Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

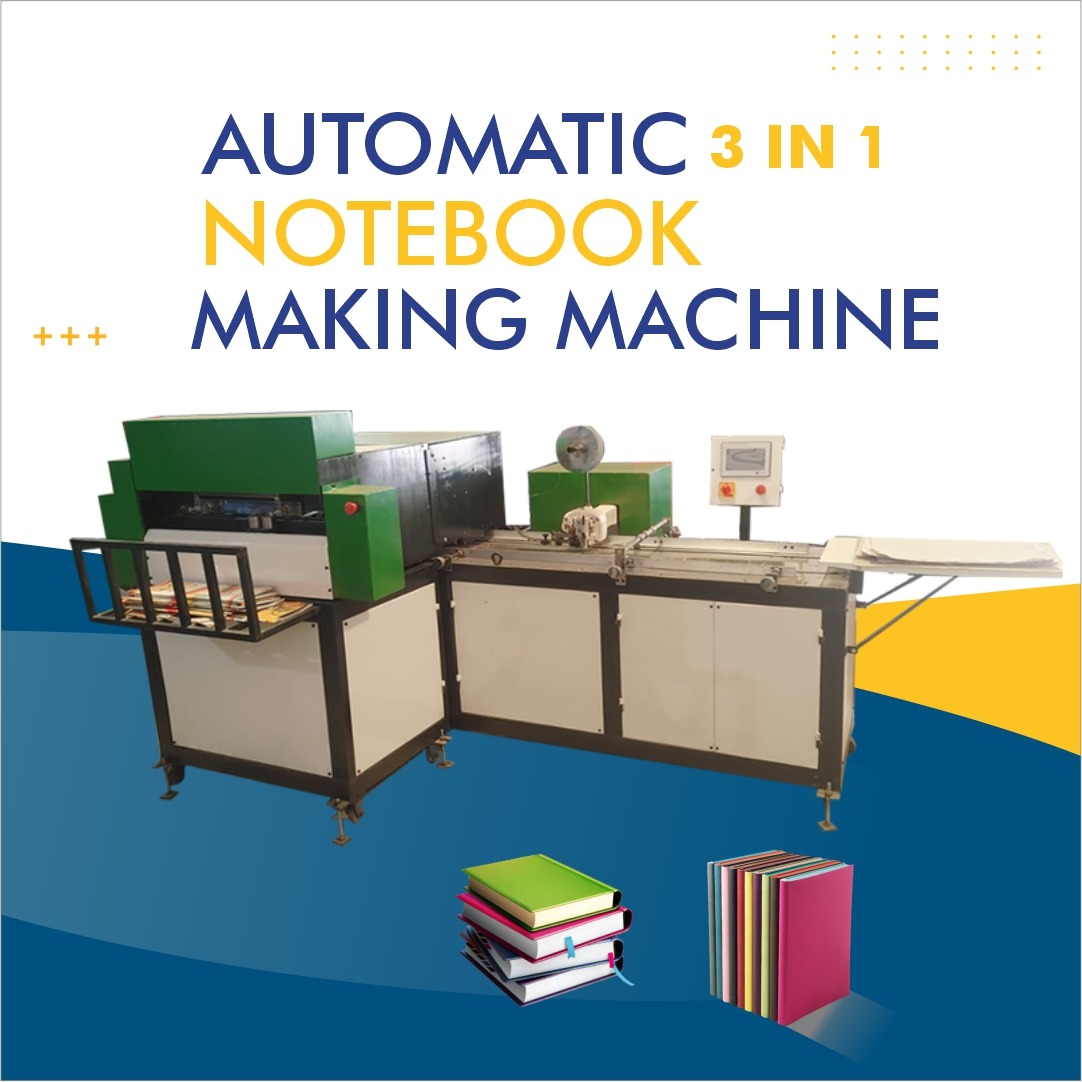

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier & Manufacturer in Chamba Himachal Pradesh | High-Quality Notebook Fabrication Equipment

Notebook Making Machine in Chamba | Himachal Pradesh

If you are searching for a notebook making machine in Chamba, Himachal Pradesh, you have come to the right place. Notebook fabrication is a promising business opportunity in the region, and investing in the correct machinery can ensure high quality output, efficiency, and business growth. Whether you’re setting up a small unit or scaling up to a medium-size production facility, choosing the right notebook making equipment is crucial.

Chamba district, while historically known for handicrafts and cottage industries, is gradually embracing modern machinery for light manufacturing. DCMSME+1 With government support for MSMEs and industrial development in Himachal Pradesh, there is scope for new entrants who bring value-added products and efficient production methods. emerginghimachal.hp.gov.in+1

This guide will help you understand types of machines, buying considerations, local aspects (Chamba / Himachal Pradesh), and how to select a reliable supplier for your notebook making plant.

Why Choose Notebook Making Business in Chamba (Himachal Pradesh)

-

Emerging Industrial Potential

Although Chamba district is considered less developed in terms of larger industrial units, it has a growing number of micro and small enterprises. DCMSME This means relatively low competition in certain modern manufacturing niches like notebook production. -

Supportive Policy Framework

Himachal Pradesh’s Department of Industries offers schemes, industrial clearances, and support for MSMEs. emerginghimachal.hp.gov.in Entrepreneurs setting up plant & machinery may benefit from incentives, subsidies, or simplified approvals. -

Local Labour & Skills

With ITIs (Industrial Training Institutes) in Chamba and nearby regions, there is potential for trained workforce for machine operation and maintenance. NCVT MIS+1 -

Logistics & Market Access

While Chamba is a hilly terrain region, its connectivity to Himachal Pradesh’s markets and possibly neighbouring states allows distribution of stationery goods. Demand for notebooks in schools, colleges, local retail remains steady. -

Growing Demand for Locally Produced Stationery

Local manufacturers can cater to regional schools, government supply tenders, shops, and even customize formats — giving competitive advantage over imported or far-off producers.

Types of Notebook Making Machines

When you plan to buy equipment for notebook production, you will encounter multiple types / models. Below are some common categories:

| Machine Type | Automation Level | Use Case |

|---|---|---|

| Manual Notebook Making Machine | Fully Manual | Suitable for cottage-scale or start-up units with low production volumes or budget constraints. |

| Semi-Automatic Notebook Making Machine | Partial Automation | Good balance between cost & output. Useful for small-to-medium scale production. |

| Automatic Notebook Making Machine | Fully Automatic | For high volume production, consistent speed & minimal manual intervention. |

Examples of Available Machines

-

The SBS NB-01 manual notebook making machine has production capacity ~3,000 notebooks/day. sbsmachine.com

-

SBS also offers semi-automatic models (e.g. SBS NB-09) capable of producing 5,000-6,000 pieces/day. sbsmachine.com

-

Automatic machines by other vendors such as Prime Machinery provide higher throughput (hundreds to over a thousand pieces/hour). guptamachinary.com

-

There are also notebook & register making machines supplied by manufacturers such as Shri Hanumant Kripa Industry. shkimachinery.com

Key Considerations When Buying Notebook Making Machine

When selecting a notebook making machine (or set of machines) for your plant in Chamba, these factors are critical:

-

Production Capacity & Throughput

Estimate how many notebooks you plan to make per day / per hour. Choose a model that meets current demand with some room for future growth. -

Automation Level

Manual machines cost less but require more labour. Semi-automatic reduces labour time. Fully automatic machines cost more upfront but offer consistency, speed, and lower per-unit labour cost. -

Footprint & Power Requirements

Hill-region units often have constraints in space & electricity load. Ensure the machine’s power rating suits local availability. Also check size & weight for transport & installation in Chamba terrain. -

Material & Build Quality

Look for machines built with durable frame (MS or steel), quality cutting blades, binding & stitching capability. This ensures low downtime, easy maintenance, and quality output. -

Cost & Financing

Upfront price, plus shipping to Chamba, installation charges, taxes, local duties (if any), and potential subsidy from state government or MSME policies. -

After-Sales Service & Maintenance

Since Chamba is remote/hilly in comparison to big cities, you should ensure vendor offers service, spare parts & technical support. Local access or quick replacement capability is beneficial. -

Regulatory Approvals & Clearances

Check compliance (safety certifications, electrical licensing), building permit if you are installing in an industrial shed / zone under Himachal Pradesh’s rules. -

Raw Material & Consumables Availability

For example paper sheets, binding thread / glue / cover boards. If you source from outside Himachal, check logistics cost and material lead-time. -

Labour Skill & Training

Train your staff (possibly from nearby ITIs) to operate the machine, perform quality checks, and manage routine breakdowns.

Setting Up Notebook Making Plant in Chamba

If you decide to set up a notebook making plant in Chamba, here is a step-by-step approach:

-

Market Research & Demand Forecast

Study nearby towns, schools, stationary shops, government supply tenders in Chamba & districts around. Estimate monthly demand, color / size / format mix. -

Select Location & Infrastructure

Choose a suitable location — maybe in an industrial area / shed within Chamba district permitted for light manufacturing. Ensure electricity, water supply, access road, storage space. -

Choose Machines & Suppliers

Based on your demand forecast, choose combination of machines (e.g. paper cutting & trimming machine, stitching / binding unit, pressing/edge-squaring, cover attaching, finishing). Request quotes from manufacturers (e.g. SBS, other brands). -

Apply for Permits & Schemes

Use Himachal Pradesh’s single window clearance or industrial scheme options to secure any subsidies, approvals or tax incentives. emerginghimachal.hp.gov.in -

Installation & Commissioning

Plan for transportation of the machine to Chamba (hilly roads), installation by vendor’s engineer, test runs, operator training, safety check & trial production. -

Quality Control & Workflow Design

Define standard operating procedures: sheet cutting, binding, checking alignment, finishing & packaging. Ensure you maintain consistent product quality (no loose binding, clean edges). -

Marketing & Sales Channels

Approach local schools, bookstores, government supply offices. Offer customized formats & printed covers. Highlight “Made in Himachal Pradesh / Local Production” as a selling point. -

Scaling Up

As demand grows, you can upgrade from manual or semi-automatic to fully automatic machines, add more units, expand formats (notebooks, registers, diaries, custom stationery).

Benefits & Challenges

| Benefits | Challenges |

|---|---|

| Lower logistic cost to serve local schools / shops | Transportation difficulty in hilly terrain |

| Ability to customize product locally | Seasonal demand fluctuations (school season etc.) |

| Employment generation for local workforce | Power outages or infrastructure constraints common in hill regions |

| Eligible for state industrial incentives | Need to maintain consistent quality to compete with outside suppliers |

Despite challenges, a well-planned notebook manufacturing unit equipped with proper notebook making machine (or machinery set) can become a sustainable business in Chamba.

Why Your Choice of Vendor Matters

Selecting a trusted vendor ensures reliability. Vendors offering proven machine models like SBS manual / semi-automatic series, or recognized brands in binding / cutting equipment, are preferable. Verify technical specifications, get customer references, request videos / demos, and ensure that spare parts can reach Chamba.

Also negotiate shipping & installation charges to hill-region location, and ask about downtime support & training for operators.

Conclusion

If you are planning to launch notebook production business in Chamba, Himachal Pradesh, investing in the right notebook making machine is a key success factor. Choose a model that fits your current demand, plan for expansion, verify vendor reliability, and ensure compliance with local infrastructure & policy norms. With proper planning, you can run an efficient, quality-driven notebook factory that serves local market and beyond.