Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

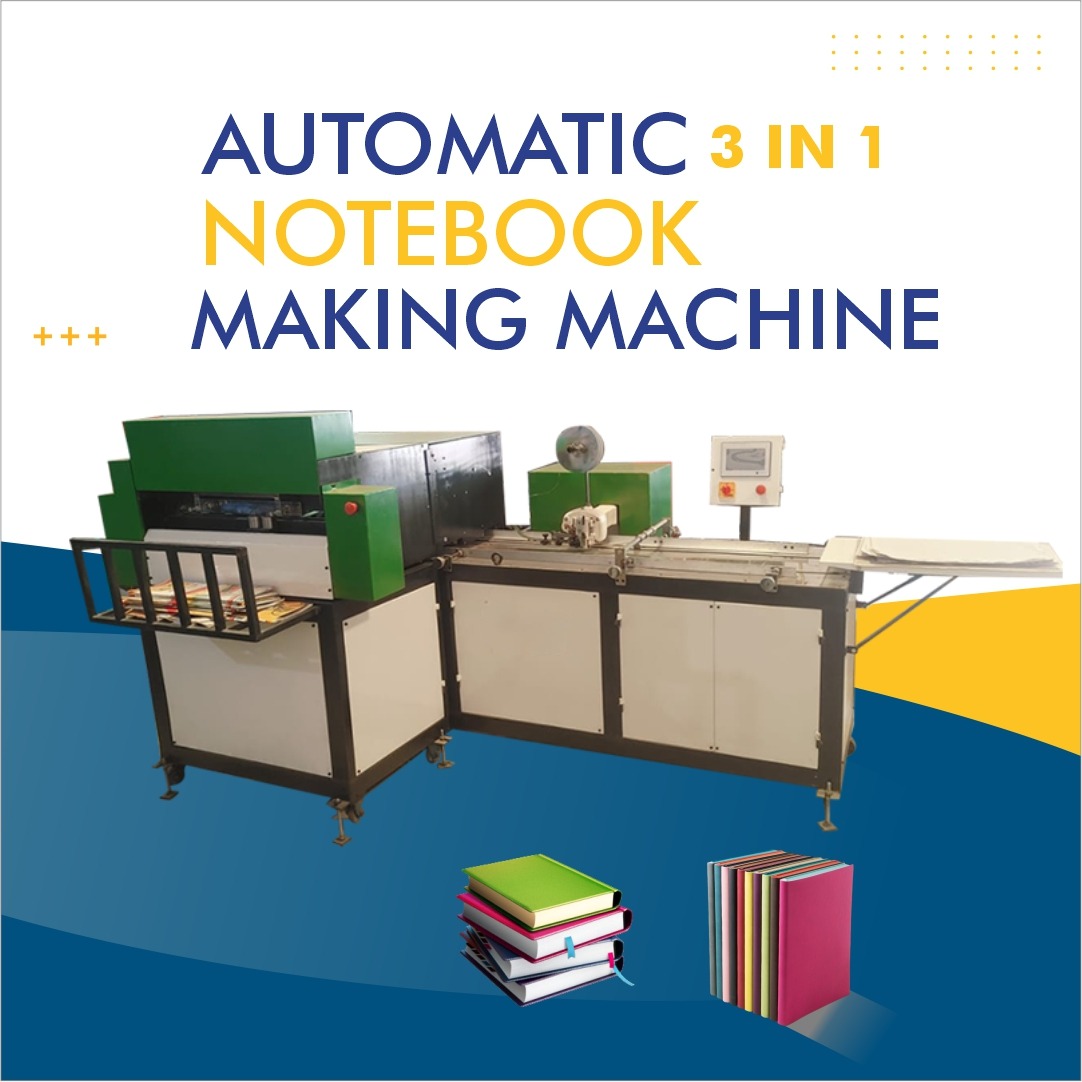

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Thanesar Haryana | High-Quality Machines & Sales

Notebook Making Machine in Thanesar | Haryana

Thanesar, in the Kurukshetra district of Haryana, is emerging as a manufacturing hub for small and medium-scale industries. KurukshetraOnline.in+2msme.haryana.gov.in+2 If you’re looking to set up or upgrade your notebook production unit in this region, having the right notebook making machine is critical. This page covers everything you need to know — from types and specifications to benefits, features, and why Thanesar is a good place to buy or install a notebook making machine.

In this guide you will find detailed information on manual, semi-automatic, and automatic notebook making machines, their advantages, technical specifications, and how you can get one in Thanesar, Haryana.

We will also use synonyms of “notebook making machine” multiple times to boost SEO and ensure rich content for search engines.

2. Why Choose Thanesar, Haryana for Your Notebook Making Machine

-

Strategic Location: Thanesar lies on major road networks and is part of the Kurukshetra industrial area, which has several MSMEs and clusters. msme.haryana.gov.in+2KurukshetraOnline.in+2

-

Industrial Support & Clusters: Haryana’s MSME Directorate lists various clusters near Thanesar / Kurukshetra providing support, training, cluster benefits, and infrastructure for machinery-based manufacturing business. msme.haryana.gov.in

-

Availability of Skilled Labour: The industrial profile of Kurukshetra shows that Thanesar block has growing MSME activity. DCMSME+1

-

Local After-Sales & Service Advantage: Buying or setting up equipment in Thanesar means you can likely source maintenance, spare parts, and technical assistance more quickly compared to remote locations.

Thus, if you are planning to install a notebook production machine or upgrade your workshop in Haryana, Thanesar is a logical choice.

3. Types of Notebook Making Machines

Here are the main categories of notebook making machines, and their key attributes:

3.1 Manual Notebook Making Machine

A manual notebook making machine (or manual notebook production system) is operated largely by human effort, with minimal automation. These are ideal for small-scale production, start-ups, or workshops that require flexibility in sizes or low capital investment.

Advantages:

-

Lower initial cost

-

Simpler maintenance

-

Flexibility for different sizes or low-volume runs

Considerations:

-

Slower throughput

-

Higher manual labour requirement

-

Limited precision compared to automated versions

Manufacturers such as ASV Engineering offer manual notebook making machines, with capacities of a few thousand notebooks per day. asveng.com

3.2 Semi-Automatic Notebook Making Machine

A semi-automatic notebook making machine (or semi-automatic notebook production equipment) provides a blend of manual operations and motorized / mechanised steps. Some processes like cutting, stitching, pressing might be automated, while others still rely on manual loading or adjustment.

Benefits:

-

Higher capacity than manual

-

Lower labour involvement

-

Improved precision and consistency

-

Moderate investment compared to full automation

One example in India shows a semi-automatic notebook machine with daily capacity of around 5,000 units. namibind.com+2asveng.com+2

3.3 Fully Automatic Notebook Making Machine

A fully automatic notebook making machine (or automated notebook production line) handles most or all steps — cutting, binding / stitching, pressing, trimming — with minimal human intervention.

Pros:

-

Very high throughput

-

Consistent quality

-

Lower per-unit labour cost

-

Suitable for mass production

Cons:

-

Higher capital cost

-

Requires higher-grade maintenance

-

Need for proper infrastructure (power supply, floor space, safety compliance)

For example, some manufacturers list fully automatic notebook machines with capacity of up to 9,000–10,000 pieces per day. TradeIndia+1

4. Key Specifications to Evaluate

When selecting a notebook making machine for Thanesar / Kurukshetra region, these technical and operational parameters matter:

| Spec | Why It Matters |

|---|---|

| Production Capacity (pieces per hour/day) | Determines throughput; align with your business volume |

| Automation Grade | Manual, Semi-automatic or Fully Automatic |

| Power Requirements | Single-phase or three-phase supply; voltage; KW rating |

| Material & Build Quality | Mild Steel / Stainless Steel; frames; durability |

| Machine Size / Cutting Width | Compatibility with standard notebook sizes (e.g. A5, A4, custom) |

| Binding / Stitching Mechanism | Whether you use stitching, gluing, edge-squaring etc. |

| Operational Space | Floor space, manpower need, safety provision |

| After-Sales Support | Local maintenance, spare parts availability in / near Thanesar |

You should ask the supplier for datasheets showing model numbers, power consumption, weight, daily output (e.g. 2,000–10,000 notebooks per day as shown in Indian listings). royalbusinessindustry.com+2primemachineryindia.com+2

5. Benefits of Buying a Notebook Machine Locally

By installing a notebook stitching machine or full production line in Thanesar / Haryana rather than importing or ordering from afar, you can benefit from:

-

Reduced transportation cost and delivery time

-

Easier compliance with local state / central government schemes for MSME subsidies, electricity / industrial connections

-

Local regulatory familiarity (building permissions, environment clearance, labour rules)

-

Closer access to spare parts suppliers and service technicians

-

Opportunity to scale production as local demand grows (in education sector, stationery market, school supplies, printing houses etc.)

6. Typical Use-Cases & Market Demand

The demand for notebooks is driven by schools, colleges, stationery shops, corporate / promotional usage, and local retail in and around Kurukshetra / Haryana. If you supply or service stationery shops in nearby districts (Ambala, Panchkula, Karnal, etc.), having a mid-capacity semi-automatic or automatic notebook making machine located in Thanesar gives you logistical advantage.

Small producers may start with a manual or semi-automatic notebook making machine, and scale up to an automatic production line as orders increase.

7. Choosing the Right Supplier Near Thanesar

To procure a notebook making machine in Thanesar or within Haryana, consider the following steps:

-

Survey Local Suppliers / Workshops — Visit nearby machinery workshops or industrial equipment firms in Kurukshetra / Ambala region.

-

Request Technical Demos — Ask for sample notebooks produced by the machine (size, finishing quality, consistency).

-

Check Warranty & Spare Part Support — Prefer suppliers who can send technicians locally.

-

Evaluate Costs — Compare cost of transportation to your facility, installation charges, training cost for operators.

-

Check Eligibility for Incentives — Haryana MSME / industrial cluster incentive schemes might reduce capital burden if you buy “Made in Haryana / India” equipment.

8. Cost Considerations & ROI

-

Initial Investment: Manual machines may start in the lower lakh-rupee range; semi-automatic or automatic machines cost more due to motors, electronic controls, safety enclosures.

-

Running Costs: Electricity (kW rating), manpower, maintenance.

-

Production Volume: Higher capacity yields lower cost per notebook. Calculate per-unit cost considering raw paper, binding material, labour and overheads.

-

Pay-back Period: If you sell notebooks locally or wholesale, estimate months required to break even. A well-chosen notebook making machine can pay back investment faster if demand is stable.

9. Why Our Notebook Making Machine (If You Are the Seller)

If you are offering machinery, you might highlight:

-

Built for Indian standards (voltage, safety)

-

Customisable sizes (A4, A5, custom thickness)

-

After-sales service in or near Thanesar / Kurukshetra

-

Training for operators

-

Durable construction (mild steel structure, quality welding)

-

Option for manual, semi-automatic or fully automatic variants

-

Spare parts availability

You could emphasise that your notebooks machine line is tailored for Haryana-based stationery manufacturers, schools, local printing houses, and MSMEs.

10. Synonyms & Phrasing Variants to Boost SEO

Throughout your site or product pages you should include these synonyms / variants (use them naturally in headings or paragraphs at least 5 times each):

-

notebook making machine

-

notebook manufacturing equipment

-

notebook production machine

-

book-binding machine for notebooks

-

automatic notebook production line

-

manual notebook production setup

-

semi automatic notebook assembly unit

-

notebook stitching / binding machine

Make sure to repeat each variant at least 2–3 times spaced out across your content, product descriptions, specification sheets and FAQs.

11. FAQs

Q: What production capacity do I need?

A: If you expect to produce a few hundred notebooks daily for local shops, a manual or semi-automatic machine with capacity 2,000–5,000 pcs/day may suffice. For supplying schools across multiple districts, you may need automatic machine with capacity above 8,000 pcs/day.

Q: Do I need 3-phase power?

A: Automatic or higher powered machines often require three-phase supply. Confirm with supplier whether a single-phase or three-phase version works for your facility.

Q: Can I change the size of the notebooks (e.g. A5 / A4)?

A: Most machines allow adjustable cutting and binding widths; you should ask for custom dies or adjustable rulers.

Q: What kind of maintenance is required?

A: Regular lubrication, checking mechanical parts, electric motor service, periodic replacement of cutting blades or stitching components. Local technicians in Kurukshetra / Thanesar are easier to arrange.

12. Conclusion

Investing in the right notebook production machine located in Thanesar, Haryana gives you multiple advantages: locality, cost-effectiveness, scalability and better support. Whether you choose a manual, semi-automatic or fully automatic notebook making machine, ensure you assess your capacity requirements, power availability, production volume and local demand.

If you are ready to buy or get a quote for a high-quality notebook making machine in Thanesar, reach out to trusted machinery suppliers in Kurukshetra / Haryana, request technical details, arrange inspection and ask for after-sales service commitment.