Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

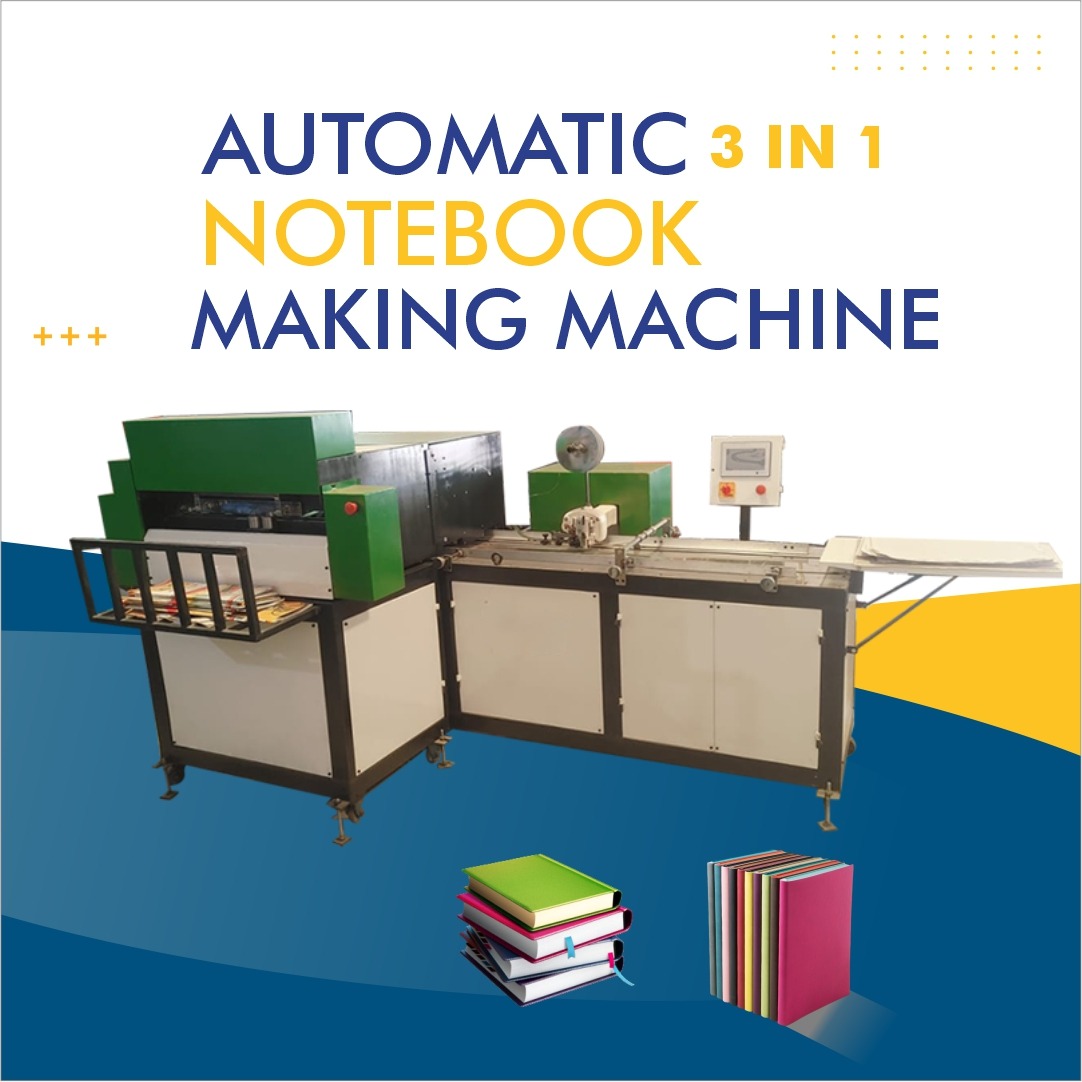

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier Samalkha | Top Quality Machines in Haryana”

“Notebook Making Machine Supplier Samalkha | Haryana

If you are searching for a reliable notebook making machine in Samalkha, Haryana, you’re at the right place. Whether you plan to start or scale your notebook manufacturing business, choosing the correct machinery is essential for quality, productivity, and profitability. This article will guide you through everything you need to know: types of machines, features, benefits, selection criteria, why Samalkha is a strategic location, and how to choose a partner for supply and after-sales service.

Below we discuss key considerations, technical specifications, and market trends to help you make informed decisions.

Why Samalkha, Haryana is a Good Location

-

Industrial Accessibility: Samalkha lies near major transport routes in Haryana, with access to road and rail networks. This makes logistics easier for both inbound raw materials (like paper, board, staples) and outbound finished notebooks.

-

Proximity to Markets: The region is close to major urban centres like Delhi NCR, Panipat, Karnal, and offers cost advantages in labour and operations.

-

Cost Advantage: Operating in Samalkha typically involves lower land and labour rates compared to metro areas, while still being accessible to suppliers and buyers.

-

Support from Local Authorities: Haryana’s industrial policy supports small and medium manufacturing units. You may benefit from local regulations, electricity supply norms, and permit procedures tailored to such manufacturing ventures.

Given these advantages, establishing or procuring your notebook production machine business base here can be wise.

Types of Notebook Making Machines

Below are common types of machines you may consider for investing in notebook production:

| Type | Description |

|---|---|

| Automatic Notebook Making Machine | Fully automated machinery that feeds paper, assembles sheets, staples or spiral binds, cuts edges, and delivers finished notebooks with minimal manual intervention. High throughput, consistent quality. |

| Semi-Automatic Notebook Machine | Requires some operator supervision (loading, monitoring, manual adjustment), ideal for small to midsize workshops or startups. |

| Manual or Hand-Operated Binding and Cutting Equipment | Suitable for very small scale production or prototyping. Lower capacity, higher manual overhead. |

| Custom or Modular Notebook Production Line | Designed for special sizes (diary, exercise, legal pads), custom binding style, multiple finishing steps; scalable or upgradable. |

| Paper Binding / Stapling / Trimming Sub-Units | Separate modules like trimming machine, edge cutter, stapler feeder, cover pasting unit, etc., which can be combined to form a notebook assembly line. |

These variants are often available via manufacturers or suppliers in and around Samalkha, or can be custom-fabricated to your specification.

Key Features & Technical Specifications

When evaluating a notebook making machine, check for the following features:

-

Production Capacity – Number of notebooks per hour or per shift. Automatic systems may produce hundreds to thousands per hour; semi-automatic ones will have lower throughput.

-

Paper Size Flexibility – Ability to handle different paper sizes (A4, A5, custom).

-

Binding Type – Staple binding, comb/spiral binding, thread-sewn binding, perfect binding (if required).

-

Trim Accuracy & Cutting Mechanism – Edge trimming precision to ensure clean finished edges.

-

Automation Level – Degree of automation in sheet feeding, stacking, stapling, cutting, and stacking of finished notebooks.

-

Material Handling – Paper weight (GSM) compatibility, cover material handling (cardboard / thick boards for covers).

-

Control Interface – PLC controls, touchscreen panel, safety interlocks.

-

Energy Consumption – Power usage per cycle, requirement for compressed air or hydraulic systems.

-

Maintenance & Spare Parts Availability – Local service centres, spare parts supply near Samalkha / Haryana region.

-

Durability & Build Quality – Sturdy frame, corrosion-resistant parts, alignment accuracy, finish quality.

-

Safety Features – Guards, emergency stop, operator ergonomics, compliance with local safety standards.

Be sure to obtain technical datasheets and perform on-site visit or demonstration (if possible) before purchasing.

Benefits of Investing in a Quality Notebook Machine

-

Consistency & Precision: Automated machines ensure each notebook is cut, bound, and trimmed uniformly, reducing wastage and increasing perceived quality.

-

Higher Output: Using a proper automatic or semi-automatic notebook making machine increases your production volume, enabling you to serve larger orders such as schools, colleges, stationery chains.

-

Cost Efficiency: Although initial investment is higher, unit cost per notebook falls with higher production run. Reduced manual labour costs and fewer rejects help margin improvements.

-

Scalability: Choosing a modular or upgradeable system allows you to expand capacity by adding sub-units like additional trimming or binding modules later.

-

Competitive Advantage: High-quality binding and finishing translate to premium feel, helping you compete with local and regional stationery producers in Delhi NCR, Haryana, and beyond.

-

Faster Turnaround: With an efficient notebook production line, lead times reduce significantly, which helps in meeting bulk orders during academic season, festivals, or tenders.

Selection Criteria: What to Consider When Buying

To ensure you choose the right notebook making machine in Samalkha, consider the following selection criteria:

-

Budget vs Return: Estimate your production volume and revenue potential. Compare the ROI period if you invest in an entry-level semi-automatic machine vs a fully automatic line.

-

Supplier Reputation: Choose a manufacturer or vendor with proven track record. Request factory visits, inspect sample notebooks, check customer references.

-

After-Sales Service & Support: Ensure local technicians, spare parts availability, preventive maintenance schedules. It is ideal if the supplier has service presence in Haryana or nearby.

-

Customization Ability: If you need non-standard notebook sizes or bindings, confirm that the supplier can modify or custom-build.

-

Warranty & Certifications: Check electrical safety certifications, machine warranty period, and compliance with local regulations.

-

Training & Documentation: The supplier should provide operator training, user manual, maintenance schedule, and spare-parts lists.

-

Footprint & Infrastructure: The machine’s physical dimensions, power requirement, foundation requirement (floor load), compressed air or cooling needs. Confirm your factory facility in Samalkha can support these.

-

Quality Samples & Trials: Ask for sample produce before full acceptance of machine, inspect binding strength, trimming alignment, page numbering consistency, and finished edges.

Use-Case Scenarios & Applications

Here are a few real-life scenarios where a notebook making machine in Samalkha could serve demand:

-

School / College Stationery Order Fulfilment: Bulk orders of exercise books and notebooks for schools in Haryana / Delhi NCR region.

-

Custom Branded Notebooks: Local entrepreneurs or printing firms needing on-demand short runs of branded notebooks (company logo, diary style, custom cover thickness).

-

Tender / Government Contracts: Supplying notebooks to government-run schools or public institutions under procurement tenders in Haryana.

-

E-Commerce / Boutique Stationery: Producing premium or designer notebooks for sale online, catering to niche markets.

-

Export-Ready Production: Once capacity is sufficient, you may serve international orders; Haryana-based machinery export compliance or cross-border logistics via road.

In each case, your choice of machine (automatic / semi-automatic / custom line) will affect lead time, quality, and overall profitability.

Investment & Cost Estimates

While the exact cost of a notebook production machine depends on specifications, automation level, and custom features, the following rough estimates may help you:

| Machine Type | Approximate Price Range* |

|---|---|

| Semi-automatic binding / cutting / trimming line | INR 5–12 lakh |

| Automatic notebook making machine with trimming, stapling, stacking | INR 15–40 lakh |

| Custom modular production line with advanced binding / cutting modules | INR 40+ lakh depending on scale and features |

*Prices may vary based on brand, capacity, customization, and local taxes. Always confirm shipping / installation / commissioning costs in Samalkha, Haryana.

You should also budget for maintenance, spare parts, operator training, and possible power backup or infrastructure upgrade costs.

How to Find a Supplier in Samalkha, Haryana

To purchase or get quotations for notebook making machines in Samalkha or nearby areas:

-

Search local industrial directories or yellow pages for manufacturers of “paper machinery,” “binding machines,” “printing & stationery equipment.”

-

Visit industrial clusters in Samalkha, Panipat, or nearby Haryana towns to identify machine fabricators.

-

Request demos or site-visits to existing workshops using similar machines.

-

Ask for references from existing notebook manufacturers in the region.

-

Verify credentials: GST registration, trade licence, customer testimonials.

You may also approach specialized machine builders or vendors in Delhi / Haryana who supply and install machinery locally. Be sure to confirm that delivery, alignment, training, and commissioning will be performed on-site at your facility in Samalkha.

Maintenance, Upkeep & Operational Tips

Once your notebook making machine is installed, following best practices helps maintain performance:

-

Establish preventive maintenance schedule (lubrication, alignment checks, wear-and-tear inspection).

-

Keep spare consumables and critical parts in stock (blades, staples / binding elements, motor belts, sensors).

-

Train operators thoroughly in safety procedures and routine upkeep.

-

Monitor machine performance metrics: throughput, reject rate, downtime. Use this data to optimise adjustments.

-

Upgrade firmware or control software if available from your manufacturer.

-

Keep records of power consumption, maintenance cost vs downtime to identify opportunities for efficiency improvements or upgrades.

Proper upkeep ensures your investment yields multiple years of reliable production.

Future Trends & Technology Upgrades

The notebook manufacturing sector is evolving. Some trends you may consider:

-

Smart Automation & IoT Integration — Machines with digital monitoring, predictive maintenance alerts, production dashboards.

-

Eco-Friendly Materials & Energy Efficiency — Lower power consumption designs, recyclable covers, green-certified manufacturing lines.

-

Flexible Production — Machines that switch quickly between sizes or binding styles to accommodate custom orders.

-

Advanced Finishing Options — UV coating, custom embossing or printing integration with binding line, enabling premium notebook products.

By selecting a modern, scalable notebook making machine now, you position your business in Samalkha for long-term competitiveness.

Conclusion

Selecting the right notebook making machine in Samalkha, Haryana involves evaluating your production needs, automation level, budget, and supplier capabilities. With the proper machinery, you can deliver high-quality notebooks at competitive cost, serve large-volume orders for schools, colleges, and businesses around Delhi NCR, and scale as demand grows.

Start by shortlisting potential suppliers, reviewing machine demos or samples, checking after-sales support in Haryana, and planning for infrastructure needs at your facility. A well-chosen notebook production line will be a cornerstone for your success in the stationery manufacturing industry.