Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

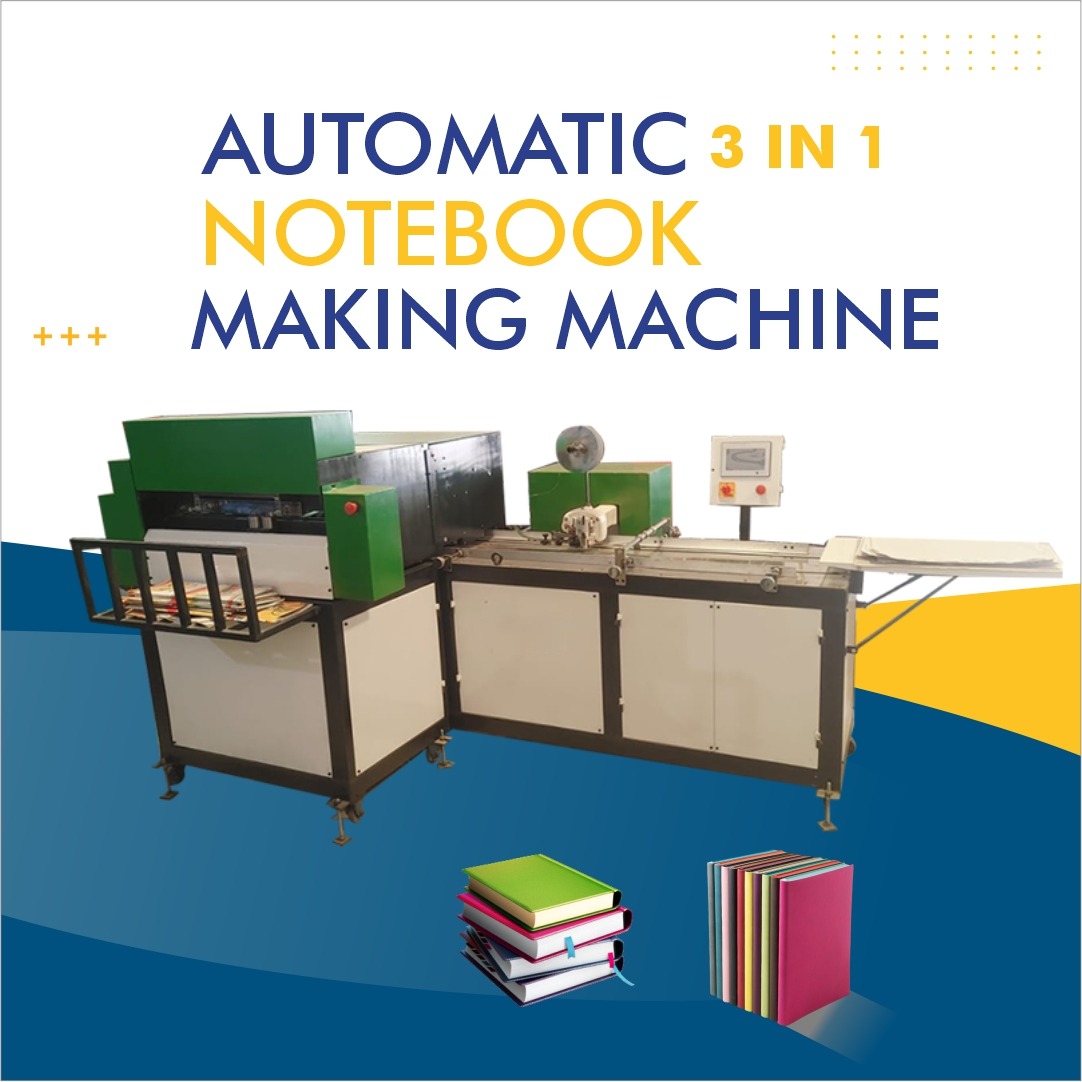

Notebook Making Machine Supplier in Pataudi Haryana | Automatic Notebook Machines India

Notebook Making Machine Supplier in Pataudi | Haryana

In today’s education-driven economy, the demand for notebooks is ever-growing. Schools, colleges, coaching centres, printing units, and stationery manufacturers all seek efficient, cost-effective methods to produce high-quality exercise books. If you are located in or near Pataudi, Haryana, and searching for a robust notebook making machine that can streamline your production line, you’ve come to the right place. This article explores everything you need to know about sourcing, installing, and operating a notebook making machine in Pataudi, Haryana.

We will cover the benefits of investing in modern automatic notebook maker equipment, the features to look for, the installation process, maintenance, regulatory aspects in Haryana, and how to choose the right manufacturer or supplier near Pataudi.

What is a Notebook Making Machine?

A notebook making machine is industrial equipment designed to automate the process of cutting, stitching (or binding), trimming, scoring, and packaging notebooks (or exercise books). These machines replace manual labour and fragmented processes, enabling high throughput, consistency, and cost savings.

Some common types include:

-

Notebook manufacturing equipment with manual feeding and semi-automatic stitching

-

Fully automatic notebook production machine with computerized control

-

Paper notebook machine that handles multi-sheet assembly, binding, edge trimming

-

Automatic notebook maker that integrates cutting, binding, numbering, and packing

-

A complete notebook production line that includes paper feeder, collator, binder, trimmer, and stacker

These variations allow stationery manufacturers in Haryana and across India to choose solutions suited to their scale and budget.

Why Choose Pataudi, Haryana for Your Notebook Making Machine?

Strategic Location

Pataudi is located in Gurgaon (Gurugram) district of Haryana, well connected via road and rail. This makes transportation of heavy machinery relatively easier compared to remote rural locations. Suppliers from Delhi-NCR and Haryana often deliver to Pataudi without excessive freight charges.

Lower Operating Costs

Operating a manufacturing unit in Haryana often benefits from lower electricity rates, industrial land availability, and proximity to stationery raw‐materials (paper mills, binding supplies).

Access to Skilled Labour

Nearby towns and villages provide access to technicians and skilled labour who can operate, maintain, or repair your notebook making machine.

Regulatory and Infrastructure Support

Haryana government encourages small and medium manufacturing units. You may obtain industrial registration, GST registration, and other certifications with relative ease when setting up near Gurgaon / Pataudi.

Given these advantages, Pataudi is an ideal location to operate a notebook production facility with modern notebook making machines.

Key Features to Look for in a Notebook Making Machine

To ensure you get value for investment, carefully evaluate features before purchasing:

-

Production Capacity

Assess how many notebooks per hour or per shift you need. Entry-level units may produce a few hundred per hour; advanced machines may deliver thousands. Match capacity to your demand forecast in Pataudi or across Haryana. -

Automation Level

-

Fully automatic notebook production machine reduces labour and boosts uniformity.

-

Semi-automatic machines may cost less and require manual intervention at certain stages.

-

Automatic notebook maker equipment often comes with a PLC interface, motorised feeders, and adjustable cutting / stitching speed.

-

-

Binding Method

Choose between stitching (thread or wire), glue binding, or perfect binding depending on your product type. Some machines offer multiple binding styles. -

Cutting / Trimming Precision

Quality trimming is critical. Manual finishing results in uneven edges; modern machines use pneumatic clamps and precise cutting blades to maintain consistent margins. -

Paper Handling & Collation

A good notebook production line includes efficient collator and feeder modules. Ensure your machine supports the size and grammage of paper sheets you plan to use (for example, A4 size exercise book pages, thickness 70-80 gsm etc). -

Control Panel & Customisation

Digital display, adjustable speed, settings for page count, cover thickness, and stitch density. This is especially useful when producing varying book lengths (e.g. 100-page, 200-page notebooks). -

Safety & Compliance

Ensure the equipment follows safety standards and regulations under Indian norms. Proper guards, emergency-stop buttons, and electrical wiring compliance are important. -

After-Sales Support

Since Pataudi is near Gurgaon / Delhi, check whether the manufacturer provides installation, training, spare parts delivery, and maintenance services locally. -

Power Consumption & Efficiency

Evaluate the energy consumption for the motor units. Efficient motor drives and software controls help reduce electricity costs. -

Footprint & Factory Layout

Verify the physical dimensions of the machine and required space in your facility. Plan for material feed area, output stacking, operator access and maintenance space.

Advantages of Investing in a Notebook Making Machine

Investing in high-quality notebook production machinery yields multiple benefits:

-

Lower cost per notebook due to automation and reduced labour

-

Improved consistency in binding and trimming quality

-

Faster turnaround times for batching and seasonal orders

-

Scalability to meet growing demand from schools and educational institutions across India

-

Competitive edge by offering customised notebook sizes, cover designs and special binding finishes

-

Better profit margins compared with manual or fragmented production methods

In Pataudi, Haryana, where educational stationery demand is strong in nearby districts and NCR suburbs, having your own automatic notebook maker can give you a significant advantage in delivery speed and quality.

Typical Workflow of a Notebook Production Line

Here’s how a typical notebook manufacturing equipment setup operates:

-

Paper Feeding & Collation

Sheets of ruled or blank paper are loaded into feeders; the machine collates them in the correct page order. -

Cover Insertion & Alignment

A cover (cardstock / decorative sheet) is aligned with inner pages. -

Stitch / Binding Operation

Stitching heads insert staples or thread; glue binding or perfect binding heads attach depending on your model. -

Trimming & Edge Finishing

Excess paper along the edges is trimmed for a clean, uniform finish. -

Corner Rounding / Creasing (Optional)

Some notebook production lines include an optional module for rounded corners or creasing for better usability. -

Stacking / Packing

Final notebooks are stacked automatically and made ready for packing or dispatch.

Throughout this workflow, sensors and PLC-based logic control paper flow, detect jams, and maintain alignment. That is typical of an automatic notebook maker machine line.

Setting Up Your Notebook Manufacturing Facility in Pataudi, Haryana

To get started:

-

Select a manufacturer or supplier

Look for companies offering notebook production machine delivery and commissioning near Haryana / Delhi. Ask for site visits, previous customer references in NCR region. -

Get quotations with specifications

Share your production targets (e.g. number of books per day), page count, sizes, binding type, and budget. Ensure the quote includes shipping to Pataudi, GST, installation, and training. -

Arrange Suitable Premises

Choose a facility with adequate floor area (consider around 100-200 sq. ft or more depending on machine size), proper ventilation, electricity supply (3-phase supply if required), drainage, and ease of material movement. -

Obtain Licences & Registrations

Register your business (Proprietorship / Pvt Ltd / MSME), obtain GST registration, check any Haryana state or district-level factory or trade licences if required. Ensure compliance with local building / fire safety norms. -

Installation & Training

The machine supplier should send technicians to your Pataudi site to install and align the machine, conduct trial runs, and train your operators. -

Quality Control & Testing

Before full-scale production, run sample batches to ensure that edge trimming, binding strength, page alignment, and cover quality meet your standards. -

Maintenance Schedule

Setup preventive maintenance procedures: regular cleaning, lubrication, blade sharpening or replacement, stitch head tune-ups, and periodic electrical checks. -

Scaling Up & Customisation

Once your facility is running smoothly, you may add optional modules (e.g. custom-printing integration, cover lamination, or embossing) to enhance your product offering.

Cost Estimates & ROI (Return on Investment)

While exact cost will depend on specifications, a typical automatic notebook production line suited for small-to-medium volume may cost anywhere from INR 5 lakh to INR 20 lakh or more (depending on automation, capacity, and features).

Your ROI depends on:

-

Cost per notebook manufactured vs selling price

-

Volume of production (daily / monthly output)

-

Labour and utility cost savings

-

Maintenance and depreciation

For example, if your automatic notebook maker helps you reduce labour expenses, improves throughput by 2 – 3× compared to manual binding, you may recover your investment in 12-24 months, depending on order volumes to schools, retailers, or institutional clients in and around Haryana / NCR.

Common Challenges & Solutions

| Challenge | Solution |

|---|---|

| Paper jam or misalignment | Ensure regular calibration of feeders, use sensors and adjust timings in PLC settings. |

| Wear and tear of stitch head or cutting knife | Maintain a spare parts inventory and follow preventive maintenance. |

| Variable paper thickness or quality issues | Source consistent paper stock and adjust feeder settings; test new batches before full runs. |

| Power fluctuation or poor supply | Install stabiliser or UPS backup, ensure 3-phase wiring complies with Indian standards. |

| Delays in spare-part delivery | Choose a manufacturer that has local presence or service office near Pataudi / Gurgaon. |

Being proactive with these issues can keep your notebook production machine working smoothly and reduce downtime.

Choosing the Right Manufacturer or Supplier

When selecting a supplier for your notebook manufacturing equipment, consider the following criteria:

-

Proven track-record delivering to businesses in Haryana / Delhi-NCR

-

Quality certifications, such as ISO or CE compliance

-

Availability of spare parts and local servicing

-

Flexibility to customise machine settings (speed, stitch type, binding style)

-

Warranty terms and duration

-

Training and support for your staff

-

Delivery and installation time frame

Request a site visit or demo. Many suppliers may offer trials or lend you time with their existing machine so you can assess performance before placing your order.

Conclusion

A high-quality, modern notebook making machine installed in Pataudi, Haryana can transform your stationery manufacturing business. It enables you to control quality, reduce costs, increase production capacity, and respond quickly to customer demands across the state or neighbouring regions.

By carefully assessing your needs, selecting the right automation level, ensuring proper installation, and planning for ongoing maintenance, your investment in a notebook production line can yield strong returns and sustainable growth.

If you’re ready to explore notebook making machines in Pataudi, Haryana, get detailed quotes from suppliers, visit demonstration sites, and plan your factory layout today. With the right equipment and planning, you can build a successful and efficient notebook production business.