Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

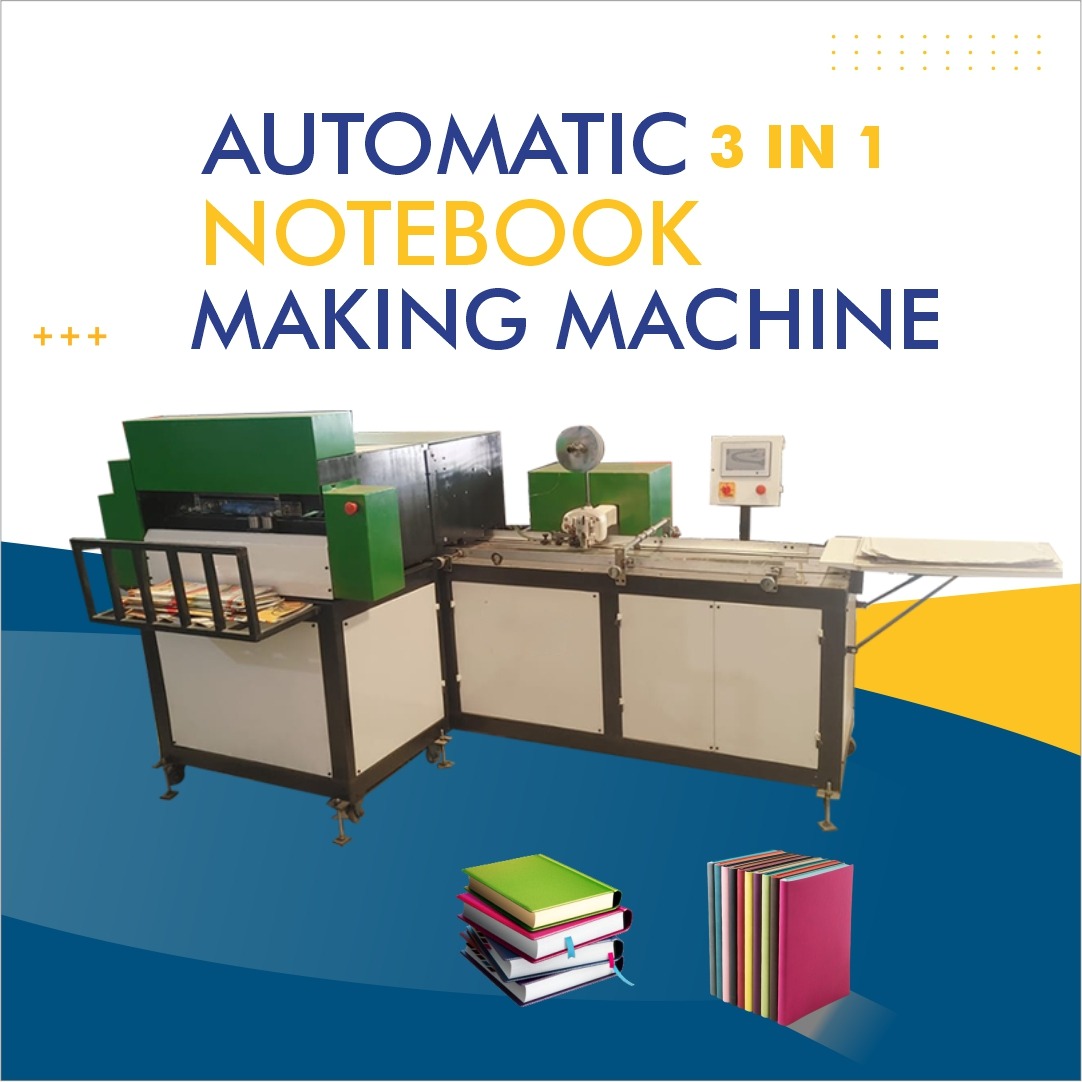

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Pundri Haryana | Leading Manufacturer & Supplier

Notebook Making Machine in Pundri | Haryana

When it comes to notebook production in Haryana, businesses seek reliability, consistency and precision. If you are located in or around Pundri, Haryana, and are looking for a notebook making machine, you have come to the right place. A well-engineered notebook maker machine can increase your productivity, reduce labor costs, and improve the quality of your product. This article will guide you through everything you need to know — from types of machines, selection criteria, and local services to maintenance and installation support around Pundri.

Over the course of this content, you’ll encounter repeated synonyms like notebook maker machine, automatic notebook machine, notebook production equipment, paper binding equipment, book binding machine, and so on, helping you get SEO-friendly visibility and understand the variety of terminology used in this industry.

Why Choose a Notebook Making Machine in Pundri, Haryana

Strategic Location

Pundri is a town in Kaithal District of Haryana, well-positioned between major industrial centers. Locating your machine supply or manufacturer here helps reduce freight costs and ensures easy accessibility of after-sales service.

Local Support & Service

Having a notebook production equipment provider in Pundri or nearby ensures that installation, commissioning, maintenance and spare parts are rapidly available without long wait times.

Competitive Pricing

Since manufacturing units are nearby, you may benefit from reduced shipping rates and lower lead times compared to sourcing machines from distant states or overseas.

Skilled Workforce

Haryana has a growing skilled workforce in mechanical engineering and fabrication. Local manufacturers often employ fabricators and electricians who understand the requirements of paper binding equipment and associated automation.

Types of Notebook Making Machines

When you browse for a notebook making machine, you will come across multiple types. It’s important to choose the one that best fits your production volume, product variety, and budget.

-

Semi-Automatic Notebook Maker Machine

Semi-automatic units require manual feeding or adjustment for certain operations. Ideal if your production scale is moderate or you want lower initial investment. -

Fully Automatic Notebook Making Machine

These machines handle major steps automatically: feeding sheets, folding, punching, clip / wire binding, gluing covers, trimming, and edge finishing. This is the automatic notebook machine suited for higher volume production. -

Spiral-Binding Notebook Production Equipment

Specific to spiral or wire-o binding, these machines are used if you produce spiral-bound notebooks, planners or wire-o diaries. -

Glue Binding / Perfect Binding Machines

If your notebooks require glued spines, you might consider glue-binding equipment that can integrate into your production line. -

Customized Notebook Manufacturing Machine

Many machine builders in Haryana can customize the design to meet your sheet size, thickness, cover finishing, trimming dimensions, and binding type.

Each of these types comes under the broader umbrella of notebook production equipment or paper binding equipment. Selection depends on your output needs, budget, and quality standards.

Key Features to Evaluate

When selecting a notebook making machine in Pundri, Haryana, or nearby, focus on the following features:

-

Production Capacity

How many notebooks per hour or per minute? Does the capacity match your target output? -

Sheet Size Compatibility

Can it handle A4, letter size, or custom dimensions? What maximum thickness of paper or cardboard cover? -

Binding Type

Wire / spiral binding, stitched binding, glue binding etc. If you plan to diversify formats, opt for flexible binding capability. -

Automation Level

Is the machine fully automatic or semi-automatic? Automatic lines reduce labor, increase speed, but cost more upfront. -

Power Consumption & Energy Efficiency

Consider electrical requirements and energy usage. More efficient designs reduce operating cost. -

Build Quality & Durability

Look for strong frames, reliable electrical components, and reputed brand of motors and controls. -

Ease of Maintenance

Availability of spare parts, local technicians, and ease of access to service around Pundri is vital. -

Safety Features

Guards, emergency stops, sensors — ensure the machine meets safety best practices. -

Price & Payment Terms

Does the supplier allow payment in stages? Are installation and training costs included?

Choosing a Supplier Near Pundri

If you’re sourcing a notebook making machine near Pundri, Haryana, consider these steps:

-

Manufacturer vs. Trader

A manufacturer in Haryana can offer customization, faster lead times, and direct technical support. A trader may offer lower upfront quotes but limited customization. -

Site Visit & Demonstration

Ask the supplier to demonstrate the notebook maker machine in operation. Inspect sample notebooks for binding quality, trimming accuracy, and finishing. -

After-Sales Support

Confirm local presence for notebook manufacturing machine servicing, availability of spare parts, and response time. -

Training & Commissioning

Ensure that the supplier provides training for operators and technicians when installing the automatic notebook machine at your facility. -

Feedback & References

Seek references from other notebook producers in Kaithal or nearby districts who have used similar equipment. -

Compliance & Standards

The machine should comply with relevant electrical and mechanical safety standards applicable in India.

Installation & Commissioning in Pundri

Once you finalize your notebook production equipment supplier, proper installation is critical:

-

Site Preparation

Ensure your facility in Pundri has the floor strength, electrical supply (voltage, phase), ventilation, and access space for machine dimensions. -

Delivery & Unpacking

Coordinate with the supplier for transport—from factory to your workshop location near Pundri, Haryana. Inspect for shipping damage. -

Mechanical Alignment

Supplier engineers will align rollers, feeding units, binding units and trimming modules to ensure consistent output. -

Electrical Wiring & Safety Setup

Ensure emergency stops, grounding, and electrical panels are installed as per safety norms. -

Trial Runs & Quality Checks

Run test batches of notebooks. Check trimming alignment, page count accuracy, binding tightness, and finished product appearance. -

Operator Training

Training operators and maintenance staff on daily checks, lubrication, parts replacement, and troubleshooting common issues. -

Documentation

Obtain user manuals, maintenance schedules, and spare-parts list from the supplier.

Maintenance & Spare Parts

Maintaining your notebook-making equipment ensures long life and consistent performance. Key suggestions:

-

Schedule Routine Inspections

Monthly checks for wear on blades, rollers, binding clips, glue nozzles, and trimming knives. -

Lubrication & Cleaning

Regular cleaning of dust and paper residue; lubrication of mechanical linkages and bearings to avoid jams. -

Wear Parts Replacement

Frequently replaced parts (e.g. blades, punches, rollers) should be stocked locally. Confirm if your supplier in Pundri stocks these. -

Technical Support

Ideally the notebook machine builder in the region can dispatch a technician for on-site servicing or remote guidance. -

Upgrades & Retrofits

As you scale production, you may need add-on modules such as automatic cover feeder, cover gluing, or barcode stamping. A local manufacturer is best placed for upgrades.

Cost Considerations & Financing

Purchasing a high-quality notebook manufacturing machine is an investment. Consider:

-

Capital Cost

Fully automatic lines cost more than semi-automatic, but yield higher throughput and lower labor cost per unit. -

Operational Cost

Power usage, operator wages, consumables (glue, binding wire/clips, trimming knives) all contribute to cost per notebook. -

Return on Investment (ROI)

Estimate how many notebooks per day you expect to produce. Compute payback period considering machine price, maintenance cost and production margin. -

Financing Options

Some local suppliers may offer installment payment plans, or you may secure a small business loan (e.g. from regional banks or government MSME schemes in Haryana). -

Government Incentives

Check for any subsidies, incentives or tax benefits under Haryana state industrial policy or MSME incentives for manufacturing equipment investment.

Case Study: Notebook Line Setup Near Pundri

Consider a small manufacturer located in a village near Pundri. They wanted to upgrade from manual binding to a semi-automatic line. After installing a semi-automatic notebook maker machine, their production increased from 200 pieces per day to 1,200 pieces per day. They also observed improved trimming accuracy, reduced waste and higher consistency in binding. With monthly maintenance support from the local supplier, downtime reduced significantly.

Later, as their demand rose, they upgraded to a fully automatic notebook making machine with spiral-binding and glued cover finishing — all sourced from within Haryana. The ROI period came down to only 18 months thanks to labor savings and higher throughput.

Frequently Asked Questions (FAQs)

Q: What is the delivery time for a notebook making machine to Pundri?

A: Delivery depends on stock availability and customization. Standard machines may take 4–6 weeks; custom modifications may add lead time. Local Haryana manufacturers may deliver faster.

Q: Can the machine handle customized notebook sizes?

A: Yes — if you work with a machine supplier who offers customization, you can build to your sheet dimensions, thickness, and binding type.

Q: Do I need skilled operators to run an automatic notebook machine?

A: Some basic training is sufficient. The supplier usually provides operator training as part of commissioning.

Q: What maintenance does the notebook making machine require?

A: Daily cleaning, periodic lubrication, blade replacements, motor checks, and sensor calibration are standard.

Conclusion

Selecting the right notebook making machine in Pundri, Haryana can dramatically improve your production capacity, product quality, and cost efficiency. Whether you choose a semi-automatic model or a fully automatic production line, ensure that you partner with a trusted local supplier who offers installation, after-sales support and spare parts availability. By evaluating the machine’s capacity, features, cost, and support mechanisms, you can make an informed investment that supports your notebook manufacturing business for years to come.