

Folding / creasing module

To fold sheets uniformly, helpful for center-pages or special layouts. -

Stacker & feeder

Automatic feeding of prepared pages and covers into binding line. -

Binding mechanism

-

Wire-or spiral binding

-

Staple / saddle-stitch binding

-

Perfect glue binding

Choose depending on your notebook format.

-

-

Punching / Perforation

Holes for ring binding or micro-perforations for tear-off sheets. -

Trimming / edge finishing

Side & head trimming to give professional finish. -

Control System & Automation

PLC-based control panel, automatic safety sensors, speed control (sheets per hour), changeover settings. -

Material Handling & Frame Quality

Heavy-duty frame, good quality rollers, guides and bearings, rust-resistant finish to suit local climate (monsoon, humidity in Jharkhand). -

After-sales & spare parts availability

Local servicing for motors, belts, knives, and electronic spare parts ensures your notebook production equipment runs with minimal downtime.

Types of Notebook Making Machines

| Type | Description | Typical Use Case |

|---|---|---|

| Manual / Semi-Automatic | Lower cost, operator-driven feeds and binding | Small workshops, startup businesses |

| Fully Automatic | Continuous feed, high capacity, minimal manual intervention | Industrial scale production |

| Modular / Hybrid | Combination of manual modules with automatic binding or finishing | Medium-scale manufacturing |

Choosing the Right Machine for Hussainabad Users

When selecting a notebook making machine near Hussainabad, Jharkhand, you need to consider:

-

Production quantity you expect (e.g. notebooks per day or per hour).

-

Sheet size & cover size (standard A4, A5, custom sizes).

-

Binding style (wire/spiral, stitched, glue).

-

Power supply & voltage compatibility in your area.

-

Budget constraints and return on investment.

-

Space available in your factory or workshop.

-

Local environment (humidity, dust, seasonal conditions in Jharkhand).

-

After-sales service & spare parts availability nearby.

Benefits of Investing in a Quality Notebook Making Machine

-

Enhanced Productivity

Automated or semi-automated notebook production equipment increases throughput, reduces manual errors, and allows you to meet high targets. -

Consistent Quality

Precision cutting, uniform binding pressure, and accurate trimming offer a high-quality notebook edge finish and guarantee reliability—helpful for school/college buyers or corporate packaging. -

Cost Efficiency

Reduced waste of paper or cover board, lower labor cost per unit, and less downtime results in lower cost per notebook. -

Scalability

As your business grows, you can upgrade parts of your machine (e.g. digital feeder, more binding heads) or install extra modules without replacing the whole system. -

Competitive Advantage

Customers looking for premium notebook finish will prefer you over competitors relying on manual binding.

Installation & Maintenance in Hussainabad

To ensure your notebook production machine serves you for many years, it is important to follow proper installation and regular maintenance routines:

-

Pre-installation site survey

Check workshop floor-load, electric wiring capacity, ventilation and dust protection before final installation. -

Commissioning and Testing

Run test batches of notebooks — check alignment, binding strength, trimming tolerance, bleed margin issues, and check machine safety features. -

Routine Maintenance Schedule

-

Daily cleaning of feed rollers, knives and guides.

-

Weekly lubrication of moving parts.

-

Monthly belt-tightening and alignment checks.

-

Annual full calibration and safety audit.

-

-

Spare Parts Stocking

Keep consumables (blades, staples, adhesives or binding wire) in stock locally in Hussainabad or nearby city (e.g. Garhwa or Latehar) to reduce downtime. -

Training Operators

Provide hands-on training to your staff about machine operation, safety and minor troubleshooting.

Use Cases & Applications

-

School & Student Notebooks

Producing lined, ruled, or graph-paper notebooks for students studying in local schools around Hussainabad and Jharkhand. -

Custom Diaries & Journals

Small businesses or freelance printers may offer personalised covers, embossing or branding — the notebook making machine must support such customisation. -

Corporate Gift Notebooks

Bulk production runs of corporate-branded notebooks and planners for offices nearby or in larger cities like Ranchi or Bokaro. -

Promotional Items

Events, expos or fairs in Jharkhand require promotional notebooks; fast turnaround and high-quality finish helps fulfil those orders.

Cost & Return on Investment

| Item | Typical Cost | Notes |

|---|---|---|

| Entry-level semi-automatic binding & trimming machine | ₹ X lakhs | Depends on capacity, binding type, and automation |

| Fully automatic notebook production equipment | ₹ Y lakhs | Higher investment but much faster throughput |

| Operating Cost (power, labor, maintenance) | Monthly estimate | Depends on electricity tariff in Jharkhand, operator wages, and maintenance frequency |

| Break-even Time | Estimated months | Based on production volume and selling price of notebooks in local market |

For example, if you plan to manufacture 5,000 A4 notebooks per day and sell them to local schools, your notebook making machine could pay for itself within 12–18 months depending on your pricing and demand consistency.

How to Select a Vendor in Hussainabad / Jharkhand

When selecting a supplier of notebook production equipment or book binding machine in Hussainabad region, consider:

-

Reputation and reviews of previous buyers.

-

On-site demonstration or factory visits.

-

Warranty period and service contract.

-

Training support for machine operators.

-

Availability of spare parts in Jharkhand or neighbouring states.

-

Customisation options for your binding style, paper size, or finishing preferences.

Case Study: Hypothetical Setup in Hussainabad

Suppose you have a small workshop in Hussainabad city centre. You wish to produce 2,000 A5 notebooks per day with spiral binding. You enquire with a machine supplier in Jharkhand who installs a compact semi-automatic notebook manufacturing machine with trimming, punching, spiral-insertion module, and final wrap/pack area. Within six months, you expand your order to local schools and fairs. Thanks to local servicing and quick spare-parts delivery, downtime is minimal. You upgrade later to a faster feeder module, scaling output to 5,000 notebooks daily.

Frequently Asked Questions (FAQ)

Q. What is the minimum investment required for a notebook making machine near Hussainabad?

A. That depends on capacity and automation level. A basic semi-automatic binding and trimming setup might start modestly, while a fully automatic line will cost more but deliver higher throughput.

Q. How can I ensure quality finish in a humid climate like Jharkhand?

A. Choose machines built with moisture-resistant material (galvanised or powder-coated frames), maintain climate-controlled storage of raw paper and covers, and calibrate binding tension regularly.

Q. Is it possible to customise the machine for non-standard sizes or branding?

A. Yes. Local manufacturers often provide custom jaw widths, custom cover sizes, or programmable settings to suit your product design.

Q. How long is the support or warranty period?

A. Ideally you should look for at least 6-12 months warranty plus local servicing for spare parts and regular maintenance agreements.

Q. What raw materials do I need to source for notebook manufacturing in Hussainabad?

A. You will need paper sheets (ruled or plain), cover boards or laminated card covers, binding wire or staples or glue, packaging materials, and possibly protective shrink-film or wrapping.

Conclusion

Investing in a good notebook making machine (or notebook production equipment) is the backbone of any notebook manufacturing venture. When you are based in Hussainabad, Jharkhand, partnering with a local supplier of book binding machine or binding equipment gives you significant advantages — lower shipping costs, quicker service, and local customisations. By carefully assessing your production volume, binding style, automation level, and maintenance support, you can achieve high quality, consistent output and good return on investment.

If you want to explore options, request a quote, or arrange a demonstration of a notebook manufacturing machine in Hussainabad, feel free to contact local suppliers or schedule a site inspection. Choose the right binding machinery today to power your notebook manufacturing business tomorrow.