Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

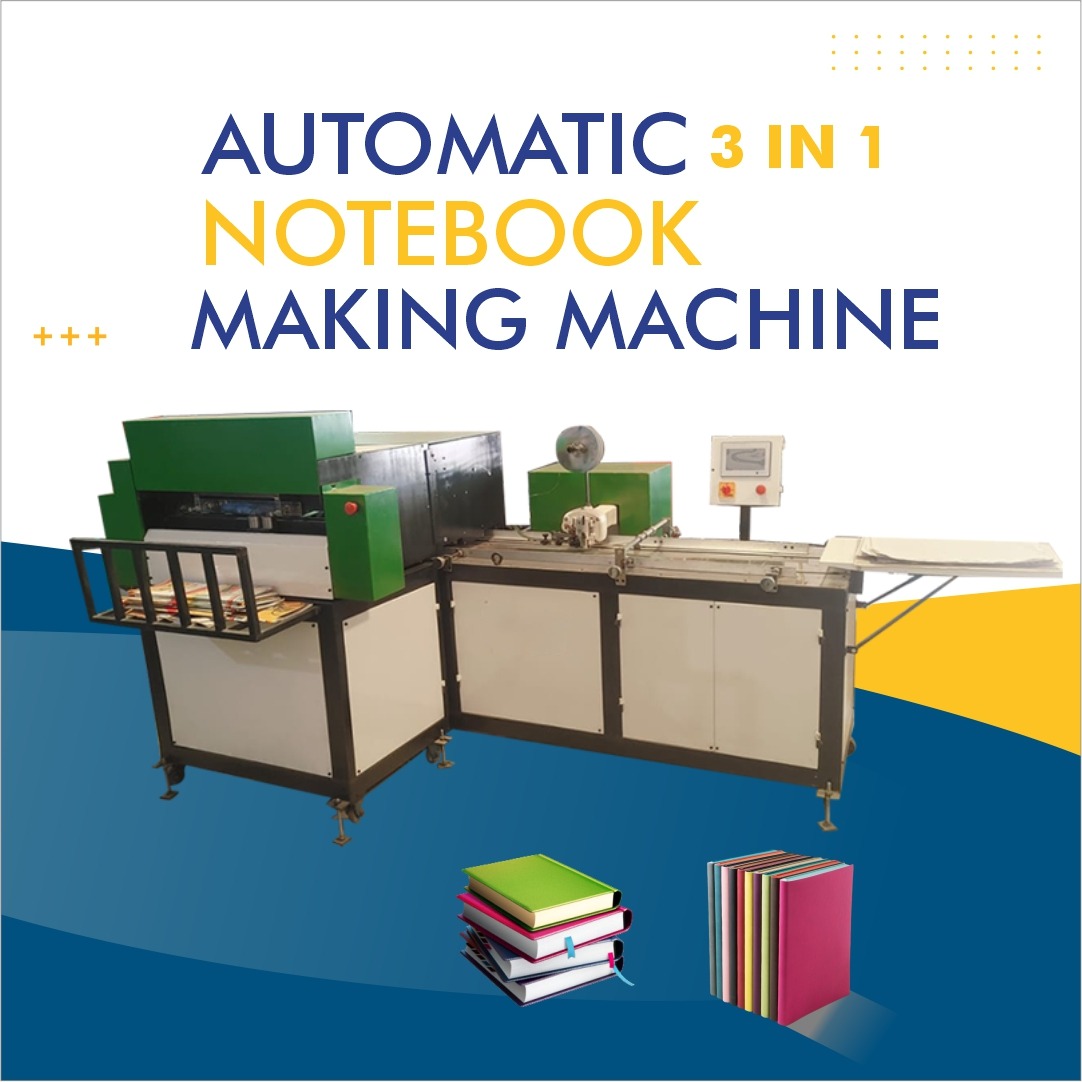

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Leading Notebook Making Machine Supplier in Panipat, Haryana | Reliable & Efficient Machines

Notebook Making Machine Supplier in Panipat | Haryana

If you are searching for a notebook making machine in Panipat, Haryana, you’re in the right place. We are a premier manufacturer and supplier of notebook making machines, offering cutting-edge technology, robust build quality, and customized designs suited to your production requirements. Our equipment helps businesses scale up notebook production with efficiency and consistency.

In this article, we walk you through why our machines stand out, the range of models available, the key specifications, advantages of buying locally in Panipat, installation and after-sales support, and how to choose the right notebook making machine for your enterprise.

Why Choose a Notebook Making Machine in Panipat, Haryana

Local Manufacturing & Reduced Lead Time

Being located in Panipat—a major industrial hub in Haryana—enables us to provide fast turnaround times on manufacturing, spare-part supply, and service response. Your notebook making machine Panipat purchase benefits from proximity to our factory premises, reducing freight times and logistic costs.

Cost-Effective & Customizable Design

We manufacture machines on-site, enabling economical customization of dimensions, binding type, margin cutting, and paper sheet size. Compared to imported or far-away suppliers, our local production ensures cost advantages and design flexibility.

Skilled Workforce & Quality Assurance

Panipat and its surrounding regions have a skilled mechanical and electrical workforce. The assembly, testing, and quality control of your notebook production equipment happen under direct supervision. Stringent inspection protocols ensure that every unit meets performance and safety standards.

After-Sales Service & Spare Parts Availability

Our local presence in Haryana means timely on-site service visits, maintenance, and ready availability of critical spare parts. Whether you run one production shift or round-the-clock operations, downtime is minimized thanks to local backup.

Range of Notebook Making Machines & Features

We offer a diverse lineup of notebook making machines suitable for small-scale units to large factory operations:

-

Semi-automatic Notebook Making Machine

-

Ideal for mid-volume production (e.g. schools, small print-shops).

-

Manual loading or binding, with automated cutting or punching.

-

Compact footprint, lower energy consumption, and moderate investment.

-

-

Fully Automatic Notebook Maker

-

High-volume production capacity (hundreds to thousands of notebooks per hour).

-

Integrated features such as paper feeding, cover insertion, spiral or staple binding, trimming, stacking.

-

Designed for industrial production lines.

-

-

Book Binding Machine / Paper Binding Machine Hybrid

-

Versatile model that can bind notebooks of different sizes, thicknesses, and binding styles.

-

Useful if you produce not only notebooks but also exercise books, diaries, or light catalogs.

-

-

Automatic Staple Binding & Punching Machine

-

Specialty unit focusing on the binding stage.

-

Combined with other modules (cutting, trimming) to complete the notebook workflow.

-

-

Customized Notebook Production Equipment

-

Tailored to specific sheet sizes, binding methods (sewn binding, staple binding, spiral coil), margin cutting, and cover lamination modules.

-

Key Technical Specifications

When evaluating a machine, you should review parameters such as:

-

Sheet Size Compatibility: A4, A5, customized sheet sizes.

-

Page Thickness / Sheet Count: ability to bind notebooks up to certain page count / sheet thickness.

-

Speed / Throughput: notebooks per hour or cycles per minute.

-

Binding Type: staple binding, spiral binding, sewn binding.

-

Cutting & Trimming Accuracy: margin trimming dimensions, corner rounding options.

-

Power Requirements: single phase or three-phase power supply, motor ratings.

-

Automation Level: manual load vs servo-controlled feeders, PLC interface, touchscreen control.

-

Machine Footprint & Weight: floor space needed, safety guards, ergonomics.

-

Material Compatibility: paper quality (gsm range), cover board thickness, binding wire gauge.

-

Control & Safety Features: emergency stop, electrical certifications, sensors for jams or misfeeds.

By comparing these features across models, you can choose a machine that matches your throughput target, paper sizes, and budget.

How to Select the Right Notebook Making Machine

Choosing the correct model involves several steps:

-

Estimate Production Volume

Calculate how many notebooks you plan to produce per day or per hour. For example, a school exercise-book line may require lower throughput than a commercial printing business. Based on that, select between semi-automatic or full-automatic models. -

Define Notebook Size & Format Range

List all the formats you will produce (e.g. A4, A5, custom sizes), the sheet count per notebook, cover dimensions, and whether you need variable sizes. Machines with adjustable guides or modular attachments are preferable for flexibility. -

Binding Style & Quality Requirements

Decide whether you want staple binding, spiral coil, sewn binding, or glue binding. Also consider binding quality: alignment precision, strength of binding, and aesthetic finish. -

Automation & User Interface

If you want minimal manual intervention, go for fully automatic, PLC-driven machines. Ensure the interface is user-friendly and maintenance-friendly. -

Budget & Return on Investment (ROI)

Compare capital cost vs expected output. A higher-capacity automatic notebook maker may cost more, but lower labour cost, less rejects, and faster production can yield better ROI over time. -

After-Sales & Service Location

Since your location is Panipat, Haryana or nearby, verify the supplier offers prompt service. Local suppliers reduce downtime and logistic overhead. -

Flexibility & Upgradability

Choose a machine that allows future upgrades (e.g. additional trimming module, or higher speed feeder). This ensures the notebook making machine grows with your business.

Benefits of Installing a Notebook Making Machine

There are numerous advantages to investing in a reliable notebook making machine:

-

Increased Productivity: Automation reduces manual labour and speeds up the binding cycle.

-

Consistent Quality: Precise cutting, trimming, alignment, and binding yield uniform notebooks batch after batch.

-

Reduced Waste: Integrated trimming and margin control reduce paper wastage.

-

Lower Labor Costs: Less manual handling means fewer staff required per shift.

-

Scalability: Once installed, operations can scale up quickly without linear increase in labour input.

-

Faster Turnaround: You can respond to bulk orders or sudden demand spikes without outsourcing.

-

Competitive Advantage: Owning your notebook production equipment gives you control over quality, pricing, and customization.

Case Study: A Client in Haryana

One of our clients in the Bahadurgarh region installed our fully automatic notebook maker with dual trimming and binding modules. Their daily output increased by over 150%. They gained flexibility to produce A4 and custom-size notebooks alternately without major downtime while meeting strict school-board standards. They cited faster order fulfillment, reduced rejects, and improved customer satisfaction.

We provided on-site training, periodic maintenance check-ups, and spare-part backup within 24 hours thanks to our Panipat-based service team.

Installation, Training & Support

When you purchase a machine from us, we handle the full lifecycle:

-

Site Assessment: We conduct a survey of your facility (floor space, power supply, civil base, ventilation).

-

Foundations & Mounting: We assist in civil base preparation, alignment, and leveling of the machine.

-

Commissioning & Trial Runs: After installation, we run sample batches of notebooks to verify binding quality, trimming precision, and cycle stability.

-

Operator Training: We train your staff on operation, safety, maintenance schedules, and cleaning procedures.

-

Preventive Maintenance Plans: Offer annual or periodic service contracts to ensure optimal performance and longevity.

-

Spare Parts & Upgrades: For wear-out parts such as cutters, staples, and trimming blades, spare-parts supply is available locally in Panipat / Haryana.

Frequently Asked Questions (FAQ)

Q. What is the typical cost of a notebook making machine in Panipat?

A. Cost depends on automation level, speed, and capacity. A semi-automatic unit may cost significantly less than a high-speed fully automatic model. We provide custom-quotation based on your specifications.

Q. Can the machine handle different sizes of notebooks?

A. Yes. We design adjustable guides and modular features such that sheet size, cover size, and binding thickness can be modified within specified ranges.

Q. Is remote support available for software or control-panel issues?

A. Yes, our machines include PLC or digital control panels. Basic troubleshooting via phone or remote connection is available; for hardware issues, we dispatch our engineer team from near Panipat.

Q. How long is the warranty and service period?

A. Standard warranty period is 12 months. Extended service contracts are available, covering periodic maintenance, wear-part replacement, and on-site visits.

Q. How much space is needed to install a full-automatic notebook maker?

A. Space depends on model, but typical floor area ranges between 3 m × 4 m up to 6 m × 5 m. Detailed site dimension plan and layout will be shared during final consultation.

Summary & Call to Action

If you plan to scale up your notebook production or want to set up a binding line in Panipat, Haryana, investing in a high-quality notebook making machine is a strategic decision. You get:

-

Local manufacturing and fast support

-

Customizable features to match your formats

-

Reliable performance and high throughput

-

Economical maintenance and spare-parts supply

Contact us today to discuss your production requirements, get a quotation, or schedule a demo at our Panipat facility. Let us help you choose the ideal notebook production equipment tailored to your business—and get you up and running with consistent high-quality notebooks.