Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

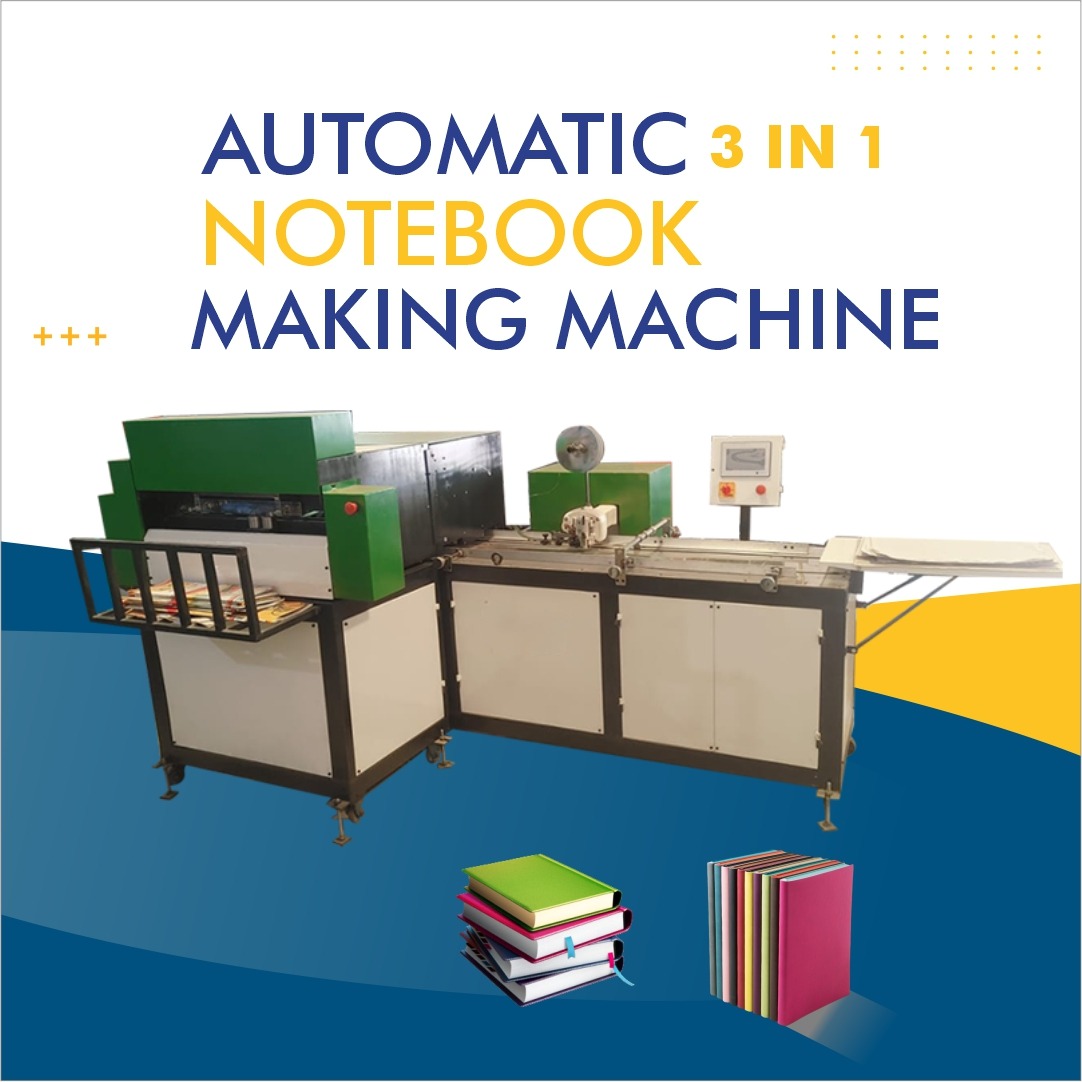

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Yamuna Nagar Haryana – Reliable Supplier & Manufacturer

Notebook Making Machine in Yamuna Nagar | Haryana

Yamuna Nagar, Haryana has emerged as a hub for industrial manufacturing units that cater to stationery machinery, among other sectors. If you are looking for a reliable notebook making machine provider in this region, this guide offers you key insights into choosing, purchasing, and maintaining such machines. We will explore types, features, benefits, specifications, local support, and cost-factors specific to Yamuna Nagar.

This content integrates important keywords throughout to help improve search-engine visibility and deliver useful information for potential buyers.

1. Why Choose Yamuna Nagar, Haryana for Your Notebook Making Machine Needs

-

Strategic manufacturing location: Yamuna Nagar is located in northern India with convenient access to major highways, raw-material sources (paper mills, cardboard suppliers), and markets such as Delhi, Punjab, Himachal, and Uttarakhand.

-

Skilled workforce: Local industrial labour and technicians experienced in mechanical and electrical production.

-

Proximity to suppliers: Stationery material sourcing (paper sheets, covers, binding supplies) is easier and less costly due to reduced logistics distance.

-

Local service & support: Choosing a provider based in Yamuna Nagar ensures faster response times for installation, maintenance, and spare-parts support.

2. Types of Notebook Making Machines Available

When selecting a notebook making machine, you will find various types tailored to production scale, automation level, and budget. Below are the main categories:

-

Automatic Notebook Making Machine

Fully automated systems that handle tasks such as page cutting, stacking, binding, stitching, trimming, and output stacking. Ideal for high-volume production. These are sometimes referred to as "automatic exercise book machine". -

Semi-Automatic Notebook Making Machine

Combines manual steps with automated operations. Useful for medium-scale production where investment cost needs to be balanced with production efficiency. -

Manual or Mechanical Notebook Machine

Lower-cost solution for start-ups or small workshops; many operations are done manually, with only parts of the process mechanized. -

Custom Notebook Making Machine

Machines designed or modified for special formats, sizes, paper weights, or binding styles (e.g., side-stitched, spiral bound, hard-cover). -

Paper Binding Machine / Book Binding Machine

Though not exactly the same as a notebook making machine, binding machines are often integrated into the production line to complete finishing operations.

Each of these categories has pros and cons depending on your production targets, budget, labour costs, and desired quality.

3. Key Features to Consider

When you evaluate notebook making machines (automatic or semi-automatic), these are the critical specifications and features to examine:

-

Production Capacity (Sheets per hour / Notebooks per hour)

An automatic notebook making machine may produce hundreds to thousands of notebooks per hour, depending on design. Semi-automatic models are slower but more flexible. -

Notebook Size Range

Ability to handle different sizes (e.g. A4, A5, school exercise book formats). Adjustability in width, height, and thickness. -

Paper Weight and Thickness Range

Capability to handle different paper GSM (grams per square metre): inner pages, cover sheets, cardboard backing. -

Binding Method

Side-stitching, centre-stitching, perfect binding, spiral binding (if integrated), glueing or thread stitch. -

Automation Level

Integration of sensors, PLC (Programmable Logic Controller), touch-screen interface, automatic feed mechanism, trimming units, counting systems. -

Precision and Finish Quality

Clean edge trimming, accurate stitching, consistent binding pressure, quality checking mechanism. -

Material of Construction

Durable frame, anti-corrosion treatment, industrial-grade motors, safety guards. -

Energy Efficiency and Power Requirements

Electric motor ratings, voltage compatibility for Haryana/India (e.g. 415 V three-phase or as per plant supply), energy consumption per shift. -

Spare Parts Availability & After-Sales Service

Local presence of technician support, ease of sourcing consumables (stitching wire, stapler staples, trimming blades etc.). -

Footprint and Workshop Layout

Floor space requirements in your facility; provision for operator access, servicing, safety compliance. -

Compliance & Safety Standards

Industries in Haryana must follow local safety regulations; ensure emergency stops, guards, CE or ISI certification where applicable.

4. Benefits of Having a Notebook Making Machine in Yamuna Nagar

Investing in a notebook making machine offers multiple advantages, especially when based in Yamuna Nagar:

-

Lower logistics cost for raw materials — being close to paper and cover suppliers reduces transport time and cost.

-

Faster turnaround time for prototyping and customization — local manufacturer can adjust machine settings quickly or supply custom formats.

-

Local regulatory familiarity — providers will be aware of electrical, mechanical, factory-safety norms applicable in Haryana.

-

Better communication & training — staff training, local operator instruction, and periodic maintenance can be handled on-site.

-

Opportunity for growth — as your demand increases (e.g. supplying local schools or regional distributors), you can scale production using upgraded models or add-on modules.

5. Investment & Pricing Factors

Cost of acquiring a notebook making machine depends on several factors:

| Factor | Description |

|---|---|

| Automation Level | Automatic machines cost more than semi-automatic or manual types. |

| Production Capacity | Higher speed or higher volume capacity raises the price. |

| Customization | Special sizes, binding types, or optional modules (like trimming unit, cover lamination, spiral binding attachment). |

| Brand & Build Quality | Regional manufacturer quality, finish, reliability, warranty terms affect price. |

| After-Sales Service Package | Inclusive commissioning, operator training, spare-parts kit, preventive–maintenance contract. |

| Installation & Shipping | Local delivery within Haryana or from nearby factory; installation effort may add to cost. |

A rough estimate for a mid-level automatic notebook making machine may range from INR 5 lakh to INR 25 lakh, depending on capacity and features. Semi-automatic models might cost INR 2 lakh to INR 10 lakh. (These numbers are indicative; always request a formal quotation.)

6. How to Choose the Right Notebook Making Machine Supplier

When evaluating suppliers in Yamuna Nagar or nearby regions, consider the following steps:

-

Verify past projects and references

Ask for case studies or existing customers using similar machines; inspect sample notebooks produced. -

Factory visit

Visit the workshop in or near Yamuna Nagar to observe manufacturing quality, test runs, and builder’s quality assurance. -

Technical specification sheet

Ensure the supplier provides detailed data: speed, power consumption, dimensions, maintenance schedule, expected life-cycle. -

Warranty and maintenance contract

Clarify warranty period and whether the supplier provides on-site maintenance, spare-parts stock, and service agreements for Haryana-based customers. -

Training & installation support

Confirm that the initial installation, calibration, and operator training will be done at your facility in Haryana. -

Flexibility & upgrades

Check whether the machine can be upgraded later with attachment modules (e.g. spiral binding unit, dust-collection, automatic feeder upgrades). -

Delivery time & spare-parts logistics

Local supplier in Yamuna Nagar or nearby ensures shorter delivery times and easier access to spare components and motor replacements.

7. Typical Workflow with a Notebook Making Machine

To help you better understand how a notebook making machine operates in a real-production environment, here’s a typical workflow for an automatic machine:

-

Paper Loading

Sheets of paper are loaded into feeders — inner pages and cover stocks. -

Counting and Stacking

Pages are accurately counted, stacked, and aligned. -

Binding / Stitching

Side-stitched or centre-stitched binding is applied by wire staples or thread stitching. -

Cutting / Trimming

Top, bottom, or side edges of the bound books are trimmed for neat finish. -

Covering & Folding

For exercise-book style notebooks, covers may be folded, glued or pressed. -

Final Quality Check

Each bundle is inspected for alignment, binding strength, and trimming accuracy. -

Output Stacking / Packaging

Finished notebooks are automatically or manually stacked and moved for packing or dispatch.

You can choose a fully integrated line where all these steps proceed continuously, or semi-automatic set-up where certain steps require manual intervention.

8. Case Study: Hypothetical Customer in Yamuna Nagar

Imagine you run a stationery production unit in Yamuna Nagar supplying exercise books to schools across Haryana and Punjab. You require production of 3,000 notebooks per day with a standard size of 200 pages each (A5 size).

-

You select an automatic notebook making machine with speed around 50 books/minute and trimming/touch-screen controls.

-

You consult a local manufacturer who offers installation within one week, operator training on-site, and supplies routine spare parts from their Yamuna Nagar location.

-

Because your raw-material supplier is nearby, paper procurement cost is lower, and you can experiment with custom cover designs in small batches.

-

Over six months you notice downtime is minimal, and after-sales service visits occur within 24 hours due to local presence — reducing your maintenance risk.

This gives you competitive advantage over purchasing machines from remote suppliers or importing from afar.

9. Maintenance & Operational Best Practices

To ensure long life and high performance of your notebook making machine, follow these best practices:

-

Schedule preventive maintenance every month: lubrication, belt tension check, wiring inspection, alignment calibration.

-

Train operators on safe usage, cleaning procedures, and changeover between sizes.

-

Keep an inventory of common spare parts (trimming blades, fasteners, stitching wire, sensors).

-

Document production logs and downtime reasons to help with troubleshooting.

-

Use genuine components and follow manufacturer’s lubrication and electrical spec recommendations.

-

Monitor energy consumption and optimize idle time to reduce electricity costs.

10. Why Synonyms & Related Terms Matter for SEO

In this content we have used synonyms and related terms like automatic notebook making machine, semi-automatic notebook making machine, paper binding machine, exercise book machine, notebook machine supplier, etc. Repetition of these terms in headings, paragraphs, and metadata helps search engines understand the relevance of this page for users seeking such machinery in Yamuna Nagar, Haryana.

Conclusion

If you are looking for a high-quality notebook making machine in Yamuna Nagar, Haryana, investing directly in a locally manufactured automatic or semi-automatic model offers numerous advantages: reduced logistics cost, faster maintenance, customization capabilities, and local support. Evaluate your production targets, budget, and machinery specifications carefully, request on-site demonstrations, and choose a supplier who can deliver long-term partnership and reliable after-sales service.

Whether you require a basic semi-automatic machine or a fully featured automatic production line, Yamuna Nagar offers strategic advantages. Get in touch with manufacturers in the region and request a detailed proposal to match your notebook production needs.