Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

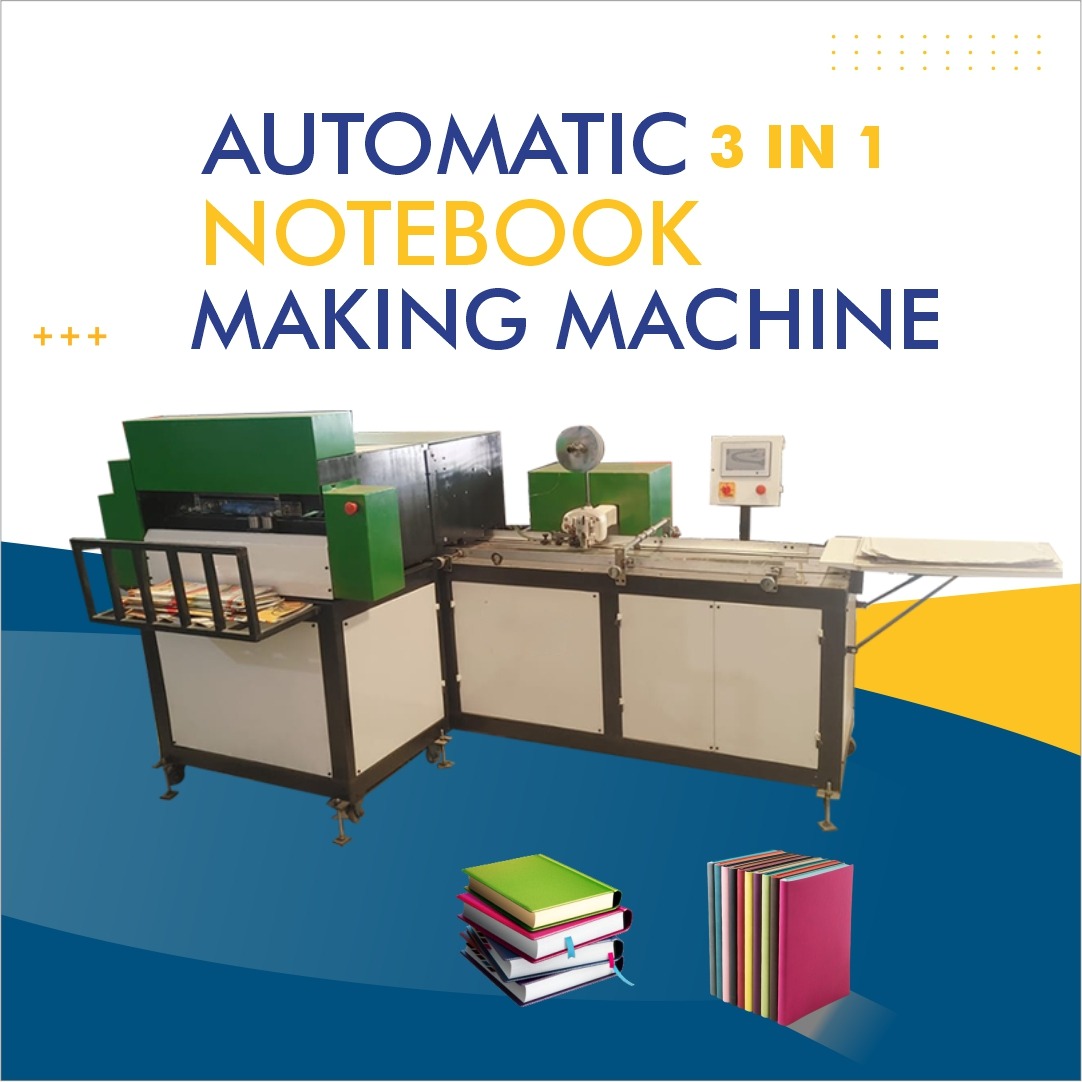

Notebook Making Machine in Tohana Haryana – Best Manufacturer & Supplier

Notebook Making Machine in Tohana | Haryana

If you are searching for a high-quality notebook making machine near Tohana, Haryana, you have come to the right place. We are a leading notebook making machine manufacturer based in Tohana, committed to delivering reliable, efficient, and cost-effective solutions for notebook production. Whether you run a small stationery unit, a school-stationery workshop, or a full-scale manufacturing facility, our machines are designed to meet your exact production requirements.

In this comprehensive guide, you will learn about:

-

Why choosing a local manufacturer in Tohana, Haryana matters

-

Types of notebook making equipment available

-

Technical specifications and features to look for

-

Synonyms and variations of notebook making machinery you might ask for

-

Buying considerations: price, support, maintenance

-

How to select the ideal notebook making machine for your production volume

Why Choose a Manufacturer in Tohana, Haryana

Proximity and Support

Being based in Tohana, our factory is ideally located to serve stationery businesses across Haryana and neighboring states such as Punjab, Rajasthan, and Uttarakhand. Local support ensures shorter delivery times, easier on-site installation, training, and maintenance.

Cost Efficiency

Manufacturing locally reduces transportation & import duties, which helps us offer competitive prices. You pay less for shipping and logistics, making the notebook making machine more affordable.

Customization Options

As a nearby manufacturer, we offer customization in capacity, paper size compatibility, and speed. Custom-designed models allow you to configure binding types, trimming options, cover styles, and automation level.

Types of Notebook Making Machinery

Depending on scale, you may consider different types of equipment:

-

Automatic Notebook Making Machine

These fully automated systems handle sheet feeding, binding (stapling/gluing/sewing), trimming, and stacking. Ideal for high-volume notebook production lines. -

Semi-Automatic Notebook Machine

A midway solution where some processes are manual (loading sheets, cover insertion), while others are automated. Suitable for medium scale workshops. -

Handmade / Manual Notebook Making Machine

For small-scale production, custom or artisan-style notebooks. Manual or semi-manual machines let you make boutique stationery products. -

Notebook Production Equipment (Auxiliary Machines)

These are supporting machines such as paper cutting machines, binding staplers, cover pasting units, trimming and stacking machines which complement the main machine for full production workflow. -

Paper Binding Equipment

Machines that bind, staple or glue sheets to convert them into notebooks. Often integrated into notebook making lines.

Synonyms & Variations (used within the text repeatedly)

Throughout this content you will see variations such as:

-

notebook production equipment

-

paper binding equipment

-

notebook manufacturing equipment

-

automatic notebook machine

-

handmade notebook machine

These help search engines connect to different phrasings users may type.

Features & Technical Specifications

When evaluating notebook making machines, these are the parameters you should check:

-

Production Speed: How many notebooks per hour/day? Automatic machines can produce hundreds to thousands per hour.

-

Notebook Size & Page Count: Compatible sizes (e.g. A4, A5, custom dimensions), page counts, cover thickness.

-

Binding Method: Stapling, gluing, sewing or spiral binding (depending on model).

-

Automation Level: Fully automatic vs semi-automatic vs manual intervention.

-

Material Compatibility: Paper weight (gsm), cover boards, laminated or printed covers.

-

Power Consumption & Electrical Requirements: Voltage (India standard), power usage, safety certifications.

-

Build Quality & Durability: Frame materials, wear-resistant components, ease of maintenance.

-

User Interface & Controls: PLC or manual controls, digital display, speed adjustment options.

-

After-Sales Support: Availability of spare parts, service engineers, upgradation possibilities locally in Haryana.

-

Price & ROI: Initial investment versus operational cost savings, long-term productivity gains.

How to Select the Right Machine

-

Assess Your Production Volume

Estimate how many notebooks you plan to produce per day or per month. If your demand is small (hundreds per day), a semi-automatic or handmade machine could be sufficient. For thousands per day, invest in an automatic notebook machine. -

Choose Correct Size and Binding Style

Decide on your target notebook sizes (for example school-notebooks, diaries, custom sizes). Ensure the machine supports trimming, cover pasting, and binding in that format. -

Compare Specifications & Pricing

Request detailed proposals from manufacturers. Compare speed, features, and maintenance requirements. A manufacturer in Tohana will typically offer lower freight costs and local support. -

Check for Local Regulations & Power Standards

Ensure the equipment meets Indian electrical and safety standards. Verify voltage, grounding, and operator safety mechanisms. -

Plan for After-Sales Service

Choose a manufacturer that offers on-site installation, operator training, and spare parts availability in Haryana. Local presence near Tohana is a strong advantage. -

Budget & Financing Options

Factor in not just the purchase cost, but also installation, training, consumables (e.g. staples, glue), and maintenance. Some suppliers provide EMI or payment plans.

Benefits of Investing in a Modern Notebook Making Machine

-

Increased Productivity

High automation reduces manual labour, speeds up production, and allows scaling without proportionally increasing workforce. -

Consistent Quality

Machines ensure consistent trimming, accurate binding, uniform size and finish — essential for school notebooks or branded stationery. -

Reduced Waste

Automated trimming and alignment reduce paper wastage. Precise cutting saves material cost. -

Scalability

Once you have a reliable machine, you can scale operations, add more lines, or diversify into new notebook formats (diaries, planners, customised covers). -

Competitive Edge

With fast turnaround and professional quality, you can compete with established stationery brands or supply to schools, publishing houses, or retailers.

Case Study: Local Use in Haryana

Consider a stationery business situated near Tohana that used to produce notebooks manually. After upgrading to a semi-automatic notebook production equipment line and trimming unit, they increased output threefold and reduced manual errors. Local technician support meant downtime was minimal and expansion into new notebook size variants became feasible without major capital overhaul.

Maintenance & Warranty

Reliable manufacturers provide:

-

Warranty period for mechanical and electrical components

-

Scheduled preventive maintenance (lubrication, alignment checks, calibration)

-

Easy access to paper binding equipment spare supplies (e.g. staples, glue pads)

-

Local service technician visits within Haryana districts

Ordering Process

-

Initial Inquiry

Contact us with your production requirements: dimensions, capacity, binding method, budget. -

Proposal & Quotation

We send you detailed specifications, drawings, pricing, delivery time (to Tohana or your location in Haryana). -

Factory Visit / Demonstration

If needed, you may visit our manufacturing unit near Tohana to see a working model. -

Manufacturing & Inspection

Machine is built, tested, quality-checked on-site. -

Delivery & Installation

Delivered to your location in Haryana. Our technicians install it, calibrate settings, and provide operator training. -

Ongoing Support

Post-installation, we remain available for technical support, spare parts supply, and upgrades.

FAQs

Q. What is the cost of a notebook making machine in Tohana, Haryana?

A. Prices vary by capacity and automation level. A semi-automatic unit may cost substantially less than a fully automatic line. Contact us with your specifications for a custom quote.

Q. Can you manufacture machines for non-standard notebook sizes?

A. Yes. As a local manufacturer we offer customization in paper size, page count, and binding type to suit your needs.

Q. What is the delivery time for machines in Haryana?

A. Standard models can be delivered within a few weeks. Custom-designed machines may require longer manufacturing and testing time.

Q. Do you provide training for operators?

A. Yes. On-site installation includes training your staff to operate, maintain, and service the machine.

Conclusion

If you are looking for a reliable notebook making machine manufacturer in or around Tohana, Haryana, we offer expertise, local support, and customizable solutions. Our notebook production equipment is engineered for quality, efficiency, and long-term performance. Reach out today to discuss your requirements and get a tailored proposal for your notebook manufacturing equipment.