Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

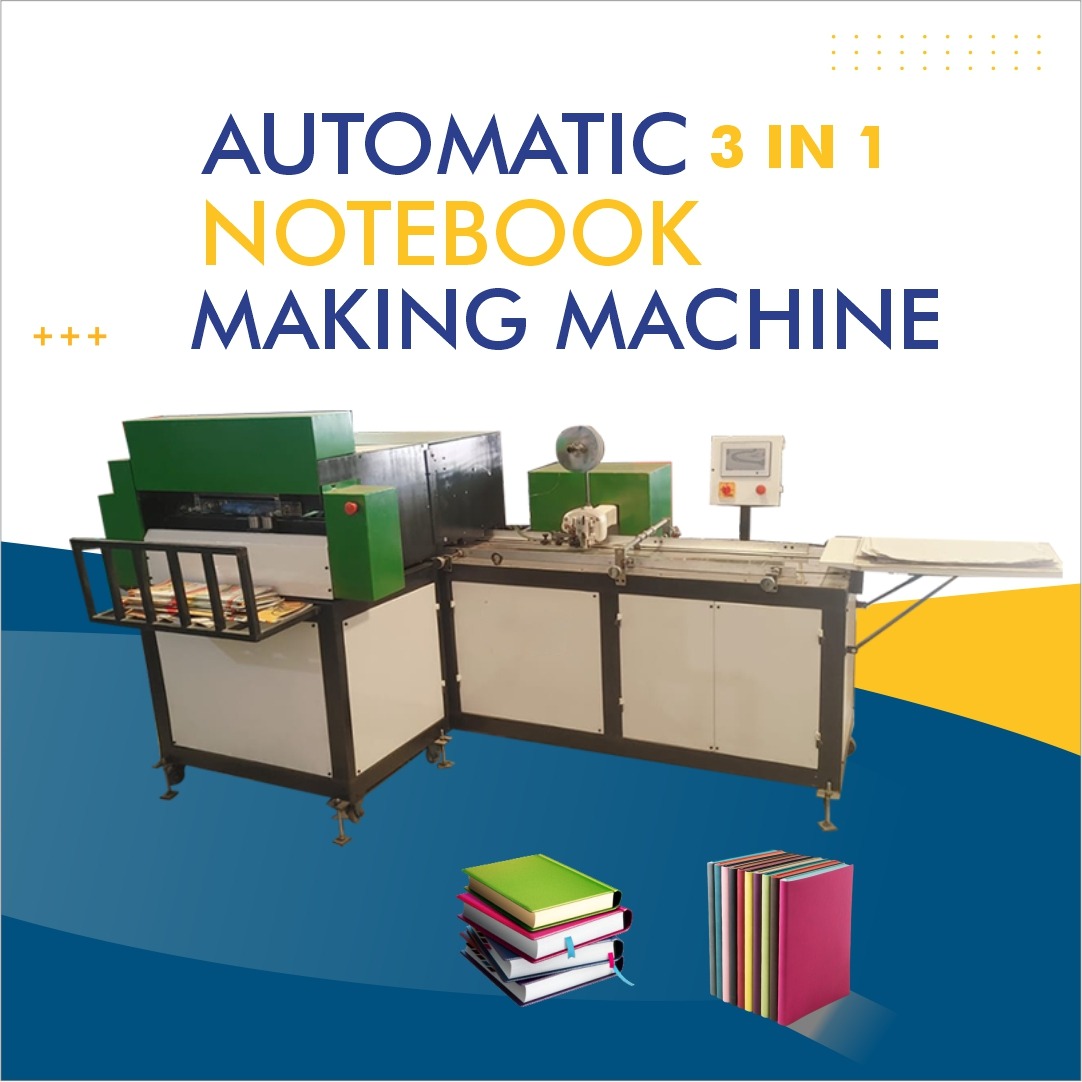

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Kangra Himachal Pradesh – Best Quality & Service

Notebook Making Machine in Kangra | Himachal Pradesh

If you are searching for a notebook making machine in Kangra, Himachal Pradesh, you’ve come to the right place. Our company specializes in designing, manufacturing, supplying, and installing top-quality notebook making machines tailored to the needs of paper-product businesses, schools, print houses, and stationery manufacturers. With years of experience in industrial machinery and a solid presence in Himachal Pradesh, we deliver reliable and efficient equipment for notebook production.

In this page you will find details on machine types, features, technical specifications, customization, benefits, installation process, maintenance, and why Kangra is an ideal location for your investment in stationery manufacturing.

2. Why choose Kangra, Himachal Pradesh

-

Strategic Location: Kangra is well-connected to major roadways and is accessible from towns like Dharamshala, Palampur, and the plains of Punjab. Transportation of heavy equipment is feasible due to reasonable infrastructure.

-

Access to Skilled Labor: Himachal Pradesh has a growing base of skilled technicians and workers accustomed to machinery installation, fabrication, and sheet-metal work.

-

Resource Availability: Raw materials like paper, binding wire, boards, adhesives, and packaging supplies are accessible via regional supply chains centered in north India.

-

Supportive Environment: Local administration often promotes small and medium enterprises (SMEs) including manufacturing units. The cooler climate helps with long-term storage and handling of paper-based production.

-

Cost Efficiency: Compared to large metros, operational costs for electricity, labor, and land may be more favorable in Kangra district.

Because of these factors, setting up or sourcing notebook making machinery within Kangra offers logistical benefits and ease of service support.

3. Types of Notebook Making Machines Offered

We provide a wide range of notebook making machines suitable for various production capacities and budgets. Here are some of the types:

a) Semi-Automatic Notebook Making Machine

-

Ideal for small to medium scale production.

-

Requires manual feeding of paper sheets, automatic punching, binding, trimming.

-

Suitable for schools, cottage industries, and local manufacturers.

b) Fully Automatic Notebook Making Machine

-

Designed for high-capacity production of notebooks with minimal manual intervention.

-

Integrates cutting, folding, punching, binding, and trimming in one continuous line.

-

Best choice for industrial-scale notebook production.

c) Spiral Binding Notebook Machine

-

Uses spiral wires or coils for binding instead of stitched or glued binding.

-

Useful for planners, diaries, calendars, and exercise books with flexible pages.

d) Wire-O / Twin-Loop Binding Equipment

-

Suitable for wire-binding style notebooks.

-

Can be part of a broader notebook production line or a separate binding station.

e) Customized Notebook Production Line

-

Based on your production volume, paper size, binding style (stitched, glued, wire binding), cover finishing (lamination, artwork), we build a tailored setup.

-

Can include feeding conveyor, punch stations, sewing/stitching station, trimming & stacking unit.

Each machine comes with options for voltage (single-phase / three-phase), motor power, control panel (PLC / manual), safety features, and optional attachments such as cover printing or embossing modules.

4. Features & Specifications

Here are some typical features you can expect:

| Feature | Description |

|---|---|

| Production Capacity | From hundreds to thousands of notebooks per hour (depending on model) |

| Supported Notebook Size | A4, A5, exercise-book sizes, custom dimensions |

| Sheet Thickness | For both single sheet and multiple-sheet folding variants |

| Binding Style | Thread-sewn, stitching, glue-bound, wire binding, spiral binding |

| Motor & Power | 1-phase or 3-phase motors, variable speed drive options |

| Control System | PLC or micro-controller based switches, emergency stop |

| Adjustment & Settings | Size adjustment knobs, depth of punch adjustment, trimming width settings |

| Material Compatibility | Paper grades (80–120 gsm), cover stock, laminated boards, adhesives |

| Safety Standards | Guards for moving parts, emergency stop, overload protection |

| Footprint & Layout | Modular frame with space-saving layout for installation in limited workshop area |

These features ensure that your notebook production machine runs reliably, produces uniform output, and can be maintained easily over time.

5. Synonyms and Keyword Variations

To help you understand diverse terminologies used in the industry, here are synonyms / related terms used for “notebook making machine” that we also support:

-

Notebook production machine – equipment to manufacture notebooks from raw sheet to finished product.

-

Stationery binding equipment – machines used for binding paper into covers for notebooks.

-

Exercise book manufacturing machine – machine line designed specifically for exercise-book formats.

-

Binder binding machine – generic name often used when binding is performed by mechanical stitching or adhesive.

-

Paper binding machinery – a broader term that refers to machines that bind paper into final assembled books or notebooks.

We use these terms interchangeably in design, quoting, and documentation.

6. Advantages of Investing in Local Machinery

• Lower Shipping and Import Costs

By purchasing from a manufacturer based in or near Kangra, you minimize transportation, customs, and freight handling delays.

• Faster Turnaround & Support

Local manufacturing means quicker lead time for delivery, installation, commissioning, and spare parts. If any maintenance is needed, service engineers can reach your site faster.

• Customisation & On-Site Repairs

Since the workshop is nearby, you can request design modifications, adjustments for local power supply, or add-ons such as embossing heads or custom cover feeders.

• Compliance with Local Norms

Machines built in Himachal Pradesh can be designed with compliance for Indian safety norms, electrical standards (CE / BIS if required), and suited for local environment (humidity, temperature).

7. Our Process: From Inquiry to Commissioning

Here is a step-by-step view of how we deliver a notebook making machine project in Kangra, Himachal Pradesh:

-

Requirement Gathering

-

You send us particulars such as the size of notebooks, binding type, daily/monthly output target, budget constraints, and power supply available.

-

We discuss your layout, workshop dimensions, and raw-material formats.

-

-

Proposal & Design

-

Based on your inputs, we propose a machine or line: dimensions, capacity, estimated price, lead time.

-

We prepare CAD drawings or layout plan for installation.

-

-

Fabrication & Assembly

-

Our workshop fabricates frame, feed trays, punching jaw, binding station, trimming knives, motors and electronics.

-

We assemble the components, perform dry-run testing at our facility.

-

-

Quality Testing

-

We run sample notebooks to test binding strength, trimming accuracy, punching alignment, speed consistency.

-

Any adjustments are made before dispatch.

-

-

Installation & Commissioning

-

Our technician team visits your site in Kangra or nearby areas.

-

We place the machine, level it, connect power supply, test run under actual material supply (paper, cover boards).

-

Training is provided to your operators for safe and efficient operation.

-

-

After-Sales Support & Maintenance

-

We provide a warranty period for performance assurance.

-

Spare parts such as blades, punching dies, binding wires/coils, control components are stocked locally.

-

Periodic maintenance contracts are available.

-

8. Applications & Use Cases

Your notebook making machine in Kangra can serve multiple applications:

-

Production of exercise books for schools and coaching centres.

-

Manufacturing of custom diaries, planners, journals for local retail sale.

-

Small-scale stationery business expanding into custom design, printed covers, laminated finishing.

-

Educational institutions setting up internal stationery unit.

-

Contract manufacturing for print-shops or college bookstores.

Across these use-cases, our machines deliver consistent quality, speed, and repeatability that manual or semi-manual binding cannot match.

9. How to Choose the Right Machine

To decide on the right notebook making machine, consider these factors:

-

Production Volume — How many notebooks per hour/day? Small volumes suit semi-automatic; higher volumes need full-automatic lines.

-

Binding Style Required — Thread-sewn stitching, wire/spiral binding, glued spine or combination.

-

Space Available — Workshop dimensions, ceiling height, power entry point location.

-

Budget & ROI — Upfront cost vs long-term savings on labour, speed, and consistency.

-

Flexibility & Customization — Whether you plan to expand sizes (A4, A5, custom), or switch between binding styles.

-

Power Specification & Local Conditions — Ensure compatibility with three-phase power, voltage fluctuations, and local humidity or dust control.

We help you run through these parameters to suggest a suitable configuration for Kangra-based units.

10. Case Studies & Testimonials

While we avoid using names for confidentiality, here is an anonymized example: a stationery firm in Kangra upgraded from manual stitching to a fully automatic notebook production machine. After installation, their output increased by over 200% while reducing rejections and labour dependency. Their ROI was achieved within 18 months due to lower waste, faster delivery to schools, and ability to accept bulk contracts from nearby towns.

Another case involved a local school’s in-house stationery unit that installed a semi-automatic exercise book manufacturing machine. They now meet their internal requirement and sell extra units in local markets, turning a fixed cost unit into a small profit centre.

11. Pricing & Payment Terms

Typical pricing depends on model selected, level of automation, size range, binding style, and additional options such as material feeders, embossing heads, or PLC control. We offer:

-

Quotation on request — send us your required specification and we share a detailed cost estimate.

-

Payment Terms — often 40 % advance at order confirmation, balance before shipment or commissioning.

-

Delivery Time — typical lead time from order to delivery and installation may range from 4 to 12 weeks depending on complexity and customization.

-

Shipping & Installation Charges — quoted separately, based on your exact location in Kangra district, handling difficulty, and site readiness.

12. Contact & Next Steps

If you are interested in exploring a high-quality notebook making machine in Kangra, Himachal Pradesh, please reach out to us with:

-

Your production capacity target (weekly/monthly)

-

Desired notebook sizes and binding style

-

Budget range

-

Available electrical power supply details

-

Workshop area dimensions

We will respond with a customized machine proposal, technical layout drawing, and price quote.

You may visit our facility by appointment for a live demonstration of machine operation using sample paper and binding styles.

Conclusion

A professional notebook making machine purchased or installed locally in Kangra (Himachal Pradesh) brings you closer to reliable production, lower operating costs, and faster support. Whether you need a semi-automatic line or a fully automatic stationery production system, our design, manufacturing, and service capabilities are geared to your success. Get in touch for a quote today and turn your notebook manufacturing idea into reality.