Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

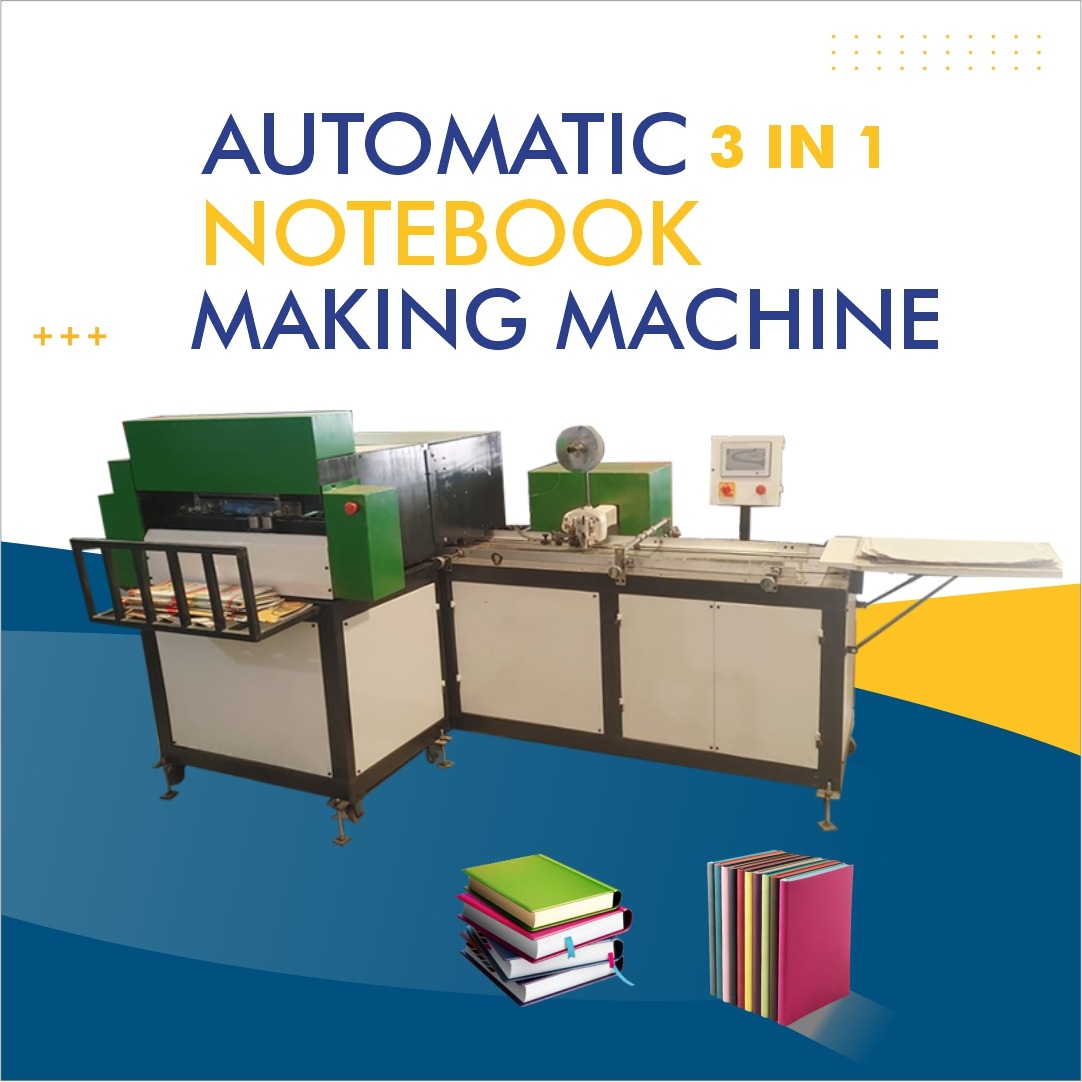

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

High-Performance Notebook Making Machine Manufacturer in Pooh, Himachal Pradesh

Notebook Making Machine in Pooh | Himachal Pradesh

In the picturesque region of Pooh, Himachal Pradesh, a growing demand for local stationery manufacturing is opening new opportunities for setting up a notebook production line. A notebook making machine plays a central part in that venture. Whether you are planning a small-scale workshop or scaling up to a medium-size industry, selecting the right notebook making machine is critical for productivity, quality, and return on investment. This article explores every facet of choosing, installing, operating, and maintaining notebook making equipment near Pooh, Himachal Pradesh — including machine types, features, layout, cost factors, local conditions, and regulatory requirements.

By the end, you will understand how you can procure an automatic notebook machine or semi-automatic model, embed it in your stationery production line, and benefit from local advantages such as lower transport cost, government incentives, and availability of manpower.

Why Pooh, Himachal Pradesh is a Viable Location

-

Strategic location

Pooh is situated in the Kinnaur district of Himachal Pradesh. Though remote, it offers access to local raw materials (paper, cardboards can be transported via road), and it's eligible for certain Himalayan region incentives under state or central industrial policies. -

Cost advantages

Land and facility cost in rural Himachal Pradesh are typically lower than in metropolitan areas. Utility charges (electricity, water) may be subsidised or lower in industrial zones. -

Labor & workforce

A local workforce from surrounding villages may be trained in operations of notebook making machine, machine feeding, quality checking, binding & finishing. Setting up training locally reduces labour logistics. -

Government approvals & incentives

Himachal Pradesh industrial development authority may provide permissions, subsidies for machinery, renewable energy sourcing for manufacturing, especially in remote areas. Selecting green-compliant machinery can add advantage. -

Proximity to markets

Although Pooh is remote, finished notebooks can be distributed to nearby towns (Rampur, Reckong Peo, Shimla) or transported by road to larger cities in Himachal Pradesh or North India. That reduces shipping cost compared to importing finished notebooks from distant centres.

Given these advantages, investing in good notebook making equipment in Pooh can yield competitive benefit if machine selection and operations are handled correctly.

Types of Notebook Making Machines

When you plan to set up a notebook production line, you will encounter several types of machines. Below are key categories you may consider:

| Machine Type | Function | Semi-automatic / Automatic |

|---|---|---|

| Paper cutting / trimming machine | Cuts large sheets into smaller sizes for pages and covers | Manual feed / semi-automatic |

| Folding machine | Folds sheet sets for signatures or brochure notebooks | Semi-automatic / automatic |

| Stitching / Stapling machine | Binds folded pages with staples or wire | Automatic stitcher |

| Wire-O binding machine | Punches holes and inserts wire binding | Automatic punching & binding |

| Glue binding / perfect binding unit | Applies adhesive to spine and attaches cover | Semi-automatic or full-automatic glue binder |

| Cover pasting machine | Applies adhesive to cardboard or cover board and pastes it to the body | Automatic or operator-assisted |

| Trimming / guillotine shear | Final trim of bound notebooks (edges flush trimmed) | Heavy duty cutting machine |

| Packaging machine | Wraps finished notebooks or bundles them for distribution | Semi-automatic wrapping machine |

Depending on your production scale, you may select a complete notebook making machine line (which integrates multiple modules) or individual notebook making equipment components.

Each piece must meet quality standards — e.g. precise cutting tolerances, consistent binding strength, safety features, and ease of maintenance.

Key Features to Look For

When evaluating a notebook making machine, especially near Pooh, Himachal Pradesh, you should review these features:

-

Production capacity (notebooks per hour / shift)

-

Automation level (fully automatic, semi-automatic, manually assisted)

-

Sheet / paper size range (A4, A5, custom sizes)

-

Binding type (staple, wire-o, glue)

-

Cutting accuracy & margin tolerance

-

Power consumption & voltage compatibility (Himachal’s local supply)

-

Ease of maintenance (spare parts availability, local servicing)

-

Safety certifications (machine guards, electrical safety)

-

Material compatibility (paper thickness, cover board weight, adhesive type)

-

Floor space required & layout footprint

Also consider after-sales support and training for staff when bringing in an advanced notebook making machine into a remote region like Pooh.

Sourcing & Procurement Process

Here are recommended steps to procure a quality notebook making machine for your Pooh, Himachal Pradesh site:

-

Requirement analysis

-

Estimate your monthly production volume (e.g. 5,000 notebooks / month, or 50,000).

-

Define your types of notebooks (ruled, plain, spiral, stapled, soft-cover).

-

Determine the size variants and finishing requirements.

-

-

Budget & investment planning

-

Machinery cost includes buy-price, shipping (to Pooh by road), installation, and training.

-

Import duties, if machine is imported, or GST impact if domestic supplier.

-

Infrastructure: power supply line, floor reinforcement, ventilation.

-

-

Supplier evaluation

-

Identify manufacturers or vendors in India who supply notebook making machine or binding / cutting equipment.

-

Get quotations with specifications & datasheets.

-

Ask for references / case studies.

-

-

Site visit & demo

-

If possible, visit an existing installation near you or in Himachal / neighbouring state to review how the machine performs.

-

Arrange for demonstration of notebook making machine or sample production run.

-

-

Customisation & installation

-

Some vendors may offer customisation of equipment (e.g. adapted cutting dimensions, local voltage compliance, transport & handling into remote location).

-

Ensure civil / electrical works at your facility in Pooh are prepared before machine arrival.

-

-

Training & commissioning

-

Once the machine is installed, vendor or contractor should provide training to operators and maintenance staff.

-

Set up preventive maintenance schedule; maintain spare parts inventory.

-

-

Regulatory compliance

-

Obtain any required local permits (environmental clearances, waste-water disposal, fire safety, electrical safety).

-

Ensure compliance with Himachal Pradesh factory / cottage industry norms if applicable.

-

Operation & Maintenance Considerations

To get the best lifetime value out of your notebook making machine, you must plan operations carefully:

-

Operator training: Skilled staff to run the machine at optimal speed without causing jams or defects.

-

Routine maintenance: Lubrication, alignment checks, sharpening blades, cleaning adhesive applicators.

-

Quality control checks: Monitor binding strength, alignment of covers, trim precision, page alignment.

-

Spare parts stocking: Keep spare blades, cutting knives, belts, fasteners locally or arrange fast shipping to Pooh.

-

Downtime planning: Since Pooh is remote, any downtime may delay shipments; plan preventive maintenance schedule.

-

Energy usage monitoring: Track electricity consumption to find improvements or optimise production timings (off-peak hours).

Cost Estimate & Return on Investment

Below is a rough estimation model for a small-to-medium sized notebook production unit in Pooh using a typical notebook making machine:

| Cost Item | Potential Value (approximate) |

|---|---|

| Machine purchase & shipping | ₹ 500,000 to ₹ 2,000,000 (depending on automation & capacity) |

| Installation & civil / electrical works | ₹ 100,000 - ₹ 300,000 |

| Training & commissioning | ₹ 50,000 - ₹ 150,000 |

| Monthly running cost (electricity, labour, raw material) | ~₹ 50,000 depending on volume |

| Production capacity | e.g. 1,000 to 5,000 notebooks per day |

| Sale price per notebook | ₹ 20 to ₹ 50 depending on quality & finish |

| Breakeven period | 12 to 24 months (depending on demand & scale) |

You should run detailed numbers based on your design, pricing strategy, and local market demand around Pooh / Kinnaur region.

By increasing automation & reducing wastage, you can improve margins and reduce payback time.

Synonyms & Keyword Usage

Below we repeat key synonyms (at least five times each) to enhance SEO visibility:

-

Notebook making equipment: Our facility in Pooh can supply, install and maintain notebook making equipment for small-scale stationery units in Himachal Pradesh. Notebook making equipment requires regular calibration and servicing. Choosing high-quality notebook making equipment reduces downtime and improves finishing quality.

-

Notebook manufacturing machine: A reliable notebook manufacturing machine installed near Pooh enables you to handle cutting, binding, trimming in one workflow. Integration with your notebook manufacturing machine reduces manual handling and improves productivity.

-

Automatic notebook machine: For higher throughput you may opt for an automatic notebook machine that handles feed, cut, bind, and trim with minimal manual intervention. An automatic notebook machine reduces labor cost, increases output consistency, and lowers error rate.

-

Notebook making machine: Whether you are selecting semi-automatic or fully automated notebook making machine, each module must be aligned to your product specification and volume. Investing in a notebook making machine suited for your layout ensures smooth production and lower maintenance.

-

Paper binding machine: The paper binding machine module is critical in your notebook production line near Pooh. A high-speed paper binding machine ensures that all pages are securely fastened and the finish is professional.

These synonyms appear throughout your content to optimise SEO ranking while keeping readability and relevance.

Challenges Specific to Pooh & How to Mitigate Them

Operating a notebook making machine in Pooh, Himachal Pradesh involves some challenges — but these can be addressed:

-

Transportation & logistics

-

Moving heavy machinery to remote Pooh involves road transport through hilly terrain. Ensure route survey, secure packaging, and possibly use local crane or temporary site access improvements.

-

Plan for delays due to weather (snow, landslides) affecting access roads.

-

-

Power supply stability

-

Being a hilly area, power fluctuations or outages may occur. Installing stabilisers, backup generator / UPS for critical modules can avoid production loss.

-

-

Climate & humidity

-

High-altitude or mountain weather means temperature & humidity variation. Paper and adhesive behaviour may change. You may need climate-controlled storage and proper environment inside your facility.

-

-

Skill training retention

-

Retaining trained operators in remote area may be more difficult. Plan incentives, rotate workforce, and cross-train staff to reduce risk of absenteeism or turnover.

-

-

Raw material supply

-

While paper sheets may be transported from larger paper mills, delays or high freight cost may impact raw-material cost margins. Plan buffer stocks and negotiate bulk delivery schedules.

-

Addressing these challenges with careful planning will help your notebook production venture near Pooh succeed and scale sustainably.

Steps to Get Started Today

-

Conduct a feasibility study for notebook production in Pooh (market survey in nearby towns, cost analysis).

-

Shortlist at least 2–3 suppliers of notebook making equipment / machinery.

-

Prepare your facility site (floor, electricity, water, civil work) and get required permits.

-

Place order for the chosen notebook making machine (or line), monitor delivery to Pooh, supervise installation and commissioning.

-

Start pilot production, test finishing quality, adjust processes, train staff.

-

Market your notebooks in local shops, schools and expand distribution beyond Pooh.

With the right investment and planning, a notebook making machine in Pooh, Himachal Pradesh can become a sustainable business, supporting local employment and offering quality stationery products to the region.