Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

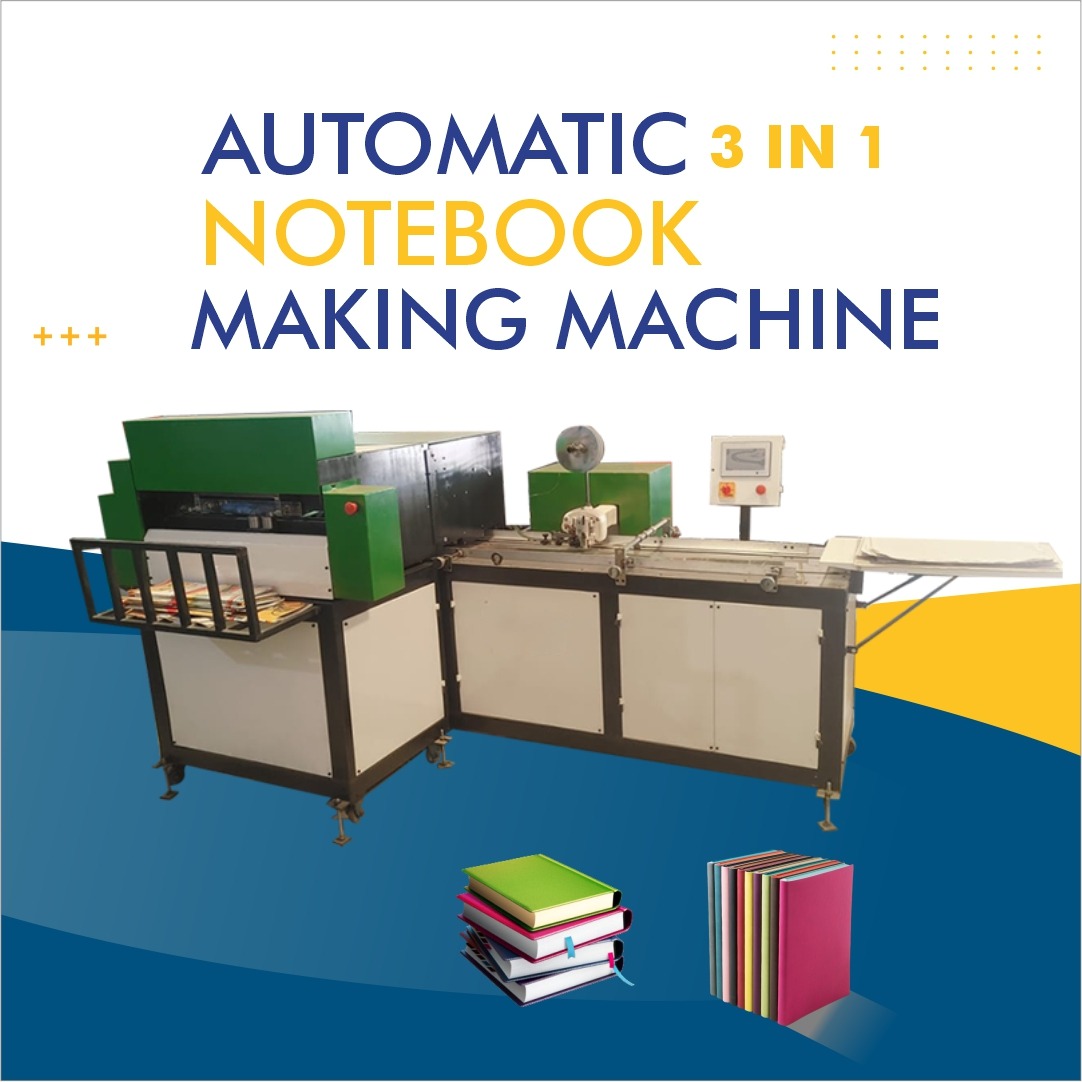

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine | Naraingarh Haryana Supplier & Manufacturer

Notebook Making Machine in Naraingarh | Haryana

If you are planning to launch or upgrade a notebook manufacturing unit in Naraingarh, Haryana, choosing the right notebook making machine is critical for quality, productivity, and cost-efficiency. Whether you need an automatic notebook maker, a semi-automatic binding machine, or a manual stitching setup, your decision will directly impact the output, turnaround times, and product durability.

In this article, we’ll guide you through everything you need to know about notebook making machines, including types available, features to consider, supplier options in Naraingarh, installation, maintenance, and cost considerations. We will also show why investing in quality equipment gives you a competitive edge in the stationery industry.

Why Location Matters: Naraingarh, Haryana

Naraingarh is strategically located in Haryana with relatively good connectivity to nearby industrial regions, access to raw materials (paper sheet suppliers, binding supplies), and skilled labor. Choosing a local machine manufacturer or supplier reduces transportation costs, ensures faster on-site support, and helps with compliance and servicing. If your production facility is based near Naraingarh or anywhere in Haryana, you benefit from local after-sales service, spare parts availability, and tailored machine adjustments suited to regional power supply conditions.

Types of Notebook Making Machines

Here are the main types of notebook making and binding machines you should consider:

-

Automatic Notebook Making Machine

-

Fully automatic systems that cut paper, stack sheets, stitch or glue binding, apply covers, and trim edges.

-

Best for high-volume production, consistent quality, and minimal manual intervention.

-

Higher upfront cost but much greater throughput.

-

-

Semi-automatic Machine

-

Combines manual and automatic steps: for instance, you manually feed paper bundles but automatic stitching or trimming.

-

Lower investment than fully automatic models; good balance for medium scale production.

-

-

Manual or Mechanical Notebook Stitching Machine

-

Best suited for small-scale or artisanal workshop setups.

-

Slower production, but lower cost and easier to maintain with basic tools.

-

-

Binding Equipment & Accessories

-

Includes edge trimming machines, cover pasting machines, punching or perforating machines, spiral binding units, and paper cutting machines.

-

Often used in combination with notebook making machine to complete the stationary production line.

-

-

Paper Cutting / Trimming Machine

-

While not always strictly “notebook making machine”, trimming equipment for precise edge finishing is critical to professional notebook quality.

-

Useful for trimming edges after binding or cutting stacks of paper to size before binding.

-

Key Features to Evaluate

When selecting a notebook making machine for your unit in Naraingarh, consider the following factors:

-

Production Capacity

Estimate your target output per hour or per day — how many notebooks do you want to produce? For higher volumes, automatic machines are ideal. -

Sheet Size & Format Compatibility

Ensure the machine supports the paper sizes (e.g. A4, A5, custom sizes), thickness of paper, number of pages per notebook, and cover material dimensions. -

Binding Method

Decide whether you prefer stitched binding (thread or wire), stapling, glue binding or spiral binding. The binding method will influence which machine model you need. -

Speed & Throughput

Machines are rated in notebooks per hour. Check whether you need continuous high-speed production or occasional runs. -

Power Requirements

Since you are in Haryana, ensure the machine can run on your local electrical supply, voltage stability, and whether backup options are needed. -

Automation Level

Fully automatic machines reduce manual labour costs and improve consistency; semi-automatic machines let you retain some manual flexibility for smaller batches. -

Maintenance & Spare Parts

Local supplier presence in Naraingarh or nearby areas in Haryana can significantly reduce downtime and maintenance cost. Check availability of spare parts locally. -

After-Sales Support

Training, installation, regular maintenance services, and technical support are all important. A supplier based near Naraingarh ensures faster response. -

Build Quality & Safety Standards

Check for ISI certification, safety interlocks, emergency stop switches, and robust frame construction to withstand continuous production.

Benefits of Choosing Local Suppliers

Choosing a notebook making machine manufacturer or supplier near Naraingarh or somewhere in Haryana comes with several advantages:

-

Reduced Transport Time & Cost

Machines are bulky. Local delivery saves on heavy transport charges and reduces risk during transit. -

Faster Installation & Commissioning

Local engineers can visit your site for installation, calibration, and operator training more swiftly than distant suppliers. -

Better Customisation

Suppliers familiar with regional business practices or local market demands may offer customization (e.g. machine frames suited for workshop conditions, paper availability in Haryana). -

Quicker Maintenance & Repairs

Downtime means lost production. Having a service centre nearby or a supplier in/near Naraingarh allows faster repairs and scheduled maintenance visits. -

Local Regulatory Compliance

Suppliers will understand local electrical regulations, factory safety norms, and industry expectations in Haryana.

Investment & Cost Considerations

When budgeting for a notebook making machine in Naraingarh, keep in mind:

-

Capital Investment

Automatic machines cost significantly more than semi-automatic or manual ones. But return on investment improves with higher output and reduced manpower. -

Operational Costs

Electricity, labor, consumables (thread, glue, staples), and maintenance need to be factored in your annual budget. Efficient machines reduce waste (paper trimming accuracy, minimal mis-aligned pages). -

Depreciation & Lifespan

A well-built machine from a reputable manufacturer should last many years with regular maintenance. Budget for periodic servicing and spare parts replacement. -

Payback Period

Estimate how long it will take to recover your investment through sales of notebooks. Higher-quality machines often shorten payback time by reducing rejects, enhancing production speed, and enabling higher pricing for reliable notebook quality.

Finding Suppliers Around Naraingarh, Haryana

Here are some steps to find reliable suppliers or manufacturers of notebook making machines locally:

-

Search industrial directories for stationery machinery suppliers in Haryana.

-

Contact engineering workshops in nearby industrial towns that specialise in stationery or paper-processing machines.

-

Ask for referrals from existing stationery businesses in and around Naraingarh, Ambala, Panchkula, or Yamunanagar.

-

Visit local trade fairs or exhibitions featuring printing and binding equipment.

-

Request demonstrations, factory visits, and test runs of sample notebooks using the machine model.

Installation & Training

After you purchase the machine, the installation and training phase is critical:

-

Coordinate with the supplier to schedule on-site installation in your production facility.

-

Ensure alignment with local safety protocols, provision for scaffolding or mounting, and adequate floor strength.

-

Operator training must cover feeding paper stacks, adjusting binding settings (thickness, cover alignment), troubleshooting misfeeds, and maintenance tasks such as lubrication or cleaning binding heads.

Maintenance Best Practices

To maintain your notebook making machine in top working condition in Naraingarh:

-

Clean the machine daily to remove paper dust and adhesive residues.

-

Lubricate moving parts periodically as per manufacturer’s instructions.

-

Inspect binding heads, knives, or trimming blades for wear; replace when dull to avoid paper tearing or misalignment.

-

Schedule preventive maintenance once every few months (check motor health, belt tension, electrical wiring inspection).

-

Keep a small stock of critical spare parts — for example, binding needles or staples, cutting blades, safety fuses, or control panel components — to minimise downtime.

Quality & Productivity Advantages

Investing in the right equipment yields many long-term advantages:

-

Better notebook edge finish and binding strength improves customer satisfaction and repeat orders.

-

Higher throughput allows you to meet large orders (for schools, corporates, promotional notebooks).

-

Lower reject rate reduces cost of scrap paper, rework, and labour involvement.

-

Ability to offer a variety of notebook types (page counts, sizes, spiral or stitched binding) makes your product line more competitive.

Conclusion

If you are considering establishing or scaling up notebook production in Naraingarh, Haryana, selecting the right notebook making machine is a foundational decision. With the right investment in automation, after-sales support, and efficient operation, your stationery business can reliably deliver high-quality notebooks on time, reduce production losses, and scale sustainably.

To move forward:

-

Shortlist a few machine models (automatic / semi-automatic) that meet your capacity and budget.

-

Request quotations including installation, shipping, and training in Naraingarh.

-

Compare lifespan estimates, spare-parts availability, and local service capabilities.

-

Plan your payback timeline based on expected production volume and margins.