Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

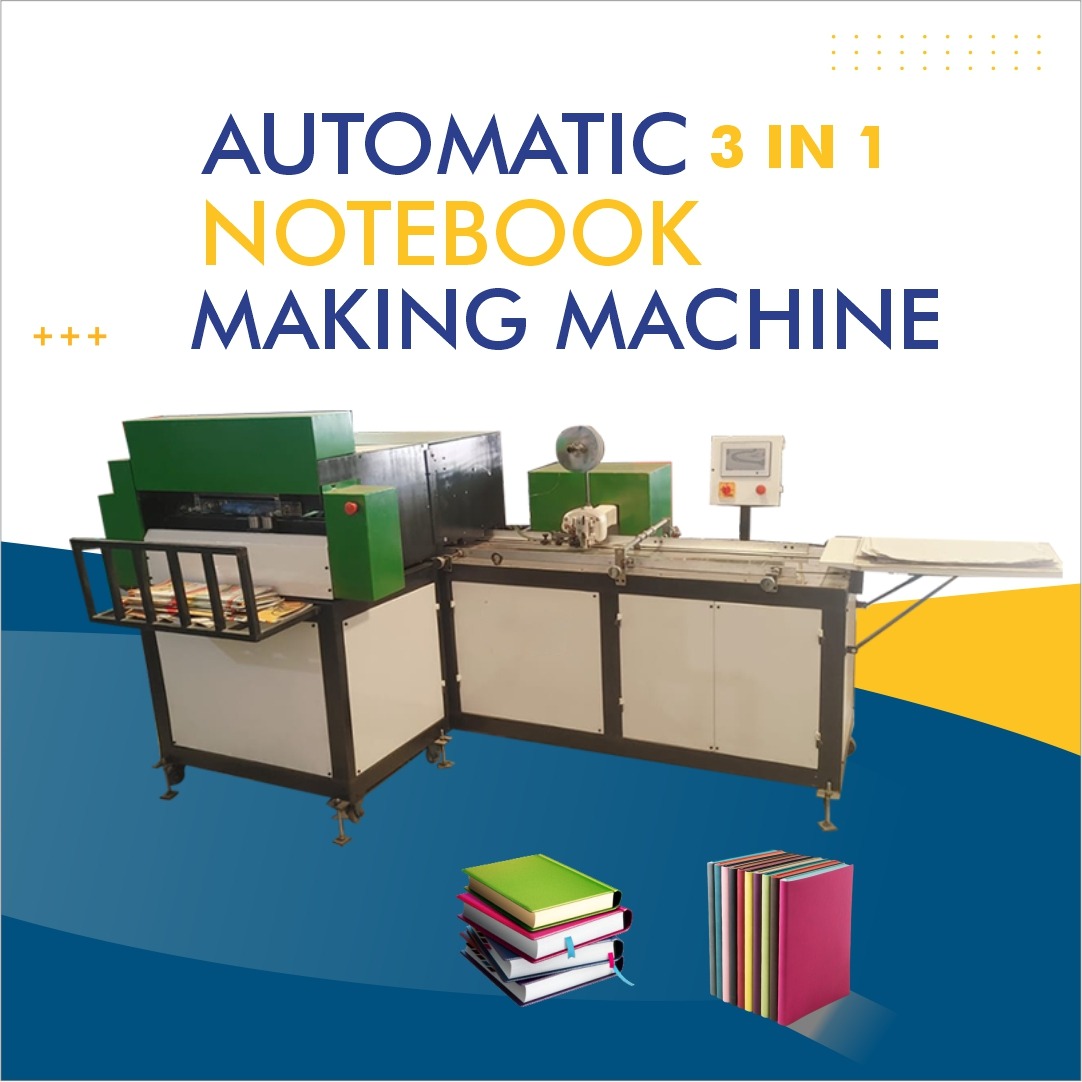

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer & Supplier in Rawalsar, Himachal Pradesh

Notebook Making Machine in Rawalsar | Himachal Pradesh

In the growing educational and stationery industry of Himachal Pradesh, having access to a reliable notebook making machine can transform local production. Whether you plan to start a small-scale notebook factory or upgrade your existing operations in Rawalsar, a notebook making machine is the core investment. This guide explores everything you need to know—from machine features and local conditions to suppliers, installation, benefits, and maintenance.

The term notebook making machine refers to equipment used for binding, cutting, folding, punching, stitching, and trimming paper to produce finished notebooks. These machines can range from manual to fully automated systems and are essential to efficient notebook production. In Rawalsar and surrounding areas, availability of local suppliers and knowledge of the Himachali climate and infrastructure makes all the difference.

Below we cover:

-

Why choose Rawalsar, Himachal Pradesh for your notebook-making setup

-

Key features to look for in a notebook making machine

-

Types of notebook making machines available

-

Cost considerations and local supply chain

-

Installation, training and support in Rawalsar

-

Maintenance and spare parts

-

Marketing your notebooks locally

-

Environmental and regulatory factors

We will also repeat and emphasize key synonyms such as booklet production machine, stationery binding machine, notebook binder equipment, paper binding machine, educational stationery machine, book binding system, spiral binding device, and automatic notebook maker throughout, to reinforce SEO relevance.

Why Choose Rawalsar, Himachal Pradesh?

Rawalsar is a small town located in Mandi district of Himachal Pradesh. While it is not an industrial hub, it is well placed within the state and has proximity to trade routes. Choosing Rawalsar as a location for notebook production offers several advantages:

-

Local Demand – Schools, coaching centers, and stationery shops in nearby towns such as Mandi, Dharamsala, and Palampur create steady demand for notebooks and stationery.

-

Skilled Labor – Himachal Pradesh has an educated workforce and there are local small-scale industries that can provide manual labor for binding tasks.

-

Lower Real Estate Cost – Compared to urban areas, setting up a manufacturing unit near Rawalsar often costs less in terms of building or warehouse space.

-

Government Incentives – Industrial policies of Himachal Pradesh may offer subsidies, tax rebates, or incentives for small-scale manufacturing units in less-developed or rural clusters.

-

Raw Materials Access – Paper suppliers and packaging material sources may be available in nearby towns; plus, transport links to larger markets such as Chandigarh or Delhi via road networks.

-

Community Integration – Smaller communities often enable better relationships with local authorities for licensing, rent permissions, and local marketing.

When you establish a notebook factory using a notebook making machine in Rawalsar, you position yourself to serve both local and regional markets. Support from local government and lower overheads compared to city locations can improve your profit margins.

Key Features to Consider in a Notebook Making Machine

When evaluating machinery, these are the critical features to assess:

-

Production Capacity: How many notebooks per hour/day the machine can produce (e.g. 1000–5000 units/day).

-

Automation Level: Manual vs semi-automatic vs fully automatic systems. An automatic notebook maker reduces labor cost but increases capital expense.

-

Binding Method: Options include stitching (staple or thread), spiral binding, glued binding, or perfect binding. A stationery binding machine may offer multiple binding modes.

-

Paper Size Range: Compatibility with A4, A5, letter size, custom sizes.

-

Cover Material Handling: Ability to handle cardboard or thick card covers for notebooks.

-

Cutting & Trimming Precision: A paper binding machine with accurate trimming is essential for quality finish.

-

Energy Requirements: Electricity supply in Rawalsar and whether the machine needs specific voltage or backup support.

-

Footprint & Layout: Space required, integration with other machines such as printing presses or cover cutters.

-

Safety & Compliance: Conforming to electrical safety standards; noise and dust controls.

-

Spare Parts Availability: Whether parts (motors, blades, rollers) can be procured locally or need import.

-

After-Sales Service & Training: Local technician availability for maintenance and training operators.

You could view the machine not only as a notebook binder equipment but as a long-term investment in quality, durability, and scalability.

Types of Notebook Making Machines

Below are common categories you may consider:

-

Manual Notebook Making Machine

-

Suitable for very small-scale production.

-

Low capital investment, but high labor requirement.

-

Good for specialty or custom-bound notebooks.

-

-

Semi-Automatic Notebook Making Machine

-

Cuts, folds, punches automatically, while binding stitching may require manual intervention.

-

Balanced option for mid-volume production in Rawalsar.

-

-

Fully Automatic Notebook Maker / Automatic Notebook Maker

-

End-to-end operation: cut, fold, stitch, trim in one integrated line.

-

Higher throughput and consistent quality.

-

Ideal if you plan to expand production beyond local markets.

-

-

Spiral Binding and Wire-O Notebook Binder

-

If your product line includes spiral notebooks, a spiral binding device or dedicated spiral binding machine might be required.

-

-

Book Binding System for Perfect-Bound Notebooks

-

For premium products such as hardcover or glued-bound notebooks, a full book binding system may be needed.

-

Each type has its price range and suitability depending on your target output and investment capacity.

Cost Considerations & Supply Chain around Rawalsar

When procuring a notebook making machine for use in Rawalsar, consider these cost elements:

-

Machine Purchase Cost: Imported vs Indian-made machines. Domestic brands may offer lower shipping and import duty.

-

Transportation Cost: Moving heavy machinery to Rawalsar may require special transport approvals and cost depending on road access and distance from supplier location.

-

Installation & Commissioning: Budget for on-site setup, calibration, and operator training.

-

Electricity & Infrastructure: If rural connectivity is less stable, you may need voltage stabilisers or backup generators.

-

Customs / Duties: If the machine or key parts are imported, customs duty or GST may apply.

-

Raw Material Transport: Paper reels/sheets, covers, binding wire or stitches must be brought in — factor transport cost from suppliers in Himachal or neighboring state suppliers.

-

Labor Costs: Local wages for operators, maintenance staff, and quality checkers.

-

Permits & Licenses: Compliance with local statutory regulations, pollution control or waste disposal policies (especially for paper waste or chemical adhesives if used).

You may need to liaise with district industry centre (DIC) or small-scale industrial departments in Himachal Pradesh for permissions and incentives.

Installation & Training in Rawalsar

After purchasing a notebook making machine for Rawalsar, ensure that:

-

The supplier or manufacturer provides full installation at your facility.

-

Technical training is delivered to machine operators — especially for semi-automatic or fully automatic models.

-

Preventive maintenance schedules are explained and documented.

-

Spare part kits are supplied locally or via courier with known lead-time.

-

You schedule trial production runs under actual conditions (humidity, local voltage, local paper quality) so issues such as paper jamming, misalignment, or stitching errors are identified and resolved.

Because Rawalsar is in hilly terrain, transport vibration, altitude-related adjustments, or insulation may require adjustments by the technician. Ensure backup support is provided.

Maintenance & Spare Parts

Maintenance is crucial for uninterrupted production. Consider the following:

-

Regular Cleaning — Paper dust accumulates; cutting blades may dull with use.

-

Lubrication & Moving Parts Check — Bearings, rollers, belts.

-

Sharp Blade Replacement — Keep extra sets of cutting blades.

-

Electrical Components Inspection — Switches, motors, emergency stop safety mechanisms.

-

Wear & Tear on Stitching Mechanism — If you use staples or thread binding, ensure spare stitching heads or wires are available.

-

Spare Motor or Electrical Parts — Prefer spares that can be procured in regional centres rather than waiting for long lead times.

Establish a local agreement with a technician (possibly from Mandi or Dharamsala region) or with the original supplier to ensure timely support for your booklet production machine.

Marketing Your Notebooks from Rawalsar

To achieve profitable returns from your notebook making investment, plan your marketing strategy:

-

Local Sales Channels – Stationery shops in Rawalsar, Mandi, nearby villages, and school / college bookstores.

-

Bulk Orders for Educational Institutions – Approach schools, coaching centers and tutorial institutes for institutional contracts.

-

Custom Printing & Branding – If you combine notebook making with printing services, offer printed covers with local art or Himalayan themes.

-

Online Orders – Use e-commerce platforms or your own website to sell branded notebooks beyond Himachal Pradesh.

-

Eco-Friendly Positioning – Use recycled paper or sustainable materials to appeal to environmentally conscious buyers.

-

Bulk Packaging & Logistics – Plan packaging and transport from Rawalsar to larger distribution points such as Chandigarh or Delhi.

Your ability to deliver high-quality notebooks reliably – enabled by a good notebook making machine – will help you build long-term customer relationships.

Environmental, Regulatory & Quality Factors

Because notebook manufacturing involves paper waste, adhesives, cutting scraps, and electrical machinery, you should consider:

-

Waste Management Protocols — Ensure proper disposal or recycling of paper off-cuts.

-

Noise and Dust Control — Maintain acceptable working conditions to comply with labour or environmental norms.

-

Energy Efficiency — Choose machine variants with lower power consumption or energy-saving modes.

-

Quality Standards — ISO or BIS standards for stationary, if needed for institutional buyers or tenders.

-

Chemical Safety — If adhesives or glues are used for binding, ensure safe handling and appropriate storage.

Complying with Himachal Pradesh’s local environmental or industrial regulations helps avoid delays or penalties when your unit expands.

Conclusion

Investing in a notebook making machine at Rawalsar, Himachal Pradesh is a promising venture that combines local demand, favourable costs, and growth potential. By selecting the right machine—whether manual, semi-automatic or fully automatic—and planning for installation, maintenance, marketing, and compliance, you can build a successful stationery manufacturing business.

If you are interested in sourcing a stationery binding machine, spiral binding device, or a complete book binding system near Rawalsar, get in touch with nearby manufacturers or suppliers in Himachal Pradesh and request quotations including installation & training.

Would you like me to help identify suppliers of notebook making machines near Himachal Pradesh, or help you prepare a cost-benefit model for setting up your notebook factory in Rawalsar?