Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

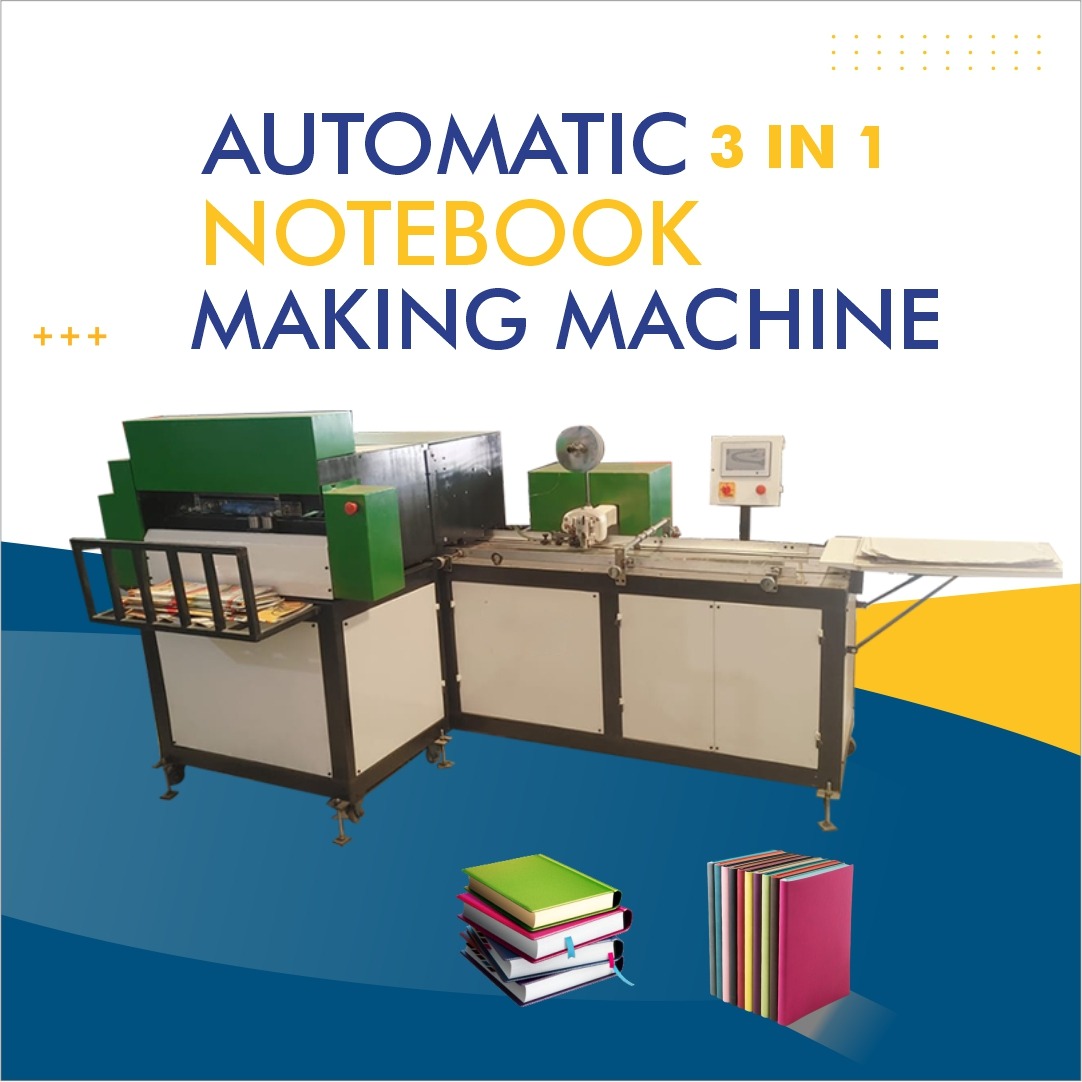

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Dagshai Himachal Pradesh | High-Efficiency Notebook Manufacturing Equipment

Notebook Making Machine in Dagshai | Himachal Pradesh

If you are looking to set up a notebook manufacturing facility around Dagshai, Himachal Pradesh, understanding the features, cost, types, and installation of a notebook making machine is essential. Whether you are startup entrepreneur or expanding an existing stationery business, choosing the right machinery can make all the difference. In this guide we cover everything from machine selection to local considerations in Dagshai and the Solan region.

About Dagshai, Himachal Pradesh

Dagshai is a small cantonment town in the Solan district of Himachal Pradesh, India. Wikipedia It lies on a hilltop overlooking the Kalka–Shimla Highway, and though it is primarily residential and school-oriented, one can envisage setting up light manufacturing operations or MSME-scale industries in nearby accessible locations. Wikipedia

Proximity to larger towns such as Solan, and road links via Kalka-Shimla route, allow transport of raw materials (paper, boards) and shipment of finished goods (notebooks, registers). The elevation is high (~1,700 m), so infrastructure (electric supply, roads, labor availability) must be assessed carefully.

Why Set Up a Notebook Making Unit Near Dagshai?

-

Strategic Location: Being close to Solan / Kumarhatti, transport to larger markets is easier.

-

Lower Real Estate Cost: Rural or semi-rural land around Dagshai may be cheaper compared to urban industrial zones.

-

Government Incentives: Himachal Pradesh may offer MSME / industrial incentives, tax concessions, or subsidies. (You should verify current subsidies for machinery & power tariff.)

-

Growing Demand: Demand for school stationery (exercise books, registers, diaries) remains stable, especially in Himachal Pradesh schools and coaching centres.

-

Scalability: Starting with semi-automatic equipment allows gradual scaling; later upgrade to fully automatic notebook making machine.

Types of Notebook Making Machines

Here are common types / variants you should consider:

-

Manual Notebook Machine

-

Basic operations done manually — sheet feeding, hand-binding, trimming.

-

Low cost, low throughput. Good for very small scale or pilot setups.

-

-

Semi-Automatic Notebook Making Machine

-

Some motorised folding, stitching, edge-squaring. Requires manual feed or supervision.

-

Suitable for modest volumes (hundreds to low thousands per day).

-

-

Fully Automatic Notebook Making Machine

-

Integrated functions: feeding, stitching, folding / cutting / trimming / edge squaring. Minimal manual labour on production line.

-

High throughput, consistent quality, ideal for scale.

-

-

Complete Notebook Making Plant

-

Multiple units bundled together: paper cutting, ruling / printing (if needed), stitching / binding, packing.

-

Best for when you want turnkey‐capable capacity.

-

Machine manufacturers in India offer a wide range of these options. For example, Bhartiya Machine Works offers semi-automatic and fully automatic notebook machines. Bhartiya Machine Works Printek Engineers offers automatic stitching-folding-edge-squaring machine. printekengineers.in

Key Features to Evaluate

When selecting a notebook making machine near Dagshai, consider the following features:

-

Production Capacity: e.g. books (notebooks) per hour. Machines may range from a few hundred to over a thousand per hour.

-

Automation Grade: semi-automatic vs fully automatic. Fully automatic reduces labour cost, increases consistency.

-

Notebook Size & Thickness Range: A4 / A5 / custom sizes; maximum spine thickness; number of sheets per notebook.

-

Edge Squaring, Stitching Type: multi-head stitching, wire-binding (center-stitch), folding capability.

-

Power Requirement: Single phase / three phase connection, voltage, motor power (HP). Ensure your site near Dagshai has stable three phase supply if needed.

-

Space & Layout: Floor space, working conditions, labour movement, safety clearances.

-

After-Sales Service & Maintenance: Local or regional service support; spares availability; training for operators.

-

Cost and Return on Investment (ROI): Upfront investment vs expected revenue from notebook sales.

Approximate Cost & Investment

Here are indicative price ranges for different machine types:

-

A semi or fully automatic notebook making machine may cost anywhere from several lakhs to tens of lakhs, depending on specification. For example, some machines in India are listed between ~₹2.5 lakh to ₹10 lakh+ depending on features. asvrengineering.com+2Bhartiya Machine Works+2

-

If you plan a complete notebook making plant (cutting + stitching + packing), additional units will add to overall capital cost.

-

Other costs include electrical installations, room / shed construction, utilities (water, drainage, lighting), labour salaries, raw material procurement (paper, boards, covers).

Break-even time will depend on your production output, cost of raw materials, sale price per notebook, and operating expenses (electricity, maintenance, labour).

Setting Up Near Dagshai – Local Considerations

To implement a notebook making machine setup in or near Dagshai, you should account for following:

-

Land & Building

-

Ensure proper building or shed with good foundation, protection from moisture (Himachal region may see rain / winter snow).

-

The terrain is hilly; ensure site is accessible during winters.

-

-

Power & Utilities

-

Check for reliable electricity supply (three-phase where required).

-

Ensure load sanction and safety measures.

-

-

Raw Materials Logistics

-

Paper rolls / sheets / cover boards will need transport by road; ensure access from suppliers likely in Solan / Kalka / Chandigarh region.

-

Storage for raw materials inside facility to protect from dampness/humidity.

-

-

Labour & Workforce

-

Source local skilled / semi-skilled labourers; may need training for machine operation.

-

Evaluate nearest towns for workforce availability (Solan, Kasauli, etc.).

-

-

Permissions & Licensing

-

Obtain any required permits, trade licence, factory / workshop registration under Himachal Pradesh rules.

-

Check environmental / waste disposal regulations (e.g. paper waste, slurry / adhesives etc.).

-

-

Transport & Market Access

-

Finished notebooks need distribution: local school supply, stationers in Solan / Shimla / Chandigarh.

-

Consider packaging and shipping costs over hilly roads.

-

-

Seasonality & Weather

-

High-altitude weather may affect moisture content of paper & storage; use de-humidifiers or climate control inside workshop if needed.

-

Operation Process & Workflow

Here’s a high-level workflow of typical notebook production using a notebook making machine:

-

Design / Ruling / Printing (optional)

-

If you want custom ruling lines or printed content, you might need ruling machine or printing stage upfront.

-

-

Paper Cutting / Trimming

-

Cut sheets to the required size (A4, A5, etc.). May require separate cutting machine or integrated cutting in plant.

-

-

Collation & Stacking

-

Gather inner sheets, front & back covers; align in stack.

-

-

Stitching / Binding

-

Using machine’s stitching head (wire-stitch / center stitch / binding).

-

-

Folding & Edge Squaring

-

Edge squaring ensures neat finish; folding (if half-fold notebooks).

-

-

Trimming / Finishing

-

Final trimming of edges; cover lining; packing.

-

-

Quality Check & Packaging

-

Inspect each notebook; pack in batches; prepare for dispatch.

-

-

Dispatch

-

Transport finished stock to buyers / retailers.

-

A well-set notebook making plant can produce consistent quality and gradually increase scale once demand stabilises.

Benefits & Challenges

Benefits

-

High return potential with consistent local demand (schools, coaching centres, offices).

-

Control over quality, ability to offer custom notebooks / registers.

-

Local manufacturing reduces dependence on imported / external suppliers.

-

Potential to expand product range (diaries, registers, custom college-notebooks).

Challenges

-

Initial capital and maintenance cost.

-

Ensuring consistent quality & raw material supply in a hilly region.

-

Transportation cost due to remote / hillside location.

-

Regulatory compliance and utilities infrastructure (power outages, weather-related disruptions).

Synonyms & Keyword Usage

Throughout this guide we have used repeated forms / synonyms such as notebook making machine, notebook manufacturing machine, automatic notebook making machine, notebook production equipment, notebook machine supplier, notebook binding machine, notebook making plant, notebook making machine Himachal Pradesh in order to boost search-engine relevance.

Steps to Proceed

If you decide to move ahead, here is a typical roadmap:

-

Market Research

-

Survey stationery demand in Solan / Shimla / surrounding region.

-

Identify price points, competitors.

-

-

Technology Choice

-

Request quotations from machine vendors (e.g. Bhartiya Machine Works, Printek Engineers, Sujata Machines).

-

Compare semi-automatic vs fully automatic variant.

-

-

Site Selection & Infrastructure

-

Identify plot or building near Dagshai / Kumarhatti / Solan.

-

Ensure connectivity, access, utilities.

-

-

Procurement & Installation

-

Place machine order; arrange civil works; install machine; test run.

-

-

Staff Recruitment & Training

-

Hire operators; arrange training; maintenance plan.

-

-

Sales & Distribution

-

Develop tie-ups with stationery retailers, schools / coaching institutes.

-

Plan packaging, branding, delivery logistics.

-

-

Scale-up & Diversification

-

After initial months, consider adding printing / design / custom notebook cover services.

-

Expand capacity by procuring additional machines or upgrading to higher-speed automatic notebook making machine.

-

Conclusion

Setting up a notebook making machine-based manufacturing unit around Dagshai, Himachal Pradesh is feasible and potentially profitable provided you plan your investment carefully, choose the right machine variant, and consider local infrastructure constraints. By selecting either semi-automatic or fully automatic equipment according to your scale, and factoring in local costs (power, building, transport), you can build a sustainable notebook manufacturing operation serving regional demand.