Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

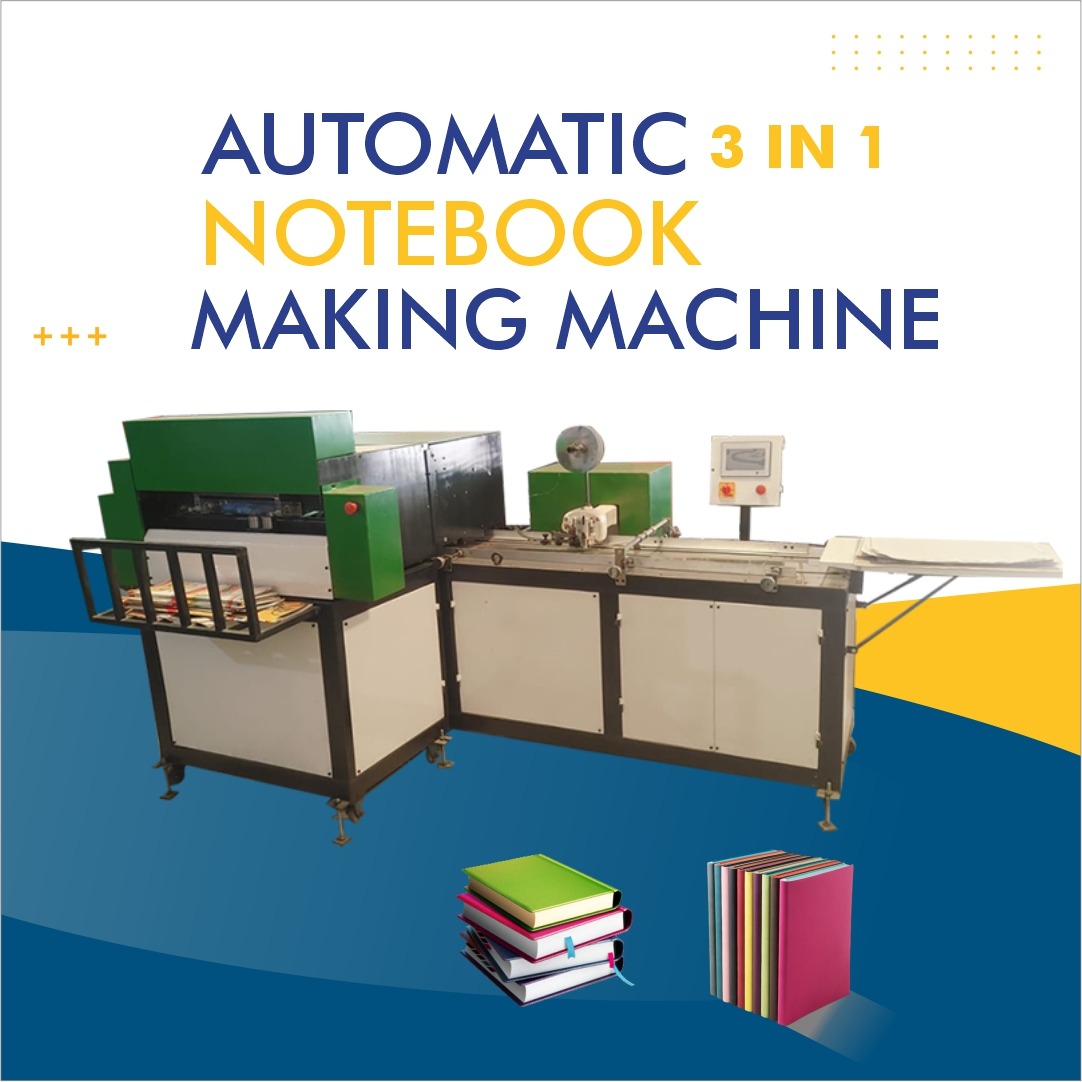

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Pragpur Himachal Pradesh | High-Quality Paper Processing Equipment

Notebook Making Machine in Pragpur | Himachal Pradesh

Pragpur, a picturesque village in Kangra district of Himachal Pradesh, is becoming a hub for small-scale artisanal production and light engineering workshops. One of the growing demands in and around this region is for notebook making machine solutions that combine affordability, durability, and local service. Whether you are a school looking to assemble your own exercise books or a startup producing premium handmade notebooks, choosing the right equipment is essential for quality, cost-effectiveness, and scalability.

In this page we explore the advantages of investing in a reliable notebook making machine in Pragpur (Himachal Pradesh), key features to look for, types of machines, operation and maintenance tips, and how to select a supplier offering good installation & after-sales service.

Why Choose a Notebook Making Machine in Pragpur, Himachal Pradesh

Local Advantage & Proximity

-

Being based in or near Pragpur gives you lower logistics cost for delivery and installation of large sheet-handling machinery.

-

Local vendors or engineers familiar with Himachal Pradesh terrain can respond quickly for maintenance and support.

-

Government permissions, power supply conditions, and material sourcing are easier to arrange when the equipment is tailored for local usage.

Quality Control & Customization

-

Notebook making machines with local customization can accommodate regional paper sizes, binding styles (thread stitching, wire binding), and cover lamination preferences.

-

If you produce locally for schools or retail markets in Himachal Pradesh, you can ensure that the finished notebooks meet regulatory or institutional norms (e.g. school standard lines, size formats).

Economic Opportunity

-

Small-scale production helps reduce import dependency, adds value locally, and generates employment in rural or semi-rural areas around Pragpur.

-

Investments in machines with good uptime and reliability allow you to scale from manual or semi-manual notebook production to partially automated workflows.

Types of Notebook Making Machines

Below are common types of notebook and book binding / production machinery you may consider:

-

Semi-Automatic Notebook Making Machines

These units combine manual feeding or setting with powered cutting, folding, or stapling. Ideal for startups with moderate volume. -

Fully Automatic Notebook Maker

These machines perform paper feeding, cutting, folding, binding, stitching, trimming and cover finishing with minimal manual intervention. Useful for higher-volume production and consistent output. -

Paper Cutting & Trimming Equipment

A precise paper cutter or trimmer to ensure edges of exercise-book sheets are neat. Accuracy is critical for alignment before binding. -

Binding / Stitching Machine

Equipment to stitch folded sheets along the spine — either wire-stitching, stapling or thread sewing. Choice depends on durability, number of pages, and presentation quality. -

Cover Lamination / Binding Press

Machines to press the cover, laminate it or glue it to the spine. Sometimes heat-press or hydraulic-press based units are used. -

Sheet Feeder / Collator

If you are assembling multiple inner-sheet signatures per notebook, a sheet collator or feeder helps arrange pages in proper order before binding.

Each subsystem may be sold separately or integrated into a combined notebook production line.

Key Features to Look For

When selecting a notebook making machine for your operation in Pragpur, Himachal Pradesh, consider these features:

-

Processing Speed & Capacity: Sheets per hour, notebooks per minute, maximum number of pages per book.

-

Machine Durability & Build Quality: Steel frame, corrosion-resistant parts, robust moving assemblies suitable for the Himalayan climate (moisture control).

-

Power Supply & Electrical Requirements: Compatibility with local voltage & power fluctuations. Backup systems or stabilizers if required.

-

Spare Parts Availability: Ability to source replacement blades, staples, motors locally or through the supplier.

-

Service & Maintenance Network: On-site service availability and remote troubleshooting by vendor.

-

Safety & Compliance: Guards around cutters or moving parts; compliance with Indian safety standards.

-

Footprint & Space Requirements: The size of the machine footprint is key if you operate from a workshop or school premises.

-

Customization Options: Ability to adjust paper size, cover trimming, binding style, or even branding elements (embossing/foil stamping optional).

-

Cost & Financing Support: Up-front cost, warranty period, optional accessories (like extra collator units), and payment terms.

How a Notebook Making Machine Works

Step-by-step overview of a typical operation workflow:

-

Paper Preparation & Collation

Sheets are cut to standard sizes (A4, A5, custom dimension). A collator arranges the required number of pages in correct sequence per book. -

Folding / Signatures Formation

If the notebook has folded sections (signatures), the machine or a supplementary folder creates creased folds. -

Binding / Stitching

The bound spine is created with staples, wire, or thread. Depending on the chosen binding method, the machine aligns and stitches multiple signatures. -

Trimming & Edge Finishing

Once binding is done, the edges (top / bottom / side) are trimmed for flush edges. Covers may be trimmed separately. -

Cover Fixing & Pressing

Covers may be laminated, glued, or heat-pressed onto the bound pages. A binding press may ensure proper adhesion and finish. -

Quality Inspection & Packaging

Each notebook is visually inspected for misalignment, loose pages, or cover defects. Then the finished notebooks are stacked or packaged for delivery.

Operating staff must be trained in loading paper stacks, adjusting machine parameters (stitch depth, cutting tolerance), and routine cleaning / lubrication.

Applications & Uses

-

School & Educational Institutions

Local schools near Pragpur can use on-site production to reduce procurement costs, ensure timely supply, and customize covers (e.g. with school logos or bilingual language headings). -

Handmade & Designer Notebook Producers

Artisans creating handcrafted or designer notebooks can benefit from semi-automatic or small-batch machines that allow for manual oversight yet deliver consistent quality. -

Small Industrial Units & Cooperatives

Women’s self-help groups or cooperatives in Kangra / Pragpur region may set up small-scale production units for retail sale or supplying to bookstores. -

Commercial Printing & Packaging Businesses

Existing printing houses may expand into notebooks or exercise books by investing in binding & finishing machinery.

Benefits of Installing in Pragpur Area

-

Reduced Transportation Cost

Raw paper rolls or cut sheets often come from nearby suppliers. Having a local machine reduces shipping weight of finished notebooks compared to centralised processing far away. -

Faster Turn-around & Custom Orders

Local proximity enables faster customization (e.g. special covers for regional events or fairs in Himachal Pradesh), shorter lead times and flexibility for urgent demands. -

Energy Efficiency & Adaptation to Local Climate

Machines tailored or configured for the temperature / humidity conditions of Himalayan foothills (Pragpur) can perform better with lower downtime due to moisture-related problems. -

Local Support & Regulatory Compliance

By sourcing or getting installation locally, you benefit from faster servicing, easier compliance with municipal or industrial-zone regulations, and smoother documentation for subsidies or incentives (if any under state government schemes).

Challenges & How to Overcome Them

| Challenge | Suggestion / Mitigation |

|---|---|

| Electricity fluctuations in rural / semi-rural setting | Use voltage stabilizers, UPS backup or generator fallback for machine-critical operations. |

| Skilled manpower availability | Train local staff or partner with nearby technical institutes for operator training. |

| Raw material (paper, covers) supply consistency | Enter into contracts with regional paper merchants; maintain buffer stocks. |

| Initial Capital Investment | Explore government subsidy schemes for small-scale manufacturing units in Himachal Pradesh; negotiate payment terms with the supplier. |

| Maintenance downtime | Maintain preventive maintenance schedule; secure spare-parts inventory with the vendor; establish service contract. |

How to Choose a Supplier for Notebook Making Machineries

When choosing from suppliers offering notebook making machine, book binding equipment or stitching / trimming units, consider the following checklist:

-

Supplier reputation & experience in North India or Himalayan region

-

Ability to deliver, install, and train on-site in Pragpur or nearby workshop

-

Warranty and support terms (e.g. 1 year warranty, local spare-parts depot)

-

References or case-studies from other schools, units or printing-businesses in Himachal Pradesh

-

Option to procure semi-automatic first before upgrading to fully-automatic

-

Flexibility for custom sizes, binding styles or production volume scaling

Ask for a live demonstration video or visit their factory if possible. Also check whether they offer PDF or digital manuals, remote support, and spare parts shipping to Kangra district or nearby regions.

Case Scenario: Small-Scale Notebook Production in Pragpur

Imagine a start-up stationery business operating from Pragpur. You plan to produce 500 notebooks per day for local schools and tourist-oriented gift shops.

-

You acquire a semi-automatic notebook maker with paper-cutting, stitching and edge-trim units.

-

You hire two operators, trained to set up the machine daily, feed papers, inspect finish.

-

With local delivery you save on freight charges, respond rapidly to custom-logo requests from schools in Kangra valley.

-

Over 12 months, you expand into tourist-gift notebooks with premium covers (fabric-laminated or embossed) using optional accessories.

-

The machine downtime is minimal because the supplier provided preventive-maintenance training and spare-parts backup locally.

This scenario shows how investing in a reliable notebook making machine near Pragpur can yield returns, build local capacity, and support creative small-business growth in Himachal Pradesh.

Maintenance & Safety Recommendations

-

Keep routine lubrication schedules for cutters, binding heads, moving rollers.

-

Clean dust and paper debris daily to avoid jamming or blade wear.

-

Use safety guards and enforce operator training to avoid injuries from cutting or automatic movements.

-

Monitor power consumption and local temperature/humidity; adjust machine settings when environmental factors vary seasonally.

-

Inspect stitching quality weekly — loose staples or misalignment must be corrected before packaging.

Future Outlook & Trends

-

Demand for eco-friendly notebooks is rising; consider integrating recycled paper stock or vegetable-based coverings.

-

Small-volume digital printing and variable-data covers allow personalized notebooks for schools, events or branding.

-

Upgrading to more automated notebook making machines can improve yield and reduce labour cost, paving the way for expansion into nearby districts and retail supply.

-

Government incentive schemes for rural manufacturing or MSMEs (micro, small & medium enterprises) in Himachal Pradesh may subsidize equipment purchases or provide support for energy-efficient machinery.

Conclusion

Investing in a high-quality notebook making machine in Pragpur, Himachal Pradesh is a practical solution for local entrepreneurs, schools, and craft-businesses. By choosing the right machine type (semi-automatic or fully automatic), ensuring supplier support, and planning for maintenance, you can build a reliable production line for notebooks and exercise books. Local benefits include lower logistics cost, faster customization, and regional employment growth.

If you are considering installing a notebook making machine near Pragpur, contact reputable suppliers or request quotations that include installation, commissioning, spare parts, and operator training. With the right planning, you can set up a sustainable small-scale notebook production unit that delivers consistent quality and adds value locally.