Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

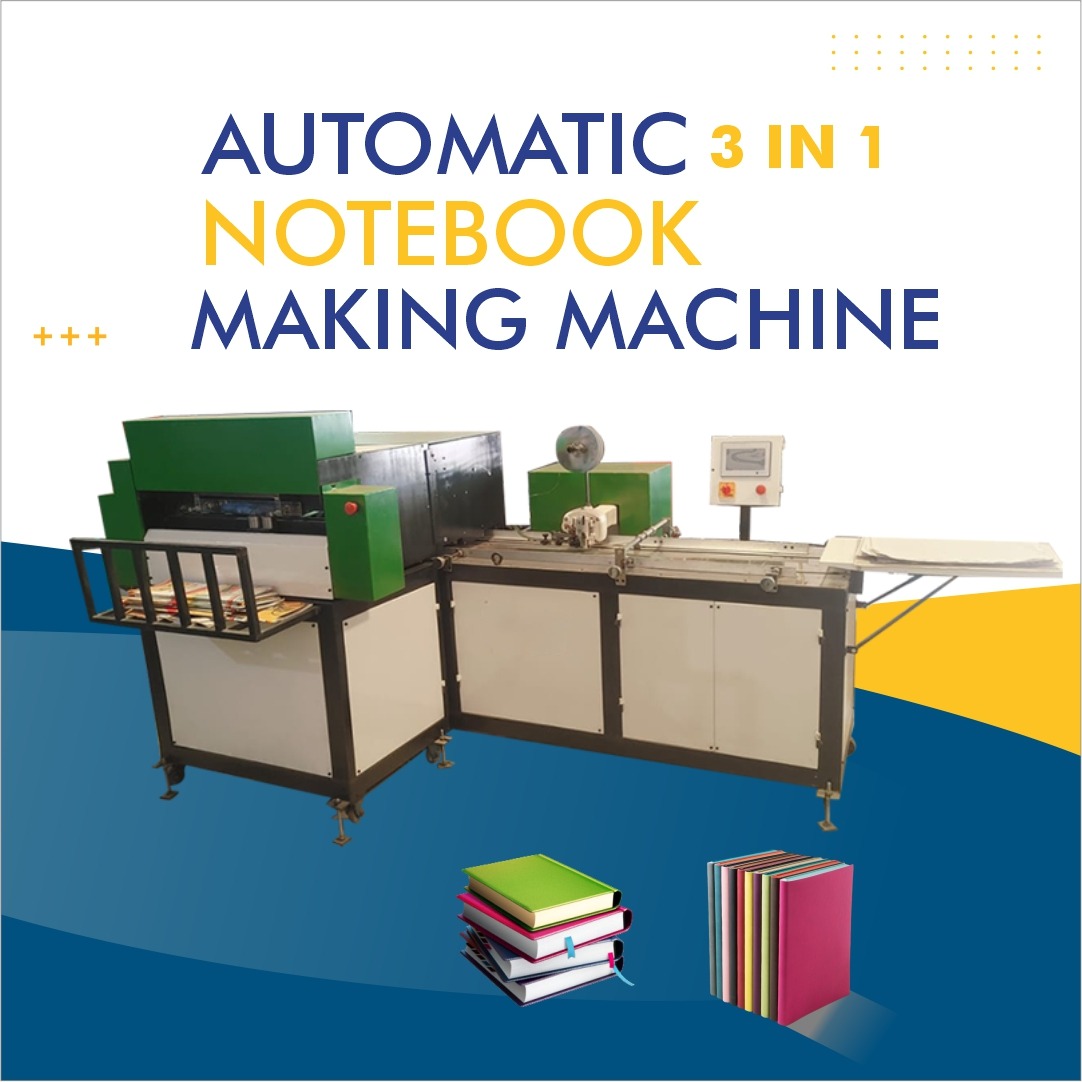

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier in Kansopur, Haryana – Automatic Notebook Making Equipment

Notebook Making Machine Supplier in Kansopur| Haryana

If you are looking to set up a modern stationery factory or upgrade your existing facility with a state-of-the-art notebook making machine, then Kansopur, Haryana is the ideal location to find high quality equipment and local support. This page highlights everything you need to know about purchasing, installing, operating, and maintaining an automatic notebook making machine in Kansopur. Whether for small-scale production or large volumes, you’ll find the right notebook making equipment and manufacturer to match your requirements.

This content covers product features, choices, local advantages, cost considerations, installation support, and after‐sales service for notebook making machines in the region.

Why Choose a Notebook Making Machine in Kansopur, Haryana

Strategic Location & Accessibility

Kansopur is well-connected by road and rail in Haryana. Being close to major industrial areas and transport links makes it easier for raw-material supply (paper, cardboard, binding supplies) and shipping finished notebooks across North India (Delhi NCR, Punjab, Uttarakhand etc.). Local production in Kansopur reduces transit time and cost compared to importing machines from distant regions.

Local Support & Service

Choosing a notebook making machine from a manufacturer or supplier operating near Kansopur means you can access installation teams quickly, spare parts fast, and technical assistance on-site. This local presence ensures minimal downtime and quicker response for maintenance or upgrades of the notebook production line.

Cost Advantages

Using a locally-manufactured or locally-supplied notebook making machine in Haryana typically reduces customs, transport, and handling overheads. Lower logistic expenditure means you can invest more in higher-quality components (motors, control panels, sensors) or automation features such as high-speed feeding, digital counters, or PLC-based control.

Compliance & Regulation

Manufacturers located in Haryana are more familiar with Indian electricity standards, safety regulations, and industrial permits. This ensures your notebook making plant remains compliant with local authorities (electrical inspection, pollution control, factory licences and so on), reducing delays.

Types of Notebook Making Machines

When choosing notebook making equipment, you will find several types depending on the speed, automation level, and product mix. Here are key categories:

-

Manual to Semi-Automatic Notebook Machine

-

Suitable for low volume production.

-

Requires more operator involvement; good for starter-level setups.

-

-

Fully Automatic Notebook Making Machine

-

High speed, PLC control, automated feeding, stitching or gluing, cutting trim, scoring, cover forming.

-

Ideal for medium to large production capacity.

-

-

High-Speed Notebook Production Line

-

Integrated process from paper loading → cutting → folding → binding → trimming → stacking.

-

Minimal manual handling; best for high turnover factories.

-

-

Specialty Notebook Making Machine

-

Custom sizes, cover styles (hard cover, flexible cover), perforated pages, spiral or wire binding add-ons.

-

Useful for premium or customized stationery brands.

-

-

Compact Notebook Making Plants

-

Smaller footprint, modular design. Good for startups or those wishing to expand gradually.

-

Each version of notebook making equipment has trade-offs in terms of cost, speed (notebooks per minute), maintenance complexity, and training requirements.

Key Features to Look For

When evaluating a notebook making machine, particularly in the context of Kansopur, consider the following features:

-

Production Speed: pages per minute or notebooks per hour. Higher-speed machines increase output but require precise calibration and more reliable components.

-

Automation Level: PLC control, sensors for paper jams, automatic trimming, digital display, etc.

-

Binding Method: saddle stitching, perfect binding, glue binding, or wire/spiral binding (if offered).

-

Sheet Size & Format Flexibility: ability to process different notebook dimensions (A4, A5, custom sizes).

-

Cover Handling: plain card cover, printed cover, embossing, lamination add-ons.

-

Feeding Mechanism: motorised paper feed, vacuum feeding, automatic alignment.

-

Precision Trimming & Cutting: ensure uniform margins, sharp edges.

-

Energy Efficiency: motors, inverter drives, lower electricity consumption.

-

Maintenance Access & Spare Parts: compatibility with locally-available parts (motors, belts, bearings) in Haryana or nearby.

-

Operator Training & Safety Standards: emergency stops, guarding, safety interlocks as per Indian safety norms.

-

After-Sales Support & Warranty: ensure supplier offers on-site training, periodic inspection and preventive maintenance.

How to Select the Right Machine

Evaluate Your Production Requirement

Begin by estimating your maximum monthly output requirement — e.g. number of notebooks per day. If you expect to produce thousands of notebooks daily, you’ll likely need a fully automatic or high-speed notebook production line.

Budget Planning

Determine your budget range, including machine cost, installation, electrical infrastructure upgrades, civil works for factory flooring, and operating personnel. Local suppliers often provide better pricing transparency and fewer hidden charges compared to imported or distant-supplier machines.

Visit the Manufacturer or Demonstration Site

Ask the supplier for a live demo or site visit. A notebook making machine in operation gives you confidence in build quality, reliability and maintenance practices. Since Kansopur is in Haryana, you may find demonstration units nearby in industrial clusters.

Customization & Modularity

Check whether the notebook making machine can be customized to add modules later — e.g. glue binding or spiral binding add-ons, or upgraded trimming section. A modular design helps you scale production without replacing the entire production line.

Warranty, Training & Spare Parts Contract

Ensure your agreement with the manufacturer includes initial operator training, spare-parts availability in Haryana, scheduled maintenance visits, and warranty terms covering mechanical and electrical subsystems.

Installation & Setup in Kansopur

-

Site Survey

Conduct a site inspection to ensure that the room or hall where the notebook making machine will be installed has adequate structural support, flooring, ventilation, drainage, and compliance with factory regulations in Haryana. -

Electrical & Utility Requirements

Confirm the power supply (voltage, phase, load capacity) and ensure reliable connections, earthing and surge protection. High-speed plants may require three-phase power, stabilisers or voltage regulation. -

Civil and Floor Work

Depending on machine footprint and weight, you may need reinforced concrete base, levelled floor plates, anti-vibration pads or platform mounting. Local contractors in Haryana may be engaged for civil works. -

Machine Commissioning & Testing

After installation, machine must be commissioned: run test batches of notebooks, calibrate trim settings, confirm stitching quality, check trimming accuracy, measure output per hour, and handle any adjustments. On-site technical personnel from supplier might assist. -

Operator Training

The supplier should provide training to local staff in Kansopur or nearby areas. This includes machine operation, daily maintenance, cleaning, and minor troubleshooting. -

Routine Maintenance Plan

Establish a maintenance schedule: lubrication points, belt tension checks, cleaning of cutters, replacement of consumable parts (blades, binding wire etc.), electrical panel inspection. Local support reduces downtime. -

Quality Control and Output Monitoring

Implement daily checks for notebook dimensions, binding strength, page alignment, cover fit, and finished product appearance. Use QC forms and data tracking to ensure consistent quality and reduce waste.

Benefits of Using Modern Notebook Making Equipment

-

Higher Productivity

Automating repetitive steps (cutting, binding, trimming) significantly increases output. You can meet large orders for schools, colleges or corporate stationery supply. -

Consistency & Precision

Electronic controls and calibrated trimming ensure uniform size and finish across batches, reducing rejects and rework. -

Cost Savings Over Time

Though initial investment may be high, automated machines reduce labour cost per unit, reduce waste, and maximize machine uptime. -

Scalability

A modular notebook making plant allows you to scale production in future — add extra binding modules, upgrade motors or control units. -

Better Marketability

High-quality finished notebooks with neat trims, strong binding, and professional appearance help you compete with branded stationery and build your own private-label notebooks.

Challenges & Solutions

| Challenge | Solution |

|---|---|

| Initial capital investment | Evaluate ROI based on projected sales, choose modular expansion, negotiate EMI or financing options |

| Skilled operator availability | Supplier-provided training, recruit local technicians, ensure proper staff orientation |

| Downtime due to breakdowns | Keep spare-parts stocked locally (belts, cutters), arrange annual preventive maintenance from the supplier |

| Power fluctuations | Use stabilisers, UPS or voltage regulators. Haryana grid may experience fluctuations—ask supplier for adaptive drive protection |

| Variation in raw-material quality | Source good quality paper and cover board; check tolerances for thickness and surface finish before feeding into machine |

Why Partner with Us (or Your Firm)

If your company is offering notebook making machines in Kansopur, Haryana, you can highlight the following selling points:

-

In-house design and manufacturing of automatic notebook making machine

-

Competitive pricing without compromising on quality

-

Local presence for installation, commission & service in Haryana region

-

Flexible customization for size, binding type, speed

-

Dedicated customer support and training for operators in Kansopur or nearby districts

-

Transparent pricing, spare part availability, long-term maintenance contract

You may highlight case studies of clients in Haryana or nearby states who have successfully installed your notebook making equipment and increased their production capacity.

Case Study / Use-Case (Optional)

You could describe a hypothetical or real example such as:

“A stationery manufacturer in Karnal expanded its monthly notebook production from 20,000 to 60,000 units after installing our fully automatic notebook production line in 2024. Downtime was reduced by 35 % and quality rejection dropped below 2 %. Installation was completed within one week, and operator training was conducted on site in Kansopur-adjacent workshop.”

Pricing & Estimates

While exact pricing depends on model, automation level, speed and customization, here are rough estimates (for illustration only):

| Model Type | Approximate Cost (INR) | Features |

|---|---|---|

| Semi-automatic basic machine | ₹ 5 Lakh – ₹ 8 Lakh | Manual feeding, trimming, basic binding |

| Fully automatic mid-speed line | ₹ 12 Lakh – ₹ 20 Lakh | PLC control, auto feed, trimming, glue or stitch binding |

| High-speed production plant | ₹ 25 Lakh and above | Integrated modules, high throughput, optional cover finishing add-ons |

These costs exclude civil work, installation, training and GST. You should request detailed quotation according to your required size and production capacity.

Getting Started

-

Reach out with your required daily/monthly notebook output.

-

Send reference notebook sizes, binding style (stapled, glued, spiral), cover material.

-

Request a layout drawing and machine footprint.

-

Confirm installation timeline and training plan.

-

Sign service-level agreement or warranty contract to ensure long-term reliability of your notebook production line.

With these steps, you can successfully set up a high-efficiency notebook making plant in Kansopur, Haryana using modern automatic machinery.

Conclusion

Investing in a reliable, high-performance notebook making machine in Kansopur, Haryana offers you operational advantage, reduced logistic cost, and faster time-to-market. Whether you are starting a new stationery unit or upgrading existing capacity, choosing the right automatic notebook making equipment, backed by local support, will help you scale production, improve quality, and stay ahead in a competitive stationery industry.