Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

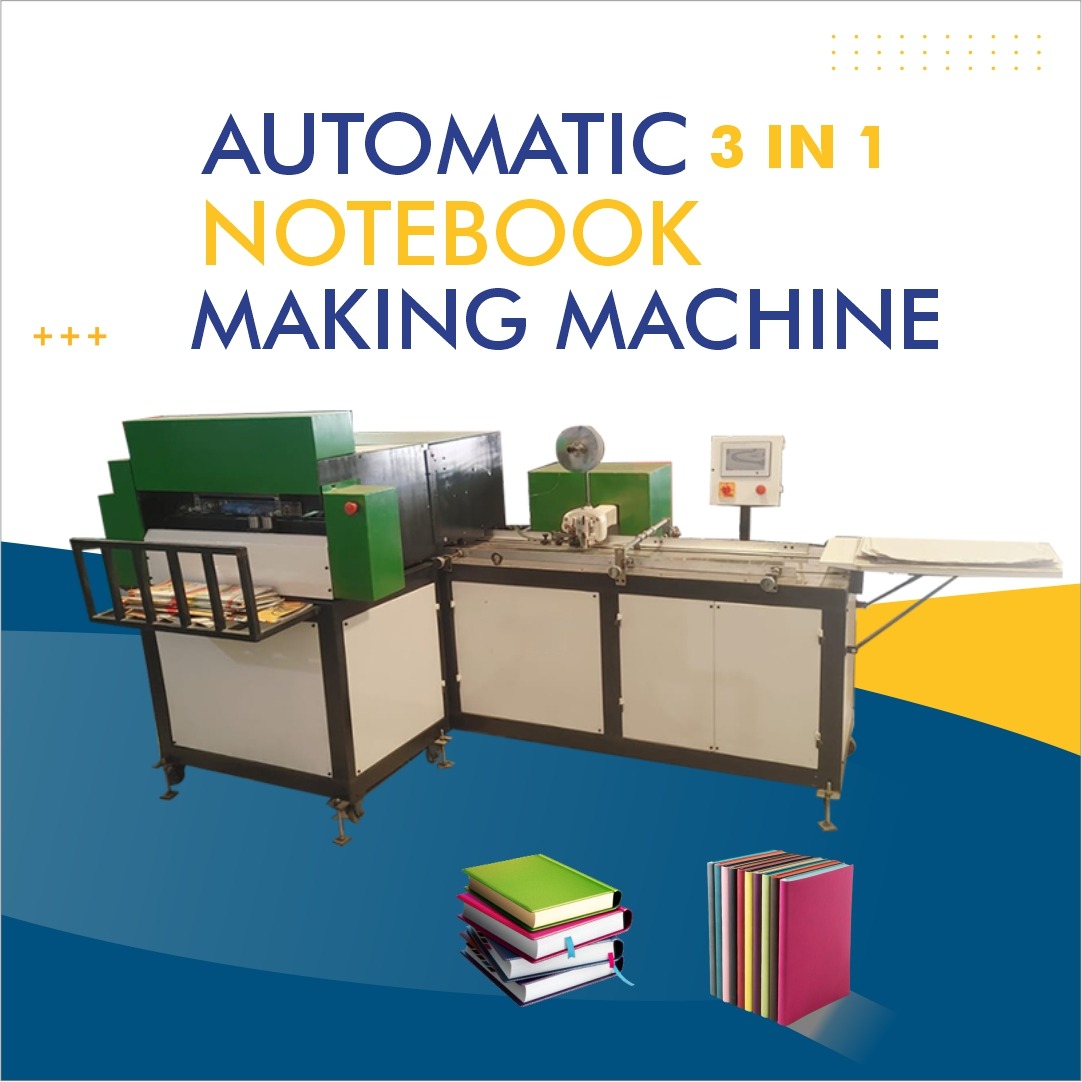

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Mahendragarh Haryana | Best Rates & Support

Notebook Making Machine in Mahendragarh | Haryana

Mahendragarh is emerging as a viable location for small-scale industries in Haryana due to its proximity to major markets and availability of government-industry support. dcmsme.gov.in+1 Whether you are planning to set up a new notebook production line or upgrade your existing facility, choosing the right notebook making machine is critical. This article will guide you through everything you need to know — from machine types, capacity, cost, local suppliers, benefits of locating in Mahendragarh, to after-sales service, installation, and maintenance.

We will repeatedly use important synonyms like machine, equipment, apparatus, machinery, and device to keep the SEO relevance high.

Why Choose Mahendragarh, Haryana for Notebook Manufacturing?

-

Strategic Location

Mahendragarh district is located in southern Haryana, bordering Rajasthan and within reachable distance of larger industrial centres. Wikipedia+2dcmsme.gov.in+2 It has access to roads, and is under the MSME / industry development schemes of Haryana. msme.haryana.gov.in+1 -

Government & MSME Support

There is an MSME / District Industries Center in Mahendragarh with a Deputy Director office located in Narnaul Industrial Area. msme.haryana.gov.in You may be eligible for MSME subsidies, grants, capital investment incentives, and plug-and-play shed facilities under newer Haryana schemes. -

Cost Advantages

Compared to bigger industrial hubs, overheads such as land, labour, and utilities may be lower in Mahendragarh. This makes the unit economics of a notebook making plant more favourable. -

Local Industrial Ecosystem

The district has a growing number of small and medium manufacturing units. cisharyana.in+1 While larger heavy industries may not dominate, there is scope to develop downstream ancillary units supplying stationery, packaging, printing, binding services, etc.

These factors make Mahendragarh a good choice for setting up or running a notebook making unit with proper machinery and equipment.

Types of Notebook Making Machines / Equipment

When you search for a notebook making machine, you will find variants across automation levels, capacity, and features. Below are the common types you may want to consider:

-

Manual Notebook Making Machine

-

A manually operated notebook making apparatus involves human effort for feeding sheets, binding, cutting, and turning operations.

-

Ideal for small production runs or pilot setup.

-

Example model: SBS NB-01 manual notebook making machine capacity ~3,000 notebooks/day. sbsmachine.com

-

Pros: Lower cost, easier to maintain. Cons: labour-intensive, lower speed.

-

-

Semi-Automatic Notebook Making Machine

-

Partial automation — some steps are automated (e.g. cutting, stitching), others need manual handling.

-

Good compromise for small to medium enterprise, balancing cost and output.

-

One example, ASV’s semi-automatic notebook making machine “36” model. asveng.com

-

-

Fully Automatic Notebook Making Machine

-

High automation level — paper feeding, cutting, stitching, trimming, packing may be integrated.

-

Suitable for larger volume production.

-

Some fully automatic machines available via TradeIndia listing show capacity up to 9,000-10,000 pieces/day. TradeIndia

-

-

Associated Apparatus (Cutting / Stitching / Folding Units)

-

Along with the main notebook making device, you may need auxiliary equipment such as cutting machine, square-edge trimming unit, folding / stitching machine. shkimachinery.com+1

-

These apparatus are often sold as part of full setup or as add-ons.

-

-

Custom / Modular Machinery

-

Depending on paper size, thickness, binding style, you can configure modular equipment.

-

Some vendors offer full-set equipment including stitcher, cutter, binder as a bundled package. sbsmachine.com

-

When selecting your machinery, you must define capacity, automation level, budget, space available, and quality requirements.

Key Specifications to Consider

Here are the main specification parameters you should evaluate for your notebook making equipment:

| Parameter | Why it matters |

|---|---|

| Capacity (pieces per day or per hour) | Determines volume you can produce; higher capacity reduces per-unit cost |

| Automation grade | Manual, semi-automatic, automatic affects labour cost and speed |

| Power consumption & electrical phase | Whether single-phase or three-phase, energy cost and installation cost |

| Machine footprint & weight | Useful for planning layout, structural load, and civil work |

| Material quality & build | Steel frame, finish, precision of cutting and binding influences final print / binding quality |

| After-sales service availability | Local maintenance / spare-part availability matters when you operate in Mahendragarh |

| Cost & return on investment (ROI) | Capital cost vs revenue from notebook sales, payback period |

Repeat-use of synonyms in context:

-

The machine must be robust enough for regular use in industrial atmosphere.

-

The equipment should support varying sizes and paper thickness.

-

The apparatus must be adjustable for A4, A5 or ruling preferences.

-

The machinery layout should integrate cutting, stitching, trimming in one workflow.

-

The device must comply with safety regulations and local electrical norms in Haryana.

How to Procure Notebook Making Machines in Mahendragarh

Sourcing Options

-

Buy & Import from Indian Manufacturers

-

There are many suppliers listed on TradeIndia, Justdial, etc., offering manual, semi-automatic and automatic notebook machines. TradeIndia+1

-

You can request quotations, technical brochures, and compare cost including freight to Mahendragarh.

-

-

Local Vendor Visit

-

Even if vendors are located outside Mahendragarh (e.g. in neighbouring industrial centres), you can negotiate delivery, installation, and commissioning support in Mahendragarh area.

-

-

Custom Build / Retrofit

-

If you already have partial equipment, you can procure individual units (cutter, stitching unit, binder) and assemble your production line as per your volume needs.

-

-

After-Sales & Maintenance Support

-

Ensure that spare parts are available within a reasonable distance (e.g. Gurgaon / Rewari / Hisar).

-

Confirm warranty policy, maintenance contract, and local support for electrical / mechanical servicing.

-

Permits & Compliance

-

Obtain approval or registration through the District Industries Center (DIC) or MSME office in Mahendragarh. msme.haryana.gov.in

-

Ensure electrical safety, factory licence (if applicable), labour regulations compliance, pollution norms (if any adhesives / inks are used for covers).

-

If you employ more than a certain number of workers or generate effluent, you may need further local approvals from Haryana authorities.

Cost Estimation & Financials

Here’s a rough financial planning outline:

-

Capital Investment

-

Manual notebook making machines may cost between ₹1,50,000 to ₹2,50,000 depending on capacity and configuration. sbsmachine.com+1

-

Semi-automatic machines tend to cost more — possibly ₹3,00,000 or higher depending on features. asveng.com

-

Fully automatic high-capacity machines can cost several lakhs to more than ₹10,00,000 depending on throughput. TradeIndia+1

-

-

Running Costs

-

Power consumption, labour wages, raw materials (paper, cover boards, adhesives), maintenance.

-

If you produce, say, 5,000 notebooks/day, running cost per notebook may drop significantly compared to smaller volumes once fixed overheads are spread.

-

-

Revenue Potential

-

Depending on the notebook specifications (size, number of pages, cover quality), you can set your selling price.

-

For B2B supply to schools, stationery stores or local shops around Mahendragarh / Narnaul, you can obtain steady demand.

-

-

Return on Investment (ROI)

-

Based on volume, margin, and capital cost, you should calculate payback period.

-

For instance, if you invest ₹5,00,000 in a semi-automatic line and generate net profit margin of ₹2 per notebook, producing 5,000 notebooks/day (≈ 1,50,000 per month), your payback could be under one year — depending on market acceptance and operational efficiency.

-

Operational Considerations & Workflow Layout

If you plan a notebook factory near Mahendragarh, consider the following workflow sequence:

-

Paper Storage & Preparation

-

Raw paper sheets, ruling printed sheets, cover boards / paperboard stored in dry condition.

-

-

Cutting Section

-

Cutting apparatus / cutter machine to trim paper to required size (A4 / A5 / customized).

-

-

Folding & Stitching / Binding Section

-

Stitching unit or binder machine for wire-stitching or thread-binding depending on design.

-

-

Covering / Lamination (optional)

-

If you plan to produce hardcover or laminated covers, you may require auxiliary equipment.

-

-

Finishing & Trimming

-

Finishing apparatus to cut margins, inspect quality, square the edges.

-

-

Packaging & Dispatch

-

Packaging area for stacking notebooks, bundling them, labelling, and dispatch to local markets or shops around Mahendragarh / Haryana.

-

You should design layout such that the machinery flow is smooth, labour movement is minimized, and maintenance access is easy. Use standard safety practices and ensure reliable power supply (Haryana grid or backup generator if needed).

Marketing & Sales Strategy

To make the notebook manufacturing business viable, you must consider the following:

-

Local Demand

Schools, coaching centres, stationery shops in Mahendragarh, Narnaul, Rewari, Gurgaon-periphery can be customers. -

Bulk Orders & Customisation

Offer customised ruled pages, cover design, branded notebooks. That can differentiate your product. -

Quality Assurance

Use good finishing, proper binding strength, consistent size & ruling. High equipment precision helps. -

Pricing & Delivery

Competitive prices with local delivery / low transport cost (given production base near Mahendragarh) will be an advantage. -

Certifications & Reputation

If you brand your product (e.g. eco-friendly paper, local “Made in Mahendragarh” stationery brand), that can add marketing appeal.

Challenges & Risk Mitigation

No venture is risk-free. Some challenges you might face include:

-

Power interruptions, variation in voltage or electrical supply quality in rural/semi-urban area. Solution: stabilisers, backup supply.

-

Competition from large stationery manufacturers or imports. Mitigation: niche/custom notebooks, value-added services.

-

Maintenance issues with imported equipment if spare parts are not locally available. Ensure you choose reliable vendors with spare-parts stocks.

You can reduce risk by selecting well-supported equipment, getting training for operators, and building relationships with spare-parts suppliers near Haryana / Delhi NCR.

Summary & Conclusion

Setting up a notebook manufacturing line in Mahendragarh, Haryana, is a realistic and promising opportunity—provided you select the right notebook making machine, plan layout properly, secure government / MSME support, and manage operations efficiently.

Whether you choose manual, semi-automatic or fully automatic machinery, your success will depend on matching capacity to demand, ensuring maintenance support, and optimising cost-efficiency. Use the local advantages of Mahendragarh — lower costs, state-level industry support, and strategic location — to build a sustainable business.