Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

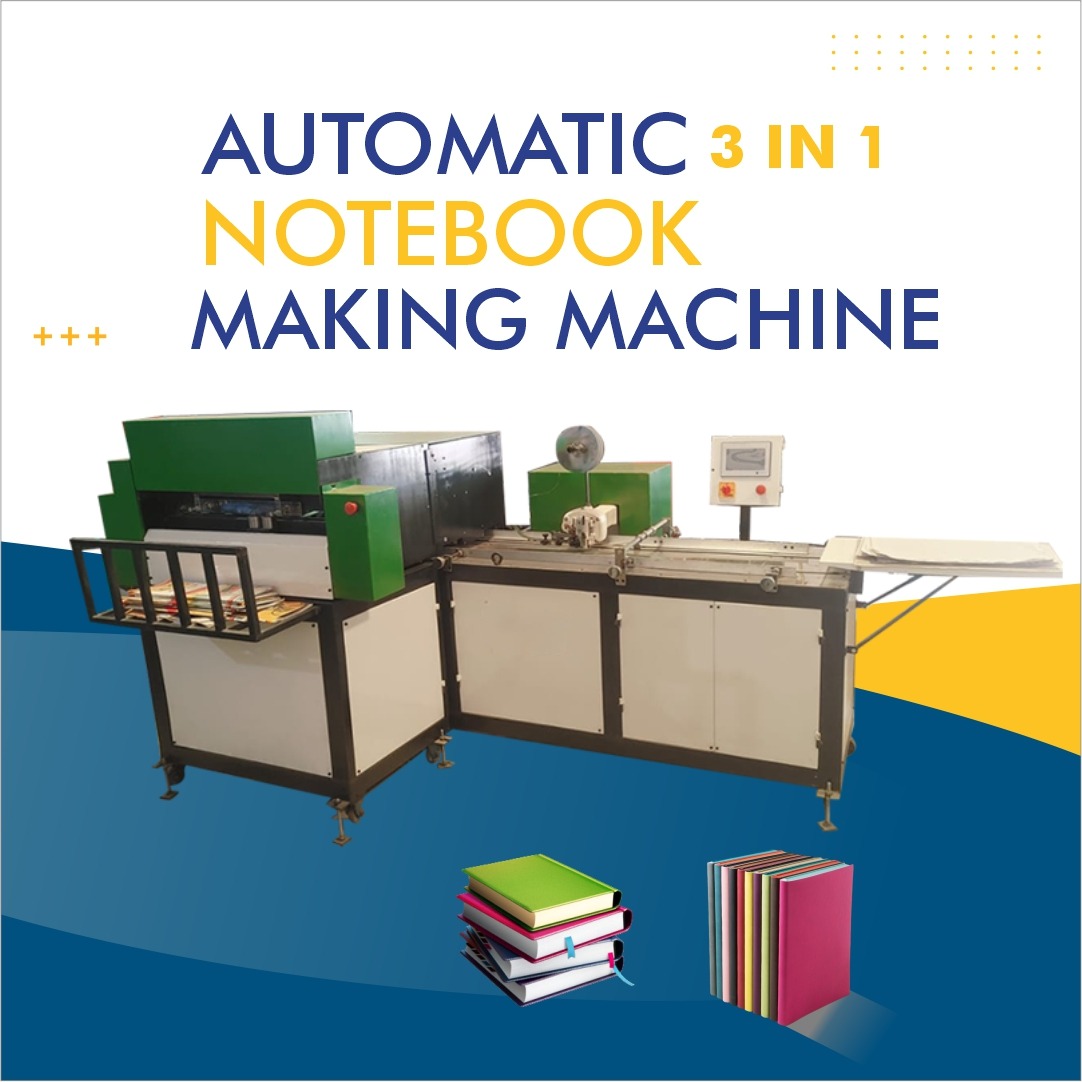

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Bhota, Himachal Pradesh – High-Quality Production Equipment

Notebook Making Machine in Bhota | Himachal Pradesh

Bhota, Himachal Pradesh, has emerged as a promising location for stationery and paper-product manufacturing. The close proximity to quality raw materials, lower transportation costs compared to larger metros, and a supportive small-scale industrial ecosystem make it an ideal place to invest in production infrastructure. If you are planning to set up or expand a stationery manufacturing unit, acquiring a notebook making machine in Bhota gives you unmatched advantages in cost efficiency, local servicing, and adaptability to your production needs.

In this guide, you will learn everything about selecting, sourcing, and installing the best notebook production machine for your facility in Bhota, HP. We will compare machine types, highlight local supplier considerations, and show you how to optimize your investment for high performance and ROI.

2. Understanding the Types of Machines

Before choosing a machine, you need to know what’s available. Here are the most common categories:

-

Notebook Making Machine

This is the general category of equipment used to manufacture notebooks, encompassing sheet cutting, page collating, binding, trimming, and cover attachment. -

Notebook Production Machine

This synonym emphasizes the full production line — from raw paper roll or pre-cut sheets to finished bound notebooks, often handling punching, stitching or gluing, trimming, and cover printing. -

Book Binding Machine

Though “book binding machine” is a broader term, many binding units used in notebook manufacturing are in fact book binding machines. These perform specific binding steps such as stitching, stapling, perfect binding or thread binding. -

Paper Binding Machine

This refers more specifically to the binding mechanism — stapler-type, adhesive binder, or thermal binding — used to assemble the internal pages of your notebook. -

Stationery Manufacturing Machine

A higher-level synonym covering not just binding but other stationery-line equipment such as paper cutting machines, cover embossers, or calendar machines, if your business diversifies beyond notebooks.

You should consider machines that integrate several functions (for example, cutting, binding, trimming) to minimize manual handling and improve throughput.

3. Key Features to Evaluate

When you search for a notebook making machine near Bhota, Himachal Pradesh, or order from further afield, these specifications are critical:

-

Production Capacity: Number of notebooks per hour or shift. Choose between semi-automatic or fully automatic lines depending on your volume.

-

Binding Method: Stitch-binding (wire or thread), adhesive binding (glue), or perfect binding. For simple school notebooks, wire or sewing binding is common.

-

Sheet Size and Format: Custom sizes like A4, A5, or square notebooks; also whether covers are laminated paper or hard cardboard style.

-

Automation Level: Manual feeding vs automatic feeder, PLC controls, touch-screen operator panel.

-

Machine Footprint: Space available in your Bhota unit; floor area, power supply voltage, and ceiling height.

-

Raw Material Compatibility: Thickness of paper, cover sheet type, spine strength.

-

Local Service & Spare Parts Availability: Since Bhota is not a major metro, ensure the supplier has service capabilities or can ship spare parts quickly.

-

Energy Efficiency: Power consumption per cycle, ability to reduce wastage (paper off-cuts, misfeeds).

-

Compliance & Safety Standards: CE certification (if imported), compliance with Indian electrical safety, and workplace–industrial safety norms.

4. Advantages of Purchasing Locally vs Importing

Local Sourcing (within India or Himachal Pradesh region)

-

Faster shipping & lower freight cost to Bhota.

-

Easier access to installation, commissioning and training at your plant.

-

Better after-sales service, spare part supply, and local technicians.

-

Possibility to inspect demonstration machines before purchase.

Importing Equipment

-

Wider variety of advanced features or higher automation levels.

-

Possibly lower unit-price for high-volume machines due to economies of scale.

-

But carries higher customs duty, longer delivery lead times to Bhota, and potentially more complex servicing support.

For many SMEs in Bhota, a hybrid strategy works: source a base model locally and import special modules if required.

5. Vendor Criteria Checklist

When evaluating a book binding machine or paper binding machine vendor for your notebook business in Bhota, Himachal Pradesh, follow this checklist:

| Criterion | What to Check |

|---|---|

| Vendor Experience | Years in stationery equipment manufacturing; reference installations nearby |

| Warranty & Support | Duration of warranty, response time for breakdowns in Bhota region |

| Customization | Ability to adjust machine size, binding style, speed to your needs |

| Training & Documentation | On-site training for operators and maintenance engineers |

| Spare Parts Availability | Whether parts are stocked within the region (e.g. in Himachal-Punjab belt) |

| Price & Payment Terms | Upfront cost, down-payment percentage, financing options |

| Quality Certification | ISO or CE marking if imported; standards for safety & reliability |

| Upgrade Options | Provision to upgrade from semi-automatic to fully-automatic in future |

6. Typical Use-Cases & Applications

Here are some scenarios where a notebook manufacturing line is useful in Bhota:

-

School Notebook Production: Producing A4 / A5 ruled notebooks with stitched binding for local schools and stationers.

-

Customized Notebooks: Printing or embossing covers for local orders, small batches.

-

Corporate Gift Stationery: Producing branded notebooks for corporate clients in Himachal Pradesh or nearby metros.

-

Diversification: Expanding into related stationery items using the same machinery ecosystem (e.g. diaries or notepads).

In all cases, you will benefit from owning your own stationery manufacturing machine rather than subcontracting the binding externally, reducing lead times and improving margin control.

7. Estimating Cost & Return on Investment

To evaluate profitability, consider:

-

Capital Investment: Cost of notebook making machine + installation, transportation to Bhota, civil works (platform, foundation), power wiring.

-

Operating Costs: Labor, electricity, maintenance, consumables (glue, staples), downtime losses.

-

Revenue per Notebook: Selling price to local retailers / clients minus cost of raw paper, cover material, printing cost.

-

Break-even Period: Divide capital investment by annual net profit – aim to break even within 2–3 years depending on scale.

-

Utilization Rate: Higher utilization of the line reduces per-unit fixed cost; invest in automation only when throughput is sufficient to justify it.

For example: if your machine can produce 2,000 notebooks per day, margins are ₹5 per notebook, you operate 300 days a year, annual gross margin ≈ ₹30,00,000. If the machine cost is ₹15 lakh, you could recover cost in under one year (excluding other fixed costs). Modify calculations based on your exact local prices in Bhota and your power tariff.

8. Steps to Implementation in Bhota, Himachal Pradesh

Here is a roadmap to implement your notebook manufacturing setup:

-

Feasibility Study & Market Research

-

Survey school demand in Bhota / surrounding towns (Hamirpur, Una, Kangra).

-

Estimate volumes and pricing dynamics for notebooks sold locally.

-

-

Select Equipment

-

Request quotes for “notebook production machine” from multiple vendors.

-

Compare semi-automatic vs fully-automatic paper binding machine lines.

-

-

Site Preparation

-

Prepare factory space in Bhota (power supply, floor load capacity, ventilation).

-

Ensure approvals from municipality or local authority if needed.

-

-

Installation & Commissioning

-

Schedule delivery & commissioning at your Bhota facility.

-

Train local workers / operators on machine usage & safety.

-

-

Trial Production & Quality Control

-

Run pilot batches for defect rate, binding strength, trimming accuracy.

-

Adjust settings for cover alignment, stitching tension, trimming margin.

-

-

Scaling & Maintenance

-

Establish preventive maintenance schedule (monthly lubrication, tightening, alignment).

-

Keep safety logs and training updates.

-

Plan capacity increase - consider upgrading the book binding machine or adding cover printer / laminator modules.

-

9. Maintenance & Troubleshooting Tips

To ensure longevity and high uptime of your notebook making line in Bhota:

-

Clean and lubricate moving parts weekly to prevent rusting (especially in Himachal’s climate).

-

Monitor binding strength periodically—loose pages may indicate tension calibration is required.

-

Keep a small inventory of critical spare parts (blades, glue nozzles, stitching wires).

-

Train at least two operators in routine maintenance to avoid downtime when primary operator is absent.

-

Maintain alignment logs to detect drift in cutting / trimming accuracy over time.

10. Real-World Example: Hypothetical Setup in Bhota

Suppose you wish to set up a medium-scale notebook factory in Bhota:

-

You purchase a semi-automatic notebook making machine capable of 5,000 A4 ruled notebooks per shift.

-

The binding module is a book binding machine (wire-stitched), with cover trimming and trimming module integrated.

-

The unit occupies 40 sq m, with 3 operators.

-

Annual Production = 1.5 million notebooks.

-

Selling price = ₹25 per piece; production cost = ₹18 per piece.

-

Annual gross profit = (₹7 × 1,500,000) = ₹1.05 crore.

-

Machine cost = ₹25 lakh; break-even within approx. 9 months (before other overheads).

As demand grows, you could add an automated stationery manufacturing machine to increase speed or diversifying into diaries using same production line motors and cutters.

11. Why Bhota is a Strategic Location

Here are some specific locational advantages of Bhota, Himachal Pradesh:

-

Lower property and lease rates compared to metro-nearby industrial zones.

-

Skilled labor availability in the surrounding rural belt.

-

Proximity to Himachal’s road network, allowing supply to towns such as Hamirpur, Una, Kangra, and even onward to Chandigarh / Punjab.

-

Potential interest from state-level incentives for small-scale industry setup in Himachal Pradesh.

These locational benefits reduce your non-manufacturing costs (overheads, transportation) and support steadier operations.

Conclusion

Investing in a notebook making machine for your facility in Bhota, Himachal Pradesh can unlock high productivity, better quality control, and improved margins compared to outsourcing binding services. By carefully selecting the right notebook production machine — one that aligns with your volume, binding style, and maintenance capacity — you can build a sustainable stationery business.

Evaluate features such as automation level, binding mechanism, local service capability, and total cost of ownership. Factor in local advantages such as lower lease costs, ease of labor sourcing, and regional incentives. With the right planning, a book binding machine or paper binding machine integrated into a stationery manufacturing line can help you scale efficiently.

Take the first step now: reach out to reputable suppliers, solicit multiple quotations, inspect site readiness in Bhota, and run a pilot batch. With proper care and operations discipline, your notebook manufacturing unit can become a profitable venture in Himachal Pradesh.