Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

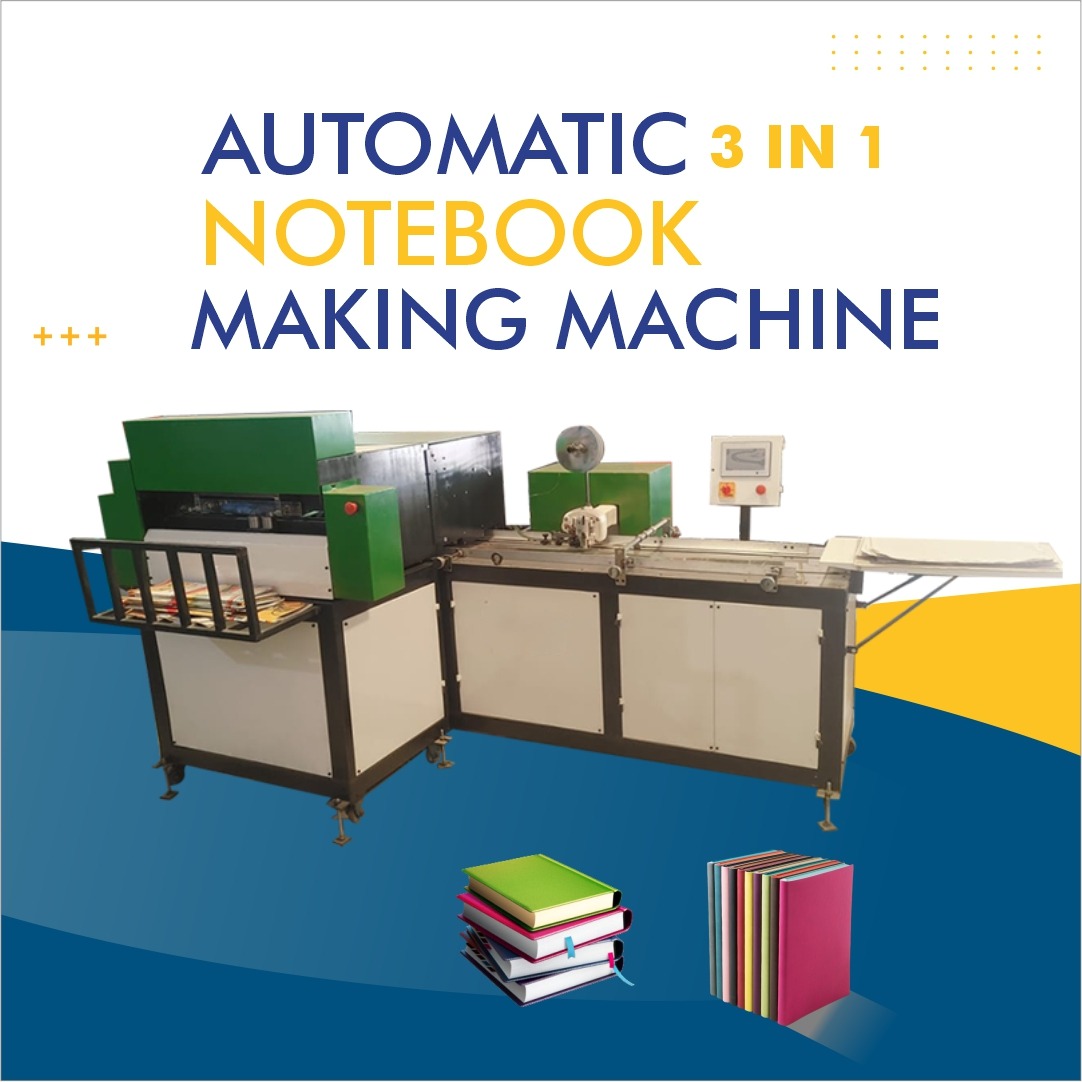

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier & Manufacturer in Pehowa, Haryana

Notebook Making Machine in Pehowa | Haryana

If you are in search of a notebook making machine in Pehowa, Haryana, you’ve come to the right place. Whether your business is expanding into school stationery production, educational supplies, or small-scale printing, selecting the right notebook manufacturing machine is critical for product quality, throughput, and profitability.

In this detailed guide you will find:

-

Overview of notebook production technology

-

Types of machines available—automatic, semi-automatic, manual

-

Key features you should evaluate

-

Why Pehowa, Haryana is becoming a hub for stationery machinery

-

Supplier and manufacturer selection criteria

-

Maintenance, spare parts, and service support

-

Cost estimates and return-on-investment (ROI) projections

We will also include frequently used synonyms such as exercise-book machine, paper binding equipment, book production equipment, etc. to help you understand the terminology used across the industry.

1. The Notebook Production Process

Producing notebooks involves several stages:

-

Sheet feeding & trimming – raw paper (sheets or reels) is fed into the machine and cut to required size.

-

Folding / Gathering – pages are collated in the correct order for each notebook.

-

Binding / Stitching – either stitched (stapled) or glued binding is applied.

-

Cover attachment – laminated or printed cover is affixed and trimmed.

-

Cutting / Perforation / Edge finishing – edges are trimmed to size, corners rounded if needed.

-

Stacking & packaging – finished notebooks are collected, packed, and prepared for distribution.

A modern automatic notebook maker integrates many of these steps, increasing speed, reducing manual labor, and improving quality consistency.

2. Types of Notebook Making Machines

Depending on scale, budget, and desired output quality, you can select among:

a) Fully Automatic Notebook Machines

These machines handle multiple stages with minimal manual intervention. Ideal for large volumes, they reduce human error, are faster, and ensure uniformity.

b) Semi-Automatic Notebook Machines

These require some manual work (feeding, stacking, setting parameters), but automate trimming, binding, and cutting steps. Suitable for medium-scale production or businesses upgrading from manual methods.

c) Manual or Table-Type Equipment

Lower cost, greater operator control, and useful for custom jobs or very low production volumes. Requires more labor but makes a good entry-point for startups.

3. Key Features to Look For

When evaluating a notebook manufacturing machine, consider the following:

-

Production speed (notebooks per minute or hour)

-

Sheet size range (A4, A5, custom) and number of leaves/pages per book

-

Binding method (stapled / stitched / glued)

-

Cover finishing options (lamination, embossing, printed cover insertion)

-

Automation level (automatic vs semi-automatic)

-

Ease of operation and maintenance

-

Energy consumption

-

Availability of spare parts

-

After-sales support and local service in Pehowa / Haryana

These features directly affect your output quality, cost per unit, and long-term uptime.

4. Why Choose Pehowa, Haryana for Purchasing or Installing Notebook Machines

Pehowa is a town in Kurukshetra district of Haryana, and its location offers several advantages:

-

Proximity to major industrial towns such as Kurukshetra, Yamunanagar, and Karnal

-

Good road connectivity with highway access to Delhi and other NCR-market areas

-

Lower operating and labor costs compared to metro cities

-

Access to regional technical workforce and workshop vendors

-

Growing demand for school stationery and educational material in North India

Local suppliers in Pehowa or nearby may provide quicker installation, lower logistics costs, and easier service calls compared with vendors located far away.

5. Selecting the Right Supplier / Manufacturer

When you approach a notebook machine supplier or manufacturer in Haryana, keep the following criteria in mind:

-

Experience & track record – number of machines installed, references in stationery industry

-

Customization capability – can they adjust the machine for different paper sizes, binding changes, or cover styles?

-

Warranty and service agreement – period covered, response-time, availability of technicians locally

-

Spare parts inventory – availability of blades, cutters, stitching heads, etc., without long lead-times

-

Training & operation support – whether they train your staff at your workshop or onsite

-

Cost of ownership – not just initial price, but electricity, maintenance, consumables, downtime

Before purchasing, ask the supplier for a site-visit to your production area in Pehowa. This helps them size the machine footprint, power requirement, and safety clearances.

6. Installation, Maintenance & After-Sales Support

A crucial part of owning a notebook making machine is reliable maintenance and quick access to spare parts. Key points include:

-

Regular preventive maintenance schedules (lubrication, calibration, cleaning)

-

Support for wear-parts such as cutting knives, stitching heads, motors, control electronics

-

On-site engineers or mobile service units familiar with Haryana zone

-

Training your operators in basic troubleshooting to reduce downtime

-

Documentation in local language or understandable English / Hindi

Local suppliers near Pehowa may keep a small service center or collaborate with nearby workshops for prompt breakdown support.

7. Cost Estimate & ROI

While prices vary greatly depending on machine size, automation, and features, here is a rough estimate and ROI analysis to guide your decision:

| Machine Type | Indicative Cost (INR) | Approximate Output | Monthly Production | Revenue Estimate | Payback Period* |

|---|---|---|---|---|---|

| Semi-automatic (medium scale) | ₹4-8 lakh | 200 notebooks/hour | 50,000* per month | ₹2-5 lakh/month (depending on selling price) | 6–12 months |

| Automatic high-capacity | ₹12-25 lakh | 500+ notebooks/hour | 1,20,000+ per month | ₹5–12 lakh / month | 8–14 months |

*Based on assumptions of working 22 days/month, 8 hours/day. Actual figures depend on your pricing model and demand in your region.

To maximize ROI, ensure high uptime, minimal waste, and consistent quality to command better margins in school stationery market.

8. Examples of Synonyms in Use

Throughout this article you’ll notice alternate terms such as:

-

Exercise-book machine — a common variation used by buyers in the education sector.

-

Book production equipment — a broader term that includes binding, cover finishing, trimming devices.

-

Paper binding equipment — emphasises the binding / stitching / gluing parts.

-

Automatic notebook maker — highlights automation features.

-

School-notebook machine — indicates its target application for educational notebooks.

Using these synonyms when you search online (for instance: “exercise-book machine Pehowa”, or “paper binding equipment Haryana”) can help you locate additional vendors or compare specifications.

9. How to Enquire & Next Steps

If you are ready to evaluate or purchase a notebook manufacturing machine in Pehowa, Haryana, here are recommended steps:

-

Specify your production capacity requirement (e.g. number of notebooks per day/month).

-

Share samples (paper type, cover design, size) with the supplier.

-

Visit the machine demo site, if available.

-

Request a detailed quote including delivery, installation, commissioning, and training.

-

Check payment terms, delivery lead time and commissioning schedule.

-

Plan your factory floor layout in Pehowa — ensure power supply, safety clearances, ventilation, and operator access.

-

Once delivered, schedule training for your staff and plan maintenance calendar.

Conclusion

Investing in the right notebook making machine in Pehowa, Haryana can give your stationery business a strong competitive edge. By choosing a reputable notebook machine manufacturer or supplier, you benefit from local support, lower logistics cost, and faster turnaround. Carefully evaluate machine features, support arrangements, and cost-of-ownership to ensure long-term profitability.